Abstract

Emerging applications such as solid-state lighting and display technologies require micro-scale vertically emitting lasers with controllable distinct lasing wavelengths and broad wavelength tunability arranged in desired geometrical patterns to form “super-pixels”. Conventional edge-emitting lasers and current surface-emitting lasers that require abrupt changes in semiconductor bandgaps or cavity length are not a viable solution. Here, we successfully address these challenges by introducing a new paradigm that extends the laser tuning range additively by employing multiple monolithically grown gain sections each with a different emission centre wavelength. We demonstrate this using broad gain-bandwidth III-nitride multiple quantum well (MQW) heterostructures and a novel top-down nanowire photonic crystal nanofabrication. We obtain single-mode lasing in the blue-violet spectral region with a remarkable 60 nm of tuning (or 16% of the nominal centre wavelength) that is determined purely by the photonic crystal geometry. This approach can be extended to cover the entire visible spectrum.

Similar content being viewed by others

Introduction

Surface-emitting photonic crystal (PC) lasers are promising light sources for the next-generation of compact and efficient light emitters used in data storage1, biomedical applications2,3, solid-state lighting4 and display technologies5. In order for these devices to be of practical use, they must be constructed to emit over a large wavelength range, particularly in the violet to visible wavelength regime. Previous realizations6,7,8,9,10,11,12,13,14 of PC lasers required complicated fabrication schemes, had limited tuning range, were reported at longer wavelengths far from the blue-violet regime, or implemented a single gain section. Here we describe a monolithic, GaN nanowire two-dimensional photonic crystal (2DPC) based laser array (optically pumped) with two distinct gain sections fabricated using a top-down approach that meet all of the requirements for next-generation laser arrays: i) the fabrication is scalable leading to tuneability over a large wavelength range that can be performed, at once, on a single substrate; ii) the necessary area of the photonic crystal is small, allowing for dense arrays; iii) the fabrication for nanowire structures is simplified since there is no need to remove the substrate6 or fabricate a distributed Bragg reflector (DBR) beneath the PC15; iv) light is emitted vertically and v) the emission is single-mode. These requirements are met using a design based upon low group velocity lasing that utilizes lateral feedback16 which allows the incorporation of additional gain materials intended for different spectral regions. This fabrication method coupled with the wide gain bandwidth of semiconductor nitride materials will enable a new class of compact, monolithic multiple-wavelength photonic devices.

Sufficiently broadened gain spectra are necessary in order to fabricate an array of lasers that span a large spectral bandwidth. One way of obtaining a broad enough gain spectrum is by choosing a material with gain that is sufficiently inhomogeneously broadened. However, these broadened gain spectra are often viewed as detrimental due to the reduced peak gain resulting in an increase of the laser threshold. The rich dispersion characteristics of PCs provide an elegant solution to this problem. It has been predicted that in 2D and 3D photonic crystals certain modes can exhibit near-zero group velocity along certain lattice directions for particular bands16 that can be utilized to reduce lasing threshold6,16,17,18,19. These modes propagate slowly enabling increased interaction time of the electromagnetic fields with the gain material thereby lowering the lasing threshold. This makes it possible to reach low lasing thresholds in material systems that exhibit a small amount of gain or a reduced gain over a larger bandwidth.

Results

Here, we exploit these characteristics of a 2DPC composed of an array of GaN nanowires in a hexagonal lattice to achieve lasing in a broad gain bandwidth system. The nanowires contain two gain sections embedded axially – one is composed of InGaN multiple quantum wells (MQWs) with an emission centred at 430 nm, the other a 150 nm thick InGaN under-layer (emission centred at 385 nm) commonly used to improve the quality of the subsequent MQW structures. We can enable selective lasing of the different gain sections by carefully designing the 2DPC parameters (e.g. lattice constant, nanowire diameter, height) to match the slow group velocity modes with the desired lasing wavelength. Figure 1 shows the band structure for a hexagonal lattice of GaN nanowires with a diameter ‘d = 0.4a’ and height ‘h = 2a’ where ‘a’ is the lattice constant. Using the plane-wave expansion method, we calculated the band structure using a hexagonal lattice periodicity in-plane and a simulation supercell of height 6a in the vertical direction to account for the finite height of the wires. While lower band indices show large dispersion, higher band indices have much less dispersion with relatively flat bands. Our design targets the higher bands (n > 16) with low group velocities and are outside of the light cone so the electromagnetic fields are expected to extend above the GaN nanowire array. Nevertheless, these fields still interact with the gain media. Utilization of the higher bands also has an added advantage of relaxing the lattice constant and nanowire dimension requirements thus easing nanofabrication constraints. Interestingly, for certain bands (20–23) we also find that the low dispersion, slow group velocity modes are close to the Γ point making normal emission possible. The small but non-zero in-plane component of the wavevector of these modes enables efficient interaction with the gain regions while the larger out-of-plane wavevector directs the lasing emission to occur preferentially in the normal direction.

Modelling of the photonic band structure of the photonic crystal lasers.

(a), Schematic of the simulated photonic crystal lattice illustrating the lattice constant ‘a’, the nanowire diameter ‘d’ and the reciprocal lattice vectors. The height of the wire is 2a with a supercell height of 6a. (b), Band structure calculated using a plane-wave expansion method for a hexagonal lattice of GaN nanowires with a diameter ‘d = 0.4a’ and height ‘h = 2a’ where ‘a’ is the lattice constant. While lower bands are more dispersive, higher bands are relatively flat with low dispersion. (c), Detailed inspection of bands 15–24 near the Γ point.

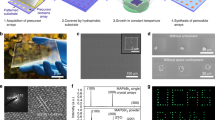

To utilize the entire available gain bandwidth of the two gain regions, we fabricated an array of 2DPCs with lattice constants ranging from 290 nm to 330 nm. For each lattice constant, the nanowire diameters ranged from d = 0.43a–0.47a and were patterned using electron-beam lithography. Figures 2a–d show the schematic of the fabrication process along with the electron microscope images of a fabricated photonic crystal and the nanowire composition. The top-down approach enables the use of high quality planar epitaxial materials thereby relaxing 1D material growth constraints. Additional details of the top-down nanowire fabrication can be found in previous publications20,21. Each device region was 100 μm × 100 μm in size and composed of an array of 10 μm × 10 μm 2DPC ‘pixels,’ each with a distinct lattice constant (Fig. 2e, 2f). All of the devices fabricated for this work had a uniform height of ~600 nm.

Fabrication of the photonic crystal lasers.

(a), The photonic crystal lasers were fabricated using a two-step top-down etch process. The III-Nitride epitaxial structure with embedded quantum wells was masked by a nickel layer patterned by e-beam lithography. First a dry etch created isotropic nanocones. A subsequent wet-etch removed the damaged material left from the dry-etch and created highly anisotropic nanowires. (b), Scanning electron microscopy (SEM) image of a fabricated photonic crystal. The nanowires measured 600 nm tall and were packed in a hexagonal lattice. Wavelength tuning was achieved by varying the lattice constant from 280 nm to 330 nm and the diameter from 120 nm to 150 nm for individual lasers. (c), High angle annular dark field scanning transmission electron microscopy (STEM) micrograph of a single nanowire from the array. The 2 gain sections are easily distinguished with the 2% In under-layer visible beneath the InGaN quantum wells. (d), High-resolution element map by energy dispersive x-ray spectroscopy (EDX) under STEM mode showing the In (green) and Ga (red) distributions. (e), False Coloured SEM of an array of laser pixels. Each pixel measures 10 × 10 μm. (f), SEM of pixels arrays spanning across a 1 cm die.

We analysed the 2DPC lasers using a micro-photoluminescence (μPL) setup that enables optical excitation of a single pixel in the array or a group of pixels by controlling the pump spot size. To further examine and illustrate the lasing threshold behaviour, we focused on a pixel with a lattice constant of 320 nm and a nanowire diameter of ~140 nm. At low pump intensity, a broad PL emission between 400–460 nm is observed. As the pump intensity is increased, a sharp peak emerges at the short wavelength edge of the PL spectrum. Further increase in the pump intensity causes the peak intensity of the narrow feature to rise rapidly in contrast to the slowly rising background PL. A series of PL and lasing spectra were generated by sweeping the pump intensity from 5 kW/cm2 to 235 kW/cm2. The peak intensity as a function of pump intensity or the so called “light-in/light-out” (LL) curve can be seen in figure 3 revealing a clear threshold behaviour. The lasing emission occurs at 415 nm with a threshold of ~130 kW/cm2. The evidence for lasing is threefold- in addition to the threshold behaviour we observed narrow spectral features (<0.2 nm) and interference patterns on the CCD images above threshold. This indicated a high degree of spatial coherence, which is another characteristic of lasing behaviour.

Spectral characterization of a representative photonic crystal laser.

Light-in light-out curve measured from the d = 143 nm and a = 320 nm array. The spectra shown were measured between 5 kW/cm2 and 235 kW/cm2. As the pump power density is increased a sharp peak begins to emerge at the short wavelength edge of the PL spectra. The intensity of this narrow peak (<0.2 nm) increased rapidly compared to the background PL. Single-mode emission was maintained at pump powers high above the threshold. The relative intensity of the laser emission to the background photoluminescence continued to increase with increasing pump power.

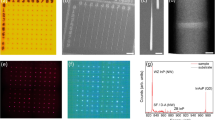

All of the devices exhibited single-mode lasing behaviour over a spectral range spanning from 380 nm to 440 nm. The lasing wavelength for all the devices with different lattice constants corresponds to a reduced frequency (a/λ) of ~0.75 to within 5%. This reduced frequency position corresponds well with the positions of the low dispersion bands shown in figure 1b. In addition to tuning the emission wavelength by changing lattice constants, it is also possible to achieve further fine tuning by changing the nanowire diameters for a given lattice constant. Thus, by suitably adjusting the lattice constant and diameter of the nanowire, a near continuum of lasing wavelengths is realized within the gain spectral region of the QWs and the underlayer. Figure 4 shows a representative collection of lasing spectra near threshold from 30 devices whose wavelengths are between 380–440 nm. Due to the wavelength dependence of the material gain longer wavelength devices have a higher pump power requirement to reach threshold, as a result these devices show a more prominent background PL. By using additional gain sections, a flatter gain profile could be obtained to minimize this effect. A careful observation of the spectra reveals two sets of peaks, one grouped between 375 and 390 nm and the second grouped between 405 and 440 nm. These two regions correspond to the emission band from the underlayer and the InGaN MQWs respectively.

Laser spectra from the nanowire photonic crystal lasers incorporating 2 gain sections.

Laser spectra from 30 representative photonic crystal lasers spanning a bandwidth from 380 nm to 440 nm. The area of each laser measured 10 μm × 10 μm. The spectra were taken close to the threshold condition for each laser. The purple highlighted region shows the contribution from the under-layer and the blue shows the contribution from the MQW.

To confirm that the different gain media sections could be accessed individually through PC design, we fabricated a control sample using the same method but without the quantum well stack and only GaN and the In0.02Ga0.98N under-layer. We found laser emission from 378 to 390 nm from this sample indicating that a portion of the broad spectrum of the final device was enhanced by the inclusion of two gain media. The observed laser emission from the under-layer sample can be seen on the left-hand side of figure 4. This demonstrates that lasing at different wavelengths can be achieved on a single chip by appropriately designing the 2DPC even on a single epitaxial wafer that is composed of multiple materials with different gain bandwidths. This implies that by incorporating MQW sections with longer emission wavelengths it would be possible to span the entire visible spectrum. The key challenge lies in achieving high enough quality MQWs to possess the necessary gain required for lasing at longer wavelengths due to their larger In concentration, which degrades the quality of the QWs. One remarkable point is that unlike conventional lasers with axial cavities, the different gain sections do not interact with each other: this is due to the lateral nature of the feedback provided by the 2DPC.

An additional advantage of this approach is the ability to fabricate densely packed micro-scale laser “pixels”. By placing the 2DPC lasers in close vicinity to one another a single pump can optically excite multiple pixels at once. Figure 5 shows the results of pumping 4 of the 2DPC lasers at one time. The spectrum clearly shows 4 independent laser lines with nearly uniform intensities. We fabricated these 2DPC lasers to have the same lattice constant of 300 nm but slightly different diameters and therefore different emission wavelengths. Figure 5b shows the far field emission pattern of the 4 lasers operating together. This demonstration shows how III-nitride 2DPC lasers could be used for active wavelength selection in future solid state lighting and display devices. Different colours and warmths can be achieved by selectively exciting (optically or electrically - in future devices) certain laser pixels each with a different emission wavelength. The work presented here is a first step towards wafer-scale laser arrays tuned over the entire UV to visible range.

Four photonic crystal laser “pixels” operating together in close vicinity.

(a), measured spectrum from four laser pixels designed to have slightly different emission wavelengths. The four lasers were optically excited simultaneously and the area of each laser measured 10 μm × 10 μm separated by approximately 5 um. (b), the far-field emission pattern from the four laser pixels imaged with the background photoluminescence, the pump wavelength has been optically filtered out and the remaining light is emitted from the 2DPC array. The scale bar represents 10 μm.

Discussion

We demonstrated surface emitting, single-mode 2DPC optically pumped lasers in the blue-violet spectral region with a remarkable 60 nm of tuning (or 16% of the nominal centre wavelength) that was determined purely by the photonic crystal geometries. We achieved this wide tuning in emission wavelength by employing two gain sections (GaN/InGaN MQWs and InGaN under-layer) covering different wavelength bands with broad gain bandwidth in conjunction with careful 2DPC design to select the lasing wavelength. Electron beam lithography was utilized to pattern the InGaN/GaN nanowire hexagonal lattice based 2DPC combined with a novel top-down nanofabrication method. The exquisite control enabled by the two-step, top-down etch process led to the creation of excellent quality nanowire arrays with controlled geometries and very high yield. The key to achieving normal direction lasing emission, with relatively low thresholds, was the use of slow group velocity modes near the Γ point of the 2DPCs at higher bands. In the future this approach can be expanded to include additional gain sections in order to cover the entire visible spectrum. The fabrication approach can also be appropriately modified to utilize doped structures to eventually create electrically injected devices. This work enables future SSL devices and displays fabricated using III-nitride 2DPC nanowire lasers to have dynamic colour tuning over a larger colour gamut.

Methods

Fabrication

The semiconductor material was grown on 2” c-plane sapphire using a Veeco D-125 metal organic chemical vapour deposition (MOCVD) reactor. The epitaxial layers consisted of an n-i-n structure of GaN, the InGaN under-layer and InGaN QWs grown on a 4-μm buffer layer of GaN. The GaN buffer layer was used to suppress Fabry-Perot type oscillations in the vertical direction by eliminating the reflection from the nanowire-substrate interface. A nickel etch mask was fabricated by lift-off that was patterned using electron-beam lithography. To transfer the photonic crystal pattern to the semiconductor material, the devices were etched using a reactive-ion dry-etch. The dry-etch step was followed by a KOH-based (AZ400K photoresist developer) wet-etch to remove the highly defective region caused by plasma damage. This wet-etch is timed to precisely control the diameter of the individual nanowires and forms highly anisotropic structures due to the selective nature of the etch chemistry.

Optical characterization

We optically excited the photonic crystal cavities at room temperature in an ultraviolet micro-photoluminescence setup. Our excitation source was a quadrupled YAG laser emitting at 266 nm, with a 10 kHz repetition rate and 500 ps pulses. The excitation peak power density of the laser was controlled by a series of neutral density filters and lenses. We used a 5 μm pump spot to characterize the threshold power. The sample was imaged by a 50X UV objective and imaged into a 300 mm spectrometer and a liquid nitrogen cooled Si CCD.

References

Ikeda, M. & Uchida, S. Blue–Violet Laser Diodes Suitable for Blu-ray Disk. physica status solidi (a) 194, 407–413 (2002).

Shapiro, H. M. Practical Flow Cytometry. Fourth edn, (John Wiley & Sons, Inc., 2003).

Gabrecht, T., Andrejevic-Blant, S. & Wagnières, G. Blue-Violet Excited Autofluorescence Spectroscopy and Imaging of Normal and Cancerous Human Bronchial Tissue after Formalin Fixation. Photochemistry and Photobiology 83, 450–459, 10.1562/2006-03-20-ra-852 (2007).

Neumann, A. et al. Four-color laser white illuminant demonstrating high color-rendering quality. Opt. Express 19, A982–A990 (2011).

Sizov, D., Bhat, R. & Zah, C. E. Gallium Indium Nitride-Based Green Lasers. J. Lightwave Technol. 30, 679–699 (2012).

Matsubara, H. et al. GaN photonic-crystal surface-emitting laser at blue-violet wavelengths. Science 319, 445–447 (2008).

Ishizawa, S., Kishino, K., Araki, R., Kikuchi, A. & Sugimoto, S. Optically Pumped Green (530-560 nm) Stimulated Emissions from InGaN/GaN Multiple-Quantum-Well Triangular-Lattice Nanocolumn Arrays. Appl. Phys. Express 4 (2011).

Scofield, A. C. et al. Bottom-up Photonic Crystal Lasers. Nano Lett. 11, 5387–5390 (2011).

Kouno, T., Kishino, K., Yamano, K. & Kikuchi, A. Two-dimensional light confinement in periodic InGaN/GaN nanocolumn arrays and optically pumped blue stimulated emission. Opt. Express 17, 20440–20447 (2009).

Kouno, T. et al. Stimulated emission on two-dimensional distributed feedback scheme in triangular GaN nanocolumn arrays. Electron. Lett. 46, 644–U665 (2010).

Painter, O. et al. Two-dimensional photonic band-gap defect mode laser. Science 284, 1819–1821 (1999).

Park, H. G. et al. Electrically driven single-cell photonic crystal laser. Science 305, 1444–1447 (2004).

Chang, L.-M. et al. Laser emission from GaN photonic crystals. Applied Physics Letters 89, 071116–071113 (2006).

Kim, D. U., Kim, S., Lee, J., Jeon, S. R. & Jeon, H. Free-Standing GaN-Based Photonic Crystal Band-Edge Laser. IEEE Photonics Technol. Lett. 23, 1454–1456 (2011).

Lu, T.-c., Chen, S.-W., Kao, T.-T. & Liu, T.-W. Characteristics of GaN-based photonic crystal surface emitting lasers. Applied Physics Letters 93, 111111–111113 (2008).

Sakoda, K. Optical Properties of Photonic Crystals. Second edn, (Springer-Verlag, 2005).

Monat, C. et al. InP-based two-dimensional photonic crystal on silicon: In-plane Bloch mode laser. Applied Physics Letters 81, 5102–5104 (2002).

Ferrier, L. et al. Surface emitting microlaser based on 2D photonic crystal rod lattices. Opt. Express 17, 9780–9788 (2009).

Ferrier, L., Rojo-Romeo, P., Drouard, E., Letatre, X. & Viktorovitch, P. Slow Bloch mode confinement in 2D photonic crystals for surface operating devices. Opt. Express 16, 3136–3145 (2008).

Li, Q. et al. Single-mode GaN nanowire lasers. Opt. Express 20, 17873–17879 (2012).

Li, Q. et al. Optical performance of top-down fabricated InGaN/GaN nanorod light emitting diode arrays. Opt. Express 19, 25528–25534 (2011).

Acknowledgements

The authors would like to thank Karen Cross and Jason Dominguez for their help with the fabrication of the 2DPC samples. The authors would like to thank Jeff Tsao for his useful discussions and help with the manuscript. This work was supported by Sandia's Solid-State-Lighting Science Energy Frontier Research Center, funded by the U. S. Department of Energy, Office of Science and Office of Basic Energy Sciences. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science. Sandia National Laboratories is a multi-program laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy's National Nuclear Security Administration under contract DE-AC04-94AL85000.

Author information

Authors and Affiliations

Contributions

J.B.W., S.H.L., A.B. and H.X. performed optical characterization of the photonic crystal laser pixels. P.L., J.B.W. and H.X. performed materials characterization including TEM. J.B.W., T.S.L. and I.B. designed the laser spectroscopy measurement system. D.D.K. performed the GaN/InGaN QW epitaxial growth. G.T.W., Q.L., H.X. and J.B.W. developed process and fabricated the nanowire photonic crystals. G.S. performed bandstructure calculations and theoretical design for lasing structure and electron beam patterning of the nanowire photonic crystals. G.S., J.B.W., L.L., I.B. and G.T.W. developed the design and performed analysis and interpretation of the measured data. All authors contributed to writing of the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information: Multi-Colour Nanowire Photonic Crystal Laser Pixels

Rights and permissions

This work is licensed under a Creative Commons Attribution-Non-Commercial-ShareAlike 3.0 Unported licence. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Wright, J., Liu, S., Wang, G. et al. Multi-Colour Nanowire Photonic Crystal Laser Pixels. Sci Rep 3, 2982 (2013). https://doi.org/10.1038/srep02982

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep02982

This article is cited by

-

Displacement Talbot lithography for nano-engineering of III-nitride materials

Microsystems & Nanoengineering (2019)

-

Carrier Dynamics and Electro-Optical Characterization of High-Performance GaN/InGaN Core-Shell Nanowire Light-Emitting Diodes

Scientific Reports (2018)

-

Horizontally assembled green InGaN nanorod LEDs: scalable polarized surface emitting LEDs using electric-field assisted assembly

Scientific Reports (2016)

-

Spatial resolution effect of light coupling structures

Scientific Reports (2015)

-

Hierarchical multicolor nano-pixel matrices formed by coordinating luminescent metal ions to a conjugated poly(4′-octyl-2′,6′-bispyrazoyl pyridine) film via contact printing

Scientific Reports (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.