Abstract

The triple phase boundary (TPB) of metal, oxide, and gas phases in the anode of solid oxide fuel cells plays an important role in determining their performance. Here we explore the TPB structures from two aspects: atomic-resolution microscopy observation and reaction dynamics simulation. Experimentally, two distinct structures are found with different contact angles of metal/oxide interfaces, metal surfaces, and pore opening sizes, which have not previously been adopted in simulations. Reaction dynamics simulations are performed using realistic models for the hydrogen oxidation reaction (HOR) at the TPB, based on extensive development of reactive force field parameters. As a result, the activity of different structures towards HOR is clarified, and a higher activity is obtained on the TPB with smaller pore opening size. Three HOR pathways are identified: two types of hydrogen diffusion processes, and one type of oxygen migration process which is a new pathway.

Similar content being viewed by others

Introduction

Among several types of fuel cells, the solid oxide fuel cell (SOFC) has the highest efficiency and could utilize various fuels1. The anode materials in SOFC are typically based on porous composites of Ni with oxides such as yttria-stabilized zirconia (YSZ) or doped ceria1,2. Linking the complex porous structure to the cell performance is a critical issue for the development of SOFC. Realistic three-dimensional (3D) microstructures were obtained after the introduction of focused ion beam-scanning electron microscopy (FIB-SEM) technique to the field of SOFC3,4,5,6. Meanwhile, numerical modeling of porous electrode characteristics has been extended from two-dimensional7,8 to 3D with the development of simulation methods, such as the lattice Boltzmann method8,9 and phase-field method10. Microscopically, the most important location related to the SOFC performance is the triple phase boundary (TPB), where the fuels are electrochemically oxidized11. The TPB structure and its local chemical environment determine the thermodynamics and kinetics of the electrochemical reaction.

Numerous works have been conducted to understand the local activity and reaction mechanism at the TPB. Patterned anodes were fabricated as ideal models to allow easy evaluation of the relationship between the TPB length and electrochemical characteristics12,13,14,15 and to develop kinetic modeling methods14,15,16,17,18,19. However, both the experimental characteristics and modeling results show large variation among different reports20,21. For example, the current densities normalized by TPB length21 obtained by Bieberle et al.13 and Yao et al.15 are about three orders of magnitude higher compared to those by Mizusaki et al.12 while different rate-determining steps were reported, respectively, in those works including either H2 adsorption/desorption on Ni surface or removal of O2− from the YSZ surface13, charge transfer reactions coupled with H2O-related process15, and Ni surface hydrogen oxidation12. First-principles calculations were also applied to the TPB, nevertheless the deduced mechanism and estimated energy barriers differ significantly even when using similar structural models22,23,24,25,26. Recently, Liu et al.21 analyzed those deviations and pointed out the significant importance of elementary processes directly related to TPB at the atomic level. This encouraged us to trace the elementary reaction mechanism at TPB more carefully. Meanwhile, a reactive force field (ReaxFF) method has been developed to model the Ni/YSZ/pore TPB and deduce the hydrogen oxidation mechanism27. However, the Ni surface amorphization and Ni decohesion from YSZ are observed at 1250 K, which, we believe, may be due to a lack in the model stability or parameter reliability.

The TPB strongly affects the properties (including electrocatalysis) of various supported metal catalysts. Owing to their small sizes and easier handlings for observation, the atomic structures of TPB in nano-catalysts, such as Ni/MgAl2O428, Pd/CeO229, Pt/SnO230, and Au/γ-Fe2O331 have been determined using transmission electron microscopy (TEM) or scanning TEM (STEM). In contrast, Ni/YSZ cermet in conventional SOFC is a bulk composite material whose particle size ranges from the submicrometer to micrometer. Its complex microstructure is challenging for the TEM specimen preparation32. Thus there has been no report on the atomic structure of TPBs in a practical cell, while significant experimental attention has been paid to the interfacial structures of Ni/YSZ33,34,35,36,37.

Considering the above-mentioned problems and difficulties in the atomic-scale researches on the TPB of SOFC, herein we report our experimental observations of realistic atomic TPB structures. In addition, we develop ReaxFF for TPB. Based on the obtained results, we computationally deduce the reaction mechanism therein. Two atomic structures of TPB, different from the models used in previous theoretical calculations, are introduced in this work. Overall, our reactive molecular dynamics (MD) simulations show that the hydrogen oxidation reaction (HOR) mechanism is notably influenced by the TPB models. Additionally, we find that the HOR can proceed through a newly discovered reaction pathway.

Results

TPB structure observation

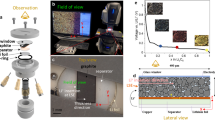

In this work, the Ni/YSZ anode was fabricated through conventional processes38. For the microscopy observation, the pores in Ni/YSZ were infiltrated with epoxy resin. The TEM specimens were extracted from the resin-embedded bulk sample by the lift-out technique using an FIB-SEM and thinned by gallium ion beam with a final voltage as low as 3 kV. In order to remove the damaged layers and the redeposition on the surfaces as much as possible, post-FIB processing was conducted using an Ar ion-milling machine with low voltages from 900 to 600 V39. Even after such mild procedure, some TPB areas were damaged by the ion beam because the sputtering rate of resin was higher than that of the anode materials.

Before showing the observed structures of TPB, we defined three angle parameters for the TPB. As shown in Supplementary Fig. 1, θNi, the so-called contact angle in metal/ceramic material, is the dihedral angle between the Ni/pore and Ni/YSZ boundaries taking ceramic as the substrate. θYSZ and θpore are defined in a similar way. Owing to the poor wettability between metallic Ni and ceramic YSZ, θNi was evaluated by Nelson et al. to be in the range of 140°–155°, based on 3D reconstruction40. Large values of θNi were also observed in our sample (Supplementary Fig. 2). The value of θYSZ falls into two main cases if we restrict the spatial scale to several nanometers around the TPB. One is when YSZ acts as a flat substrate to the Ni particle (θYSZ = 180°, Supplementary Fig. 1a), which corresponds to a small pore opening size (θpore) and is the dominant case in Supplementary Fig. 2. If the above-mentioned statistical values of θNi are adopted40, θpore should be in the range of 25°–40°. In the other case, YSZ does not extend in a straight way from the Ni/YSZ interface to the TPB area, and θYSZ is much smaller than 180° (Supplementary Fig. 1b), thereby a big pore opening size (θpore) is obtained with a value usually exceeding 90° as pointed out by red arrows in Supplementary Fig. 2. Hereafter, these two TPB structures will be referred to as TPB-1 and TPB-2 types, respectively.

TPB-1 has a small θpore, and one such example is indicated by the yellow arrow in Supplementary Fig. 2. The TEM observation was conducted in two directions of YSZ: the [0\(\bar 1\)3] and [001] zone axes, which have an included angle of 18.4°. The corresponding orientation relationships between Ni and YSZ are Ni[12\(\bar 3\)]//YSZ[0\(\bar 1\)3] (Supplementary Fig. 3) and Ni[1\(\bar 1\)0]//YSZ[001] (Supplementary Fig. 4), respectively. The abrupt Ni/YSZ and resin/YSZ interfaces were maintained after rotation (Fig. 1a, b), which indicates that they were always parallel to the observation directions. However, the Ni/resin interface (Ni surface) shows an apparent slope (marked by an arrow in Fig. 1a), which becomes abrupt in Fig. 1b. This phenomenon indicates that only the latter observation direction was parallel to the Ni surface. The contact angle between Ni and YSZ (θNi) was measured from Fig. 1b to be 145°, which is in good agreement with the previously reported values40. Herein, θpore equals the supplementary angle of θNi, namely 35°.

Atomic structure of triple phase boundary-1. a Low-magnification transmission electron microscopy (TEM) image at YSZ[0\(\bar 1\)3] zone axis. The arrow in a points out the slope feature of Ni surface in this observation direction. b Low-magnification high-angle annular dark-field–scanning TEM (HAADF-STEM) image at YSZ[001] zone axis. The dash arc in b stands for the contact angle (θNi). c High-resolution TEM image at YSZ[0\(\bar 1\)3] zone axis. The arrow in c denotes a pore after electron beam damage of the resin. d HAADF-STEM image at YSZ[001] zone axis. The arrow in d points to a thin layer of NiO on the Ni surface. Scale bars in a, b: 50 nm; in c, d: 1 nm

The high-resolution TEM (HRTEM) image at the YSZ[0\(\bar 1\)3] zone axis is shown in Fig. 1c. The YSZ(200) plane is exposed to the gas phase and in contact with the Ni(111) plane. Along the Ni/YSZ interface, small steps could be detected that appeared blurred owing to the lattice overlap, as shown in Supplementary Fig. 5. The “steps” are where the Ni and YSZ are not perfectly parallel along the TEM observation direction or in the image plane. They are believed to be a part of the interfacial migration process that has been previously observed in NiO/YSZ41 and Ni/YSZ42 as well as other metal–ceramic systems such as Ag/ZnO43 and Cu/MgO44. During the baking and reduction processes of NiO/YSZ, the interfacial layers of both Ni(O) and YSZ are expected to migrate due to many factors, such as thermal expansion, lattice shrinkage during reduction, lattice misfit, oxygen bonds change, etc. The migration of Ni, O, and Zr(Y) should proceed toward thermodynamic equilibrium. The interfacial distance between the contacting Ni and YSZ layers was measured to be 0.238 nm from the HRTEM image after background filtering (Supplementary Fig. 5). This value is intermediate to the lattice distances of Ni(111) and YSZ(200) planes and close to the reported value of 0.244 nm for a metal–metal (Ni-Zr) featured interconnection33 that was observed in a Ni/YSZ specimen having the same orientation as TPB-1 and prepared by the reduction/ion milling procedures similar to those adopted in the present study. Namely, the oxygen tends to be lost from the Ni/YSZ interface in TPB-1, and we attribute this to the NiO reduction process rather than the ion damage during FIB preparation. The final voltage adopted by us in FIB is 3 kV, which will cause a damage depth of around 5 nm if the milled material is silicon45. Furthermore, we adopted low voltage post-polishing by using Ar ion during the cooling with liquid nitrogen. This process removed most of the damaged layers on the specimen surfaces, especially the non-resin areas. All those procedures resulted in a damaged layer of merely <3 nm, judging from the Ni or YSZ surfaces in Fig. 1 and Supplementary Fig. 6. The specimen is estimated to have a thickness of about 70 nm near the Ni surface (resin) according to the geometrical parameters of the slope in Fig. 1a and the known angles. Therefore, the thin damaged layer on the surface will not change the whole structure of the specimen. Actually, O loss from the Ni/YSZ interface is not surprising because the anode was reduced under a 2% humidified hydrogen environment. Reportedly, O-Ni and Zr-Ni bonds are energetically favorable35 and the O content at the interface may change with its partial pressure in the gas36. Thus the O content at the Ni/YSZ interface in TPB-1 is expected to be augmented with increasing oxygen partial pressure in the atmosphere.

When the YSZ zone axis is changed to [001], the Ni surface can be indexed to (220) as shown in Fig. 1d. Actually, the dihedral angle between Ni(220) and Ni(111) planes in a single crystal is 35°, which is identical to θpore and confirms that the Ni surface facing the pore is the Ni(220) plane. Partial oxidation was found on the Ni surface (as pointed out by an arrow in Fig. 1d) but not at the TPB. Because of the damaged layers and thickness difference between the grain edges and bulk, the STEM contrast was weakened. We also found another region of interest with the same orientation and configuration as the one shown in Fig. 1d. In fact, its HRTEM image (Supplementary Fig. 6) exhibits the ion damage on the surfaces more clearly and supports the facet index. Therefore, we obtained the atomic structure near TPB, showing the Ni(220) and YSZ(200) surfaces to the pore at an interfacial orientation of Ni[1\(\bar 1\)0]//YSZ[001] and Ni(111)//YSZ(200). The same oriented interfacial structure was observed in the Ni/YSZ samples prepared by directionally solidified eutectics33 and molecular beam epitaxy34. This is, in fact, one of the most stable interfaces found in Ni/YSZ cermet37.

Clear TEM images on TPB-2 were obtained from a specimen shown in Fig. 2 and Supplementary Fig. 7 with different magnifications. Apparently, this TPB has a larger θpore than that in TPB-1. An HRTEM image (Fig. 2b) was taken at the Ni[11\(\bar 2\)] zone axis. It was found that YSZ is close to the [001] zone axis, which can be seen more clearly from the diffraction patterns in Supplementary Fig. 7. The Ni(111) and YSZ(020) planes exposed to the resin (pore) and YSZ(200) planes act as one of the contact surfaces at the Ni/YSZ interface. θNi and θpore were measured to be 167° and 103° from the dihedral angles between Ni(111) and YSZ(200) and between Ni(111) and YSZ(020), respectively. Hence, θpore in TPB-2 is about two times larger than that in TPB-1. The Ni(2\(\bar 2\)0) planes display a dihedral angle of 76.8° to the Ni/YSZ interface. These planes show a lattice misfit of merely 0.4%, relative to the YSZ(020) plane, when taking into consideration that two layers of Ni(2\(\bar 2\)0) planes match with one layer of YSZ(020) plane. Such a good match would stabilize the interface, although the contact surface of Ni phase was estimated to be a high-index (957) plane. Previously, we have reported other high-index interfaces that ubiquitously exist in the conventional Ni/YSZ anode37. Later in this study, we will compare the structures of TPB-2 and TPB-1 in terms of their HOR activity.

Force field development

In order to perform reliable calculation for the Ni/YSZ/H2 systems, we optimized the parameters adopted in the previously published ReaxFF descriptions of Ni and YSZ27,46,47. POTFIT48 code, combined with LAMMPS49, was used to determine the new ReaxFF parameters for H-O-H, YSZ-H2, Ni-H2, Ni-H, Ni-YSZ, and O-O interactions, together with 24 additional energy values corresponding to the intermediate energy profiles of the HOR at TPB. The parameters were optimized to fit an extensive set of interaction energies in the Ni/YSZ/H2 systems, and the fitting results are shown in Fig. 3 and Supplementary Figs. 8–12. Figure 3a shows that the H-O-H equilibrium angle of the published ReaxFF has a deviation of about 4° compared with that of the first-principles results, whereas our developed ReaxFF shows only 1°. For the published ReaxFF, the energy of nondissociative adsorption of H2 on YSZ(Y-site) is overestimated by 64% in comparison with the first-principles data (Fig. 3b), whereas the overestimation obtained with our developed ReaxFF is reduced to 33%. Also, it is shown in Fig. 3c that the discrepancy of 0.6 Å obtained for the equilibrium Ni-H2 distance using the published ReaxFF has been eliminated with our ReaxFF. As shown in Fig. 3d, the magnitude of the interaction energy of Ni-YSZ interface at the equilibrium distance is underestimated by 86% with the published ReaxFF, while the underestimation is only 9% by using our ReaxFF. In summary, our developed ReaxFF parameters can reproduce the results of the first-principle calculations with much higher accuracy than the published ReaxFF27. More details on the way we evaluate the deviations between ReaxFF simulations and first-principles calculations can be found in Supplementary Notes 1, while the higher accuracy of the developed ReaxFF can be further proved by the comparison data in Table 1 and Supplementary Tables 1–11. In addition, the interactions of H-O-H, YSZ-H2, Ni-H2, Ni-H, Ni-YSZ, and O-O are described in Supplementary Notes 2–6 and the energies for the HOR are described in Supplementary Note 7.

Interaction energies and angle-energy curves. a H-O-H angle energy as a function of angle (θ). b YSZ(111) (Y-site)–H2 interaction energy. c Ni(220)–H2 interaction energy. d Ni(111)–YSZ(111) interaction energy. b–d are plotted as a function of distance (r). The interaction energy and angle energy are expressed as relative to the equilibrium structure, through single-point energy calculations by changing (r) and (θ). The insets show the models that are used for the energy calculation. Balls represent hydrogen (H), oxygen (O), zirconium (Zr), yttrium (Y), and nickel (Ni) atoms. YSZ(111) slab with 3-layer Zr/Y and 6-layer O is used in b and the entire structure is shown in d

TPB modeling and TEM image simulation

Based on the observed images, the initial atomic models were built in Material Studio by taking into account the actual lattice distances and crystal orientations. In an effort to validate the initial models, the QSTEM50 software was used to simulate the TEM images by the multislice method. The observed and simulated images as well as the model for TPB-1 are shown in Fig. 4a, b, d. For TPB-1, there was a good agreement between the simulated (Fig. 4b) and observed (Fig. 4a) images, except for the possible thinning and damage of Ni and YSZ surfaces in Fig. 4a. To clarify the interfacial distance between Ni and YSZ, we superimposed the model on the experimental image in Fig. 4c. In the experimental image, it was difficult to determine the exact TPB region. Therefore, we constructed two more models by increasing the number of Ni layers toward the gas phase, resulting in different interfacial distances of 1.9, 1.8, and 1.7 Å between Ni and O at the TPB region, hereafter referred to, respectively, as model-1 (Fig. 4 and Supplementary Fig. 13a), model-2 (Supplementary Fig. 13b), and model-3 (Supplementary Fig. 13c). The model of TPB-2 will be illustrated in a later section.

Reaction dynamics

Before simulating the reaction dynamics, we optimized the structures of TPB-1 by adding hydrogen (H) atoms at randomly selected atop sites of Ni surfaces. To investigate the hydrogen oxidation process, we prepared the model with adsorbed H assuming that the adsorption is sufficiently fast and is in equilibrium. The surface coverage of H is predicted to be 7%, which is the maximum coverage under the conditions of 1073 K and 1 atm with 100% H2 following the reported calculation method51. After the optimization, H atom on the Ni(220) surface is found to be at the long bridge site.

For model-1, a single pathway was observed during the simulation as shown in Fig. 5a. In particular, H moved on the Ni(220) surface to react with O at the TPB site, resulting in the formation of OH (see the series of snapshots in Supplementary Fig. 14). This pathway is noted herein as HOR-I, which was reported by Vogler et al.18 using kinetic modeling and defined as an H spillover process. Subsequently, in their density functional theory (DFT) calculations Shishikin et al.22, Cucinotta et al.23, and Liu et al.26 concluded that the H spillover process is the most favorable pathway. Liu et al. also found that the reaction barrier of this process varies from 0.46 to 0.57 eV depending on the local structures of TPB sites. This process was also identified by employing ReaxFF-MD simulations27. For our simulation, a total of 3 OH species were formed after 700 ps. One of them moved to the YSZ surface near TPB with the distances of 2.7 and 2.1 Å from the nearest Ni and Zr atoms, respectively. The other two OH species gradually moved toward the Ni(220) surface sites, which was specified as the OH spillover or back-transfer in the kinetic study by Goodwin et al.19. In contrast, the OH spillover process was not favorable according to the above-mentioned DFT calculations22,23,26, while it was not perceived in the ReaxFF-MD simulations27.

Reaction dynamics simulations for triple phase boundary-1. a Hydrogen oxidation reaction (HOR)-I pathway. b HOR-II pathway. The trajectory of hydrogen (H) starts from the arrow, and the circle denotes the final position where OH species is formed after a simulation period of 700 ps. The local environment near the formed OH species is presented in the magnified image, which is linked to the circle by dotted lines. c HOR-III pathway. A trajectory of oxygen (O) starts from the arrow, and the circle denotes the final position where OH species is formed after a simulation period of 700 ps. The local environment near the formed OH species is presented in the magnified image, which is linked to the circle by dotted lines. Trajectories are shown along the Ni[1\(\bar 1\)0] and YSZ[001] directions

Two other HOR pathways were observed on model-2 during the simulation. One pathway is dominated by H atom incorporation into the interstitial site of the Ni lattice and diffusion to the interface between Ni and YSZ. In this case, H eventually combines with O at the Ni/YSZ interface to form OH. This pathway was labeled as HOR-II (Fig. 5b), which has been discussed theoretically by Weng et al.52. They concluded that a barrier of 0.89 eV needs to be overcome for H diffusion through the Ni bulk, while the surface diffusion barrier is only 0.1 eV. Nevertheless, experiments have proved the enhanced H diffusion and absorption in Ni lattice at high temperatures53,54. Another pathway, which is referred to as HOR-III, is associated with O atom migration from YSZ to the Ni(220) surface through the Ni bulk to react with H on Ni surface to form OH. A trajectory of O together with the snapshot of the formed OH is shown in Fig. 5c. A series of snapshots with time for HOR-II and HOR-III are provided in Supplementary Fig. 14. To validate the determined ReaxFF parameters for O migration into the Ni bulk, we calculated the NiO formation energy to be −0.8 eV, which is in reasonable agreement with the first-principles calculation result (−1.0 eV)55. Besides, we did not observe O migration into the Ni bulk during optimization (see Supplementary Fig. 15). This result supports the fact that O migration in Ni can occur at certain two-phase interfaces like TPB-1 under high temperature (see Supplementary Fig. 16). Experimentally, O migration through the Ni bulk had been reported for Ce-Zr oxide-supported Ni catalyst56.

For model-3, two OH species are formed. One of them is formed through the HOR-III pathway and remains on the Ni surface site. The other OH, formed via HOR-I, is found to be 2.88 and 2.0 Å away from the nearest Ni and Zr, respectively.

In short, we observed three pathways for the formation of OH in HOR after the above simulations on TPB-1, namely, HOR-I (H diffusion on Ni surface toward TPB), HOR-II (H diffusion through Ni bulk to Ni/YSZ interface), and HOR-III (O migration from YSZ to Ni surface through bulk transfer).

For TPB-2 (Fig. 2b), the YSZ phase was not at the exact [001] zone axis. However, we adopted an ideal YSZ[001] model to represent the observed TPB structure for simplicity, and the model is presented in Supplementary Fig. 17. It should be noted that, owing to the high index (957) of the Ni surface, it is not worthy to increase the number of YSZ(020) layers toward the gas phase, as it may lead to improper contact between them at the TPB region. Therefore, we constructed only one model instead. After optimization, the H atom was located at the fcc site of Ni(111) surface. In this simulation, a single OH is formed through the HOR-I pathway. A trajectory of H is also shown in Supplementary Fig. 17. Note that the OH remains at TPB, having distances of 1.7 and 2.3 Å from the nearest Ni and Zr, respectively. The other two pathways (HOR-II and HOR-III) may also occur, because O and H migration into the Ni bulk is detected (Supplementary Fig. 18), indicating the relatively low activity of HOR through those processes compared to TPB-1.

In order to clarify the impact of the TPB structures as well as the different reaction pathways, we repeated all calculations six more times by changing the H positions on the Ni surface. The resulting time-averaged number of OH normalized by the TPB length is summarized in Table 2. It is calculated as \(\left( {{\sum} {N_{{\mathrm{OH}}}{\mathrm{d}}t/t} } \right)\)/l, where NOH is the number of OH while dt, t, and l indicate the time step between frames, the total simulation time, and TPB length, respectively. The TPB lengths of TPB-1 and TPB-2 are 27.167 and 27.170 Å, respectively, which are almost the same. From TPB-1, the OH formations through the HOR-I pathway were found as nine, four, and five times during the simulations using model-1, model-2, and model-3, respectively. In addition, only one OH formation through the HOR-II pathway was observed in simulations using either model-1 or model-3, while model-2 exhibited three OH formations. Finally, the HOR-III pathway was not detected in model-1, whereas simulations using model-2 and model-3 displayed OH formation through the HOR-III pathway once and twice, respectively. By contrast, the TPB-2 simulations showed four and one OH formations via the HOR-I and HOR-III pathways, respectively. Therefore, our simulations indicate that TPB-1 was more active than TPB-2 and that the activity at TPB-1 was influenced by the different interfacial distances between Ni and O. The HOR-I pathway seems to be the easiest pathway regardless of the models, and this agrees well with many studies using DFT calulations22,23,26.

Apart from the HOR pathways observed in this study, an O spillover process, namely O migration from YSZ to Ni surface leading to the formation of OH, was previously reported by using kinetic modeling method16,57,58. Later, this process was examined by Ammal et al.24 through DFT calculations and found to dominate over the H migration pathway. Fu et al. also investigated the O spillover process, coexisting with the H spillover process25. From our dynamics simulations, it can be concluded that the number of O migration was limited: for TPB-1 (model-1) four O atoms migrate, while only one O atom migrates during the simulation using TPB-2. Liu et al. also pointed out the importance of this process for the higher activity based on a kinetic study21. Therefore, it is indicated that the TPB-1 structure is favorable compared to TPB-2, while the relatively slow kinetics does not lead to the formation of OH species.

Finally, we did not observe H2O formation during the simulations. This may be due to the rate-limiting step of the OH + H reaction, as well as the limited number of H atoms, the consumption of H atoms because of OH formation, or limited simulation time. DFT calulations22,23,26, ReaxFF-MD27, and kinetic modeling18 have concluded that H2O is formed near the TPB for HOR-I, while Goodwin et al. reported H2O formation on the Ni surface site19. In this study, MD simulations indicated that all pathways are possible for H2O formation.

Discussion

The motivation of this work is to understand the TPB on an atomic scale and simulate the HOR process on realistic models. First, we fabricated a conventional Ni/YSZ half-cell, and then we prepared high-quality TEM specimens through an FIB lift-out technique and moderate post-polishing. Finally, the TPB structures were observed by TEM and STEM, through which the visualization of the real atomic structure of TPB to the best of our knowledge is realized for the first time. Herein we demonstrated the existence of two TPB structures (TPB-1 and TPB-2), which are different from the structures assumed in the reported simulations. In TPB-1, Ni and YSZ formed a stable interface with an orientation of Ni[1\(\bar 1\)0]//YSZ[001] and Ni(111)//YSZ(200), and the Ni(220) and YSZ(200) surfaces were open to the pore. Near TPB-2, the Ni/YSZ interface was Ni(957)//YSZ(200) while Ni(111) and YSZ(020) were exposed to the pore. In these two structures, the angle (θpore) between the Ni and YSZ surfaces was very different, being 35° and 103°, respectively.

After constructing models based on these realistic structures, we carried out ReaxFF simulations. In order to obtain reliable simulation data, we began with extensive development of ReaxFF parameters for Ni/YSZ/H2 systems to clarify the HOR at TPB. Compared to the results of first-principles calculations, our developed ReaxFF parameters produced much smaller average energy deviations that are only about one third of those obtained from published ReaxFF parameters as shown in Table 1.

Using our own ReaxFF parameters and realistic models, three pathways for OH formation in HOR were observed during the reaction dynamics simulations: HOR-I (H diffusion on Ni surface toward TPB), HOR-II (H diffusion through Ni bulk to Ni/YSZ interface), and a new pathway HOR-III (O migration from YSZ to Ni surface through bulk transfer). Besides, the migration process of H and O was influenced by the TPB structures. The TPB-1 type structure was also found to be more active compared to TPB-2. Moreover, it was predicted that H2O may form at distinct sites on account of the OH back-transfer process. Our simulation results on the three models of TPB-1 and one model of TPB-2 indicate that the HOR pathway depends on many factors around the TPB, and it could be tuned by adjusting the local atomic structures. This finding agrees well with a recent study of dopant effect on HOR pathway, which changes with different cation dopants on ZrO259. In addition, there are many more reports on surface pathways like HOR-I than on the bulk pathways including HOR-II and HOR-III observed in our simulation. Therefore, we propose that more studies should be carried out both theoretically and experimentally on the bulk pathways.

Finally, we would like to correlate our results to the anode performance and durability enhancement from three points of view. First, we found that HOR-1 pathway (H diffusion on Ni surface toward TPB) seems to be the easiest one regardless of TPB structures. Hence, the performance can be enhanced by increasing the TPB length3,6. This is actually a well-known fact and can be realized experimentally by adjusting the Ni/YSZ ratio, Ni grain refinement, Ni infiltration, and so on as long as the mechanical robustness is well maintained. Second, we observed a new pathway (HOR-III) that proceeds via the diffusion of O in the bulk Ni. During this process, Ni may be partially oxidized, especially under high fuel utilization conditions, which will lead to performance degradation and mechanical disruption. Therefore, care must be taken to ensure mild operation parameters. Dopants could also be added into Ni/YSZ cermet to suppress the Ni oxidation60. Third, we concluded that TPB-1 type has higher activity toward HOR than TPB-2 type. The TPB-1 type was also more often observed in our TEM analysis, and it represents Ni standing on a flat YSZ substrate at TPB with very stable interface. Hence, the performance and durability are supposed to be improved if more TPBs of TPB-1 type exist, which could be achieved by reducing the particle size ratio of Ni(O)/YSZ61 and enhancing the thermal treatment under the condition of avoiding excessive Ni coarsening. However, those motions should be considered globally because the anode performance is a comprehensive output of various factors.

Methods

Cell preparation

A YSZ (8 mol% yttria stabilized zirconia) electrolyte-supported half-cell was fabricated in a conventional way. First, NiO and YSZ with a weight ratio of 55:45 were ball-milled in ethanol. After drying the ethanol, the NiO/YSZ powder was grinded with 8 wt.% ethyl cellulose and α-terpineol solvent to make the slurry, which was then screen-printed onto the YSZ electrolyte support (thickness = 1 mm). The half cell was sintered at 1400 °C for 3 h. Finally, the reduction of NiO was carried out in humid H2 (2% H2O) at 800 °C for 2 h.

TEM specimen preparation and atomic structure observation

The pores of the porous electrode were first infiltrated by epoxy resin under vacuum in a CitoVac (Struers) system, so that the bulk cell could be readily handled in the next step. TEM specimen lift-out was performed using an FIB-SEM (HITACHI MI4000L) instrument. The specimen polishing was performed while the FIB voltage decreased from 30 to 3 kV. To remove the damaged/amorphous layers on the two sides of the specimen as much as possible, final polishing was carried out in an Ar ion milling machine (NanoMill Model 1040, Fischione) with a cold stage (−165 °C) at voltages between 0.6 and 1 kV. Structure observation at different scales was performed with JEOL JEM3200FSK (TEM and STEM modes, 300 kV) and JEOL JEM-ARM200F (TEM and STEM modes, 200 kV). Both machines were equipped with energy-dispersive X-ray spectroscopy detectors for elemental analysis.

TEM image simulation

STEM image simulations were performed using the QSTEM software (V2.22)50 based on the multislice method with the experimental parameters used in the JEOL ARM200F. The following electron beam parameters were employed: acceleration voltage = 200 kV, chromatic aberration CC = 1.6 mm, spherical aberration CS = 0.0011 mm, fifth-order spherical aberration C5 = 1.756 mm, convergence angle α = 24 mrad, and high-angle annular dark-field–STEM detector acceptance semi-angle of 90–370 mrad. During the microscope operation, the two-fold astigmatism and focus were continuously adjusted by the user and can be identified manually from the live imaging and fast Fourier transforms of the live image. However, in the simulations the two-fold astigmatism and high-order aberrations were neglected.

Force field theory

The ReaxFF62 is based on the concept of bond order (BO), which is calculated according to the following equation:

where \(r_0^\sigma\), \(r_0^\pi\), and \(r_0^{\pi \pi }\) are respectively the single, double, and triple bonds as a function of interatomic distances rij. \(p_{{\mathrm{bo}}1}\), \(p_{{\mathrm{bo}}2}\), \(p_{{\mathrm{bo}}3}\), \(p_{{\mathrm{bo}}4}\), \(p_{{\mathrm{bo}}5}\), and \(p_{{\mathrm{bo}}6}\) are parameters of the ReaxFF.

The total system energy consists of several partial energy terms that depend on the BOs, such as the bond energy (Ebond) which in ReaxFF is given as:

where De is the dissociation energy for each bond type. pbe1 and pbe2 are parameters of the ReaxFF.

Besides Ebond, other contributors to the total energy include: the lone pair electrons, under- and over-coordination terms, valence angle energy, torsion energy terms, as well as van der Waals (vdW) and Coulomb interactions, which do not depend on the BOs. Details of the force field can be found elsewhere62,63. For the interactions of H-O-H, YSZ-H2, Ni-H2, Ni-H, Ni-YSZ, and O-O, we developed a new set of ReaxFF for the atomic, bonding, off-diagonal (used to describe BO and vdW pair interactions)46, and angle parameters. All these parameters are included in Supplementary Data 1.

Quantum mechanical calculations

In order to fit the ReaxFF parameters, QM calculations were performed using the first-principles DFT method implemented in the VASP code64,65. The exchange–correlation interactions were described by the Perdew–Burke–Ernzerhof functional. Spin-polarized calculations were applied throughout. To describe the electron–ion interactions, the projector augmented wave method was adopted. The cutoff energy of the plane wave basis set was 400 eV. The electronic tolerance for a self-consistent loop and the energy tolerance for the ionic relaxation were 1 × 10−6 and 1 × 10−5 eV/atom, respectively. The nudged elastic band calculation has been described elsewhere21.

Fitting procedure

To fit the ReaxFF potential, we utilized the algorithm described in POTFIT48. The target function for minimization is based on the deviation between the calculated ReaxFF values and DFT reference values with the following equation:

where n is the number of configuration structures, EFP,i is the reference values (such as energies) from first-principles DFT calculation, EReaxFF,i(α) is the calculated ReaxFF values on the ith structure after parametrization by α; we and uk are the global and individual structural weights for the energy; and Zs, ZF, and ws indicate the stress, the force, and the global weights for the stress, respectively. In our fitting, wsZs was neglected. For Ni/YSZ/H2 systems, we have fitted 69 parameters to improve the H-O-H, YSZ-H2, Ni-H2, Ni-H, Ni-YSZ, and O-O interaction energies plus 24 energies for the HOR.

MD and mechanics simulations

First, models were built by using the lattice distances observed in the experiment (see Fig. 4). Then they were allowed to change due to the lattice expansion of Ni and YSZ in the course of isobaric–isothermal simulation at a temperature of 1073 K and a pressure of 1 atm. The main reaction dynamics was calculated under the canonical ensemble corresponding to the constant volume and temperature condition. The temperature and pressure were controlled with the Nose–Hoover thermostat66 and barostat67, respectively.

The lattice parameters of two heterogeneous phases usually cannot perfectly match. Therefore, to obtain a well-matched Ni/YSZ interface, we expanded or compressed (for TPB-1 and TPB-2, respectively) the softer nickel crystal according to the misfit as calculated in Eq. (4):

where n and m are the number of unit cells for YSZ and Ni, respectively, and a is the plane lattice parameter. The misfit was minimized down to 3%. We used periodic boundary conditions to simulate an infinite horizontal surface. Because the simulation box length along the z axis was long, the periodicity in the z direction was virtually removed. We ran the MD trajectory for 700 ps. To optimize the TPB structures, we employed the FIRE method68. All MD and energy minimization calculations were carried out with USER-REAXC package69 as implemented in the LAMMPS code49.

Data availability

The data that support the findings of this study are available within the paper and its Supplementary Information and Data. Other relevant data are available from the corresponding authors upon reasonable request.

References

Wachsman, E. D. & Lee, K. T. Lowering the temperature of solid oxide fuel cells. Science 334, 935–939 (2011).

Atkinson, A. et al. Advanced anodes for high-temperature fuel cells. Nat. Mater. 3, 17–27 (2004).

Wilson, J. R. et al. Three-dimensional reconstruction of a solid-oxide fuel-cell anode. Nat. Mater. 5, 541–544 (2006).

Iwai, H. et al. Quantification of SOFC anode microstructure based on dual beam FIB-SEM technique. J. Power Sources 195, 955–961 (2010).

Cronin, J. S., Wilson, J. R. & Barnett, S. A. Impact of pore microstructure evolution on polarization resistance of Ni-Yttria-stabilized zirconia fuel cell anodes. J. Power Sources 196, 2640–2643 (2011).

Viveta, N. et al. Effect of Ni content in SOFC Ni-YSZ cermets: A three-dimensional study by FIB-SEM tomography. J. Power Sources 196, 9989–9997 (2011).

Kenjo, T., Osawa, S. & Fujikawa, K. High temperature air cathodes containing ion conductive oxides. J. Electrochem. Soc. 138, 349–355 (1991).

Joshi, A. S., Grew, K. N., Peracchio, A. A. & Chiu, W. K. S. Lattice Boltzmann modeling of 2D gas transport in a solid oxide fuel cell anode. J. Power Sources 164, 631–638 (2007).

Suzue, Y., Shikazono, N. & Kasagi, N. Micro modeling of solid oxide fuel cell anode based on stochastic reconstruction. J. Power Sources 184, 52–59 (2008).

Chen, H.-Y. et al. Simulation of coarsening in three-phase solid oxide fuel cell anodes. J. Power Sources 196, 1333–1337 (2011).

Irvine, J. T. S. et al. Evolution of the electrochemical interface in high-temperature fuel cells and electrolysers. Nat. Energy 1, 15014 (2016).

Mizusaki, J. et al. Kinetic studies of the reaction at the nickel pattern electrode on YSZ in H2–H2O atmospheres. Solid State Ion. 70/71, 52–58 (1994).

Bieberle, A., Meier, L. P. & Gauckler, L. J. The electrochemistry of Ni pattern anodes used as solid oxide fuel cell model electrodes. J. Electrochem. Soc. 148, A646–A656 (2001).

Utz, A., Störmer, H., Leonide, A., Weber, A. & Ivers-Tiffée, E. Degradation and relaxation effects of Ni patterned anodes in H2-H2O atmosphere. J. Electrochem. Soc. 157, B920–B930 (2010).

Yao, W. & Croiset, E. Stability and electrochemical performance of Ni/YSZ pattern anodes in H2/H2O atmosphere. Can. J. Chem. Eng. 93, 2157–2167 (2015).

Bieberle, A. & Gauckler, L. J. State-space modeling of the anodic SOFC system Ni, H2–H2O|YSZ. Solid State Ion. 146, 23–41 (2002).

Bessler, W. G., Gewies, S. & Vogler, M. A new framework for physically based modeling of solid oxide fuel cells. Electrochim. Acta 53, 1782–1800 (2007).

Vogler, M., Bieberle-Hütter, A., Gauckler, L., Warnatz, J. & Bessler, W. G. Modelling study of surface reactions, diffusion, and spillover at a Ni/YSZ patterned anode. J. Electrochem. Soc. 156, B663–B672 (2009).

Goodwin, D. G., Zhu, H. Y., Colclasure, A. M. & Kee, R. J. Modeling electrochemical oxidation of hydrogen on Ni–YSZ pattern anodes. J. Electrochem. Soc. 156, B1004–B1021 (2009).

Grew, K. N. & Chiu, W. K. S. A review of modeling and simulation techniques across the length scales for the solid oxide fuel cell. J. Power Sources 199, 1–13 (2012).

Liu, S. et al. Predictive microkinetic model for solid oxide fuel cell patterned anode: Based on extensive literature survey and exhaustive simulations. J. Phys. Chem. C 121, 19069–19079 (2017).

Shishkin, M. & Ziegler, T. Hydrogen oxidation at the Ni/yttria-stabilized zirconia interface: a study based on density functional theory. J. Phys. Chem. C 114, 11209–11214 (2010).

Cucinotta, C. S., Bernasconi, M. & Parrinello, M. Hydrogen oxidation reaction at the Ni/YSZ anode of solid oxide fuel cells from first principles. Phys. Rev. Lett. 107, 206103 (2011).

Ammal, S. C. & Heyden, A. Combined DFT and microkinetic modeling study of hydrogen oxidation at the Ni/YSZ anode of solid oxide fuel cells. J. Phys. Chem. Lett. 3, 2767–2772 (2012).

Fu, Z., Wang, M., Zuo, P., Yang, Z. & Wu, R. Importance of oxygen spillover for fuel oxidation on Ni/YSZ anodes in solid oxide fuel cells. Phys. Chem. Chem. Phys. 16, 8536–8540 (2014).

Liu, S., Ishimoto, T., Monder, D. S. & Koyama, M. First-principles study of oxygen transfer and hydrogen oxidation processes at the Ni-YSZ-gas triple phase boundaries in a solid oxide fuel cell anode. J. Phys. Chem. C 119, 27603–27608 (2015).

Merinov, B. V., Mueller, J. E., van Duin, A. C. T., An, Q. & Goddard, W. A. III. ReaxFF reactive force-field modeling of the triple-phase boundary in a solid oxide fuel cell. J. Phys. Chem. Lett. 5, 4039–4043 (2014).

Helveg, S. et al. Atomic-scale imaging of carbon nanofibre growth. Nature 427, 426–429 (2004).

Cargnello, M. et al. Control of metal nanocrystal size reveals metal-support interface role for ceria catalysts. Science 341, 771–773 (2013).

Daio, T. et al. Lattice strain mapping of platinum nanoparticles on carbon and SnO2 supports. Sci. Rep. 5, 13126 (2015).

Akita, T., Maeda, Y. & Kohyama, M. Low-temperature CO oxidation properties and TEM/STEM observation of Au/γ-Fe2O3 catalysts. J. Catal. 324, 127–132 (2015).

Bassim, N. D. et al. Minimizing damage during FIB sample preparation of soft materials. J. Microsc. 245, 288–301 (2012).

Dickey, E. C., Fan, X. & Pennycook, S. J. Direct atomic-scale imaging of ceramic interfaces. Acta Mater. 47, 4061–4068 (1999).

Dickey, E. C. et al. Preferred crystallographic orientation relationships of nickel films deposited on (100) cubic-zirconia substrates. Thin Solid Films 372, 37–44 (2000).

Beltrán, J. I., Gallego, S., Cerdá, J., Moya, J. S. & Muñoz, M. C. Bond formation at the Ni/ZrO2 interface. Phys. Rev. B 68, 075401 (2003).

Nahor, H. & Kaplan, W. D. Structure of the equilibrated Ni(111)-YSZ(111) solid–solid interface. J. Am. Ceram. Soc. 99, 1064–1070 (2015).

Liu, S.-S., Jiao, Z., Shikazono, N., Matsumura, S. & Koyama, M. Observation of the Ni/YSZ interface in a conventional SOFC. J. Electrochem. Soc. 162, F750–F754 (2015).

Liu, S.-S., Takayama, A., Matsumura, S. & Koyama, M. Image contrast enhancement of Ni/YSZ anode during the slice-and-view process in FIB-SEM. J. Microsc. 261, 326–332 (2016).

Mitome, M. Ultrathin specimen preparation by a low-energy Ar-ion milling method. Microscopy 62, 321–326 (2013).

Nelson, G. J. et al. Three-dimensional microstructural changes in the Ni–YSZ solid oxide fuel cell anode during operation. Acta Mater. 60, 3491–3500 (2012).

Dravid, V. P., Lyman, C. E., Notis, M. R. & Revcolevschi, A. High resolution transmission electron microscopy of interphase interfaces in NiO–ZrO2 (CaO). Ultramicroscopy 29, 60–70 (1989).

Dickey, E. C. et al. Structure and bonding at Ni–ZrO2 (cubic) interfaces formed by the reduction of a NiO–ZrO2 (cubic) composite. Microsc. Microanal. 3, 443–450 (1997).

Vellinga, W. P. & Hosson, J. T. M. D. Atomic structure and orientation relations of interfaces between Ag and ZnO. Acta Mater. 45, 933–950 (1997).

Zhang, Z. et al. The peculiarity of the metal-ceramic interface. Sci. Rep. 5, 11460 (2015).

Kato, N. I. Reducing focused ion beam damage to transmission electron microscopy samples. J. Electron Microsc. 53, 451–458 (2004).

Mueller, J. E., van Duin, A. C. T. & Goddard, W. A. Development and validation of ReaxFF reactive force field for hydrocarbon chemistry catalyzed by nickel. J. Phys. Chem. C 114, 4939–4949 (2010).

van Duin, A. C. T., Merinov, B. V., Jang, S. S. & Goddard, W. A. III ReaxFF reactive force field for solid oxide fuel cell systems with application to oxygen ion transport in yttria-stabilized zirconia. J. Phys. Chem. A 112, 3133–3140 (2008).

Brommer, P. & Gähler, F. Potfit: effective potentials from ab-initio data. Model. Simul. Mater. Sci. Eng. 15, 295–304 (2007).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Koch, C. Determination of Core Structure Periodicity and Point Defect Density along Dislocations. PhD thesis, Arizona State Univ. (2002).

Blaylock, D. W., Ogura, T., Green, W. H. & Beran, G. J. O. Computational investigation of thermochemistry and kinetics of steam methane reforming on Ni(111) under realistic conditions. J. Phys. Chem. C 113, 4898–4908 (2009).

Weng, M. H. et al. Kinetics and mechanisms for the adsorption, dissociation, and diffusion of hydrogen in Ni and Ni/YSZ slabs: a DFT study. Langmuir 28, 5596–5605 (2012).

Louthan, M. R. Jr., Donovan, J. A. & Caskey, G. R. Jr. Hydrogen diffusion and trapping in nickel. Acta Met. 23, 745–749 (1975).

Wayman, M. L. & Weatherly, G. C. The H–Ni (hydrogen-nickel) system. J. Phase Equilib. 10, 569–580 (1989).

Yu, J., Rosso, K. M. & Bruemmer, S. M. Charge and transport in NiO and aspects of Ni oxidation from first principles. J. Phys. Chem. C 116, 1948–1954 (2012).

Hoang, T. M. C., Geerdink, B., Sturm, J. M., Lefferts, L. & Seshan, K. Steam reforming of acetic acid – a major component in the volatiles formed during gasification of humin. Appl. Catal. B Environ. 163, 74–82 (2015).

Rossmeisl, J. & Bessler, W. G. Trends in catalytic activity for SOFC anode materials. Solid State Ion. 178, 1694–1700 (2008).

Bessler, W. G. A new computational approach for SOFC impedance from detailed electrochemical reaction–diffusion models. Solid State Ion. 176, 997–1011 (2005).

Iskandarov, A. M. & Tada, T. Dopant driven tuning of the hydrogen oxidation mechanism at the pore/nickel/zirconia triple phase boundary. Phys. Chem. Chem. Phys. 20, 12574–12588 (2018).

Welander, M. M., Zachariasen, M. S., Hunt, C. D., Sofie, S. W. & Walker, R. A. Operando studies of redox resilience in ALT enhanced NiO-YSZ SOFC anodes. J. Electrochem. Soc. 165, F152–F157 (2018).

Prakash, B. S., Kumar, S. S. & Aruna, S. T. Properties and development of Ni/YSZ as an anode material in solid oxide fuel cell: a review. Renew. Sust. Energy Rev. 36, 149–179 (2014).

van Duin, A. C. T., Dasgupta, S., Lorant, F. & Goddard, W. A. III ReaxFF: a reactive force field for hydrocarbons. J. Phys. Chem. A 105, 9396–9409 (2001).

Senftle, T. P. et al. The ReaxFF reactive force-field: development, applications and future directions. Npj Comput. Mater. 2, 15011 (2016).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Hoover, W. G. Canonical dynamics: equilibrium phase-space distributions. Phys. Rev. A 31, 1695 (1985).

Hoover, W. G. Constant-pressure equations of motion. Phys. Rev. A 34, 2499 (1986).

Bitzek, E., Koskinen, P., Gahler, F., Moseler, M. & Gumbsch, P. Structural relaxation made simple. Phys. Rev. Lett. 97, 170201 (2006).

Aktulga, H. M., Fogarty, J. C., Pandit, S. A. & Grama, A. Y. Parallel reactive molecular dynamics: numerical methods and algorithmic techniques. Parallel Comput. 38, 245–259 (2012).

Acknowledgements

This work was supported by JST-CREST (JPMJCR11C2). Activities of the INAMORI Frontier Research Center were supported by the KYOCERA Corporation. L.C.S. thanks Professor A.C.T. van Duin (Pennsylvania State University) and Dr. B.V. Merinov (California Institute of Technology) for sharing their ReaxFF parameters and fruitful discussion. L.C.S. also thanks Dr. S. Liu (Kyushu University) for providing the theoretical data.

Author information

Authors and Affiliations

Contributions

S.-S.L. prepared the sample and carried out the microscope operation. L.C.S. performed the parameterization of ReaxFF, computational simulations, and modeling. A.I. (currently on leave of absence from the Institute for Metals Superplasticity Problems of RAS, Khalturin St. 39, Ufa, 450001, Russia) assisted the technical set-up of POTFIT, and T.I. aided the simulations. T.Y. assisted the TEM operation and QSTEM simulation. Y.U., S.M., and M.K. conceived and supervised the project. S.-S.L. and L.C.S. composed the manuscript and prepared the figures. All the authors discussed the results, commented, and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, SS., Saha, L.C., Iskandarov, A. et al. Atomic structure observations and reaction dynamics simulations on triple phase boundaries in solid-oxide fuel cells. Commun Chem 2, 48 (2019). https://doi.org/10.1038/s42004-019-0148-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-019-0148-x

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.