Abstract

Bacterial spot, caused by Xanthomonas spp., is a highly destructive disease of tomatoes worldwide. Copper (Cu) bactericides are often ineffective due to the presence of Cu-tolerant strains. Magnesium oxide (MgO) is an effective alternative to Cu bactericides against Xanthomonas spp. However, the effects of particle size on bactericidal activity and fruit elemental levels are unknown. In this study, nano (20 nm) and micron (0.3 and 0.6 µm) size MgO particles were compared for efficacy. Nano MgO had significantly greater in vitro bactericidal activity against Cu-tolerant X. perforans than micron MgO at 25–50 µg/ml. In field experiments nano and micron MgO applied at 200 and 1,000 µg/ml were evaluated for disease control. Nano MgO at 200 µg/ml was the only treatment that consistently reduced disease severity compared to the untreated control. Inductively Coupled Plasma Optical Emission Spectroscopy revealed that nano MgO applications did not significantly alter Mg, Cu, Ca, K, Mn, P and S accumulation compared to fruits from the untreated plots. We demonstrated that although both nano MgO and micron MgO had bactericidal activity against Cu-tolerant strains in vitro, only nano MgO was effective in bacterial spot disease management under field conditions.

Similar content being viewed by others

Introduction

Tomato (Solanum lycopersicum) is an economically important crop in the United States and worldwide. Just in 2017, the total tomatoes production amounted to 12.5 million metric tons in the United States. The value of this crop totaled $1.67 billion dollars1. Bacterial spot is one of the most damaging diseases that can cause major yield reductions in the tomato market around the world, especially in where the high humidity and temperatures create a favorable environment2,3,4. Bacterial spot disease of tomato is caused by four distinct Xanthomonas species5. In Florida, which is the largest fresh market tomato producer in the United States1, X. perforans is the dominant causal agent of bacterial spot of tomato. Although the disease has been around since its discovery in South Africa in 19146, effective disease management strategies for bacterial spot are currently limited. Given that Florida’s tomato production industry has a long history with bacterial spot disease, the pathogen has developed resistance toward bactericides including streptomycin7,8 and copper (Cu)2,9.

Cu-tolerant Xanthomonas strains were isolated in the 1960s, as grower’s noticed the diminishing efficacy of Cu bactericides9. Subsequently it was found that addition of ethylene- bis-dithiocarbamates (EBDC) to Cu bactericides provided better disease control and improved Cu solubility9,10. Since Cu-tolerant Xanthomonas strains are sensitive to Cu-EBDC, this option remains the standard treatment for tomato producers in Florida and elsewhere. However, when environmental conditions are optimal for disease development, even Cu-EBDC is ineffective against bacterial spot disease of tomato11,12.

Efforts to identify alternatives to Cu-EBDC have been extensive over the last two decades. For instance, bacteriophages have been extensively studied and are commercially available for managing bacterial spot disease13,14,15,16. However, bacteriophages are highly sensitive to environmental factors, which can decrease their efficacy17,18. Other available alternatives to Cu include plant defense activators such as acibenzolar S-methyl15, and plant-growth-promoting rhizobacteria that provide limited disease control under field conditions19. Currently, Florida’s tomato growers use a combination of Cu bactericides, plant defense activators, bio-fungicides, and cultural practices for bacterial spot management2. Importantly, nanoparticles including magnesium oxide (MgO), have been recently shown to have potential to be an alternative to Cu-EBDC20,21,22,23.

Nanoparticles by definition are materials smaller than or equal to 100 nanometers (nm)24 and are increasingly being developed for plant disease management25,26. Prior studies have demonstrated the improved antibacterial ability of metal and metal oxide nanoparticles compared to their micron particles27,28,29,30. Nair et al. demostrated that zinc oxide (ZnO) nanoparticles (40 nm) at 5 mM had bactericidal activity against both Gram-negative bacteria (Escherichia coli) and Gram-positive bacteria (Staphylococcus aureus), whereas the micron ZnO (1.2 μm) did not. In addition, Raghupathi et al. reported that ZnO nanoparticles (25 nm) had higher bactericidal activity against methicillin sensitive Staphylococcus aureus strains compared to the micron particles (0.2 µm). Furthermore, ZnO nanoparticles (~12 nm) at 4 mM had high antibacterial activity against methicillin resistant S. aureus strains and activity was similar to that against methicillin sensitive strains. The literature suggests that using smaller size particles of metal or metal oxides may lead to greater antibacterial activity toward antibiotic resistant bacterial pathogens affecting humans and animals28,31,32. For instance, Li et al. demonstrated that silver (Ag) nanoparticles (~120 nm) at 12.5 µg/ml were bactericidal to antibiotic-resistant Neisseria gonorrhoeae. Not only were nanoparticles known to have bactericidal activity against human pathogens, but several studies over past decade have demonstrated efficacy for plant disease management20,22,33,34,35. Bacterial spot disease of tomato is a model disease for many recent studies on the use of nanoparticles for management of Cu-tolerant bacterial strains20,21,22,23.

In a previous field study23, magnesium oxide nanoparticle (nano MgO) (US Research Nanomaterials, Inc., Houston, TX, USA) at 200 µg/ml significantly reduced disease severity of bacterial spot disease of tomato compared to the untreated control, whereas the grower’s standard (Cu-EBDC) did not significantly reduce disease severity compared to the untreated control in the field23 (P < 0.05). There was no negative impact on tomato fruit yield due to nano MgO treatments. Based on elemental analysis of fruit samples, nano MgO treatments did not impact accumulation of Mg, Cu, Ca, K, Mn, P, and S compared to the untreated control. Therefore, the study suggested that nano MgO could be a potential bactericide against bacterial spot disease of tomato without potential side effects due to elemental accumulation in the fruit.

Despite the fact that MgO is generally recognized as a safe (GRAS) compound36, multiple studies have described the fate of MgO nanoparticles in the environment as poorly understood37,38,39,40. In addition, regulatory guidelines for nanoparticles are still being developed by the U.S. Environmental Protection Agency (EPA)41,42 and Food and Drug Administration (FDA)41. Therefore, understanding the environmental fate and toxicology of nanoparticles such as MgO continues to be an important research area43,44.

Due to the potential concerns to the environmental fate of nanoparticles45,46,47, comparative studies into the efficacy of micron-size particles for disease control is a relevant area given that this approach may be more acceptable for commercialization under the current EPA regulations41,48. Unlike nanoparticles, micron-sized particles are considered lower risk to the environment. In addition, Sawai et al. demonstrated that micron-sized MgO (micron MgO) also has antibacterial activity against human pathogens. Since nano MgO showed antibacterial activity in the past49,50, the potential of micron MgO to provide a similar level of crop disease reduction in the field as the MgO nanoparticles should be explored.

We hypothesized that similar to nano MgO, micron MgO will have greater antibacterial properties compared to commercial micron size Cu in vitro, and will provide more effective control of bacterial spot of tomato in the field. The goal of this study was to determine if MgO particle size is critical to increased efficacy against bacterial spot disease of tomato. The objectives of this study were to (i) evaluate the efficacy of nano- and micron-size MgO against Cu-tolerant X. perforans in vitro and in the field, and (ii) to evaluate whether the different size of MgO material leads to different accumulation of Mg or other elements in the fruit.

Results

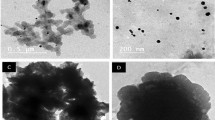

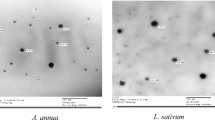

Bactericidal activity of different particle size of MgO compared with Cu bactericide

The bactericidal activity was confirmed by the viability assay (Fig. 1A–F). Bacterial mortality was nearly 100% (red fluorescence) after treatment with 100 µg/ml MgO (20 nm, 0.3 and 0.6 µm) (Fig. 1D–F) for 4 h similar to the heat treated positive control (Fig. 1B). In comparison, the Cu bactericide (Kocide 3000) (Fig. 1C) had 80.7% alive cells (green fluorescence), which was similar to the untreated control (80% alive cells) (Fig. 1A).

Viability assay of Cu-tolerant X. perforans GEV485 treated with 100 µg/ml MgO (20 nm, 0.3 µm, and 0.6 µm). Untreated, heated treated, and the Cu bactericide Kocide ® 3000 were used as controls. Cells stained with the LIVE/DEAD® BacLight™ Bacterial Viability Kit green florescence indicate live cells and red florescence indicate dead cells. Micrographs were taken on a Nikon Eclipse Ti inverted microscope (Nikon, Melville, NY) at ×40 fluorescent optics using NIS-Elements imaging software (Ver. 3.0; Nikon).

Effect of MgO particle size on in vitro growth of X. perforans

Both nano and micron (20 nm, 0.3, and 0.6 µm) MgO had significant antimicrobial activity at 100 µg/ml against the Cu-tolerant strain, X. perforans GEV485 after 4 h (Fig. 2A,B). The minimum bactericidal concentration (MBC) for nano MgO against Cu-tolerant X. perforans strain was 25–50 µg/ml, whereas the MBC for micron MgO (0.3 and 0.6 µm) was 100 µg/ml (Fig. 2A,B).

(A) In vitro inhibition of Cu-tolerant Xanthomonas perforans strain GEV485 following exposure to MgO particles for 4 h. Treatments were as follows: 20 nm, 0.3 μm and 0.6 μm MgO at 100, 50, 25, and 12.5 μg/ml. The treatments were compared with water control (UT) at incubation times of 4 h. Error bars indicate standard error of the mean. P value of 0.05 was used in the IBM SPSS using Student-Newman-Keuls statistical analysis. (B) Repeated in vitro inhibition of Cu-tolerant Xanthomonas perforans strain GEV485 following exposure to MgO particles for 4 h. Treatments were as follows: 20 nm, 0.3 μm and 0.6 μm MgO at 100, 50, 25, and 12.5 μg/ml.

Comparison of field efficacy of MgO with Cu and Cu-EBDC for management of tomato bacterial spot

In the first field experiment, conducted during spring 2016 in Quincy, FL, plants that received either concentration of nano MgO (20 nm) (1,000 µg/ml or 200 µg/ml) had significantly less disease compared to the untreated control, but were not different from the other treatments (Table 1). Of the two larger size MgO particle sizes tested, only 0.3 µm MgO at 1,000 µg/ml significantly reduced disease severity compared to the untreated control. Both Cu bactericide and Cu-EBDC were not significantly different from the control. Treatment applications did not cause any phytotoxicity on the tomato plants (data not shown).

In the second trial during fall 2016 at Quincy, FL, (Table 1), both concentrations (1,000 and 200 µg/ml) of the nano-MgO (20 nm) significantly reduced disease severity compared to the untreated control, whereas the grower’s standard Cu-EBDC did not significantly reduce disease in the field trials compared to the untreated control (Table 1). Neither of the micron MgO (0.3 µm and 0.6 µm) treatments showed significant disease reduction compared to the untreated control in this trial (Table 1). No phytotoxicity was observed for any of the treatments in this experiment (data not shown). There were no significant impacts on total yield due to MgO treatments in both field trials (Table 2).

Accumulation of metals in harvested tomato fruits treated with MgO

In the spring 2016 trial (Table 3), there were no significant differences for any of the elements (Al, B, Ca, Cu, Fe, K, Mg, Mn, Mo, Na, P, S, and Zn) (Table S1) when comparing nano MgO (20 nm) treated fruit with the untreated controls. Similarly, fruit collected from micron MgO (0.3 µm and 0.6 µm) treated plots, at both concentrations of 0.3 µm MgO and 1,000 µg/ml of 0.6 µm MgO had no significant differences in elemental concentration compared to the untreated control. As for Cu bactericide (Kocide 3000) and the grower standard (Cu-EBDC), both treatments showed significantly higher Cu concentrations relative to the untreated control. The Cu bactericide treated fruits contain Cu that is twice as high (4.5 mg/kg higher) as the untreated fruit. For the fruit collected in fall 2016 trial (Tables 3), 1,000 µg/ml of 0.3 µm MgO treatment showed significantly higher Al content in the peel, with approximately 4 mg/kg more Al in dry weight compared to the untreated control (Table 3). However, Al did not significantly accumulate in either whole fruit or flesh for the 1,000 µg/ml of 0.3 µm MgO. Fruit receiving 1,000 µg/ml 0.3 µm MgO also contained significantly higher levels of Ca in the whole fruit (+8 mg/kg more in fresh weight) and peel (+0.043 mg/kg more in fresh weight) compared to the untreated control. The Cu-EBDC treatment showed significantly higher Ca content (+12.26 mg/kg more in fresh weight); values were at nearly two-fold of that accumulated in the untreated fruit (Table 3). Unlike the spring trial, Cu content of the fruit was not significantly impacted by the Kocide 3000 or Cu-EBDC treatment.

Discussion

In this study, we compared nano and micron size MgO for in vitro bactericidal activity to copper-tolerant X. perforans bacterial cells. We demonstrated in the viability assay that both nano (20 nm) and micron (0.3 µm and 0.6 µm) MgO at concentrations as low as 100 µg/ml had high bactericidal activity (100% percent reduction) after 4 h. In comparison, Cu bactericide (Kocide 3000) was similar (19.3% mortality) to the untreated control (20% mortality). These results indicate that both nano (20 nm) and micron (0.3 µm and 0.6 µm) MgO at 100 µg/ml were more effective against Cu-tolerant X. perforans compared to Cu bactericide. However, in the in vitro assay, the MBC of nano-MgO (20 nm) against Cu-tolerant X. perforans was 25–50 µg/ml, whereas the MBC of micron (0.3 µm and 0.6 µm) MgO was 100 µg/ml. Therefore, this experiment demonstrated that nano MgO (20 nm) had significantly greater bactericidal activity compared to micron (0.3 µm and 0.6 µm) MgO (P < 0.05) in vitro. This finding was consistent with the results of Huang et al. that the MgO antibacterial activity is size dependent in vitro. Huang et al. demonstrated that the bactericidal efficacy against Bacillus subtilis var. niger increased from 93% to 97%, when the MgO nanoparticle size decreased from 69 nm to 26 nm. However, that report focused on the MgO nanoparticles less than 100 nm, whereas in this study, we focused on evaluating antibacterial activity of nano (20 nm) and micron MgO (0.3 µm and 0.6 µm) against Cu-tolerant X. perforans.

Since both nano and micron MgO showed bactericidal activity against Cu-tolerant X. perforans in vitro, we compared the effectiveness of these materials with Cu bactericide and grower standard Cu-EBDC in the field. According to the field experiments, only nano MgO (20 nm) as low at 200 µg/ml provided significant disease reduction consistently compared with the untreated control (P < 0.05) in both 2016 Spring and Fall field trials in Quincy, FL. In 2016 Fall field trial, nano MgO (20 nm) even provided greater disease control than the grower’s standard Cu-EBDC (P < 0.05). Although both nano (20 nm) and micron (0.3 µm and 0.6 µm) MgO had antibacterial activity in vitro, the field trial experiments showed that only nano MgO (20 nm) could significantly reduce disease severity in the field.

In the past decade, nano MgO particles have been shown to have antimicrobial activity against several mammalian pathogens51,52. Additionally, MgO nanoparticles (~50 ± 10 nm) at concentrations as low as 100 μg/ml resulted in high inhibition rates of fungal spore germination of several fungal plant pathogens including Alternaria alternata, Fusarium oxysporum, Rhizopus stolonifer, and Mucor plumbeus53. Recently, a limited number of studies have explored utilizing Mg nanomaterials to manage bacterial pathogens23,54. Based on these studies, antibacterial mechanisms were proposed for MgO nanoparticle against bacterial cell at the nano-bio interface. Liao et al. used transmission electron microscopy (TEM) to show that MgO nanoparticles could cause membrane damage on X. perforans. Cai et al. suggested that reactive oxygen species (ROS) accumulation could play an important role for the antibacterial efficacy of MgO, inducing DNA damage, against Ralstonia solanacearum. These findings demonstrate the potential of utilizing MgO nanoparticles to manage plant pathogens in agriculture systems. Furthermore, MgO is a more sustainable treatment option since, unlike Cu, it is not on the list of the EPA’s Toxic Release Inventory (TRI) Program or in the Integrated Risk Information System36. Last but not least, by using MgO nanoparticles as alternatives to Cu bactericide would reduce the selective pressure on the developing Cu-tolerant X. perforans in the field.

The fate of engineered nanomaterials is a concern along with approaches involving material release into the environment. Due to the use of MgO in medical field such as cancer research, studies investigating the toxicity of MgO nanoparticles toward mammals have been conducted55,56. Lai et al. demonstrated that when compared to ZnO and TiO2, MgO nanoparticles ( < 50 nm) had the least toxicity to human neural cells. Gerloff et al. evaluated the cytotoxicity and oxidative DNA damage effect of MgO nanoparticles (8 nm) in human intestinal Caco-2 cells. The study showed that MgO nanoparticles (8 nm) did not cause significant membrane damage on Caco-2 cells in the cytotoxicity study. However, in order to fit the National Nanotechnology Initiative (NNI), which supports responsible development of nanotechnology, studies on the fate and effects of nanoparticle MgO in the environment are limited37,38,39,40; such work should be done to ensure the sustainability of such approaches as part of nano-enabled agriculture.

The metallic elemental composition derived from nano and micron MgO treatments in fruit is of relevant concern to the research community and general public. As shown in this study, there were no significant differences for any of the elements (Al, B, Ca, Cu, Fe, K, Mg, Mn, Mo, Na, P, S, and Zn) (Table S1) when comparing nano MgO (20 nm) treated fruit with the untreated controls. This finding is consistent with our previous study in which the nano MgO treatments did not impact accumulation of elemental concentration in the fruit compared to the untreated control23. In 2016 Spring trial (Table 3), similar to nano MgO (20 nm), micron MgO (0.3 µm and 0.6 µm) did not alter the elemental composition compared to fruits in the untreated control. However, fruits collected from Cu bactericide (Kocide 3000) and the grower standard (Cu-EBDC) treated plots showed significantly higher Cu concentrations (+0.2 mg/kg in fresh weight) relative to the untreated control. The study by Liao et al. also revealed that Cu-EBDC treated fruits had significantly greater Cu accumulation based on fresh weight more than the untreated control. Though consumption of tomato treated with Cu bactericide might lead to more Cu exposure, the concentration is still within the daily dietary limit57,58. In addition, unlike the spring trial, the Cu concentration of fruit was not significantly impacted by the Kocide 3000 or Cu-EBDC treatment in the fall trial. Former studies suggest that different environmental conditions such as crop variety, heavy metal exposure time, and location may affect Cu accumulation or elemental composition in crops59,60,61. Although applying Cu bactericides may increase Cu content in the fruit slightly without immediate risk to the consumer, field runoff containing Cu still pose ecological risk to non-target aquatic organisms62,63,64. In addition, Cu accumulation in the soil will potential cause phytotoxicity to tomato plants65,66. Thus it is still critical to find effective alternatives against bacterial spot to avoid intense Cu application in agriculture system.

In conclusion, although both micron (0.3 µm and 0.6 µm) and nano (20 nm) MgO have bactericidal activity against Cu-tolerant X. perforans in vitro, whereas micron MgO did not significantly reduce disease severity as effectively as nano MgO in the field. Importantly, the efficacy of MgO against bacterial spot disease of tomato is size dependent. Nano MgO bactericide still has great potential to become an alternative to Cu bactericides against bacterial spot disease of tomato as long as regulatory clearance can be obtained.

Materials and Methods

Bacterial strains and storage

X. perforans strain GEV485 (Cu-tolerant), isolated from tomato in Florida, was used in this study. Bacterial cells from pure cultures of these strains were suspended in sterile 30% glycerol solution and stored at −80 °C. Prior to use, bacteria were grown on nutrient agar (NA) medium (BBL, Becton Dickinson and Co., Cockeysville, MD) at 28 °C and were transferred every 24 to 48 h. Bacterial cells were collected from cultures grown on NA for 24 h, suspended in 0.01 M MgSO4, and the suspensions were adjusted to A600 = 0.3 at λ = 600 nm (~5 × 108 CFU/ml).

Magnesium oxide particles

Magnesium oxide particles (MgO, 99 + %, 20 nm, 0.3 and 0.6 µm) were purchased in powder form from US Research Nanomaterials, Inc. (Houston, TX, USA). The powder was suspended in autoclaved deionized water, and sonicated with a Branson B-22-4 Ultrasonic Cleaner (Danbury, CT, USA) for 10 min in sterile deionized water. The suspension was adjusted to 1,000 µg/ml and used as a stock suspension.

In vitro experiment evaluating minimum inhibitory concentration

X. perforans strain GEV485 (Cu-tolerant) was cultured from −80 °C storage and was suspended in sterile tap water and suspensions were diluted to 105 CFU/ml. Twenty micoliters of the bacterial suspension were transferred to 2 mL of MgO (20 nm, 0.3 and 0.6 µm) at different concentrations (100, 50, 25, and 12.5 µg/ml) in glass tubes. Sterile tap water served as the control. The tubes were incubated on a shaker (200 rpm) at 28 °C. Fifty microliters were sampled from each tube and plated on nutrient agar. Bacterial colonies were counted on each plate and converted to colony forming units (CFU)/ml.

Viability assay evaluating bactericidal activity

X. perforans strain GEV485 was used for the viability assay. Bacterial cells were incubated in nutrient broth (BBL, Becton Dickinson and Co., Cockeysville, MD) at 28 °C on a shaker at 300 rpm for 16 h to log phase. Bacterial cells were pelleted by centrifugation (16,872 × g for 10 min) and resuspended in 0.01 M MgSO4, and the suspensions were adjusted to A600 = 0.3 at λ = 600 nm (~5 × 108 CFU/ml). Then 4.5 mL of the bacterial suspension were transferred to 500 μl of the following treatments in sterile glass tubes: 3 particle sizes of MgO (i.e., 20 nm, 0.3, or 0.6 µm), Cu bactericide (Kocide® 3000 (DuPont, Wilmington, DE)) at 1,000 µg/ml. Sterilized tap water served as the control. The tubes were incubated on a shaker (300 rpm) at 28 °C for 4 h. After washing with 1 mL 0.85% NaCl twice, 1 ml samples from each tube were stained using the LIVE/DEAD BacLight Bacterial Viability kit (L7007, Molecular Probes, Invitrogen). The stain was a mixture of 1.5 ml Component A (SYTO 9 dye, 1.67 mM/Propidium iodide, 1.67 mM) with 1.5 ml Component B (SYTO 9 dye, 1.67 mM/Propidium iodide, 18.3 mM). Following addition of the stain, the sample was incubated in darkness for 15 min at room temperature. Micrographs were taken on a Nikon Eclipse Ti inverted microscope (Nikon, Melville, NY) at ×40 fluorescent optics using NIS-Elements imaging software (Ver. 3.0; Nikon, Melville, NY). The dead cell/ all cell ratio was calculated by ImageJ67.

Field experiments

Different MgO particle sizes were tested against bacterial spot disease of tomato in two field trials (Season one: 18 Apr 2016 to 13 June 2016 in Quincy, FL; Season two: 13 Sep 2016 to 18 Oct 2016 in Quincy, FL). Each treatment had four replications consisting of 15 BHN 602 variety tomato plants. The plots were arranged in a completely randomized block design. Experimental plots were spaced 1.8 m apart and plants were spaced 50.8 cm within the row68. Fertilizers were applied to plots based on soil type and cooperative extension recommendations69. Tomato transplants were grown in 128-cell containers under greenhouse conditions before transplanting. After transplanting, the treatments were sprayed on the foliar parts of tomatoes at the rate of 1.2 liter for four plots one week prior to bacterial inoculation. The treatments consisted of 200 and 1,000 µg/ml of 20 nm, 0.3 µm, and 0.6 µm of MgO suspension, sonicated in Branson B-22-4 Ultrasonic Cleaner (Danbury, CT, USA) for 10 min, with constant shaking while applying; Kocide 3000 (2.1 g/liter), the grower standard Kocide 3000 (2.1 g/liter) in combination with Penncozeb 75DF (1.2 g/liter; United Phosphorus, Inc., King of Prussia, PA) (Cu-EBDC) and an untreated control (water). To ensure adequate disease development in the field plots, a suspension of Cu-tolerant X. perforans strain GEV485 was adjusted to 5 × 108 CFU/ml in deionized water and was applied to the foliage in the field by spraying the 1st, 8th, and 15th plant in each plot. One liter of each treatment was applied to each plot weekly with CO2 pressurized spray boom with five nozzles until one week before fruit harvest. Plants were assessed for bacterial spot disease severity and phytotoxicity using the Horsfall-Barratt disease severity scale70 every week after inoculation until harvest. The area under disease progress curve (AUDPC) was then calculated71. There were four replications per treatment and the experiment was conducted three times. Twelve out of fifteen plants, excluding the two towards the two ends of plots, were harvested for assessing the yield. Mature green or early breaker stage fruit were harvested and graded by USDA standards72. At least two harvests were made for each field experiment, which is common for fresh market tomato production in Florida.

Elemental analysis of the fruits

At harvest, five medium-sized mature-green stage fruits, with diameters between 5.72 and 6.43 cm according to the USDA standards72,73,74 were collected from each of the treatments. The fruit were harvested from outside of the canopy from the first and the last plants of each of four plots from the 2016 Spring and Fall Quincy trial at 7 days after final application. The harvested fruit were hand-washed and sent to Department of Analytical Chemistry, The Connecticut Agricultural Experiment Station, New Haven, CT, USA. Four to eight grams of fresh tomato fruit with peel and flesh, and four to eight grams each of peel only and flesh only samples were dried in an electric oven at 70 °C for 48 h. Dried samples were pre-digested overnight with 2 ml of concentrated nitric acid and 2 ml of H2O2. After the pre-digestion step, these samples were digested at 115 °C for 45 min and then cooled to room temperature. The samples were filtered through cotton plugs and the volume was adjusted to 50 ml. The samples were stored at room temperature until analysis. Al, B, Ca, Cu, Fe, K, Mg, Mn, Mo, Na, P, S, and Zn concentrations were determined by Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) using the Atom Scan 16 (Thermo-Jarrell Ash, Franklin, MA, USA). Analysis was performed following the methods described in previous studies75,76,77.

Statistical analysis

The data collected from the in vitro assays and field experiments were evaluated for statistical significance using ANOVA followed by pair-wise comparisons using either the Least Significant Difference (LSD) for field studies, and the Student Newman-Keuls (SNK) method for in vitro and elemental accumulation experiments in IBM® SPSS® Statistics Version 22. A p-value of 0.05 was used to evaluate significance.

References

USDA. Vegetables 2017 Summary. National Agricultural Statistics Service (2018).

Potnis, N. et al. Bacterial spot of tomato and pepper: diverse Xanthomonas species with a wide variety of virulence factors posing a worldwide challenge. Molecular plant pathology 16, 907–920, https://doi.org/10.1111/mpp.12244 (2015).

Horvath, D. M. et al. Transgenic resistance confers effective field level control of bacterial spot disease in tomato. PloS one 7, e42036 (2012).

Pohronezny, K. The effect of bacterial spot on yield and quality of fresh market tomatoes. Hortic Sci 18, 69–70 (1983).

Jones, J. B., Lacy, G. H., Bouzar, H., Stall, R. E. & Schaad, N. W. Reclassification of the xanthomonads associated with bacterial spot disease of tomato and pepper. Systematic and applied microbiology 27, 755–762, https://doi.org/10.1078/0723202042369884 (2004).

Doidge, E. M. A tomato canker. Annals of Applied Biology 7, 407–430 (1921).

Thayer, P. & Stall, R. In Proc. Fla. State Hort. Soc. 163–165.

Stall, R. & Thayer, P. Streptomycin resistance of the bacterial spot pathogen and control with streptomycin. Plant Dis. Rep 46, 389–392 (1962).

Marco, G. M. & Stall, R. E. Control of Bacterial Spot of Pepper Initiated by Strains of Xanthomonas-Campestris Pv-Vesicatoria That Differ in Sensitivity to Copper. Plant Disease 67, 779–781, https://doi.org/10.1094/Pd-67-779 (1983).

Conover, R. A. & Gerhold, N. R. In Proceedings of the… annual meeting of the Florida State Horticultural Society (USA).

Jones, J. & Jones, J. P. In Proc. Fla. State Hortic. Soc. 244–247.

Obradovic, A., Jones, J. B., Momol, M. T., Balogh, B. & Olson, S. M. Management of tomato bacterial spot in the field by foliar applications of bacteriophages and SAR inducers. Plant Disease 88, 736–740, https://doi.org/10.1094/Pdis.2004.88.7.736 (2004).

Balogh, B. et al. Improved efficacy of newly formulated bacteriophages for management of bacterial spot on tomato. Plant Disease 87, 949–954 (2003).

Flaherty, J., Somodi, G., Jones, J., Harbaugh, B. & Jackson, L. Control of bacterial spot on tomato in the greenhouse and field with H-mutant bacteriophages. HortScience 35, 882–884 (2000).

Obradovic, A. et al. Integration of biological control agents and systemic acquired resistance inducers against bacterial spot on tomato. Plant Disease 89, 712–716 (2005).

Momol, M. T. et al. Integrated management of bacterial spot on tomato in Florida. (University of Florida Cooperative Extension Service, Institute of Food and Agricultural Sciences, EDIS, 2002).

Iriarte, F. et al. Factors affecting survival of bacteriophage on tomato leaf surfaces. Applied and environmental microbiology 73, 1704–1711 (2007).

Jones, J. et al. Bacteriophages for plant disease control. Annu. Rev. Phytopathol. 45, 245–262 (2007).

Ji, P. et al. Integrated biological control of bacterial speck and spot of tomato under field conditions using foliar biological control agents and plant growth-promoting rhizobacteria. Biological control 36, 358–367 (2006).

Paret, M. L., Vallad, G. E., Averett, D. R., Jones, J. B. & Olson, S. M. Photocatalysis: effect of light-activated nanoscale formulations of TiO2 on Xanthomonas perforans and control of bacterial spot of tomato. Phytopathology 103, 228–236 (2013).

Strayer-Scherer, A. et al. Advanced copper composites against copper-tolerant Xanthomonas perforans and tomato bacterial spot. Phytopathology 108, 196–205 (2018).

Strayer, A. L., Öçsoy, I., Tan, W., Jones, J. & Paret, M. L. Low Concentrations of a Silver-Based Nanocomposite to Manage Bacterial Spot of Tomato in the Greenhouse. Plant Disease (2015).

Liao, Y. et al. Nano-Magnesium oxide: A novel bactericide against copper-tolerant Xanthomonas perforans causing tomato bacterial spot. Phytopathology (2018).

Masciangioli, T. & Zhang, W.-X. Environmental technologies at the nanoscale. Environmental Science & Technology 37, 102A–108A, https://doi.org/10.1021/es0323998 (2003).

Mazzaglia, A., Fortunati, E., Kenny, J. M., Torre, L. & Balestra, G. M. Nanomaterials in plant protection. Nanotechnology in Agriculture and Food Science 7, 115–133 (2017).

Fortunati, E., Mazzaglia, A. & Balestra, G. M. Sustainable control strategies for plant protection and food packaging sectors by natural substances and novel nanotechnological approaches. Journal of the Science of Food and Agriculture 99, 986–1000 (2019).

Padmavathy, N. & Vijayaraghavan, R. Enhanced bioactivity of ZnO nanoparticles—an antimicrobial study. Science and technology of advanced materials 9, 035004 (2008).

Raghupathi, K. R., Koodali, R. T. & Manna, A. C. Size-dependent bacterial growth inhibition and mechanism of antibacterial activity of zinc oxide nanoparticles. Langmuir 27, 4020–4028 (2011).

Nair, S. et al. Role of size scale of ZnO nanoparticles and microparticles on toxicity toward bacteria and osteoblast cancer cells. Journal of Materials Science: Materials in Medicine 20, 235 (2009).

Yamamoto, O. Influence of particle size on the antibacterial activity of zinc oxide. International Journal of Inorganic Materials 3, 643–646 (2001).

Roy, A. S., Parveen, A., Koppalkar, A. R. & Prasad, M. A. Effect of nano-titanium dioxide with different antibiotics against methicillin-resistant Staphylococcus aureus. Journal of Biomaterials and Nanobiotechnology 1, 37 (2010).

Li, L.-H. et al. Non-cytotoxic nanomaterials enhance antimicrobial activities of cefmetazole against multidrug-resistant Neisseria gonorrhoeae. PloS one 8, e64794 (2013).

Servin, A. et al. A review of the use of engineered nanomaterials to suppress plant disease and enhance crop yield. Journal of Nanoparticle Research 17, 1–21 (2015).

Dimkpa, C. O., McLean, J. E., Britt, D. W. & Anderson, A. J. Antifungal activity of ZnO nanoparticles and their interactive effect with a biocontrol bacterium on growth antagonism of the plant pathogen Fusarium graminearum. Biometals 26, 913–924 (2013).

Chen, H. & Yada, R. Nanotechnologies in agriculture: new tools for sustainable development. Trends in Food Science &. Technology 22, 585–594 (2011).

Clydesdale, F. M. A proposal for the establishment of scientific criteria for health claims for functional foods. Nutrition reviews 55, 413–422 (1997).

Ghobadian, M., Nabiuni, M., Parivar, K., Fathi, M. & Pazooki, J. Toxic effects of magnesium oxide nanoparticles on early developmental and larval stages of zebrafish (Danio rerio). Ecotoxicology and environmental safety 122, 260–267 (2015).

Neal, A. L. What can be inferred from bacterium–nanoparticle interactions about the potential consequences of environmental exposure to nanoparticles? Ecotoxicology 17, 362 (2008).

Gelli, K., Porika, M. & Anreddy, R. N. R. Assessment of pulmonary toxicity of MgO nanoparticles in rats. Environmental toxicology 30, 308–314 (2015).

Auffan, M. et al. In Nanoethics and nanotoxicology 325–357 (Springer, 2011).

Choi, J.-Y., Ramachandran, G. & Kandlikar, M. The impact of toxicity testing costs on nanomaterial regulation. Environmental Science & Technology 43, 3030–3034, https://doi.org/10.1021/es802388s (2009).

Albrecht, M. A., Evans, C. W. & Raston, C. L. Green chemistry and the health implications of nanoparticles. Green chemistry 8, 417–432 (2006).

Bobo, D., Robinson, K. J., Islam, J., Thurecht, K. J. & Corrie, S. R. Nanoparticle-based medicines: a review of FDA-approved materials and clinical trials to date. Pharmaceutical research 33, 2373–2387 (2016).

Bawa, R. Regulating nanomedicine-can the FDA handle it? Current Drug Delivery 8, 227–234 (2011).

Sun, T. Y., Gottschalk, F., Hungerbuhler, K. & Nowack, B. Comprehensive probabilistic modelling of environmental emissions of engineered nanomaterials. Environmental pollution 185, 69–76, https://doi.org/10.1016/j.envpol.2013.10.004 (2014).

NSET/NEHI. Quantifying Exposure to Engineered Nanomaterials (QEEN) from Manufactured Products. NNI Publications and Reports, https://www.nano.gov/sites/default/files/pub_resource/qeen_workshop_report_2016.pdf (2015).

Nel, A. E. et al. Understanding biophysicochemical interactions at the nano–bio interface. Nature materials 8, 543 (2009).

Holdren, J. P., Sunstein, C. R. & Siddiqui, I. A. Memorandum for the Heads of Executive Departments and Agencies: Policy Principles for the US Decision-Making Concerning Regulation and Oversight of Applications of Nanotechnology and Nanomaterials. (2011).

Sawai, J. Quantitative evaluation of antibacterial activities of metallic oxide powders (ZnO, MgO and CaO) by conductimetric assay. Journal of Microbiological Methods 54, 177-182 (2003).

Sawai, J. et al. Antibacterial characteristics of magnesium oxide powder. World Journal of Microbiology and Biotechnology 16, 187–194 (2000).

Aruoja, V., Dubourguier, H.-C., Kasemets, K. & Kahru, A. Toxicity of nanoparticles of CuO, ZnO and TiO 2 to microalgae Pseudokirchneriella subcapitata. Science of the total environment 407, 1461–1468 (2009).

Huang, L. et al. Controllable preparation of Nano-MgO and investigation of its bactericidal properties. Journal of Inorganic Biochemistry 99, 986–993 (2005).

Wani, A. & Shah, M. A unique and profound effect of MgO and ZnO nanoparticles on some plant pathogenic fungi. Journal of Applied Pharmaceutical Science 2, 4 (2012).

Cai, L. et al. Magnesium oxide nanoparticles: Effective agricultural antibacterial agent against Ralstonia solanacearum. Frontiers in Microbiology 9 (2018).

Gerloff, K., Albrecht, C., Boots, A. W., Förster, I. & Schins, R. P. Cytotoxicity and oxidative DNA damage by nanoparticles in human intestinal Caco-2 cells. Nanotoxicology 3, 355–364 (2009).

Lai, J. C. et al. Exposure to titanium dioxide and other metallic oxide nanoparticles induces cytotoxicity on human neural cells and fibroblasts. International journal of nanomedicine 3, 533 (2008).

Gaetke, L. M. & Chow, C. K. Copper toxicity, oxidative stress, and antioxidant nutrients. Toxicology 189, 147–163 (2003).

Winge, D. R. & Mehra, R. Host defenses against copper toxicity. International review of experimental pathology 31, 47–83 (1990).

Ke, W., Xiong, Z.-T., Chen, S. & Chen, J. Effects of copper and mineral nutrition on growth, copper accumulation and mineral element uptake in two Rumex japonicus populations from a copper mine and an uncontaminated field sites. Environmental and Experimental Botany 59, 59–67 (2007).

Alaoui-Sossé, B. et al. Effect of copper on growth in cucumber plants (Cucumis sativus) and its relationships with carbohydrate accumulation and changes in ion contents. Plant Science 166, 1213–1218 (2004).

Arora, M. et al. Heavy metal accumulation in vegetables irrigated with water from different sources. Food chemistry 111, 811–815 (2008).

Arnold, G., Luckenbach, M. & Unger, M. Runoff from tomato cultivation in the estuarine environment: biological effects of farm management practices. Journal of experimental marine biology and ecology 298, 323–346 (2004).

Dietrich, A. M. & Gallagher, D. L. Fate and environmental impact of pesticides in plastic mulch production runoff: Field and laboratory studies. Journal of agricultural and food chemistry 50, 4409–4416 (2002).

Rice, P. J. et al. Comparison of copper levels in runoff from fresh‐market vegetable production using polyethylene mulch or a vegetative mulch. Environmental Toxicology and Chemistry: An International Journal 21, 24–30 (2002).

Rhoads, F., Olson, S. & Manning, A. Copper toxicity in tomato plants. Journal of Environmental Quality 18, 195–197 (1989).

Kaplan, M. Accumulation of copper in soils and leaves of tomato plants in greenhouses in Turkey. Journal of Plant Nutrition 22, 237–244 (1999).

Schneider, C. A., Rasband, W. S. & Eliceiri, K. W. NIH Image to ImageJ: 25 years of image analysis. Nature methods 9, 671 (2012).

McAvoy, T., Freeman, J. H., Rideout, S. L., Olson, S. M. & Paret, M. L. Evaluation of grafting using hybrid rootstocks for management of bacterial wilt in field tomato production. HortScience 47, 621–625 (2012).

Vallad, G. E., Smith, H. A., Dittmar, P. J. & Freeman, J. H. Vegetable Production Handbook of Florida University of Florida, IFAS Extension, Gainesville, FL 2017–2018 (2017).

Barratt, R. & Horsfall, J. An improved grading system for measuring plant disease. Phytopathology 35, 655 (1945).

Campbell, C. L. & Madden, L. V. Introduction to plant disease epidemiology. (John Wiley & Sons. 1990).

USDA. p. 1–11 (Agric. Marketing Serv., U.S. Dep. Agric. 1976).

Kelley, W. T. et al. Commercial tomato production handbook (2010).

Agriculture, U. D. O. United States standards for grades of fresh tomatoes (1997).

Mattina, M. I., Lannucci-Berger, W., Musante, C. & White, J. C. Concurrent plant uptake of heavy metals and persistent organic pollutants from soil. Environmental pollution 124, 375–378 (2003).

Musante, C. & White, J. C. Toxicity of silver and copper to Cucurbita pepo: differential effects of nano and bulk‐size particles. Environmental toxicology 27, 510–517 (2012).

Stilwell, D. & Graetz, T. Copper, chromium, and arsenic levels in soil near highway traffic sound barriers built using CCA pressure-treated wood. Bulletin of environmental contamination and toxicology 67, 303–308 (2001).

Acknowledgements

The funding of this project was from the Florida Tomato Committee. We thank the farm crew at North Florida Research and Education Center and Gulf Coast Research and Education Center of the University of Florida for the support in field preparation and management of the trials, and G. V. Minsavage and R. E. Stall for supporting greenhouse experiments. In addition, we would like to thank L. De La Fuente, E. Naranjo Feliciano, and J. A. Rollins for the assistance in conducting the bacterial cell viability assay.

Author information

Authors and Affiliations

Contributions

Y.L., M.P. and J.J. conceptualized and designed the experiments; Y.L., A.S., R.D., L.R., J.W., G.V., J.F. and M.P. conducted the experiments and collected data; Y.L., R.D. and J.C. analysed the data; Y.L., M.P., J.J., R.D., J.W. and J.C. interpreted the data; Y.L., M.P. and J.J. prepared the manuscript and all Tables and Figures; and A.S., R.D., L.R., J.W., J.F., and G.V. reviewed and edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liao, Y.Y., Strayer-Scherer, A., White, J.C. et al. Particle-size dependent bactericidal activity of magnesium oxide against Xanthomonas perforans and bacterial spot of tomato. Sci Rep 9, 18530 (2019). https://doi.org/10.1038/s41598-019-54717-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-54717-7

This article is cited by

-

Physiological and molecular advances in magnesium nutrition of plants

Plant and Soil (2021)

-

Use of magnesium nanomaterials in plants and crop pathogens

Journal of Nanoparticle Research (2021)

-

Epidemiology, diversity, and management of bacterial spot of tomato caused by Xanthomonas perforans

Applied Microbiology and Biotechnology (2021)

-

Guest Edited Collection: Nanotechnology in agriculture

Scientific Reports (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.