Abstract

A non-enzymatic simultaneous (coined coetaneous) kinetic resolution of a racemic alkyne and racemic azide, utilising an asymmetric CuAAC reaction is reported. The use of a CuCl (R,R)-Ph-Pybox catalyst system effects a simultaneous kinetic resolution of two racemic starting materials to give one major triazolic diastereoisomer in the ratio 74:12:4:10 (dr 84:16, 90% ee maj). The corresponding control reaction using an achiral copper catalyst gives the four possible diastereoisomers in a 23:27:23:27 ratio, demonstrating minimal inherent substrate control.

Similar content being viewed by others

Introduction

The copper-catalysed azide-alkyne cycloaddition (CuAAC) pioneered by both Meldal and Sharpless has become a ubiquitous molecular fragment-linking reaction1,2,3. The product 1,4-substituted, 1,2,3-triazoles, along with their alkyne and azide building blocks, in enantioenriched forms are important motifs4,5,6,7,8,9. Triazoles for example, have become crucial to research arenas including fragment based drug discovery (FBDD) and supramolecular chemistry10. Whilst scalemic alkynes and azides are important building blocks for a myriad of transformations4,5.

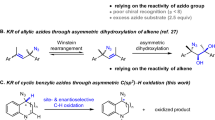

Catalytic kinetic resolution (KR) occurs when one enantiomer of a racemic substrate is preferentially activated towards reaction by a chiral catalyst (through competing diastereomeric transition states), leading to more rapid formation of one enantiomer of product. At 50% conversion of starting racemic material, effective catalytic KR will have occurred if high ee of product and high ee of unreacted starting material are obtained. The effectiveness of a kinetic resolution may be judged by a criterion named selectivity factor (s). Selectivity factor is the ratio of the rate constants for reaction of each enantiomer in a given asymmetric transformation11. Enzymes are capable of performing catalytic KR, albeit under a narrow range of conditions with limited substrate scope12,13. Kinetic resolution has been widely studied11. Fu and co-workers have championed catalytic KR, applying planar chiral DMAP-derivative catalysts to the successful KR of secondary alcohols14,15,16. Catalytic KR has also been successfully employed in copper-catalysed azide-alkyne cycloadditions leading to enantioenriched chiral triazoles and the recovery of enantioenriched starting materials (Scheme 1i and ii)17,18,19,20,21, and complete consumption of starting materials in the case of dynamic kinetic resolution22. Desymmetrisation by asymmetric triazole formation has also been successfully achieved23,24,25.

Parallel kinetic resolution is a well-established field, where a single chiral starting materials’ enantiomers undergo simultaneous divergent asymmetric transformations yielding different enantioenriched products from either enantiomer of starting material26,27,28,29. For example Fu and co-workers utilised parallel kinetic resolution to resolve 4-alkynals (Scheme 2)30.

Parallel Kinetic Resolution of 4-Alkynals, Fu and co-workers30 Path (i) Reaction of enantiomer (R) to form cyclobutaneone product. Path (ii) Reaction of enantiomer (S) to form cyclopentenone product.

Herein, we investigate a simultaneous, rather than parallel, kinetic resolution of two racemic substrates, under control of a single chiral catalyst, and coin the term coetaneous resolution to describe it. Upon coetaneous resolution of two racemic substrates, the ideal scenario would be formation, at 50% conversion, of a single diastereoisomer of the product formed from one enantiomer of each substrate. This ideal process would leave the opposite enantiomers of the substrates unreacted in high enantiopurity. Thus, simultaneously kinetically resolving two chiral starting materials under one reaction and product manifold.

We chose to focus on the CuAAC of racemic substrates, such that, under catalyst control, the starting materials (chiral azides and alkynes) could react selectively to give a major stereoisomer, among the four possible expected diastereomeric triazole products. Conversely, in the case where no substrate control exists, the use of an achiral catalyst will lead to equal consumption of starting material enantiomers and delivery of an equimolar distribution of the four stereoisomers of product (Fig. 1). Asymmetric synthesis using two catalysts to control the formation of two stereogenic centres has been elegantly demonstrated by Carreira and co-workers. See refs26,27,31,32.

Results and Discussion

Based on previous work on catalytic kinetic resolution of alkynes and azides, we chose the PyBox ligand family for creation of a chiral copper catalyst and selected (R,R)-Ph-PyBox as a suitable ligand for our investigations20,25,33,34. To investigate the potential for coetaneous catalytic kinetic resolution we focused on substrates with demonstrable efficacy in standard catalytic kinetic resolutions. Quaternary oxindole 1 (as employed in Scheme 1i), was selected as the alkyne-containing component. Oxindoles are important, biologically-relevant, scaffolds having found wide application, including as calcium channel blockers35, anti-angiogenics36, antitumour agents37,38,39 and analgesics35. Azide 3 (as employed in Scheme 1ii) was chosen owing to its previously reported application in the first catalytic kinetic, copper-catalysed triazole forming, resolution by Fokin and co-workers20.

We have previously explored the selectivity of alkyne 1 towards kinetic resolution and found an intriguing solvent dependency upon selectivity18, however resolution of azide 3 had not been employed under those same conditions (shown in Scheme 1i). In order to probe this azide 3 was reacted with 0.5 equivalents of phenyl acetylene, 15 mol% L1 and CuCl (12.5 mol%) in acetone-d6 and the reaction progress was monitored in-situ via proton nuclear magnetic resonance (1H NMR) spectroscopy.

From the resolution of azide 3 in acetone a selectivity factor of s = 7.4 was determined (Table 1, entry 1). Since, resolution of alkyne 1 had been shown to be superior, in a previous study, when 2,5-hexanedione had been employed as reaction solvent the resolution of 3 was repeated using this dione solvent (unlocked 1H NMR spectroscopy reaction monitoring, see ESI) which gave conversions and selectivity in line with that when acetone was used as solvent (s = 7.1), (Table 1, entries 1 and 2 versus 3 and 4) suggesting that the dione solvent-effect is manifest primarily in alkyne rather than azide selectivity.

The inherent diastereoselectivity of the CuAAC of a reaction of 1 with 3 was probed (Scheme 3i), to determine any contribution to diastereoselectivity from substrate bias. Compounds 1 and 3 were reacted together with tris[(1-benzyl-1H-1,2,3-triazol-4-yl)methyl]amine (TBTA) as an achiral ligand giving a product diastereoisomer ratio of 23:27:23:27 via HPLC, thus demonstrating there was little inherent diastereoselectivity between the two substrates in the CuAAC reaction (Scheme 3ii).

(i) Coetaneous Kinetic Resolution of Azides and Alkynes. Conversion was determined by 1H NMR spectroscopy. Enantioenrichment of 6 and 1 was determined by HPLC using a chiral stationary phase. “Stereochemical nomenclature to describe diastereoisomers as follows: The first letter inside the brackets refers to the stereochemical descriptor at the oxindole stereogenic centre, the second letter within the brackets refers to stereochemical descriptor at the stereogenic centre adjacent to the triazole ring”. Enantioenrichment of azide 3 was determined by GC using a chiral stationary phase. (ii) HPLC trace of outcomes using conditions: (a) Alkyne 1 (1 equiv.) to azide 3 (1 equiv.), TBTA (15.0 mol%), CuCl (12.5 mol%) in 2,5-hexanedione at 0 °C for 96 h. (iii) HPLC trace using conditions; or (b) Alkyne 1 (1 equiv.) to azide 3 (1 equiv.), CuCl (12.5 mol%), L1 (15.0 mol%) in 2,5-hexanedione at 0 °C for 96 h.

The coetaneous kinetic resolution of 1 and 3 was then attempted. To our delight, it was found that a mixture of 1:1 of 3 and 1 in the presence of 15 mol% L1 and 12.5 mol% CuCl catalyst provided a 74:12:4:10 diastereoisomeric ratio of product 6 (Scheme 3iii). This showed that indeed the reaction successfully resolved the two starting materials simultaneously.

To enable comparison of the selectivity for each enantiomer in this diastereo- and enantio- selective process the selectivity factors for each enantiomer of alkyne 1 and azide 3 were determined as follows. Using enantiopure substrates as the limiting reagent the selectivity towards that component could be analysed (Table 2). The absolute configuration of 1 was evidenced by X-ray diffractometry of a single crystal of an iodo alkyne derived from one enantiomer of enantiopure alkyne 1 (see compound 7 ESI) and the absolute configuration of 3 by comparison to it and by employing in the synthesis literature data and protocols (see ESI). Thus, also allowing for assignment of the absolute stereochemistry of the products (6, as noted in Scheme 3, and see ESI).

From the data presented in Table 2 it can be seen that consumption of racemic alkyne is faster and more selective (in a reaction catalysed by a catalyst derived from L1) in combination with (S) azide. As well as the observation that consumption of racemic azide is essentially equally rapid in combination with either enantiomer of alkyne (in a reaction catalysed by a catalyst derived from L1), with only a slight difference in selectivity, it being subtly better with (R) alkyne. These, and earlier, data reveal two important features, firstly issues of selectivity are more dependent upon alkyne than azide stereochemistry (in this example) and secondly that across these four experiments with a single enantiomer component the faster reacting and more selective examples involve (S) azide and (R) alkyne, which corresponds to the major product (of Scheme 3 iii) being formed from these same two enantiomers. Thus, adding support for the hypothesis that a coetaneous kinetic resolution is taking place.

Conclusions

These preliminary findings are to the best of our knowledge the first non-enzymatic example of two racemic starting materials being successfully kinetically resolved by the same catalyst to an enantioenriched diastereomeric product. We recognise that in this first study substrate scope is limited and hope this strategy can be applied to other types of substrates and increase the efficiency of resolution procedures. It is interesting to consider if this kind of selectivity may be operating in any systems of nature and we hope to be able to explore the scope and mechanistic aspects of this reaction.

Methods

Synthesis of (1-Azidoethyl)benzene (3)

To a solution of sodium azide (105 mg, 1.61 mmol, 1.10 equiv.) in DMSO (6 mL) was added (1-bromoethyl)benzene (200 μL, 271 mg, 1.47 mmol, 1 equiv.). The reaction mixture was allowed to stir at rt for 2 h. To this mixture was added water (10 mL) and subsequently extracted with ether (3 × 10 mL). The organic extracts were combined, washed with water (2 × 10 mL) and brine (10 mL) and then dried over MgSO4, filtered and concentrated under reduced pressure to give (1-azidoethyl)benzene 3 as a pale yellow oil, in 40% (84.0 mg) yield. Characterisation was in agreement with reported literature values40. 1H NMR (300 MHz, CDCl3) δ 7.25–7.40 (m, 5H, Ar-H), 4.60 (q, J 6.8, 1H, CH), 1.52 (d, J = 6.8, 3H, CH3); 13C NMR (101 MHz, CDCl3) δ 140.90, 128.80, 128.15, 126.41, 61.12, 21.59; IR νmax (ATR)/cm−1 3032, 2979, 2090, 1244; MS AP+ m/z 120.1 [M-N2+H]+, 105.0 [M-N3]+; GC (CP-Chirasil-Dex CB), FID, t(S) = 28.1 min, t(R) = 28.4 min.

General procedure for the synthesis of enantiopure azides

Under an atmosphere of nitrogen, the corresponding alcohol (2.54 mmol, 1.00 equiv.) was dissolved in anhydrous toluene (4 mL) to this was added diphenylphosphoryl azide (DPPA) (633 μL, 810 mg, 2.94 mmol, 1.20 equiv.). The mixture was cooled to 0 °C for 5 mins and DBU (440 μL, 448 mg, 2.94 mmol, 1.20 equiv.) added. The reaction mixture was allowed to warm to room temperature and stirred for 18 h. The reaction was subsequently quenched with water (10 mL) and aq. HCl 5% v/v (10 mL) and extracted with EtOAc (2 × 10 mL). The combined organic fractions were dried over MgSO4 and concentrated under reduced pressure, the crude reside was purified by flash column chromatography (20:1 hexane/EtOAc).

(S)-(1-Azidoethyl)benzene (3 (S))

Prepared from (R)-phenylethanol according to general procedure, colourless oil 3 (S) (131 mg, 35%). 1H NMR (300 MHz, CDCl3) δ 7.50–6.97 (m, 5H, Ar-H), 4.57 (q, J 6.8, 1H, CH), 1.49 (d, J 6.8, 3H, CH3); 13C NMR (101 MHz, CDCl3) δ 140.90, 128.80, 128.14, 126.41, 61.12, 21.80; MS ESI+ m/z 147.1 [M]+, 105.1 [M-N3]+, 77.0 [M-C2H4N3]+; GC (CP-Chirasil-Dex CB), FID, t = 28.1 min.

(R)-(1-Azidoethyl)benzene (3 (R))

Prepared from (S)-phenylethanol according to the general procedure, colourless oil 3 (R) (150 mg, 40% yield). 1H NMR (300 MHz, CDCl3) δ 7.42–7.18 (m, 5H, Ar-H), 4.56 (q, J 6.8, 1H, CH), 1.48 (d, J = 6.8, 3H, CH3); 13C NMR (101 MHz, CDCl3) δ 140.90, 128.80, 128.16, 126.41, 61.12, 21.58; MS ESI+ m/z 147.1 [M]+, 105.1 [M-N3]+, 77.0 [M-C2H4N3]+; GC (CP-Chirasil-Dex CB), FID, t = 28.4 min.

Synthesis of racemic 4-phenyl-1-(1-phenylethyl)-1H-1,2,3-triazole (5)

Phenylacetylene (20.0 mg, 0.20 mmol, 1.00 equiv.), (1-azidoethyl)benzene 3 (30.0 mg, 0.20 mmol, 1.00 equiv.) and sodium ascorbate (39.0 mg, 0.20 mmol, 1.00 equiv.) were added to a solution of CuSO4||5H2O (5.00 mg, 0.020 mmol, 10 mol%) in MeOH (4 mL). The reaction mixture was allowed to stir for 24 h at rt. The reaction was quenched with aq. ammonia solution 5% v/v (5 mL) and extracted with EtOAc (2 × 10 mL). The combined organic extracts were dried over MgSO4 and concentrated under reduced pressure to yield 4-phenyl-1-(1-phenylethyl)-1H-1,2,3-triazole 5 as a cream solid (13.0 mg, 26%). Characterisation was consistent with reported literature values41. 1H NMR (300 MHz, CDCl3) δ 7.76–7.82 (m, 2H, Ar-H), 7.64 (s, 1H, CH), 7.26–7.45 (m, 8H, Ar-H), 5.86 (q, J 7.1, 1H, CH,), 2.02 (d, J 7.1, 3H, CH3,); 13C NMR (101 MHz, CDCl3) δ 147.80, 139.92, 130.67, 129.07, 128.79, 128.58, 128.10, 126.55, 125.69, 118.40, 60.29, 21.32; IR νmax (ATR)/cm−1 3090, 2991; MS ESI+ m/z 272.1 [M + Na]+, 250.1 [M + H]+; HPLC (Phenomenex Cellulose 1) acetonitrile/water 60:40, 1.0 mL/min, λ = 210 nm, t = 8.4 and 9.1 min.

Synthesis of 1-benzyl-3-methyl-3-((1-(1-phenylethyl)-1H-1,2,3-triazol-4-yl)methyl)indolin-2-one (6)

To a solution of 1-benzyl-3-methyl-3-(prop-2-yn-1-yl)indolin-2-one 1 (100 mg, 0.36 mmol, 1 equiv.) in acetone (5 mL) was added copper (I) chloride (1.80 mg, 0.018 mmol, 5 mol%), TBTA (9.60 mg, 0.018 mmol, 5 mol%) and (1-azidoethyl)benzene 3 (60.0 mg, 0.40 mmol, 1.10 equiv.) in acetone (1 mL). The mixture was heated to reflux and stirred for 96 h. The reaction mixture was then quenched with aq. ammonia 5% v/v (5 mL) and extracted with EtOAc (3 × 10 mL). The combined organic extracts were washed with water (10 mL), died over MgSO4 and concentrated under reduced pressure. The crude residue was purified by automated flash column chromatography Combiflash Rf (0–100% hexane/EtOAc, 12 mins) to yield the triazole 6 as a colourless oil (65.0 mg, 42% yield). Reported as a mixture of diastereoisomers. 1H NMR (400 MHz, CDCl3) δ 7.32–7.19 (m, 12H (residual solvent ignored), Ar-H), 7.15–7.02 (m, 8H, Ar-H), 7.00–6.88 (m, 6H, Ar-H), 6.72 (s, 1H, Triazole CH), 6.68 (s, 1H, Triazole CH), 6.56–6.48 (m, 2H, Ar-H), 5.54–5.62 (m, 2H, CH), 4.55–4.76 (m, 4H, CH2), 3.16–3.38 (m, 4H, CH2), 1.79 (d, J 7.1, 3H, CH3), 1.69 (d, J 7.1, 3H, CH3), 1.52 (s, 3H, CH3), 1.51 (s, 3H, CH3); 13C NMR (101 MHz, CDCl3) δ 179.93, 142.97, 142.88, 142.17, 140.24, 140.19, 135.97, 135.86, 132.97, 128.86, 128.71, 128.20, 128.16, 127.80, 127.51, 127.48, 127.29, 127.19, 126.20, 126.17, 123.30, 123.22, 122.52, 122.45, 120.80, 120.39, 108.85, 108.77, 59.78, 59.56, 48.57, 48.54, 43.51, 34.49, 34.45, 23.32, 21.17, 20.81; IR νmax (ATR)/cm−1 3032, 2968, 2925, 1705, 1610; MS ESI+ m/z 445.2 [M + Na]+, 423.2 [M + H]+; HRMS ESI+ Calculated for C27H26N4ONa+ = 445.1999 Found 445.2007; HPLC (Cellulose 3) acetonitrile/water 30:70, 1.0 mL/min, λ = 210 nm, 45 min, 55 min, 59 min, 67 min.

Synthesis of (R)-1-benzyl-3-methyl-3-((1-((S)-1-phenylethyl)-1H-1,2,3-triazol-4-yl)methyl)indolin-2-one (6 (R,S))

To a solution of (R)-1-benzyl-3-methyl-3-(prop-2-yn-1-yl)indolin-2-one 1 (R) (30.0 mg, 0.11 mmol, 1.00 equiv.) in methanol (5 mL) was added (S)-(1-azidoethyl)benzene 3 (S) (16.0 mg, 0.11 mmol, 1.00 equiv.), CuSO4||5H2O (3.00 mg, 0.011 mmol, 10 mol%) and sodium ascorbate (5.00 mg, 0.022 mmol, 20 mol%). The reaction was stirred at 50 °C for 24 h. After this time the reaction was quenched with the addition of aq. ammonia solution 5% v/v (5 mL), the reaction was then extracted with EtOAc (2 × 10 mL). The combined organic fractions were dried over MgSO4 and concentrated under reduced pressure. The crude residue was purified by automated flash column chromatography Combiflash Rf (0–100% EtOAc/hexane gradient, 15 mins). This yielded (R)-1-benzyl-3-methyl-3-((1-((S)-1-phenylethyl)-1H-1,2,3-triazol-4-yl)methyl)indolin-2-one 6 (R,S) as a yellow oil (29.0 mg, 62%). 1H NMR (400 MHz, CDCl3) δ 7.29–7.18 (m, 6H, Ar-H), 7.14–7.07 (m, 3H, Ar-H), 7.04 (td, J 7.7, 1.3, 1H, Ar-H), 6.97–6.89 (m, 3H, Ar-H), 6.72 (s, 1H, Triazole CH), 6.50 (d, J 7.7, 1H, Ar-H), 5.57 (q, J 7.1, 1H, CH), 4.65 (ABq, ΔδAB = 0.14, J 15.6, 2H, CH2), 3.27 (ABq, ΔδAB = 0.14, J 14.3, 2H, CH2), 1.79 (d, J 7.1, 3H, CH3), 1.51 (s, 3H, CH3); 13C NMR (101 MHz, CDCl3) δ 179.92, 142.88, 142.16, 140.25, 135.91, 132.98, 128.85, 128.70, 128.15, 127.79, 127.48, 127.19, 126.16, 123.22, 122.44, 120.80, 108.84, 59.78, 48.53, 43.50, 34.45, 23.32, 21.16; MS AP+ m/z 423.2 [M + H]+; HRMS AP+ Calculated for C27H27N4O+ = 423.2179 Found 423.2187; IR νmax (ATR)/cm−1 2925, 2855, 1707, 1489, 1467, 1356, 1174, 855, 741, 698; HPLC (Phenomenex Cellulose 3) acetonitrile/water 30:70, 1.0 mL/min, λ = 250 nm, t = 49 mins.

Synthesis of 1-benzyl-3-methyl-3-(1-((S)-1-phenylethyl)-1H-1,2,3-triazol-4-yl)indolin-2-one (6 (rac-S))

Compound 3 (85.0 mg, 0.31 mmol, 1.00 equiv.) and 1 (S) (50.0 mg, 0.34 mmol, 1.10 equiv.) were dissolved in MeOH (5 mL). To this solution was added CuSO4.5H2O (7.70 mg, 0.031 mmol, 10 mol%) and sodium ascorbate (61.0 mg, 0.31 mmol, 1.00 equiv.) and the resulting mixture stirred for 5 mins at rt. After this time N,N-diisoproylethylamine (100 μL, 7.40 mg, 5 mol%) was added and the mixture left to stir at rt for 48 h. The reaction mixture was then quenched by the addition of aqueous ammonia solution 5% v/v (5 mL). The resulting solution was extracted with EtOAc (3 × 10 mL). The combined organic fractions were washed with water (10 mL) dried over MgSO4 and concentrated under reduced pressure. The recovered crude material was purified by automated flash column chromatography Combiflash Rf (0–100% hexane/EtOAc gradient 12 mins). This yielded 1-benzyl-3-methyl-3-(1-((S)-1-phenylethyl)-1H-1,2,3-triazol-4-yl)indolin-2-one 6 (rac,S) as a colourless oil (72.0 mg, 57% yield). The 1H NMR spectrum of the product was consistent with compound 6. HPLC (Phenomenex Cellulose 3) acetonitrile/water 30:70, 1.0 mL/min, λ = 210 nm, 45 min, 67 min.

Catalysis

Representative procedure for kinetic resolution of (1-Azidoethyl)benzene (3)

To an oven dried Radley’s multi-reactor tube were added L1 (6.70 mg, 0.018 mmol, 15.0 mol%), CuCl (1.50 mg, 0.015 mmol, 12.5 mol%) and 2,5-hexanedione (1 mL), these were stirred together at rt for 1 h. To this solution was added phenylacetylene (6.20 mg, 0.06 mmol, 0.50 equiv.) in 2,5-hexanedione (0.5 mL) and the resulting mixture stirred for 15 mins at rt before being cooled to 0 °C and stirred for a further 15 mins. (1-azidoethyl)benzene 3 (17.8 mg, 0.12 mmol, 1.00 equiv.) in 2,5-hexanedione (0.5 mL) was then added and the reaction mixture stirred for 96 h at 0 °C. The reaction mixture was then quenched with the addition of aq. ammonia solution 5% v/v (5 mL) then extracted with ether (2 × 10 mL). The combined organic extracts were dried over MgSO4 and concentrated under reduced pressure. Conversion of the reaction was determined through 1H NMR spectroscopy of the recovered crude material. Enantiomeric excess was determined by chiral GC. The remaining azide and triazolic product were isolated by automated flash column chromatography Combiflash Rf (0–40% hexane/EtOAc, 15 mins).

General procedure for the kinetic resolution of 1 with Azide 3

To an oven dried Radley’s multi-reactor tube L1 (6.70 mg, 0.018 mmol, 15.0 mol%) and CuCl (1.50 mg, 0.015 mmol, 12.5 mol%) followed by 2,5-hexanedione (1 mL) were added. After stirring at rt for 1 h, compound 1 (33.4 mg, 0.12 mmol, 1 equiv.) dissolved in 2,5-hexanedione (0.5 mL) was added. The reaction mixture was stirred for a further 15 mins before being cooled to 0 °C for 15 min. Azide 3 (R) (8.90 mg, 0.06 mmol, 1 equiv.) dissolved in 2,5-hexanedione (0.5 mL) was then added. The reaction mixture was stirred at 0 °C for 96 h. The reaction was then quenched by addition of aqueous ammonia 5% v/v (5 mL). The reaction mixture was then extracted with ethyl acetate (2 × 10 mL), dried over MgSO4 and concentrated under reduced pressure. Conversion was determined by integration of the 1H NMR spectrum of the recovered material. The remaining starting material and the triazolic product were subsequently isolated by automated column chromatography Combiflash Rf (0–100% hexane/EtOAc gradient 12 mins). Enantiomeric excess and diastereomer ratio of 6 and enantiomeric excess of 1 were determined by chiral HPLC.

General procedure for the kinetic resolution of 3 with Alkyne 1

To an oven dried Radley’s multi-reactor tube was added L1 (6.70 mg, 0.018 mmol, 15.0 mol%) and CuCl (1.50 mg, 0.015 mmol, 12.5 mol%) followed by 2,5-hexanedione (1 mL), the resulting solution was allowed to stir at rt for 1 h. After this time compound 1 (16.7 mg, 0.06 mmol, 0.5 equiv.) dissolved in 2,5-hexanedione (0.5 mL) was added. The reaction mixture was allowed to stir at rt for a further 15 mins after which it was cooled to 0 °C in an ice bath and stirred for a subsequent 15 mins. After this time had passed azide 3 (17.8 mg, 0.12 mmol, 1 equiv.) dissolved in 2,5-hexanedione (0.5 mL) was added. The reaction mixture was stirred for 96 h at 0 °C before being quenched by the addition of aqueous ammonia 5% v/v (5 mL). The resulting solution was extracted with EtOAc (2 × 10 mL), the combined organic fractions were dried over MgSO4 and concentrated under reduced pressure. Chiral GC was carried out on the crude recovered material to measure the ee of the remaining azide 3. The remaining crude material was the purified by automated flash column chromatography Combiflash Rf (0–100% hexane/EtOAc gradient, 12 mins). The dr and ee of the triazolic product was then determined by chiral HPLC.

General procedure for simultaneous kinetic resolution of 1 and 3

To an oven dried Radley’s multi-reactor tube was added L1 (6.70 mg, 0.018 mmol, 15.0 mol%) and CuCl (1.50 mg, 0.015 mmol, 12.5 mol%) followed by 2,5-hexanedione (1 mL), the resulting solution was allowed to stir at rt for 1 h. After this time compound 1 (33.4 mg, 0.12 mmol, 1.00 equiv.) dissolved in 2,5-hexanedione (0.5 mL) was added. The reaction mixture was allowed to stir at rt for a further 15 mins after which it was cooled to 0 °C in an ice bath and stirred for a subsequent 15 mins. After this time had passed azide 3 (17.8 mg, 0.12 mmol, 1 equiv.) dissolved in 2,5-hexanedione (0.5 mL) was added. The reaction mixture was stirred for 96 h at 0 °C before being quenched by the addition of aqueous ammonia 5% v/v (5 mL). The resulting solution was extracted with EtOAc (2 × 10 mL), the combined organic fractions were dried over MgSO4 and concentrated under reduced pressure. Chiral GC was carried out on the crude recovered material to measure the ee of the remaining azide 3. The remaining crude material was the purified by automated flash column chromatography Combiflash Rf (0–100% hexane/EtOAc gradient, 12 mins). The dr and ee of the triazolic product 6 and ee of the recovered alkyne 1 was then determined by HPLC with a chiral stationary phase.

Supplementary information is available that includes detailed experimental procedures, NMR spectrums, HPLC traces and X-ray crystallographic information. Citations therein should be referred to in relation to published procedures40,41,42,43,44 and a pre-peer reviewed preprint was submitted prior to peer assessment of this manuscript45.

References

Lewis, W. G. et al. Click Chemistry In Situ: Acetylcholinesterase as a Reaction Vessel for the Selective Assembly of a Femtomolar Inhibitor from an Array of Building Blocks. Angew. Chem. Int. Ed. 41, 1053-1057, 10.1002/1521-3773(20020315)41:6<1053::AID-ANIE1053>3.0.CO;2-4 (2002).

Tornøe, C. W., Christensen, C. & Meldal, M. Peptidotriazoles on Solid Phase: [1,2,3]-Triazoles by Regiospecific Copper(I)-Catalyzed 1,3-Dipolar Cycloadditions of Terminal Alkynes to Azides. J. Org. Chem. 67, 3057–3064, https://doi.org/10.1021/jo011148j (2002).

Kolb, H. C., Finn, M. G. & Sharpless, K. B. Click Chemistry: Diverse Chemical Function from a Few Good Reactions. Angew. Chem. Int. Ed. Engl. 40, 2004–2021 (2001).

Meldal, M. & Tornøe, C. W. Cu-Catalyzed Azide−Alkyne Cycloaddition. Chem. Rev. 108, 2952–3015, https://doi.org/10.1021/cr0783479 (2008).

Thirumurugan, P., Matosiuk, D. & Jozwiak, K. Click Chemistry for Drug Development and Diverse Chemical–Biology Applications. Chem. Rev. 113, 4905–4979, https://doi.org/10.1021/cr200409f (2013).

Amblard, F., Cho, J. H. & Schinazi, R. F. Cu(I)-Catalyzed Huisgen Azide−Alkyne 1,3-Dipolar Cycloaddition Reaction in Nucleoside, Nucleotide, and Oligonucleotide Chemistry. Chem. Rev. 109, 4207–4220, https://doi.org/10.1021/cr9001462 (2009).

Chinchilla, R. & Nájera, C. Chemicals from Alkynes with Palladium Catalysts. Chem. Rev. 114, 1783–1826, https://doi.org/10.1021/cr400133p (2014).

El-Sagheer, A. H. & Brown, T. Click chemistry with DNA. Chem. Soc. Rev. 39, 1388–1405, https://doi.org/10.1039/B901971P (2010).

Moses, J. E. & Moorhouse, A. D. The growing applications of click chemistry. Chem. Soc. Rev. 36, 1249–1262, https://doi.org/10.1039/b613014n (2007).

Jinks, M. A. et al. Stereoselective Synthesis of Mechanically Planar Chiral Rotaxanes. Angew. Chem. 130, 15022–15026, https://doi.org/10.1002/ange.201808990 (2018).

Kagan, H. B. & Fiaud, J. C. In Topics in Stereochemistry (eds E. L. Eliel & S. H. Wilen) 249–330 (John Wiley & Sons, Inc., 2007).

Schofer, S. H., Kaftzik, N., Wasserscheid, P. & Kragl, U. Enzyme catalysis in ionic liquids: lipase catalysed kinetic resolution of 1-phenylethanol with improved enantioselectivity. Chem. Commun., 425-426, https://doi.org/10.1039/B009389K (2001).

Ghanem, A. & Aboul-Enein, H. Y. Application of lipases in kinetic resolution of racemates. Chirality 17, 1–15, https://doi.org/10.1002/chir.20089 (2005).

Arai, S., Bellemin-Laponnaz, S. & Fu, G. C. Kinetic Resolution of Amines by a Nonenzymatic Acylation Catalyst. Angew. Chem. Int. Ed. 40, 234–236, 10.1002/1521-3773(20010105)40:1<234::AID-ANIE234>3.0.CO;2-K (2001).

Ruble, J. C., Latham, H. A. & Fu, G. C. Effective Kinetic Resolution of Secondary Alcohols with a Planar−Chiral Analogue of 4-(Dimethylamino)pyridine. Use of the Fe(C5Ph5) Group in Asymmetric Catalysis. J. Am. Chem. Soc. 119, 1492–1493, https://doi.org/10.1021/ja963835b (1997).

Fu, G. C. Asymmetric Catalysis with “Planar-Chiral” Derivatives of 4-(Dimethylamino)pyridine. Acc. Chem. Res. 37, 542–547, https://doi.org/10.1021/ar030051b (2004).

Brittain, W. D. G. et al. The Bull-James assembly as a chiral auxiliary and shift reagent in kinetic resolution of alkyne amines by the CuAAC reaction. Org. Biomol. Chem. 14, 10778–10782, https://doi.org/10.1039/C6OB01623E (2016).

Brittain, W. D. G., Buckley, B. R. & Fossey, J. S. Asymmetric Copper-Catalyzed Azide–Alkyne Cycloadditions. ACS Catal 6, 3629–3636, https://doi.org/10.1021/acscatal.6b00996 (2016).

Brittain, W. D. G., Buckley, B. R. & Fossey, J. S. Kinetic resolution of alkyne-substituted quaternary oxindoles via copper catalysed azide-alkyne cycloadditions. Chem. Commun. 51, 17217–17220, https://doi.org/10.1039/C5CC04886A (2015).

Meng, J.-c, Fokin, V. V. & Finn, M. G. Kinetic resolution by copper-catalyzed azide–alkyne cycloaddition. Tetrahedron Lett. 46, 4543–4546, https://doi.org/10.1016/j.tetlet.2005.05.019 (2005).

Alexander, J. R., Ott, A. A., Liu, E.-C. & Topczewski, J. J. Kinetic Resolution of Cyclic Secondary Azides, Using an Enantioselective Copper-Catalyzed Azide–Alkyne Cycloaddition. Org. Lett. 21, 4355–4358, https://doi.org/10.1021/acs.orglett.9b01556 (2019).

Liu, E.-C. & Topczewski, J. J. Enantioselective Copper Catalyzed Alkyne–Azide Cycloaddition by Dynamic Kinetic Resolution. J. Am. Chem. Soc. 141, 5135–5138, https://doi.org/10.1021/jacs.9b01091 (2019).

Chen, M.-Y. et al. Catalytic Asymmetric Huisgen Alkyne–Azide Cycloaddition of Bisalkynes by Copper(I) Nanoparticles. ChemCatChem 10, 280–286, https://doi.org/10.1002/cctc.201701336 (2018).

Chen, M.-Y. et al. Tao-Phos-controlled desymmetrization of succinimide-based bisalkynes via asymmetric copper-catalyzed Huisgen alkyne–azide click cycloaddition: substrate scope and mechanism. Rsc Adv 6, 58698–58708, https://doi.org/10.1039/C6RA13687G (2016).

Zhou, F. et al. Asymmetric Copper(I)-Catalyzed Azide–Alkyne Cycloaddition to Quaternary Oxindoles. J. Am. Chem. Soc. 135, 10994–10997, https://doi.org/10.1021/ja4066656 (2013).

Vedejs, E. & Chen, X. Parallel Kinetic Resolution. J. Am. Chem. Soc. 119, 2584–2585, https://doi.org/10.1021/ja963666v (1997).

Miller, L. C., Ndungu, J. M. & Sarpong, R. Parallel Kinetic Resolution Approach to the Cyathane and Cyanthiwigin Diterpenes Using a Cyclopropanation/Cope Rearrangement. Angew. Chem. Int. Ed. 48, 2398–2402, https://doi.org/10.1002/anie.200806154 (2009).

Kato, K., Motodate, S., Takaishi, S., Kusakabe, T. & Akita, H. Parallel kinetic resolution of propargyl ketols: formal synthesis of (+)-bakkenolide A. Tetrahedron 64, 4627–4636, https://doi.org/10.1016/j.tet.2008.02.101 (2008).

Kreituss, I. & Bode, J. W. Flow chemistry and polymer-supported pseudoenantiomeric acylating agents enable parallel kinetic resolution of chiral saturated N-heterocycles. Nat. Chem 9, 446–452, https://doi.org/10.1038/Nchem.2681 (2017).

Tanaka, K. & Fu, G. C. Parallel Kinetic Resolution of 4-Alkynals Catalyzed by Rh(I)/Tol-BINAP: Synthesis of Enantioenriched Cyclobutanones and Cyclopentenones. J. Am. Chem. Soc. 125, 8078–8079, https://doi.org/10.1021/ja035489l (2003).

Krautwald, S. & Carreira, E. M. Stereodivergence in Asymmetric Catalysis. J. Am. Chem. Soc. 139, 5627–5639, https://doi.org/10.1021/jacs.6b13340 (2017).

Krautwald, S., Sarlah, D., Schafroth, M. A. & Carreira, E. M. Enantio- and Diastereodivergent Dual Catalysis: α-Allylation of Branched Aldehydes. Science 340, 1065–1068, https://doi.org/10.1126/science.1237068 (2013).

Osako, T. & Uozumi, Y. Enantioposition-Selective Copper-Catalyzed Azide–Alkyne Cycloaddition for Construction of Chiral Biaryl Derivatives. Org. Lett. 16, 5866–5869, https://doi.org/10.1021/ol502778j (2014).

Osako, T. & Uozumi, Y. Mechanistic Insights into Copper-Catalyzed Azide–Alkyne Cycloaddition (CuAAC): Observation of Asymmetric Amplification. Synlett 26, 1475–1479, https://doi.org/10.1055/s-0034-1380534 (2015).

Abbadie, C. et al. Analgesic effects of a substituted N-triazole oxindole (TROX-1), a state-dependent, voltage-gated calcium channel 2 blocker. J. Pharmacol. Exp. Ther. 334, 545–555, https://doi.org/10.1124/jpet.110.166363 (2010).

Laird, A. D. et al. SU6668 Is a Potent Antiangiogenic and Antitumor Agent That Induces Regression of Established Tumors. Cancer Res. 60, 4152–4160 (2000).

Galliford, C. V. & Scheidt, K. A. Pyrrolidinyl-Spirooxindole Natural Products as Inspirations for the Development of Potential Therapeutic Agents. Angew. Chem. Int. Ed. 46, 8748–8758, https://doi.org/10.1002/anie.200701342 (2007).

Kamano, Y. et al. Convolutamydine A, a novel bioactive hydroxyoxindole alkaloid from marine bryozoan Amathia convoluta. Tetrahedron Lett. 36, 2783–2784, https://doi.org/10.1016/0040-4039(95)00395-S (1995).

Natarajan, A. et al. Novel Arylsulfoanilide−Oxindole Hybrid as an Anticancer Agent That Inhibits Translation Initiation. J. Med. Chem. 47, 4979–4982, https://doi.org/10.1021/jm0496234 (2004).

Lakshman, M. K. et al. Facile synthesis of 1-alkoxy-1H-benzo- and 7-azabenzotriazoles from peptide coupling agents, mechanistic studies, and synthetic applications. Beilstein J. Org. Chem. 10, 1919–1932, https://doi.org/10.3762/bjoc.10.200 (2014).

Shao, C. et al. Carboxylic Acid-Promoted Copper(I)-Catalyzed Azide−Alkyne Cycloaddition. J. Org. Chem. 75, 7002–7005, https://doi.org/10.1021/jo101495k (2010).

Sheldrick, G. M. A short history of SHELX. Acta Crystallographica, Section A A64, 112–122, https://doi.org/10.1107/S0108767307043930 (2008).

Dolomanov, O. V., Bourhis, L. J., Gildea, R. J., Howard, J. A. K. & Puschmann, H. OLEX2: a complete structure solution, refinement and analysis program. J. Appl. Crystallogr 42, 339–341, https://doi.org/10.1107/S0021889808042726 (2009).

Sheldrick, G. M. SHELXT - Integrated space-group and crystal-structure determination. Acta Crystallogr. Sect. A: Found. Crystallogr A71, 3–8, https://doi.org/10.1107/S2053273314026370 (2015).

Brittain, W. D. G. et al. Simultaneous Clicknetic Resolution Coetaneous catalytic kinetic resolution of alkynes and azides through asymmetric triazole formation. ChemRxiv. https://doi.org/10.26434/chemrxiv.5663623.v1 (2017).

Payne, D. T., Fossey, J. S. & Elmes, R. B. P. Catalysis and Sensing for our Environment (CASE2015) and the Supramolecular Chemistry Ireland Meeting (SCI 2015): Dublin and Maynooth, Ireland. 8th–11th July. Supramol. Chem. 28, 921–931, https://doi.org/10.1080/10610278.2016.1150595 (2016).

Fossey, J. S. & Brittain, W. D. G. The CASE 2014 symposium: Catalysis and sensing for our environment, Xiamen 7th-9th November 2014. Org. Chem. Front. 2, 101–105, https://doi.org/10.1039/C4QO90045F (2015).

Acknowledgements

J.S.F., A.G.D. and W.D.G.B. would like to thank the University of Birmingham for support. B.R.B. thanks Loughborough University and Research Councils UK for a RCUK Fellowship. J.S.F. would like to thank the Royal Society for an Industrial Fellowship and the EPSRC for funding (EP/J003220/1). J.S.F., W.D.G.B. and B.R.B. acknowledge the support of a Wellcome Trust ISSF award within the University of Birmingham. All investigators are grateful for a Royal Society Research Grant (2012/R1) that underpins this project. Dr. Chi Tsang, Dr Peter Ashton and Dr Allen Bowden are thanked for helpful discussions about mass spectrometry and HPLC analysis respectively. W.D.G.B. would also like to thank the Royal Society of Chemistry, Society for Chemical Industry and the School of Chemistry at the University of Birmingham for travel grants facilitating productive discussions via the CASE Network46,47.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Brittain, W.D.G., Dalling, A.G., Sun, Z. et al. Coetaneous catalytic kinetic resolution of alkynes and azides through asymmetric triazole formation. Sci Rep 9, 15086 (2019). https://doi.org/10.1038/s41598-019-50940-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-50940-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.