Abstract

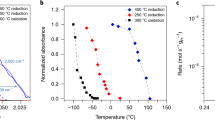

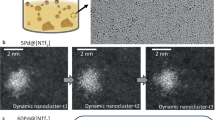

Controlling the morphology of noble metal nanoparticles during surface depositions is strongly influenced by precursor–substrate and precursor–deposit interactions. Depositions can be improved through a variety of means, including tailoring the surface energy of a substrate to improve precursor wettability, or by modifying the surface energy of the deposits themselves. Here, we show that carbon monoxide can be used as a passivation gas during atomic layer deposition to modify the surface energy of already deposited Pt nanoparticles to assist direct deposition onto a carbon catalyst support. The passivation process promotes two-dimensional growth leading to Pt nanoparticles with suppressed thicknesses and a more than 40% improvement in Pt surface-to-volume ratio. This approach to synthesizing nanoparticulate Pt/C catalysts achieved high Pt mass activities for the oxygen reduction reaction, along with excellent stability likely facilitated by strong catalyst–support interactions afforded by this synthetic technique.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Debe, M. K. Electrocatalyst approaches and challenges for automotive fuel cells. Nature 486, 43–51 (2012).

Kongkanand, A. & Mathias, M. F. The priority and challenge of high-power performance of low-platinum proton-exchange membrane fuel cells. J. Phys. Chem. Lett. 7, 1127–1137 (2016).

Shao, M., Peles, A. & Shoemaker, K. Electrocatalysis on platinum nanoparticles: particle size effect on oxygen reduction reaction activity. Nano Lett. 11, 3714–3719 (2011).

Nesselberger, M. et al. The particle size effect on the oxygen reduction reaction activity of pt catalysts: influence of electrolyte and relation to single crystal models. J. Am. Chem. Soc. 133, 17428–17433 (2011).

Perez-Alonso, F. J. et al. The effect of size on the oxygen electroreduction activity of mass-selected platinum nanoparticles. Angew. Chem. Int. Ed. 51, 4641–4643 (2012).

Zhang, J., Yang, H., Fang, J. & Zou, S. Synthesis and oxygen reduction activity of shape-controlled Pt3Ni nanopolyhedra. Nano Lett. 10, 638–644 (2010).

Wang, J. X. et al. Oxygen reduction on well-defined core-shell nanocatalysts: particle size, facet, and Pt shell thickness effects. J. Am. Chem. Soc. 131, 17298–17302 (2009).

Stephens, I. E. L., Bondarenko, A. S., Grønbjerg, U., Rossmeisl, J. & Chorkendorff, I. Understanding the electrocatalysis of oxygen reduction on platinum and its alloys. Energy Environ. Sci. 5, 6744 (2012).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Li, M. et al. Ultrafine jagged platinum nanowires enable ultrahigh mass activity for the oxygen reduction reaction. Science 354, 1414–1419 (2016).

Jiang, K. et al. Efficient oxygen reduction catalysis by subnanometer Pt alloy nanowires. Sci. Adv. 3, e1601705 (2017).

Higgins, D. C. et al. Morphology and composition controlled platinum-cobalt alloy nanowires prepared by electrospinning as oxygen reduction catalyst. Nano Energy 10, 135–143 (2014).

Chen, C. et al. Highly crystalline multimetallic nanoframes with three-dimensional electrocatalytic surfaces. Science 343, 1339–1343 (2014).

Zhang, L. et al. Platinum-based nanocages with subnanometer-thick walls and well-defined, controllable facets. Science 349, 412–416 (2015).

Duan, H. et al. Ultrathin rhodium nanosheets. Nat. Commun. 5, 3093 (2014).

Wang, J. X. et al. Kirkendall effect and lattice contraction in nanocatalysts: a new strategy to enhance sustainable activity. J. Am. Chem. Soc. 133, 13551–13557 (2011).

Adzic, R. R. et al. Platinum monolayer fuel cell electrocatalysts. Top. Catal. 46, 249–262 (2007).

Herrero, E., Buller, L. J. & Abruña, H. D. Underpotential deposition at single crystal surfaces of Au, Pt, Ag and other materials. Chem. Rev. 101, 1897–1930 (2001).

Wang, J. X. et al. Oxygen reduction on well-defined core-shell nanocatalysts: Particle size, facet, and Pt shell thickness effects. J. Am. Chem. Soc. 131, 17299–17302 (2009).

Zhang, Y. et al. High performance Pt monolayer catalysts produced via core-catalyzed coating in ethanol. ACS Catal. 4, 738–742 (2014).

Zhang, J. et al. Platinum monolayer electrocatalysts for O2 reduction: Pt monolayer on Pd(111) and on carbon-supported Pd nanoparticles. J. Phys. Chem. B 108, 10955–10964 (2004).

Sasaki, K. et al. Core-protected platinum monolayer shell high-stability electrocatalysts for fuel-cell cathodes. Angew. Chem. Int. Ed. 49, 8602–8607 (2010).

Okada, T. Theory for water management in membranes for polymer electrolyte fuel cells. Part 2. The effect of impurity ions at the cathode side on the membrane performances. J. Electroanal. Chem. 465, 18–29 (1999).

Singh, J. A., Yang, N. & Bent, S. F. Nanoengineering heterogeneous catalysts by atomic layer deposition. Annu. Rev. Chem. Biomol. Eng. 8, 41–62 (2017).

O’Neill, B. J. et al. Catalyst design with atomic layer deposition. ACS Catal. 5, 1804–1825 (2015).

Lu, J. et al. Coking- and sintering-resistant palladium catalysts achieved through atomic layer deposition. Science 335, 1205–1208 (2012).

Cheng, N. et al. High stability and activity of Pt electrocatalyst on atomic layer deposited metal oxide/nitrogen-doped graphene hybrid support. Int. J. Hydrog. Energy 39, 15967–15974 (2014).

Chen, Y. et al. Atomic layer deposition assisted Pt-SnO2 hybrid catalysts on nitrogen-doped CNTs with enhanced electrocatalytic activities for low temperature fuel cells. Int. J. Hydrog. Energy 36, 11085–11092 (2011).

Cheng, N. et al. Extremely stable platinum nanoparticles encapsulated in a zirconia nanocage by area-selective atomic layer deposition for the oxygen reduction reaction. Adv. Mater. 27, 277–281 (2015).

Du, Q., Wu, J. & Yang, H. Pt@Nb-TiO2 catalyst membranes fabricated by electrospinning and atomic layer deposition. ACS Catal. 4, 144–151 (2014).

Inaba, M., Suzuki, T., Hatanaka, T. & Morimoto, Y. Fabrication and cell analysis of a Pt/SiO2 platinum thin film electrode. J. Electrochem. Soc. 162, F634–F638 (2015).

Wang, H. et al. Direct and continuous strain control of catalysts with tunable battery electrode materials. Science 354, 1031–1036 (2016).

Cheng, N. et al. Atomic scale enhancement of metal–support interactions between Pt and ZrC for highly stable electrocatalysts. Energy Environ. Sci. 8, 1450–1455 (2015).

Xie, J., Yang, X., Han, B., Shao-Horn, Y. & Wang, D. Site-selective deposition of twinned platinum nanoparticles on TiSi2 nanonets by atomic layer deposition and their oxygen reduction activities. ACS Nano 7, 6337–6345 (2013).

Shao, M., Chang, Q., Dodelet, J.-P. & Chenitz, R. Recent advances in electrocatalysts for oxygen reduction reaction. Chem. Rev. 116, 3594–3657 (2016).

Liao, W. & Ekerdt, J. G. Effect of CO on Ru nucleation and ultra-smooth thin film growth by chemical vapor deposition at low temperature. Chem. Mater. 25, 1793–1799 (2013).

Babar, S. et al. Growth inhibitor to homogenize nucleation and obtain smooth HfB2 thin films by chemical vapor deposition. Chem. Mater. 25, 662–667 (2013).

Liu, Y., Gokcen, D., Bertocci, U. & Moffat, T. P. Self-terminating growth of platinum films by electrochemical deposition. Science 338, 1327–1330 (2012).

Nutariya, J., Fayette, M., Dimitrov, N. & Vasiljevic, N. Growth of Pt by surface limited redox replacement of underpotentially deposited hydrogen. Electrochim. Acta 112, 813–823 (2013).

Wang, H., Jiang, K., Chen, Q., Xie, Z. & Cai, W.-B. Carbon monoxide mediated chemical deposition of Pt or Pd quasi-monolayer on Au surfaces with superior electrocatalysis for ethanol oxidation in alkaline media. Chem. Commun. 52, 374–377 (2016).

Brimaud, S. & Behm, R. J. Electrodeposition of a Pt monolayer film: using kinetic limitations for atomic layer epitaxy. J. Am. Chem. Soc. 135, 11716–11719 (2013).

Novak, S., Lee, B., Yang, X. & Misra, V. Platinum nanoparticles grown by atomic layer deposition for charge storage memory applications. J. Electrochem. Soc. 157, H589 (2010).

Baker, L. et al. Growth of continuous and ultrathin platinum films on tungsten adhesion layers using atomic layer deposition techniques. Appl. Phys. Lett. 101, 111601 (2012).

Puurunen, R. L. & Vandervorst, W. Island growth as a growth mode in atomic layer deposition: a phenomenological model. J. Appl. Phys. 96, 7686–7695 (2004).

Lee, H. B. R. & Bent, S. F. Formation of continuous Pt films on the graphite surface by atomic layer deposition with reactive O3. Chem. Mater. 27, 6802–6809 (2015).

Xu, S. et al. Building upon the Koutecky-Levich equation for evaluation of next-generation oxygen reduction reaction catalysts. Electrochim. Acta 255, 99–108 (2017).

Dendooven, J. et al. Independent tuning of size and coverage of supported Pt nanoparticles using atomic layer deposition. Nat. Commun. 8, 1074 (2017).

Bosch, R. H. E. C., Bloksma, F. L., Huijs, J. M. M., Verheijen, M. A. & Kessels, W. M. M. Surface infrared spectroscopy during low temperature growth of supported Pt nanoparticles by atomic layer deposition. J. Phys. Chem. C 120, 750–755 (2016).

Hoye, R. L. Z. et al. Research update: atmospheric pressure spatial atomic layer deposition of ZnO thin films: reactors, doping, and devices. APL Mater. 3, 40701 (2015).

Longrie, D., Deduytsche, D., & Detavernier, C. Reactor concepts for atomic layer deposition on agitated particles: a review. J. Vac. Sci. Technol. A 32, 10802 (2014).

Aaltonen, T., Ritala, M., Sajavaara, T., Keinonen, J. & Leskelä, M. Atomic layer deposition of platinum thin films. Chem. Mater. 15, 1924–1928 (2003).

Dendooven, J. et al. Low-temperature atomic layer deposition of platinum using (methylcyclopentadienyl)trimethylplatinum and ozone. J. Phys. Chem. C 117, 20557–20561 (2013).

Setthapun, W. et al. Genesis and evolution of surface species during Pt atomic layer deposition on oxide supports characterized by in situ XAFS analysis and water−gas shift reaction. J. Phys. Chem. C 114, 9758–9771 (2010).

MacKus, A. J. M., Garcia-Alonso, D., Knoops, H. C. M., Bol, A. A. & Kessels, W. M. M. Room-temperature atomic layer deposition of platinum. Chem. Mater. 25, 1769–1774 (2013).

Hämäläinen, J., Puukilainen, E., Sajavaara, T., Ritala, M. & Leskelä, M. Low temperature atomic layer deposition of noble metals using ozone and molecular hydrogen as reactants. Thin Solid Films 531, 243–250 (2013).

Rupprechter, G., Dellwig, T., Unterhalt, H. & Freund, H. J. High-pressure carbon monoxide adsorption on Pt(111) revisited: a sum frequency generation study. J. Phys. Chem. B 105, 3797–3802 (2001).

Steininger, H., Lehwald, S. & Ibach, H. On the adsorption of CO on Pt(111). Surf. Sci. 123, 264–282 (1982).

Primet, M., Basset, J. M., Mathieu, M. V. & Prettre, M. Infrared study of CO adsorbed on Pt Al2O3. A method for determining metal-adsorbate interactions. J. Catal. 29, 213–223 (1973).

Shinozaki, K., Zack, J. W., Pylypenko, S., Pivovar, B. S. & Kocha, S. S. Oxygen reduction reaction measurements on platinum electrocatalysts utilizing rotating disk electrode technique: II. Influence of ink formulation, catalyst layer uniformity and thickness. J. Electrochem. Soc. 162, F1384–F1396 (2015).

Malis, T., Cheng, S. C. & Egerton, R. F. EELS log-ratio technique for specimen-thickness measurement in the TEM. J. Electron Microsc. Tech. 8, 193–200 (1988).

Liu, H.-C., Osborne, J. R., Osborn, M. & Dahlen, G. A. Advanced CD-AFM probe tip shape characterization for metrology accuracy and throughput. In Proc. SPIE (ed. Archie, C. N.) 65183K (2007).

Villarrubia, J. S. Algorithms for scanned probe microscope image simulation, surface reconstruction, and tip estimation. J. Res. Natl Inst. Stand. Technol. 102, 425 (1997).

Qian, X. & Villarrubia, J. S. General three-dimensional image simulation and surface reconstruction in scanning probe microscopy using a dexel representation. Ultramicroscopy 108, 29–42 (2007).

Giannozzi, P. et al. QUANTUM ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter 21, 395502 (2009).

Acknowledgements

This work was supported financially by the Volkswagen Group of America. Part of this work was performed at the Stanford Nano Shared Facilities (SNSF), supported by the National Science Foundation under award ECCS-1542152. S.X. thanks support from and discussions with L. Johal, G. Li, Z. Lu and Y. Liu. D.H. acknowledges support from the Banting Postdoctoral Fellowship, administered by the government of Canada. J.T. acknowledges funding from the Austrian Science Fund (FWF) under contract J3505-N20. P.S. acknowledges financial support from the Austrian Science Fund (FWF) under contract J3980-N27.

Author information

Authors and Affiliations

Contributions

S.X. conceived the PALD process and conducted the initial feasibility tests with P.S., D.T., J.Pr. and J.T. under the supervision of F.B.P.; S.X., Y.K. and D.H. tested catalytic performance of PALD-deposited Pt under the supervision of F.B.P. and T.F.J.; S.X., J.Pa., D.T., S.S. and B.H.L. performed material characterizations and analysed the data; S.X., D.H., M.O., J.Pr., Y.K., T.G., T.D.S., T.F.J. and F.B.P. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figures 1–14, Supplementary Tables 1–4, Supplementary References

Rights and permissions

About this article

Cite this article

Xu, S., Kim, Y., Park, J. et al. Extending the limits of Pt/C catalysts with passivation-gas-incorporated atomic layer deposition. Nat Catal 1, 624–630 (2018). https://doi.org/10.1038/s41929-018-0118-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-018-0118-1

This article is cited by

-

First-principles study on the d-band center of Pt alloyed with 3d transition metals

Journal of the Korean Physical Society (2023)

-

The effect of a gas atmosphere on the formation of colloidal platinum nanoparticles in liquid phase synthesis

Colloid and Polymer Science (2023)

-

Engineering gold-platinum core-shell nanoparticles by self-limitation in solution

Communications Chemistry (2022)

-

Recent Progress on Asymmetric Carbon- and Silica-Based Nanomaterials: From Synthetic Strategies to Their Applications

Nano-Micro Letters (2022)

-

Self-regeneration of supported transition metals by a high entropy-driven principle

Nature Communications (2021)