Abstract

Reduction and oxidation in transition-metal oxides are keys to develop technologies related to energy and the environment. Here we report the selective topochemical reduction observed when artificial superlattices with transition-metal oxides are treated at a temperature below 300 °C with CaH2. [CaFeO2] m /[SrTiO3] n infinite-layer/perovskite artificial superlattice thin films were obtained by low-temperature reduction of [CaFeO2.5] m /[SrTiO3] n brownmillerite/perovskite artificial superlattice thin films. By the reduction only the CaFeO2.5 layers in the artificial superlattices were reduced to the CaFeO2 infinite layers whereas the SrTiO3 layers were unchanged. The observed low-temperature reduction behaviors strongly suggest that the oxygen ion diffusion in the artificial superlattices is confined within the two-dimensional brownmillerite layers. The reduced artificial superlattice could be reoxidized and thus, the selective reduction and oxidation of the constituent layers in the perovskite-structure framework occur reversibly.

Similar content being viewed by others

Introduction

Oxygen-deficient perovskites AFeO3-δ (A = Sr or Ca) (δ = 0∼1.0) attract much attention because they show wide varieties in crystal structures and physical properties as a function of oxygen content and thus they have been studied extensively for more than 40 years1,2,3,4. For example, SrFeO3 (δ = 0) is a simple perovskite, contains iron ions with unusually high valence state (Fe4+), which is stabilized by a strong oxidizing atmosphere and exhibits metallic conductivity1,5,6. SrFeO2.5 (δ = 0.5), on the other hand, is synthesized at an ambient condition and its brownmillerite structure consists of alternate layers of Fe3+ octahedra and tetrahedra and is an antiferromagnetic insulator7. Although it was not possible to produce a perovskite with Fe2+ by using any reduction techniques, recently low-temperature topochemical reduction made the brownmillerite SrFeO2.5 to an infinite-layer structure SrFeO2 (δ = 1.0)8,9,10. Such a wide range of oxygen nonstoichiometry could also be exploited in applications for electrochemical energy generation and storage devices11,12,13.

The infinite-layer structure AFeO2 is the first iron oxide with Fe2+ with an unusual square-planar coordination of oxygen and is made from the corresponding brownmillerite AFeO2.5 by reducing it at a low temperature with CaH2 (refs. 8 and 14). This reduction reaction changes the iron from Fe3+ with a tetrahedral or octahedral coordination to Fe2+ with an unusual square-planar coordination15. A similar reaction with CaH2 also reduces a perovskite LaNiO3 to an infinite-layer structure LaNiO2 with unusual square-planar coordinated monovalent Ni (refs. 16–18). Thus, the low-temperature reduction removes oxygen atoms from the fundamental perovskite-structure framework and adjusts the oxidation state and the oxygen coordination of cations19,20.

AFeO2 is also obtained in a single-crystalline thin film form by the reduction of AFeO2.5 thin film21,22. Interestingly, the topotactic reduction of thin films of the brownmillerite CaFeO2.5 to the infinite-layer CaFeO2 revealed that there are two ways of oxygen rearrangement that have different kinetics. Both a-axis oriented and b-axis oriented CaFeO2.5 thin films changed to the c-axis oriented CaFeO2 films, but the complete reduction of the b-axis oriented film took longer time than that of the film oriented on the a axis23. Thus, the low-temperature reduction behaviors seen in the thin film samples provide us deep insight into oxygen-ion rearrangement in oxides.

Similar oxygen release and rearrangement were seen in the reduction of an artificial brownmillerite superlattice thin film consisting of CaFeO2.5 and SrFeO2.5 to an infinite-layer-structure superlattice thin film consisting of CaFeO2 and SrFeO2 (ref. 24). The oxygen atoms in the constituent brownmillerite-structure oxides are released from the superlattice layers of the thin film. This raised an interesting question as to what happens during the reduction of artificial superlattice thin films consisting of the brownmillerite CaFeO2.5 and the perovskite SrTiO3. Because SrTiO3 is rather stable in any atmosphere, the oxygen rearrangement facilities are expected to be different between the two constituent layers. The reduction behaviors of such artificial superlattices are investigated in the work reported here.

Results

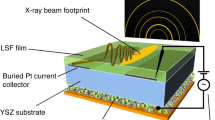

Brownmillerite/perovskite artificial superlattices, [CaFeO2.5] m /[SrTiO3] n (m = 4, 6 and 8; n = 1, 2, 3 and 4), were prepared on single-crystal SrTiO3(001) substrates by pulsed laser deposition. The reflection high energy electron diffraction (RHEED) intensity oscillation during the growth of a [CaFeO2.5]4/[SrTiO3]3 superlattice is shown in Fig. 1. The observed clear oscillation pattern confirms that both CaFeO2.5 and SrTiO3 are grown in a layer-by-layer growth mode. As reported in a previous paper24, b-axis-orientated [CaFeO2.5]2 7.4 Å thick, a thickness corresponding to one FeO6 octahedron and one FeO4 tetrahedron, grew during a single RHEED oscillation. Thus, the deposition of CaFeO2.5 for the two oscillations produces m = 4 layers. One-unit-cell-thick SrTiO3 (3.91 Å) can also be deposited during a single RHEED oscillation.

As shown in the X-ray diffraction pattern of the [CaFeO2.5]4/[SrTiO3]1 superlattice in Fig. 2a (the structure model is shown in Fig. 2b), the (0 0 l) diffraction peaks confirm the successful growth of the superlattice structure. Note that the stacking direction of the artificial superlattice is defined here as the c direction. The X-ray diffraction patterns of the m = 8 (n = 1, 2, 3 and 4) and m = 6 (n = 1, 2, 3 and 4) superlattices prepared in the present study are also shown in Supplementary Figs. S1 and S2, respectively. As shown in Fig. 3, the out-of-plane lattice constants of the as-deposited [CaFeO2.5] m /[SrTiO3] n brownmillerite/perovskite superlattices are on the line of 3.70 [ = b (CaFeO2.5: 14.8 Å)/4] × m + 3.91 × n Å. These results thus clearly show that the brownmillerite/perovskite superlattices were prepared as designed.

XRD patterns and crystal structures of artificial superlattices.

(a) X-ray diffraction patterns of the as-deposited [CaFeO2.5]4/[SrTiO3]1 brownmillerite/perovskite superlattice and the reduced [CaFeO2]4/[SrTiO3]1 infinite-layer/perovskite superlattice. Also shown at the bottom is the X-ray diffraction pattern calculated from the superlattice structure model of [CaFeO2]4/[SrTiO3]1 shown in Figure 2c. (b), (c) Crystal structures of (b) the [CaFeO2.5]4/[SrTiO3]1 brownmillerite/perovskite superlattice and (c) the reduced [CaFeO2]4/[SrTiO3]1 infinite-layer/perovskite superlattice. The brownmillerite and infinite-layer structures are drawn with Ca in green, Fe in brown and O in red and the perovskite structure is drawn with Sr in blue and TiO6 octahedra in light blue.

Out-of-plane lattice constants of as-deposited and reduced artificial superlattices.

(a) Relation between the number m of CaFeO2.5 layers and the out-of-plane lattice constants of (○) as-deposited and (□) reduced [CaFeO2.5] m /[SrTiO3]1 brownmillerite/perovskite superlattices. The lattice constants of the as-deposited superlattices fit the blue line (3.70×m + 3.91) and those of the reduced superlattices fit the red line (3.35×m + 3.91). (b) Relation between the number n of SrTiO3 layers and the out-of-plane lattice constants of (○) as-deposited and (□) reduced [CaFeO2.5]6/[SrTiO3] n brownmillerite/perovskite superlattices. The lattice constants of the as-deposited superlattices fit the blue line (3.70×6 + 3.91×n) and those of the reduced superlattices fit the red line (3.35×6 + 3.91×n). (c) Same as (b) but for [CaFeO2.5]8/[SrTiO3] n superlattices. The out-of-plane lattice constants of the as-deposited and reduced films follow (3.70×8 + 3.91×n) and (3.35×8 + 3.91×n), respectively.

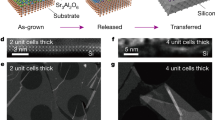

The films were then treated, in evacuated glass tubes, with CaH2 at 280 °C for 48 h. After the reduction process, the (0 0 l) peak positions of the thin films in the X-ray diffraction patterns changed to higher angles (see Fig. 2a and Supplementary Figs. S1 and S2) and thus the out-of-plane lattice constants decreased significantly. The 18.9 Å out-of-plane lattice constant of the as-deposited m = 4 and n = 1 film, for example as seen in Fig. 2a, decreased to 17.9 Å. What is of particular interest here is that the reduced out-of-plane lattice constant is very close to the lattice constant of an artificial superlattice, which consists of four unit cells of the infinite-layer-structure CaFeO2 and one unit cell of SrTiO3. The observed diffraction intensities shown in Fig. 2a are also consistent with those simulated for the superlattice structure model with the infinite-layer CaFeO2 and the perovskite SrTiO3 shown in Fig. 2c.

The reduction of the CaFeO2.5 brownmillerite layer to the infinite-layer structure CaFeO2 in the superlattice was also confirmed by a cross-sectional high-angle annular dark-field scanning transmission electron microscope (HAADF-STEM) image shown in Fig. 4. Although the four-coordinated Fe and six-coordinated Fe in the brownmillerite structure are distinguishable in the HAADF-STEM image (see inset of Fig. 4), such features are not evident in the reduced superlattice, suggesting that all Fe in the reduced film are square-planar coordinated by oxygen ions. The alternate stacking of eight layers of CaFeO2 and three layers SrTiO3 is clearly seen with sharp interfaces. It should also be noted that the bright Sr column distances in the image of the SrTiO3 layer in the reduced film do not change from those of the as-deposited SrTiO3. This implies that no significant oxygen deficiencies are introduced in the SrTiO3 layers after the low-temperature reduction.

HAADF-STEM image of reduced artificial superlattice thin film.

HAADF-STEM image of the reduced [CaFeO2]8/[SrTiO3]3 superlattice. The blue, sky blue, green and red spheres respectively represent Sr, Ti, Ca and Fe atoms. Inset shows a typical HAADF-STEM image of brownmillerite CaFeO2.5, where FeO6 octahedra and FeO4 tetrahedra are distinguishable as illustrated on the image.

The out-of-plane lattice constants of all the reduced superlattices can be fitted with the formula 3.35 [ = c (CaFeO2)] × m + 3.91 × n Å. As shown in Fig. 3, the reduction in the out-of-plane lattice constant always corresponds to the thickness decrease due to the change from brownmillerite CaFeO2.5 to infinite-layer CaFeO2. It is thus clear that the reduced superlattices consist of the infinite-layer CaFeO2 and the perovskite SrTiO3 and that only the brownmillerite CaFeO2.5 layers were reduced by the low-temperature annealing (see the structure in Fig. 2c). The result is completely different from the reduction of the [CaFeO2.5]/[SrFeO2.5] superlattice, in which both constituent brownmillerite CaFeO2.5 and SrFeO2.5 layers were reduced to the infinite-layer structures.

Discussion

Transition-metal ions are well known to show variation in their oxidation states. The oxidation states of Fe, for example, are typically 2+ and 3 + and those of Ti are 2+, 3+ and 4+. The present results with the [CaFeO2.5]/[SrTiO3] artificial superlattices clearly show that the Fe3+ in the CaFeO2.5 brownmillerite is reduced to Fe2+ whereas Ti4+ in SrTiO3 is not reduced under the same reducing atmosphere with CaH2. This is, of course, related to the difference in reduction facilities between Fe3+ (the third ionization energy; 30.6 eV) and Ti4+ (the fourth ionization energy; 43.3 eV). In addition, octahedral coordination with oxygen ions for Ti4+ is pretty stable, but square planar and tetrahedral coordinations are difficult to stabilize.

The results thus suggest the difference in oxygen rearrangement facilities between the two constituent layers and also raise interesting discussion as to how the oxygen atoms are released and rearranged in the present brownmillerite/perovskite superlattices. In the reduction process, if we assume that the oxygen ions are released mainly from the film surface, the results appear to imply that the oxygen ions pass through the perovskite SrTiO3 layers. Considering the fairly large lateral size of the film samples (5 mm × 5 mm × 70 nm-thick), this oxygen diffusion process is possible. In the brownmillerite structure the oxygen ions travel by way of atomic vacancy sites, whereas in the perovskite SrTiO3 structure they travel by way of exchange reactions in the octahedron. On the other hand, suppose that the oxygen ions are released mainly from the sides of the film sample, the oxygen ions travel within the two-dimensional brownmillerite layers, instead of passing through the SrTiO3 layers.

Note here that the time required for the complete reduction of the brownmillerite/perovskite superlattices is almost the same irrespective of the thickness of SrTiO3 layers. Although the actual oxygen diffusion should occur along both perpendicular and parallel directions of the films and the dominant diffusion process may depend on the reduction temperature, the present results strongly suggest that the oxygen diffusion through the thin SrTiO3 layer is not the main pathway at 280 °C. Therefore, at low temperatures like 280 °C, the stable SrTiO3 layers can act as barriers for the oxygen diffusion and the oxygen ion diffusion is confined within the two-dimensional brownmillerite layers. It was indeed reported that the coherent interface in epitaxial ZrO2:Y2O3/SrTiO3 heterostructures increased oxygen mobility at room temperature25,26,27. This suggests that the specific two-dimensional structural feature has important roles in oxygen diffusion in solids, especially at low temperatures.

The reduced infinite-layer/perovskite artificial superlattice could be reoxidized to the brownmillerite/perovskite superlattice by annealing it in an oxidizing atmosphere. Oxygen atoms could be released selectively from the brownmillerite layers and also incorporated into the infinite-layer structure. Thus, the selective reduction and oxidation in the perovskite-structure framework occur reversibly. The results also give a potential application of the artificial superlattice as a two-dimensional oxygen reservoir.

In conclusion, [CaFeO2] m /[SrTiO3] n infinite-layer/perovskite superlattices were prepared by low-temperature reduction of [CaFeO2.5] m /[SrTiO3] n brownmillerite/perovskite superlattices. The brownmillerite/perovskite superlattices were made by pulsed laser deposition in a layer-by-layer growth mode by monitoring the RHEED intensity oscillation during the deposition. The structure analysis of X-ray diffraction data and the HAADF-STEM observation confirmed the successful reduction of the films to the infinite-layer/perovskite superlattices. By the low-temperature reduction with CaH2, only the brownmillerite CaFeO2.5 layers were reduced to the infinite-layer structure CaFeO2 in the superlattices whereas the SrTiO3 layers were unchanged. The results strongly suggest that, in the low-temperature reduction of the [CaFeO2.5]/[SrTiO3] artificial superlattices, the stable SrTiO3 layers can act as barriers for the oxygen diffusion and the oxygen ion diffusion is confined within the two-dimensional brownmillerite layers.

Methods

The artificial superlattice thin films were prepared from CaFeO2.5 and SrTiO3 ceramic targets by pulsed laser deposition using a KrF excimer laser pulse (λ = 248 nm) (COHERENT COMPex-Pro 205 F). The polycrystalline brownmillerite CaFeO2.5 was synthesized by solid-state reaction of Fe2O3 and CaCO3 at 1200 °C for 36 h in air. Brownmillerite/perovskite superlattices, [CaFeO2.5] m /[SrTiO3] n (m = 4, 6 and 8; n = 1, 2, 3 and 4), were prepared on single-crystal SrTiO3(001) substrates with atomically flat terraces and unit-cell steps. The deposition started with CaFeO2.5 and then SrTiO3 was deposited. The oxygen partial pressure during the depositions was 10−5 Torr and the substrate temperature was monitored with a pyrometer and kept at 600 °C.

The thickness of each layer was controlled by in situ observation of reflection high energy electron diffraction (RHEED) intensity oscillation and the total thickness of the artificial superlattice was checked by measuring the Raue fringes in X-ray diffraction profiles and by measuring the X-ray reflectivity of the film. The deposited artificial superlattice thin films were embedded with about 0.25 g CaH2 powder in glass tubes in an argon-filled glove box and the tubes were sealed under vacuum conditions, after which they were kept at 280 °C for 48h. The residual products and unreacted CaH2 on the film surface were removed by rinsing in 2-butanone.

The structures of the superlattices were evaluated by 2θ-θ X-ray diffraction measurements with Cu Kα radiation (PANalytical X'Pert MRD) and the observed diffraction intensities for the artificial superlattice thin films were compared to the calculated ones by the simulation program RIETAN-200028. The structures were also studied by cross-sectional high-angle annular dark-field scanning transmission electron microscope (HAADF-STEM) observations with a JEM-9980TKP1.

References

MacChesney, J. B., Sherwood, R. C. & Potter, J. F. Electric and magnetic properties of the strontium ferrates. J. Chem. Phys. 43, 1907–1913 (1965).

Takeda, Y. et al. Phase relation in the oxygen nonstoichiometric system, SrFeO x (2.5 ≤ x ≤ 3.0). J. Solid State Chem. 63, 237–249 (1986).

Hodges, J. P. et al. Evolution of oxygen-vacancy ordered crystal structures in the perovskite series Sr n Fe n O 3n-1 (n = 2, 4, 8 and ∞) and the relationship to electronic and magnetic properties. J. Solid State Chem. 151, 190–209 (2000).

Woodward, P. M., Cox, D. E., Moshopoulou, E., Sleight, A. W. & Morimoto, S. Structural studies of charge disproportionation and magnetic order in CaFeO3 . Phys. Rev. B 62, 844–855 (2000).

Hayashi, N., Terashima, T. & Takano, M. Oxygen-holes creating different electronic phases in Fe4+-oxides: Successful growth of single crystalline films of SrFeO3 and related perovskites at low oxygen pressure. J. Mater. Chem. 11, 2235–2237 (2001).

Lebon, A. et al. Magnetism, charge order and giant magnetoresistance in SrFeO3-δ single crystals. Phys. Rev. Lett. 92, 037202 (2004).

Schmidt, M. & Campbell, S. J. Crystal and magnetic structures of Sr2Fe2O5 at elevated temperature. J. Solid State Chem. 156, 292–304 (2001).

Tsujimoto, Y. et al. Infinite-layer iron oxide with a square-planar coordination. Nature 450, 1062–1065 (2007).

Kohler, J. Square-planar coordinated iron in the layered oxoferrate(II) SrFeO2 . Angew. Chem. Int. Ed. 47, 4470–4472 (2008).

Tassel, C. et al. Stability of the infinite layer structure with iron square planar coordination. J. Am. Chem. Soc. 130, 3764–3765 (2008).

Sammells, A. F., Schwartz, M., Mackay, R. A., Barton, T. F. & Peterson, D. R. Catalytic membrane reactors for spontaneous synthesis gas production. Catal. Today 56, 325–328 (2000).

Badwal, S. P. S. & Ciacchi, F. T. Ceramic membrane technologies for oxygen separation. Adv. Mater. 13, 993–996 (2001).

Shao, Z. & Haile, S. M. A high-performance cathode for the next generation of solid-oxide fuel cells. Nature 431, 170–173 (2004).

Tassel, C. et al. CaFeO2: A new type of layered structure with iron in a distorted square planar coordination. J. Am. Chem. Soc. 131, 221–229 (2009).

Hayward, M. A. & Rosseinsky, M. J. Materials chemistry: Cool conditions for mobile ions. Nature 450, 960–961 (2007).

Hayward, M. A., Green, M. A., Rosseinsky, M. J. & Sloan, J. Sodium hydride as a powerful reducing agent for topotactic oxide deintercalation: Synthesis and characterization of the nickel(I) oxide LaNiO2 . J. Am. Chem. Soc. 121, 8843–8854 (1999).

Kawai, M. et al. Reversible changes of epitaxial thin films from perovskite LaNiO3 to infinite-layer structure LaNiO2 . Appl. Phys. Lett. 94, 082102 (2009).

Kawai, M. et al. Orientation change of an infinite-layer structure LaNiO2 epitaxial thin film by annealing with CaH2 . Cryst. Growth Des. 10, 2044–2046 (2010).

Hayward, M. A. & Rosseinsky, M. J. Anion vacancy distribution and magnetism in the new reduced layered Co(II)/Co(I) phase LaSrCoO3.5-x . Chem. Mater. 12, 2182–2195 (2000).

Hadermann, J., Abakumov, A. M., Adkin, J. J. & Hayward, M. A. Topotactic reduction as a route to new close-packed anion deficient perovskites: Structure and magnetism of 4H-BaMnO2+x . J. Am. Chem. Soc. 131, 10598–10604 (2009).

Inoue, S. et al. Single-crystal epitaxial thin films of SrFeO2 with FeO2 “infinite layers”. Appl. Phys. Lett. 92, 161911 (2008).

Shimakawa, Y. et al. Topotactic changes in thin films of brownmillerite SrFeO2.5 grown on SrTiO3 substrates to infinite-layer structure SrFeO2 . Cryst. Growth Des. 10, 4713–4715 (2010).

Inoue, S. et al. Anisotropic oxygen diffusion at low temperature in perovskite-structure iron oxides. Nat. Chem. 2, 213–217 (2010).

Matsumoto, K. et al. Artificial superlattice thin film of infinite-layer structure [CaFeO2]/[SrFeO2]. Appl. Phys. Express 3, 105601 (2010).

Garcia-Barriocanal, J. et al. Colossal ionic conductivity at interfaces of epitaxial ZrO2:Y2O3/SrTiO3 heterostructures. Science 321, 676–680 (2008).

Kilner, J. A. Ionic conductors: Feel the strain. Nat. Mater. 7, 838–839 (2008).

Guo, X. & Maier, J. Ionically conducting two-dimensional heterostructures. Adv. Mater. 21, 2619–2631 (2009).

Izumi, F. & Ikeda, T. A Rietveld-analysis program RIETAN-98 and its applications to zeolites. Mater. Sci. Forum 321–324, 198–203 (2000).

Acknowledgements

We thank S. Inoue and S. Isoda for discussions. This work was supported in part by a Grant-in-Aid for Scientific Research 19GS0207, by the Global Centers of Excellence Program “International Center for Integrated Research and Advanced Education in Materials Science” and by a grant for the Joint Project of Chemical Synthesis Core Research Institutions from the Ministry of Education, Culture, Sports, Science and Technology of Japan. The work was also supported by Japan Science and Technology Agency, CREST.

Author information

Authors and Affiliations

Contributions

K.M. and Y.S. conceived and designed the study. K.M. and M.K. performed the experiments with the help of A.S. and N.I. M.H. and H.K. made the HAADF-STEM observation. All of the authors discussed the results. K.M. and Y.S. wrote the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Figures

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Matsumoto, K., Haruta, M., Kawai, M. et al. Selective reduction of layers at low temperature in artificial superlattice thin films. Sci Rep 1, 27 (2011). https://doi.org/10.1038/srep00027

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep00027

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.