Abstract

Current battery systems have severe cost and resource restrictions, difficultly to meet the large scale electric storage applications. Herein, we report an all-organic Na-ion battery using p-dopable polytriphenylamine as cathode and n-type redox-active poly(anthraquinonyl sulphide) as anode, excluding the use of transition-metals as in conventional electrochemical batteries. Such a Na-ion battery can work well with a voltage output of 1.8 V and realize a considerable specific energy of 92 Wh kg−1. Due to the structural flexibility and stability of the redox-active polymers, this battery has a superior rate capability with 60% capacity released at a very high rate of 16 C (3200 mA g−1) and also exhibit an excellent cycling stability with 85% capacity retention after 500 cycles at 8 C rate. Most significantly, this type of all-organic batteries could be made from renewable and earth-abundant materials, thus offering a new possibility for widespread energy storage applications.

Similar content being viewed by others

Introduction

Existing battery technologies are all based on redox chemistry of less-common metals and their oxides, which face severe cost and resource restrictions for widespread applications of electric energy storage such as in electric vehicles and renewable power stations1,2,3. To meet growing demands for green and sustainable electric power storage, Na-ion batteries are recently revisited as a promising alternative to current Li-ion technology, due to their material abundance, low-cost and environmental benignity4,5.

Recent researches on Na-ion battery are mostly directed on the development of inorganic Na intercalation materials6. Several types of layered transition metal oxides7,8, phosphates9 and hexacyanides10,11 were demonstrated to have certain reversible capacities as Na-insertion cathodes, these materials suffer from their low capacity utilization or sluggish kinetics, due to the stronger coordination of larger Na ions in the rigid inorganic lattices than their lithium counterpart. Meanwhile, a number of Na-alloyable metals such as Sn12 and Sb13 were recently revealed as high capacity Na-storage anodes14, these metals are also scarce resources and difficult to support large scale electric storage applications.

Redox-active polymers15,16,17 seem to be a good choice of electrode-active materials for Na-ion batteries because their structural diversity and materials sustainability. As a flexible framework, organic polymers can accommodate larger Na ions reversibly without much spatial hindrance, thus facilitating to achieve a fast kinetics for Na+ insertion and extraction reactions18,19,20. More significantly, organic polymers are potentially low-cost, environmentally friendly and possibly accessible from abundant biomass resources. However, despite tremendous work has been done on developing polymeric electrode materials for Li-ion batteries and electrochemical supercapactors, very few of them have been devoted for Na-ion batteries. Very recently, Hong et al.18 and Hu et al.19 demonstrated reversible Na+ insertion behaviour of organic carboxylate, Na2C8H4O4, with a nearly 2 Na storage capacity ~ 300 mAh g−1 as an anode material. Meanwhile, our group has also revealed feasible applications of p-doped polymers such as nitro-substituted polyaniline20 and Fe(CN)64--doped polypyrrole21,22, as cathode materials and n-type polythiophene23 as an anodic host for Na-ion batteries, all of which exhibit considerable redox capacity and cyclability in Na+ electrolyte. Unfortunately, these organic cathodes and anodes were all singly tested in half cell experiments and have not been paired for a Na-ion battery.

In principle, a Na-ion battery can be constructed by use of a pair of organic cathode and anode, as long as this pair of organic electrodes has sufficient potential difference and can be coupled well to carry out a battery reaction. Such an all-organic Na-ion battery would be greatly attractive for large scale electric storage applications because of its low cost and eco-friendlyness. In this paper, we report an all-organic Na-ion battery based on polytriphenylamine (PTPAn) cathode and poly(anthraquinonyl sulfide) (PAQS) anode, where the charge/discharge reactions go through the doping/dedoping of electrolyte cations into/from PTPAn cathode simultaneously with the association/disassociation of Na ions into/from the PAQS anode. Since the PTPAn cathode and PAQS anode operate at a quite high potential of 3.6 V and at a lower potential of 1.8 V (vs. Na+/Na), this all-organic battery can output a discharge voltage of ~ 1.8 V with superior rate capability and cyclability.

Results

The selection of the PTPAn/PAQS redox couple for a Na-ion battery is mainly based on the reversible p-dopability of PTPAn at a high potential and the strong n-type redox activity of PAQS at relatively low potentials, which enable an effective voltage output. In addition, these two redox polymers are highly electroactive and structurally stable, possibly achieving a Na-ion battery with high rate capability and long term cyclability.

p-Type redox behaviors of PTPAn cathode

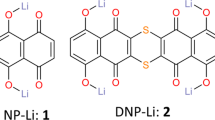

PTPAn and its derivatives have been actively investigated as a fast hole-transport material for organic optoelectronic devices24. Because of its unique structure with electroactive polyaniline units embedded on highly conductive polyparaphenylene chains, we tried to use PTPAn as polymer cathode for Li-ion batteries and found its superior capacity utilization, stable cyclability and high rate capability25. As shown in Figure 1, the cathodic reaction of PTPAn takes place through the reversible redox process between triphenylamine and triphenylamine radical cation, accompanying with the association/dissociation of the electrolyte anion(PF6−) into/from the polymer chains. However, the p-type redox property of PTPAn in Na-containing electrolytes is not clear up to date.

Figure 2 shows electrochemical response of PTPAn in a NaPF6 electrolyte. The structural characterization of the synthesized PTPAn sample is given in Electronic Supplementary Information (Figure S1). As shown in the cyclic voltammograms (CV) of Fig. 2a, a pair of well-defined redox peaks with almost similar peak areas appear at 3.4 and 3.7 V (vs. Na/Na+), characterizing the reversible p-doping reaction of the PTPAn polymer. Accordingly, galvanostatic charge/discharge curves of the Na/PTPAn cells as shown in Fig. 2b exhibit sloping charge and discharge curves at a quite high voltage of ~ 3.6 V and the reversible discharge capacity reaches 98 mAh/g, corresponding to a 90% utilization of its theoretical 1e redox capacity (109 mA g−1). Cycled at various high rates (Fig. 2c), the PTPAn cathode can still displays a surprisingly high rate capability, giving a reversible capacity of 96 mAh g−1 and 88 mAh g−1 at 2 C and 20 C rate (1C = 100 mA g−1), respectively. On continuous cycling at a constant current of 5 C rate, the PTPAn cathode shows a stable reversible capacity of 88 mAh g−1 with 97% capacity retention after 200 cycles (Fig. 2d).

Electrochemical redox properties of PTPAn in a mixed DOL/DME electrolyte saturated with NaPF6.

(a) CV curves at a scan rate of 5 mV s−1; (b) Charge and discharge profiles at a constant current of 50 mA g−1; (c) Cycling performance of PTPAn at different C-rates (1C = 100 mA g−1); (d) Cycling performance of PAQS at 5C rate. The charge-discharge capacities were derived from 2032 coin type Na-PTPAn cells, measured at voltage interval of 2.7–3.9 V.

It should be mentioned that the electrochemical performance of the PTPAn polymer observed in a NaPF6 electrolyte is very much similar to that measured from a LiPF6 electrolyte(Supplementary Fig. S2) except for a slight decrease in the working potential, suggesting that the cathodic reaction proceeds through reversible p-doing/dedoping of the PF6− anions. Though this p-doped polymer is not a Na host material, it can still serve as an effective cathode for Na ion batteries by hosting concomitant PF6− anions along with Na+ insertion into the anodic material.

Anodic Na storage in PAQS polymer

PAQS was known to have n-type redox activity through reversible electrochemical association of cations with its redox-active anthraquinonyl groups26,27,28, as shown in Figure 3. In previous studies, Song et al. discovered the Li-storage reaction of the PAQS polymer with a reversible capacity of 185 mAh g−1 and a stable cyclability during 200 cycles when used as an anodic host for Li-ion batteries26. Considering that the replacement of smaller Li+ by larger Na+ ions may facilitate the redox reaction of the anthraquinonyl groups29, we tested electrochemical feasibility of PAQS polymer as a possible Na–storage anode.

The FTIR and 13C NMR spectra of the as-synthesized PAQS are displayed in Supplementary Fig. S3 and S4, confirming that the polymer chains consist of regular arrangement of anthraquinonyl sulfide unit. To further enhance electric conductivity, the PAQS polymer was composited with a highly conductive carbon by ball milling before electrochemical applications.

Figure 4 displays the electrochemical characteristics of PAQS in NaPF6 electrolyte. As shown in Fig. 4a, the CV responses of the PAQS anode are quite different between initial and subsequent cathodic scans. At initial cathodic scan, the first reduction peak at 1.85 V appeared weaker and the second reduction peak at 1.49 V was relatively larger, suggesting an electrochemical activation process for PAQS as observed previously for Li-storage anode28. After the first activation cycle, two pairs of symmetric redox peaks at 1.85/2.18 V and at 1.46/1.8 V emerged with similar intensities and areas and kept almost unchanged at subsequent cycles, implying a two-step redox reaction of the anthraquinonyl groups in the PAQS chains. In contrast with the CV feature in Li+- electrolyte (Supplementary Fig. S6)28, the two pairs of redox peaks from the PAQS anode are well separated with ~ 300 mV potential difference, possibly due to a larger coulombic or steric repulsion for the second step Na+ association when the first Na+ ion is associated with the anthraquinonyl group of the polymer.

Electrochemical characterizations of PAQS.

(a) CV curves at a scan rate of 5 mV s−1; (b) Charge and discharge profiles at a constant current of 180 mAg−1; (c) Cycling performance of PAQS at different C-rates; (1C = 200 mA g−1); (d) Cycling performance of PAQS at 8 C rate (1600 mA g−1). The electrolyte was a mixed DOL/DME solution saturated with NaPF6. The charge-discharge capacities were derived from 2032 coin type Na-PAQS cells, measured at the voltage interval of 1.2–2.8 V vs Na+/Na.

Fig. 3b shows the charge-discharge curves of the PAQS polymer with respect to Na. In accord with the CV data, the PAQS electrode shows two stepped charge and discharge at 2 V and at 1.5 V, respectively, revealing a two-step redox reaction. The total discharge capacity is 220 mAh g−1, corresponding to a 98% utilization of its theoretical 2 Na storage capacity.

The PAQS anode has demonstrated not only a high capacity, but also a high rate capability. As displayed in Fig. 4c, the PAQS anode delivers a surprisingly high capacity of 210 mAh g−1 and 175 mAh g−1 at considerably high rate of 2 C (400 mA g−1) and 16 C (3200 mA g−1), respectively. Even at a very high rate of 30 C, the discharge capacity can still reach 160 mAh g−1, corresponding to a 73% utilization of its reversible capacity, which is very rarely observed for Na insertion reactions. Fig. 4d shows the cycle performance of a Na/PAQS cell at a constant current of 8 C rate (1600 mA g−1). The cell exhibited very stable cycling performance with almost indiscernible capacity decay and kept its coulombic efficiency around 100% during successive 200 cycles. Such an excellent cyclability arises apparently from the electrochemical reversibility of the anthraquinone units and the structural stability of the PAQS chains.

A prototype all-organic Na-ion battery

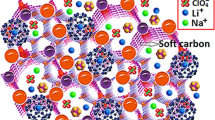

Encouraged by the suitable p- and n-type redox activities of PTPAN and PAQS polymers, we used these two polymers to construct an all-organic Na-ion battery. The cell reaction of such an all-organic battery is expressed in Eq. (1) – (3). During the charge process, the PAQS anode is n-type redox-active to accept electrons from an external circuit with Na+ association, while the PTPAn cathode is p-doped to donate its electrons to an external circuit with PF6− association for charge counterbalance. At reversed discharge, Na+ cations and PF6− anions are disassociated from the anodic PAQS and cathodic PTPAn chains, respectively, while the electrons flow from the anode to the cathode through the external circuit.

Electrochemical performances of coin type PAQS/PTPAn cells are demonstrated in Figure 5. As shown in Fig. 5a, the cell works very well with an average voltage of ~ 1.8 V. As an anode-limited design, the reversible capacity of the cell is determined by the mass of anode material and the realized capacity of the cell reaches 220 mAh g−1 (the full capacity of the PAQS anode) after a few cycles, suggesting a complete electrochemical utilization of the polymer materials. More strikingly, this all-organic cell displays a surprisingly high rate capability with a reversible capacity of 130 mAh g−1 and 118 mAh g−1 at very high rate of 16 C and 32 C, respectively (Fig. 5b). In addition, this cell also exhibit a superior cycling stability with 85% capacity retention and 99% columbic efficiency over 500 cycles at 8 C rate (Fig. 5c), which far exceed all the organic-based batteries reported so far30,31. Taking into account the total mass weight of the cathode and anode materials, the theoretical energy density of cell attains to 92 Wh kg−1. In general, electrode materials possess about 60% of the total weight of the practical batteries. Thus, our organic battery may achieve a practical specific energy of ~ 55 Wh kg−1, which is competitive with the specific energy densities of conventional Pb acid, Ni-Cd and Ni-MH batteries (25 ~ 50 Wh kg−1).

Electrochemical performances of the all-organic PAQS/PTPAn cells with an optimized mass ratio of PTPAn: PAQS = 2.5:1.

(a) Charge and discharge curves at 1C rate (1C = 200 mA g−1); (b) Cycling capacities at varies C-rates; (c) Cycling performance of PAQS at 8 C rate.The charge-discharge capacities were derived from 2032 coin type cells, measured at the voltage interval of 0–2.7 V.

It should be pointed out that several types of all-organic rechargeable batteries have been proposed very recently and demonstrated electrochemical feasibility30,31,32,33. For instance, Nishide's group firstly utilized a p-type poly(TEMPO-substituted norbornene) cathode in conjunction with an n-type poly(galvinoxylstyrene) anode to construct a totally radical polymer-based battery30. Also, their group found some radical polymers bearing pendant nitroxide groups to have bipolar (p- and n-dopable) redox activities, capable to be used as both cathode and anode for constructing a symmetric all-organic battery33. However, these radical batteries have very low specific energy densities, because of their low working voltage (<1 V) and small redox capacity (~50 mAh g−1). Very recently, our group have revealed an all-organic lithium ion battery using bipolar polyparaphenylene (PPP) as both cathode- and anode-active materials31. This new battery can operate at a high voltage of 3.0 V with fairly high capacity, benefiting from the large voltage gap between its p-type reaction and n-type reaction of PPP electrode. However, the capacity utilization and cycleability of the PPP-based cell is relatively poor, possibly due to a mismatching between the anode and the cathode. In comparison, the PTPAn/PAQS battery developed in this work demonstrates greatly enhanced electrochemical performance both in terms of energy density and long-term cyclability. More significantly, this battery system uses natural abundant Na+ electrolyte rather than expensive Li+ electrolyte, thus offering a low cost and environmentally friendly alternative to the existing batteries.

Discussion

Though our organic Na-ion battery has a much lower specific energy than the advanced Li-ion batteries due to its low voltage, this deficiency could be overcome by exploring suitable electrode-active polymers with higher p-doping potential and lower n-doping potential. Undoubtedly, a large diversity of organic structures would enable the feasibility of finding and developing such electrode-active polymers, therefore achieving high voltage and high capacity organic batteries.

It should be noted that the organic battery has an instinct drawback of low volumetric energy density. As far as we know, organics usually have much lower mass density than inorganics, because of its highly branched structure and large porosity. However, this may not a problem where the volume issue is not the strict limitation, such as in thin film flexible electronics and grid-scale energy storage applications.

Another problem with our organic Na-ion battery is that the electrolyte participates in the battery reaction, causing a consumption of electrolyte. As illustrated in Fig. 1 and Fig. 3, each PTPAN unit combines with 2 PF6− during the charge process, while each PAQS unit combines with 2 Na+. Thus, for practical battery applications, excessive electrolyte is needed to allow fast electric storage reactions and high ion conduction.

Nevertheless, our work has demonstrated, for the first time, a viable Na-ion battery using polymeric cathode and anode. This battery offers new possibilities to create high energy/power density, cost-effective, environmentally friendly energy storage system for future large scale applications.

In summary, we have successfully constructed an all-organic Na-ion battery by use of PTPAn cathode and PAQS anode. Different from “rocking-chair” type batteries, this Na-ion battery works through reversible Na+-doping/dedoping reactions at the anode with simultaneous PF6−-doping/dedoping reactions at the cathode during charge/discharge processes. Because the cathodic p-doping reaction and anodic n-type reaction are well separated and have excellent redox reversibility, the organic battery can be discharged at 1.8 V with a considerable specific energy of 92 Wh kg−1, stable cyclability and superior rate capability. Most significantly, this type of battery is made from low cost and environmentally benign organic polymers, offering a new possibility for widespread energy storage applications.

Methods

Material preparation

PAQS was synthesized by a polycondensation reaction of Na2S and1,5-Dichloroanthraquinone. Anhydrous Na2S was obtained by removing the hydrated water from Na2S·9H2O (Lingfeng Chemical reagent co., Ltd, Shanghai, China) through azeotropic dehydration in benzene at 135°C. After evaporation of benzene, a stoichiometric quantity of 1,5-Dichloroanthraquinone (Alfa Asser) and N-methyl-2-pyrrolidone (NMP) was added into the mixture and then refluxed at 150°C for 10 h under magnetic stirring. After the reaction was completed, the solid was filtered, then washed alternately with de-ionized water and acetone and finally dried in vacuum oven over night at 60°C. PTPAn was obtained by an oxidative polymerization of triphenylamine monomer (purity ≥ 99.0%, Zhenjiang Haitong Chemical Industry Co., Ltd., Jiangsu, China) using FeCl3 oxidant and under the purge of dry N2, in a similar way as described in ref. 25.

Physical characterizations

Infrared (IR) absorption measurements were conducted using KBr pellets on AVATAR 360 spectrometer (NICOLET 5700 FTIR Spectrometer) in range of 400–4000 cm−1. Solid–state 13C NMR was performed with Inova 300 MHz Spectrometer (Varian Inc., USA). SEM micrographs were observed on a nova nanosem 450 scanning electron microscope (FEI Company, Holland).

Electrochemical measurements

Electrochemical characterization of the PAQS and PTPAn materials was separately evaluated in a half-cell configuration of CR2032-type coin cells using sodium disks as counter electrodes. The electrolyte was a mixed solution of 1,2-dimethoxy ethane (DME) and 1,3-dioxolane (DOL) (1:1 by volume) saturated with NaPF6. The separator was a microporous membrane (Celgard 2400). The PAQS anode were prepared by mixing 40% PAQS powders, 50% Ketjen Black (KB) and 10% polytetrafluroethylene (wt.%) and rolling the electrode mixture into a ~ 0.1 mm think film. The anode was finished by pressing the electrode film onto aluminium mesh, then punching the electrode into ϕ2 mm disks and drying the anodic disks in vacuum for 24 h at 60°C. The PTPAn cathode consisted of 60% active material, 30% Super P carbon and 10% polytetrafluroethylene (wt.%), made in the same way as the PAQS anode. Prototype all-organic Na-ion cells were constructed using the PAQS anode and PTPAn cathode with an anode-limited design, where a slightly excess of the cathode material was used, so that the cell capacity was determined by the anode material.

References

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Dunn, B., Kamath, H. & Tarascon, J.-M. Electrical energy storage for the grid: A Battery of choices. Science 334, 928–935 (2011).

Yang, Z., Zhang, J., Kintner-Meyer, M. C. W., Lu, X., Choi, D., Lemmon, J. P. & Liu, J. Electrochemical energy storage for green grid. Chem. Rev. 111, 3577–3613 (2011).

Palomares, V., Serras, P., Villaluenga, I., Hueso, K. B., Carretero-Gonzalez, J. & Rojo, T. Na-ion batteries, recent advances and present challenges to become low cost energy storage systems. Energy Environ. Sci. 5, 5884–5901 (2012).

Kim, S.-W., Seo, D.-H., Ma, X., Ceder, G. & Kang, K. Electrode materials for rechargeable sodium-ion batteries: Potential alternatives to current lithium-ion batteries. Adv. Energy Mater. 2, 710–721 (2012).

Slater, M. D., Kim, D., Lee, E. & Johnson, C. S. Sodium-ion batteries. Adv. Funct. Mater. 23, 947–958 (2012).

Yabuuchi, N., Kajiyama, M., Iwatate, J., Nishikawa, H., Hitomi, S., Okuyama, R., Usui, R., Yamada, Y. & Komaba, S. P2-type Nax[Fe1/2Mn1/2]O2 made from earth-abundant elements for rechargeable Na batteries. Nature Mater. 11, 512–517 (2012).

Cao, Y., Xiao, L., Wang, W., Choi, D., Nie, Z., Yu, J., Saraf, L. V., Yang, Z. & Liu, J. Reversible sodium ion insertion in single crystalline manganese oxide nanowires with long cycle life. Adv. Mater. 23, 3155–3160 (2011).

Jian, Z., Zhao, L., Pan, H., Hu, Y.-S., Li, H., Chen, W. & Chen, L. Carbon coated Na3V2(PO4)3 as novel electrode material for sodium ion batteries. Electrochem. Commun. 14, 86–89 (2012).

Qian, J., Zhou, M., Cao, Y., Ai, X. & Yang, H. Nanosized Na4Fe(CN)6/C composite as a low-cost and high-rate cathode material for sodium-ion batteries. Adv. Energy Mater. 2, 410–414 (2012).

Wu, X., Deng, W., Qian, J., Cao, Y., Ai, X. & Yang, H. Single-crystal FeFe(CN)6 nanoparticles: a high capacity and high rate cathode for Na-ion batteries. J. Mater. Chem. A 1, 10130–10134 (2013).

Liu, Y., Xu, Y., Zhu, Y., Culver, J. N., Lundgren, C. A., Xu, K. & Wang, C. Tin-coated viral nanoforests as sodium-ion battery anodes. ACS Nano 7, 3627–3634 (2013).

Qian, J. F., Chen, Y., Wu, L., Cao, Y. L., Ai, X. P. & Yang, H. X. High capacity Na-storage and superior cyclability of nanocomposite Sb/C anode for Na-ion batteries. Chem. Commun. 48, 7070–7072 (2012).

Qian, J., Wu, X., Cao, Y., Ai, X. & Yang, H. High capacity and rate capability of amorphous phosphorus for sodium ion batteries. Angew. Chem., Int. Ed. 52, 4633–4636 (2013).

Novak, P., Muller, K., Santhanam, K. S. V. & Haas, O. Electrochemically active polymers for rechargeable batteries. Chem. Rev. 97, 207–282 (1997).

Milczarek, G. & Inganäs, O. Renewable cathode materials from biopolymer/conjugated polymer interpenetrating networks. Science 335, 1468–1471 (2012).

Liang, Y., Tao, Z. & Chen, J. Organic electrode materials for rechargeable lithium batteries. Adv. Energy Mater. 2, 742–769 (2012).

Park, Y., Shin, D.-S., Woo, S. H., Choi, N. S., Shin, K. H., Oh, S. M., Lee, K. T. & Hong, S. Y. Sodium terephthalate as an organic anode material for sodium ion batteries. Adv. Mater. 24, 3562–3567 (2012).

Zhao, L., Zhao, J., Hu, Y.-S., Li, H., Zhou, Z., Armand, M. & Chen, L. Disodium terephthalate (Na2C8H4O4) as high performance anode material for low-cost room-temperature sodium-ion battery. Adv. Energy Mater. 2, 962–965 (2012).

Zhao, R., Zhu, L., Cao, Y., Ai, X. & Yang, H. X. An aniline-nitroaniline copolymer as a high capacity cathode for Na-ion batteries. Electrochem. Commun. 21, 36–38 (2012).

Zhou, M., Zhu, L. M., Cao, Y. L., Zhao, R. R., Qian, J. F., Ai, X. P. & Yang, H. X. Fe(CN)6−4-doped polypyrrole: a high-capacity and high-rate cathode material for sodium-ion batteries. RSC Adv. 2, 5495–5498 (2012).

Zhou, M., Xiong, Y., Cao, Y., Ai, X. & Yang, H. Electroactive organic anion-doped polypyrrole as a low cost and renewable cathode for sodium-ion batteries. J. Polym. Sci. Part B Polym. Phys. 51, 114–118 (2013).

Zhu, L., Niu, Y., Cao, Y., Lei, A., Ai, X. & Yang, H. n-Type redox behaviors of polybithiophene and its implications for anodic Li and Na storage materials. Electrochim. Acta 78, 27–31 (2012).

Adachi, C., Tsutsui, T. & Saito, S. Organic electroluminescent device having a hole conductor as an emitting layer. App. Phys. Lett. 55, 1489–1491 (1989).

Feng, J. K., Cao, Y. L., Ai, X. P. & Yang, H. X. Polytriphenylamine: A high power and high capacity cathode material for rechargeable lithium batteries. J. Power Sources 177, 199–204 (2008).

Song, Z. P., Zhan, H. & Zhou, Y. H. Anthraquinone based polymer as high performance cathode material for rechargeable lithium batteries. Chem. Commun. 448–450 (2009).

Song, Z. P., Xu, T., Gordin, M. L., Jiang, Y. B., Bae, I. T., Xiao, Q. F., Zhan, H., Liu, J. & Wang, D. H. Polymer-graphene nanocomposites as ultrafast-charge and -discharge cathodes for rechargeable lithium batteries. Nano Lett. 12, 2205–2211 (2012).

Xu, W., Read, A., Koech, P. K., Hu, D., Wang, C., Xiao, J., Padmaperuma, A. B., Graff, G. L., Liu, J. & Zhang, J.-G. Factors affecting the battery performance of anthraquinone-based organic cathode materials. J. Mater. Chem. 22, 4032–4039 (2012).

Pletcher, D. & Thompson, H. A microelectrode study of the influence of electrolyte on the reduction of quinones in aprotic solvents. J. Chem. Soc., Faraday Trans. 94, 3445–3450 (1998).

Suga, T., Ohshiro, H., Sugita, S., Oyaizu, K. & Nishide, H. Emerging N-Type redox-active radical polymer for a totally organic polymer-based rechargeable battery. Adv. Mater. 21, 1627–1630 (2009).

Zhu, L. M., Lei, A. W., Cao, Y. L., Ai, X. P. & Yang, H. X. An all-organic rechargeable battery using bipolar polyparaphenylene as a redox-active cathode and anode. Chem. Commun. 49, 567–569 (2013).

Song, Z. & Zhou, H. Towards sustainable and versatile energy storage devices: an overview on organic electrode materials. Energy Environ. Sci. 6, 2280–2301 (2013).

Suga, T., Sugita, S., Ohshiro, H., Oyaizu, K. & Nishide, H. p-and n-type bipolar redox-active radical polymer: Toward totally organic polymer-based rechargeable devices with variable configuration. Adv. Mater. 23, 751–754 (2011).

Acknowledgements

The authors acknowledge the financial support by the National natural Science Foundation of China (Grant No. 21333007 and No. 21303125).

Author information

Authors and Affiliations

Contributions

J.Q. and H.Y. proposed the conceptual idea. W.D. prepared the electrode materials, constructed the all-organic Na-ion battery, tested its performance and wrote the first draft of the manuscript. X.L. and J.F. supported the solid NMR test. X.W. assisted for the IR test. Y.C. and X.A. contributed to discussions of results. All authors read and approved the final manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Deng, W., Liang, X., Wu, X. et al. A low cost, all-organic Na-ion Battery Based on Polymeric Cathode and Anode. Sci Rep 3, 2671 (2013). https://doi.org/10.1038/srep02671

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep02671

This article is cited by

-

Flexible polytriphenylamine-based cathodes with reinforced energy-storage capacity for high-performance sodium-ion batteries

Science China Materials (2022)

-

Research of dual-ion polymer batteries based on N-butyl-N-methylpiperidinium bis(trifluoromethylsulfonyl)imide ionic liquid electrolyte

Ionics (2022)

-

Molecular and Morphological Engineering of Organic Electrode Materials for Electrochemical Energy Storage

Electrochemical Energy Reviews (2022)

-

Enhancing electrochemical performances of small quinone toward lithium and sodium energy storage

Rare Metals (2022)

-

High Rate and Long Lifespan Sodium-Organic Batteries Using Pseudocapacitive Porphyrin Complexes-Based Cathode

Nano-Micro Letters (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.