Abstract

Energetic material is a reactive substance that contains a great amount of potential energy, which is extremely sensitive to external stimuli like force. In this work, one-molecule-thick single-crystalline nanosheets of energetic material were synthesized. Very small force applied on the nanosheet proves to lead to the rotation of the tilted nitro groups and subsequently change of current of the nanosheet. We apply this principle to design high-sensitive force sensor. A theoretical model of force-current dependence was established based on the nanosheets' molecular packing structure model that was well supported with the high resolution XPS, AFM analysis results. An ultra-low-force with range of several picoNewton to several nanoNewton can be measured by determination of corresponding current value.

Similar content being viewed by others

Introduction

The growing interest in the field of nanomechanics drives the need for more accurate force measurements down to nanoNewtons for determination of nanomechanical properties of micro- and nano-devices. The comprehensive understanding of the behaviors and properties of materials at nanometer length and nanonewton force scales is one of the critical challenges to be addressed for design and improvement of next generation materials and devices and there are many issues1,2,3 that must be addressed to achieve reliable and quantitative measurements of forces at nano/picoNewton scale. Therefore, researches of ultra-low-force measuring methods and high force sensitive materials are extremely important and urgent. In recent years, some researchers have made important steps based on magnetic flux quantization in a superconducting annulus4, single-molecule force spectroscopy5 and protein-tension6. However, the disadvantages of expensive instruments, cellular complexity and wild-type function losing after protein integration have hampered their widespread adoption7. So, Investigation on ultra high force-sensitive materials and their nano-devices at piconewton scale still has an important significance, particularly the very thin film that have the advantages in design and fabrication micro- and nano-mechanical systems.

Energetic material (EM) is a kind of reactive substance that contains a great amount of potential energy, which has greatly promoted the development of aerospace industry,infrastructure,airbag, weapon, etc8. It is extremely sensitive to stimuli such as impact, friction, heat, static electricity, or electromagnetic radiation. Under those stimuli, EM can be initiated to undergo very rapid, self-propagating reactions that results in the formation of gas products, the liberation of heat. Benefiting from this feature, special sensors that detect those stimuli with super high precision are expected to be developed. The nitro group is one of the most common explosophores used globally in high EMs, for example, TNT (2,4,6-Trinitrotoluene). Researchers believe that nitro groups are far more sensitive to outside stimuli and prove to be trigger spots in nitro EMs9,10. If a small force is applied on a few or a limited number of nitro groups, it will cause nitro groups warping or distortion and will change the conductivity of EM molecules due to conjugated electroconductivity of nitro groups. So ultra-low-force measuring will alternatively be realized by sensing mechanics effect, such as bond tilting, molecular deformation, resistance change, etc.

In the past few years, considerable attention has been focused on two-dimensional (2D) monolayer sheets comprising one atomic or molecular layer, due to their unique structural and phychemical properties. For example, graphene11,12, boron nitride, dichalcogenides13 and oxides14,15,16,17. Most those nanosheets possess chemical stability, which were widely applied in optical and optoelectronic fields. It is a challenge to form the monolayer sheets of highly reactive substances like EMs. Intramolecular reactions of EM monolayer will easily be initiated under very weak stimuli due to its high surface energy and high amount of stored chemical energy in molecules.

If EM is present in the form of monolayer sheets, all the atoms are exposed on the surface. Simple ultra-low-force may deform nitro groups or initiate the intramolecular reactions. Conversely, we may apply this principle to design high-sensitive force sensor. In monolayer sheets, nitro groups will be more sensitive to force than those in free crystals and the number of nitro groups under force can be accurately calculated to obtain an effective force sensing model. Besides, the monolayer sheets of EM may have other unique properties and applications owing to their sensitivity to stimuli of heat, static electricity and electromagnetic radiation, for example, the sheets can be used to create reactive patterns by etching with micro-current for optoelectronic application. In fact until now, no studies have been found that address the preparation of EM monolayer nanosheet and its application in micro sensors.

In this communication, one-molecule-thick single-crystalline nanosheets of EM 2,6-diamino-3,5-dinitropyrazine-1-oxide (LLM-105, Fig. 1a shows the molecular structure) supported on highly oriented pyrolytic graphites (HOPG) were for the first time prepared by using vapour self-assembling method. The shape, surface morphology and molecular packing structure of LLM-105 nanosheets have been investigated through experimental data analysis combined computer simulation. A theoretical model of force-current dependence is proposed based on the principle that nitro group rotation under force leads to the nanosheet thickness decrease and conductivity increase. Furthermore, the validity of model was confirmed by the measured results of AFM as a calibration.

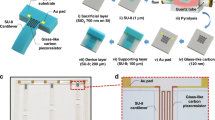

AFM images of LLM-105 nanosheets and the computed model of the molecular packing structure on HOPG surfaces.

(a) Configuration of a single LLM-105 molecule, The atoms are labeled with numbers and letters in the blanks for convenience in description of the intermolecular hydrogen bonds. (b) Topographical image of a LLM-105 nanosheet in contact mode, measured with a gold coated tip under atmosphere and room temperature. The images were recorded at tip load of 0.1 nN,The sheet presents a rectangular shape and a lateral dimension more than 1.0 um × 1.0 um. (c) Line profile along the blue line in a, shows a profile of the nanosheet. It reveals that the sheet has a completely flat plane surface and the thickness averages about 0.8 nm. (d) High-magnification current image of LLM-105 nanosheet with size of 20 nm×20 nm under the conductive AFM mode with load of 0.2 nN, bias of 0.2 V and scanning rate of 0.5 Hz. The inset of d shows a high resolution current image with size of about 5 nm×5 nm. The bright patches are relative high current and the dark patches are relative low current. The bright spots are arranged regularly. The black arrows and blue arc are used to label the distances in corresponding directions and included angle of two directions, respectively. (e) Top view of the computed 2D structure model of the nanosheet. The black circles mark the regions of adjacent two tilted nitro groups with torsion angle of about 154°. The black arrows and numbers note the directions and distances between circles, respectively. (f) Side view of the computed 2D structure model of the nanosheet. (g) Magnification image of computed model outlined in e with a black parallelogram. The torsion angles of N(1)-C(6)-N(7)-O(8) focus on two values, one if 154°, the other is 167°. In a,e,f,g, C, N, O and H atoms are indicated in gray, blue, red and white balls, respectively.

Results

Analysis of atomic force microscopy (AFM) images in the topographic mode (Fig. 1b) shows that LLM-105 was assembled as sheets with a rectangular shape and a lateral dimension of more than 1 μm. From the line sections shown in Fig. 1c, the thickness is measured between the sheet and the substrate surface, which yielded a value of 0.83 nm with a completely flat plane surface. And the calculation results show that the distance between top of the nanosheet and HOPG substrate is about 0.51 nm (Fig. 1d). It means that nanosheet is of one-molecule-thick (typically °1 nm). The surface details of nanosheets can be more clearly observed in high-magnification current image of 20 nm×20 nm with a conductive AFM at 0.1 V (Fig. 1d). Bright patches means relative high current. It is found that periodicity bright spots are presented on the surface of the sheets and the distances of the spots were about 1.4 nm in direction of A and 1.8 nm in direction of B, respectively (inset of Fig. 1d).

In order to determine the molecular packing structure of LLM-105 nanosheets within the HOPG plane, the optimized molecular packing structure has been studied by using density functional theory (DFT) calculations. The simulation results show that LLM-105 molecules can be packed periodically into a monolayer structure on HOPG surface. Two adjacent LLM-105 molecules form centrosymmetric dimers via strong N-H…O hydrogen bond N(13)…O(15′) (Fig. 1a shows the atom serial numbers). The N(10)O2 groups have nearly the same plane with the pyrazine ring, while the N(7)O2 groups are rotated with respect to the ring plane due to the strong repulsive force between a pair of closely nitro groups (Fig. 1e, Fig. 1g). There are two kind of tilted nitro groups with different torsion angle of N(1)-C(6)-N(7)-O(8), one is 167° and the other is 154°. So there exist two kinds of dimers and one dimmer aggregate coplanar with another different kind of dimmer to generate a flat tetramer via intermolecular N-H…O hydrogen bonds N(13)-H(13B)…O(8′) and N(14)-H(14A)…O(9′). As a basic unit, the tetramer is arrayed periodically to form a one-molecule-thick single-crystalline nanosheet via intermolecular hydrogen bonds and the π-π stacked attraction between LLM-105 molecular and graphite layers. The single-crystalline exhibits p2 symmetry with unit cell parameters of a = 1.81 nm, b = 2.13 nm and γ = 139.84°. Two adjacent tilted nitro groups with torsion angle of about 154° form a bulge onto the sheet surface and the bulge height above the ground of graphite layer is about 0.51 nm (Fig. 1f). The regular, periodic bulges are labeled with circles and the distance of the circles were 1.39 nm and 1.81 nm in the direction of A and B, respectively (Fig 1e). Their included angle is about 88°. Meanwhile, when conductive AFM tip scans over the nanosheet with a weak voltage, the bulges are closer to the tip than other region within the sheet surface and the conjugated delocalized electrons of nitro groups have better conductivity, which will result in relatively large current passing through the bulges and form periodicity bright spots in conductive AFM image (Fig. 1d). Distances and direction between the bright spots are in good agreement with those of circles in Fig 1e.

In X-ray Photoelectron Spectroscopy (XPS) of the nanosheets, there exist N1s peaks with binding energy range between 395 eV and 410 eV (shown in Fig. 2a). Comparison of the high resolution N1s spectrum of nanosheets and that of the free LLM-105 crystal (Fig. 2b) exhibits obviously binding energy shifts due to different crystal forms and the different chemical environments of these two samples. It is worthwhile to note that two new peaks appear at around 406.7 eV and 405.8 eV that are assigned to the nitro groups, which means that there are three different nitro groups in nanosheets. The concentration rate of three nitro groups about 1:1:2 for 154° nitro group, 167° nitro group and planar nitro group, respcetively. Above molecular packing model shows that one quarter of nitro groups are tilted with torsion angle of 154°, another quarter are tilted with torsion angle of 167° and two others are parallel to pyrazine ring plane. Additionally, our theoretical results indicate that the smaller the torsion angle of nitro group, the more deviating from pyrazine plane, the higher binding energy in N1s XPS spectra (See Supplemental Information).

High resolution X-ray Photoelectron Spectroscopy (XPS) of LLM 105 collected in the N 1s region.

(a) N 1s XPS spectrum of nanosheets supported on HOPG substrate. The spot size was 0.5 mm and scan number is 10, The spectrum is fit with six components at 406.7, 405.8, 405.1, 402.4, 399.7 and 399.4 eV, assigned to nitrogen from nitro group with torsion angle of 154°, nitro group with torsion angle of 167°, planar nitro group, -N(O) = C- group, amino-group and -N = C- group, respectively. (b) N 1s XPS spectrum of free LLM-105 crystal with scan number of 8. It is fit with four components at 405.2, 400.2 403.1 and 405.7 ev, assigned to the nitrogen of nitro group, -N(O) = C- group, amino-group and -N = C- group, respectively.

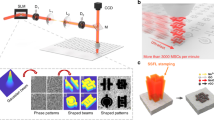

The tilted nitro groups are closer to HOPG than planar nitro groups, which improve the conductivity of the one-molecule-thick nanosheets due to the delocalized π-clouds in nitro groups. Fig. 3a shows typical current-voltage (I–V) curves for an Au coated tip in contact with a LLM-105 nanosheet on HOPG. 10 times repeated experiments lead to almost the similar curves, which indicate that the nanosheets are stable at this range of voltage and force. Those curves appear symmetric and show a reasonably linear slope at low bias voltage. The approximate linear portion of the I-V characteristic between ±0.3 V was used to define the nanosheet resistance equal to 1/slope. At higher bias values, the current shows a nonlinear increase. Voltage excursions beyond 1.5 V typically results in a dramatic increase in current and further rise in voltage will lead to nanosheet break. The most probable reason is that under high current, LLM-105 decomposes and forms gas molecules to escape into space, which led to breakdown of the nanosheet at the point of contact with AFM tip. By using this feature, two square patterns (Fig. 3c) and the logo of our institute(Fig. 3d)are directly written on the nanosheet under the program that controls the tip-moving route path. ICM is the abbreviation of our institute, Institute of Chemical Materials. A similar experimental was conducted on grapheme oxide (GO) nanosheet that contains no energetic groups under same conditions, no obvious changes was observed (see Supplemental Information).

I-V curves of the LLM-105 nanosheets and patterns on nanosheets.

(a) the I-V curve of the LLM-105 nanosheet on HOPG at a voltage ranged from −1.0~1.0 V conducted by a conductive AFM tip at a load of 1 nN. There are ten almost overlapping curves that indicate the nanosheet is stable under the voltage less than 1.0 V. (b) I-V characters of the nanosheet at large bias scale with the same tip and load as a. Ten curves are similar and it is showed that the nanosheet becomes unstable when the voltages surpass 1.5 V. Further rise in voltage will lead to nanosheet break, which provides the possibility of pattern fabrication in LLM-105 nanosheets. (c) Dynamic force microscope (DFM) topographical of LLM-105 nanosheet on HOPG, the dark squares in nanosheet in regions of 50 nm×50 nm and 200 nm×200 nm were scanned at bias value of 5 V with conductive AFM. (d) The logo pattern of our institute, ICM, wrote on an explosive nanosheet of LLM-105. “ICM” is the abbreviation of “Institute of Chemical Materials”.

Discussion

LLM-105 has a skeleton of pyrazine ring with a conjugated system of six π-electrons delocalized over the ring and has alternating nitro- and amino-groups in combinaton with N-oxide moiety that are capable of the formation of both the intra- and inter-molecular hydrogen bonds18. Driven by the intermolecular hydrogen-bond interactions and chemical bonding of π-π stacking attraction between the LLM-105/graphite layers, LLM-105 gaseous molecules are absorbed on the surface of HOPG substrate and undergo self-assembly to form nanosheets. The molecular self-assembly process is the result of an intricate balance between adsorbate–adsorbate and adsorbate–substrate interactions. Dimension and shape of the aggregation on the HOPG surface are controlled by forces including Van der Waals interactions and π–π stacked interactions between the LLM-105 and graphite layers, electrostatic interactions between closed nitro groups, forces of intermolecular hydrogen-bond among LLM-105 molecules. The chemical bonding of π-π stacked attraction prompts the molecules to aggregate coplanar. The intermolecular hydrogen-bond interaction constrains the molecules to array compactly and regularly to form a two-dimensional crystal with p2 symmetry (Fig 1e). The binding energy in N1s XPS spectra are in good agreement with the computed model of LLM-105 molecular packing structure on HOPG plane and the computed packing structure of nitro groups is in good agreement with AFM analysis results. The great correspondence of theoretical simulation and experimental results verified that the molecular packing model is accurate and reliable.

According to the molecular packing model, a quarter of nitro groups in the nanosheets are tilted from pyrazine ring plane with torsion angle of 154°. Under tip force, the most deformation of nanosheet is taken up by rotation of the 154° nitro groups, because the elastic deformation caused by van der Waals forces is very small compared with the twisted deformation of the tilted nitro groups (See Supplemental Information). Ultra-small tip force will lead to the rotation of the tilted nitro groups and thinning of the nanosheet and increase of current. Based on the torsion of the nitro groups, a one-to-one dependency between current and force may be established. As such, a high-sensitive force sensor is expected to be fabricated from the one-molecule-thick nanosheets of energetic material and the schematic of the measurement architecture is shown in Fig. 4d.

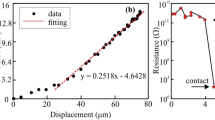

Dependence of force-current for LLM-105 nanosheets on HOPG substrate.

(a) logarithm of the curren of LLM-105 nanosheet as a function of applied bias at tip load of 0.2 nN, 1.5 nN, 3.0 nN, 6 nN and 7.5 nN. It shows the conductivity of the nanosheets was increased exponentially with the force. (b) The force-current experimental data (symbols) and theoretical fits (solid lines) at a constant bias of 0.5 V. A relation curve is drawn on the base of the currents at 30 different loads from 150 pN to 9.2 nN. The curve fits well with the calculating model described in text. It indicates that the calculating model is accurate and reliable and a load below 150 pN can be calculated by the model. (c) A SEM image of a typical gold-coated tip with an end radius of about 40 nm (the scale bar is 300 nm). (d) Schematic of the measurement architecture, the 154° nitro group will twist under tip load, resulting the conductivity of the nanosheet increase. When tip force is applied on LLM-105 nanosheet, the 154° nitro groups will rotate anticlockwise, the sheet will move toward HOPG and make the sheet thinner and current increase.

Fig. 4a is the I-V characteristics of the nanosheets as a function of tip load. All the I–V curves, obtained with one tip, have a similar profile at loads in the ranges from 0.15 nN to 9.2 nN (our computed results indicated that when the tip force was below 9.6 nN, the role of nitro groups with torsion angle of 167° can be neglected, shown in Supplemental Information). The curves are smooth, good linear and non-overlapping. It is revealed that we can establish a good one-to-one relationship between current and force. Using this relationship and by detecting the tunneling current, an ultra-low force could be measured with good reproducibility and high precision. However, not all the molecular nanosheets are applicable for measurement of the micro force with this method. Graphene oxide (GO) nanosheets and titania nanosheet were used to investigate the structure of tilted nitro groups that cause the LLM-105 nanosheets high sensitive to external force. Unlike LLM-105, GO contains conjugated six-membered ring structures and no conductive nitro groups. I–V curves of GO nanosheet are not smooth and oscillating, which indicates that current through GO nanosheet is unstable and has no a one-to-one correspondence with force and current (see supplemental information). Furthermore, the GO nanosheet is less sensitive to force than LLM-105 nanosheet. Titania nanosheet is not conductive at low voltage and breakdowns at high voltage. For GO nanosheets and titania nanosheet, it is difficult to establish a good relationship between current and force and those two nanosheets are not suitable for making high sensitive force sensor.

In Fig. 4a, with the force increase, the conductivity of nanosheet increase significantly and it is observed that the curves are remarkably sensitive to applied force. In generally, there are two reasons19,20 that can result in the increase of the current with increasing the tip force. One is the contact area between the tip and nanosheets is extended, the other is the increases of the tunneling current density of the nanosheet induced by the nanosheet deformation. In this work, we have taken into both of factors to investigate force-current dependence of nanosheet. Under the ultra-low force below 9.6 nN, the deformation of the nanosheet is mainly caused by the rotation of 154° nitro groups. The electron transfer of the one-molecule-thick nanosheet, can just be thought as the electrons transporting through a LLM-105 molecular junction with a tunneling progress, the junction conductivity depended the thickness of the nanosheet, the molecular HOMO-LUMO energy gap, the electrode work function, the contact properties between the nanosheet and electrode (physical or chemical contact) and junction bias. The tunneling progress can be simply modeled as a rectangle barrier tunneling21. The barrier length is the nanosheet thickness and the barrier height is depend on the molelar HOMO-LUMO energy gap and the electrode work function and applied bias. At a constant bias, the tunneling current density j decreased exponentially with the barrier length L, it can be expressed by equation (1):

Where j0 is the current density at absent barrier, β is the decay factor that primarily depends on the electronic structure of the nanosheet, the barrier length L is the average thickness of nanosheet (0.83 nm). When the thickness was reduced by applied force, the current density will be increased exponentially. The tip can be looked as a sphere with a radius R of 40 nm (Fig 4c), so the contact area A and the deformation δ can be charactered by Hertz mode22 and shows in following equations:

Where F is the tip Force and the K is the effective modulus given by:

E1 is Young's modulus for the Au coated tip (69 GPa)23, E2 is the modulus for the nanosheet. υ1 and υ2 is the Piosson's ratios for the tip and nanosheet that can be assumed to be 0.33.

So the tunneling current I can be expressed as a function with F by following:

Where  ,

,  , the factor β is presumed to keep a constant with the nanosheet deformation, so the parameter of C and B can keep as a constant for the load. At a constant bias of 0.5 V, the force-current experimental data as symbols and theoretical fits by equation (5) as a solid line are in Fig. 4b. The force-current dependence model is in good coincidence with the experimental data.

, the factor β is presumed to keep a constant with the nanosheet deformation, so the parameter of C and B can keep as a constant for the load. At a constant bias of 0.5 V, the force-current experimental data as symbols and theoretical fits by equation (5) as a solid line are in Fig. 4b. The force-current dependence model is in good coincidence with the experimental data.

Although it is a simple mode that the increase mechanism of current density with the deformation cannot be discussed in detail here, the force sensitivity of current density can be confirmed by this model. The whole LLM-105 molecule is supported by tilting quarter nitro group on the HOPG surface like a molecule spring. When the force increases faintly the molecule would be pushed to the HOPG surface with the tilted nitro group lying down and the conductivity of the molecule would be increased significantly. Compared with elastic deformation of the film thickness, nitro group torsion deformation would increase force-sensitivity up to about two orders of magnitude.

In conclusion, we have synthesized one-molecule-thick nanosheet of LLM-105 energetic material with a rectangular shape and a lateral dimension more than 1.0 um × 1.0 um via vapour self-assembling method. The computed molecular packing model of LLM-105 nanosheets indicates that LLM-105 tetramers array periodically to form a single-crystalline nanosheet of p2 symmetry via intermolecular hydrogen bonds and the π-π stacked attraction. Due to the strong repulsive force, a part of adjacent nitro groups are tilted from pyrazine ring plane with torsion angle of 154°. The molecular packing structure model is good coincidence with high-magnification conductive AFM images and high resolution N1s XPS spectra, which verifies the molecular packing model has a high accuracy. The nanosheet is very sensitive to electricity and force stimuli. Its sensitivity to electricity offers a way to write optional patterns on the nanosheet and its sensitivity to force provides an opportunity to fabricate high-sensitive force sensor. Very small tip force applied on the nanosheet will lead to the rotation of the tilted nitro groups and increase of current. A theoretical model of force-current dependence is obtained by using the unique feature that nitro group torsion is very sensitive to force. The force-current experimental data made by AFM supports our force-current model well. Depending on the model, the force with the range of several picoNewton to several nanoNewton can be measured by determination corresponding current value.

Methods

Experimental

Crude LLM-105 was synthesized by u the method reported by Pagoria, P. F. et al24,25 and then refined to 99.5% purity by recrystallization from dimethyl sulfoxide. 0.1 g LLM-105 powder was added to the sample plate that was fixed on an evaporating equipment. Increased the sample plate temperature to 220°C at atmospheric pressure and hold for 20 min. Then a 1 cm2 piece of HOPG substrate was cleaved and placed 15 cm above the sample for 40 s. The LLM-105 vapor was deposited on the surface of HOPG and assembly formed monolayer sheets. XPS was accomplished using a VG ESCALAB 250 Instrument equipped with a dual X-ray anode (Mg and Al). Data was obtained with Mg Kαradiation at 200 W.

The topography of LLM-105 nanosheet was charactered by conductive AFM (Seiko) with the tip load at 0.1 nN and the molecular image was got by current image at 0.1 V with the Au-coated tip. The measurement was made using conductive AFM with a spring constant of 0.15 N/m and tip radius of 50 nm. The conductance of the tip was verified on cleaved HOPG before and after use and the I–V characters of LLM-105 nanosheet was obtained by averaged result with ten measurements at different point at same load.

Simulation

Considering the intermolecular hydrogen-bond interactions and π-π stacking attraction between the LLM-105/graphite layers, a [001] crystal surface of graphite was cleaved with surface vectors of u (10, 5, 0) and v (−13, −16, 0) to study the crystal structure of LLM-105. Thus, a model consisting of 8 molecules in lamellae was adopted as the monolayer on graphite surface, using periodic boundary conditions. The height of supercell is 23 Å and giving a vacuum region of about 16 Å to insure negligible interaction between adjacent LLM-105 and graphite slabs. In this work, the density functional theory (DFT) calculation was performed by the Cambridge serial total energy package (CASTEP)26 code, in which a plane wave basis set was used. The exchange and correlation interactions were modeled using the generalized gradient approximation (GGA) and the Perdew-Burke-Ernzerhof (PBE)27 functional. The Vanderbilt ultrasoft pseudopotential28 was used with a cutoff energy of 340 eV. Geometric convergence tolerances were set for maximum force of 0.03 eV/Å, maximum energy change of 10-5 eV/atom, maximum displacement of 0.001 Å and maximum stress of 0.5 GPa. Density mixing electronic minimisation was implemented and the self-consistent field (SCF) tolerance was set to “fine” with high accuracy of 10-6 eV/atom for energy convergence.

References

Müller, D. J. & Dufrene, Y. Atomic force microscopy as a multifunctional molecular toolbox in nanobiotechnology. Nature Nanotech. 3, 261–269 (2008).

Yildiz, A. et al. Myosin V walks hand-over-hand: Single fluorophore imaging with 1.5-nm localization. Science 300, 2061–2065. (2003).

Mohideen, U. & Roy, A. Precision measurement of the Casimir force from 0.1 to 0.9 um. Phys.Rev.Lett. 81, 4549–4552 (1998).

Choi, J. H., Kim, M. S. & Park, Y. K. Quantum-based mechanical force realization in piconewton range. Appl. Phys. Lett. 90, 073117 (2007).

Dufrene, Y. F. et al. Five challenges to bringing single-molecule force spectroscopy into living cells. Nat. Methods 8, 123–127 (2011).

Grashoff, C. et al. Measuring mechanical tension across vinculin reveals regulation of focal adhesion dynamics. Nature 466, 263–266 (2010).

Stabley, D. R., Jurchenko, C., Marshall, S. S. & Salaita, K. S. Visualizing mechanical tension across membrane receptors with a fluorescent sensor.Nat. Methods 9, 64–67 (2012).

Badgujar, D. M., Talawar, M. B., Asthana, S. N. & Mahulikar, P. P. Advances in science and technology of modern energetic materials: An overview.J. Hazard. Mater 151, 289–305 (2008).

Zhang, C. Y. et al. Investigation of correlation between impact sensitivities and nitro group charges in nitro compounds. J. Phys. Chem. B 109, 8978–8982 (2005).

Gilberto, A. & Itamar, B. Topological analysis of the molecular charge density and impact sensitivity models of energetic molecules. J. Phys. Chem. A 115, 9055–9068 (2011).

Novoselov, K. S. et al. Electric field effect in atomically thin carbon films. Science 306, 666–669 (2004).

Geim, A. K. & Novoselov, K. S. The rise of graphene. Nat. Mater. 6, 183–191 (2007).

Novoselov, K. S. et al. Two dimensional atomic crystals. Proc. Natl Acad. Sci. USA 102, 10451–10453 (2005).

Li, W. B. et al. Engineered interfaces of artificial perovskite oxide superlattices via nanosheet deposition process. ACS Nano 4, 6673–6680 (2010).

Liu, G. et al. Visible light responsive nitrogen doped anatase TiO2 sheets with dominant {001} facets derived from TiN. J. Am. Chem.Soc. 131, 12868–12869 (2009).

Osada, M. et al. Orbital reconstruction and interface ferromagnetism in self-assembled nanosheet superlattices. ACS Nano 5, 6871–6879 (2011).

Osada, M. & Sasaki, T. Two-dimensional dielectric nanosheets: novel nanoelectronics from nanocrystal building blocks. Adv. Mater 24, 210–228 (2012).

Averkiev, B. B., Antipin, M. Y., Yudin, I. L. & Sheremetev, A. B. X-ray structure study of three derivatives of dinitropyrazine.J. Mol. Struct 606, 139–146 (2002).

Son, K. A., Kim, H. I. & Houston, J. E. Role of stress on charge transfer through self-assembled alkanethiol monolayers on Au. Phys.Rev.Lett. 86, 5357–5360 (2001).

DelRio, F. W. et al. Elastic, adhesive and charge transport properties of a metal-molecule-metal junction: the role of molecular orientation, order and coverage. Langmuir 26, 1688–1699 (2010).

Wold, D. J. & Frisbie, C. D. Fabrication and characterization of metal-molecule-metal junctions by conducting probe atomic force microscopy.J. Am. Chem. Soc. 123, 5549–5556 (2001).

Johnson, K. L. Contact Mechanics. Cambridge University Press, P84 (1985).

Salvadori, M. C. et al. Measurement of the elastic modulus of nanostructured gold and platinum thin films. Phys. Rev. B, 67 153404–153406 (2003).

Pagoria, P. F. et al., Synthesis, scale-up and experimental testing of LLM-105. Presented at the Insensitive Munitions and Energetic Materials Technology Symposium, San Diego, CA, (1998).

Lee, G. S. et al. Synthesis of amino- and nitro-substituted heterocycles as insensitive energetic materials. 2001 Insensitive Munitions and Energetic materials Technology Symposium, Bordeaux, France (2001).

Segall, M. D. et al. First-principles simulation: ideas, illustrations and the CASTEP code. J. Phys-Condens. Mat 14, 2717–2744 (2002).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Vanderbilt, D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys Rev B. 41, 7892–7895 (1990).

Acknowledgements

The authors thank Dr. Longyu Liao and Dr. Fachun Zhong for their help in XPS analysis and synthesis of LLM-105 raw material. This work was supported by the National Natural Science Foundation of China (grant no. 11002128, 11272292, 11172276) and the Foundation of China Academy of Engineering Physics (grant no. 2009A0302017).

Author information

Authors and Affiliations

Contributions

Yang G.C. and Hu H.L. designed and performed the experiments. Yang G.C. and Zhou Y. conceived the experiments and wrote the manuscript. Hu Y.J. and Shi W.M. carried out the DFT calculations. All authors discussed the results and commented.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Yang, G., Hu, H., Zhou, Y. et al. Synthesis of one-molecule-thick single-crystalline nanosheets of energetic material for high-sensitive force sensor. Sci Rep 2, 698 (2012). https://doi.org/10.1038/srep00698

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep00698

This article is cited by

-

Pb(II) removal in water via adsorption onto deep eutectic solvent fabricated activated carbon

Applied Water Science (2021)

-

Bioinspired hierarchical interface design for improved mechanical and safety properties in energetic polymer composites

Journal of Materials Science (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.