Abstract

This contribution addresses an analytical model to predict the ignition time of PMMA (Polymethyl methacrylate) subjected to a time-decreasing incident heat flux. Surface temperature, transient mass flux and ignition time of PMMA are thoroughly studied based on the exact solutions of in-depth temperature. Critical mass flux is utilized as the ignition criteria. An approximation methodology is suggested to simplify the unsolvable high order equations and deduce the explicit expressions of ignition time. A numerical model is employed to validate the capability of the developed model. The results show that no ignition occurs when the decreasing rate of heat flux increases larger than a critical value. The agreement of the transient mass flux between analytical and numerical models is good at high decreasing rate but turns worse as the decreasing rate declines. However, this enhanced discrepancy affects the ignition time prediction slightly. The inverse of the square root of the ignition time is linearly correlated with the decreasing rate of heat flux, and it becomes significantly sensitive to the decreasing rate when the decreasing rate approaching its critical value. Meanwhile, the value of critical mass flux has appreciable influence on the ignition time prediction.

Similar content being viewed by others

Introduction

Pyrolysis and the subsequent ignition under external incident heat flux (HF) are important for fire protection since they determine the occurrence of fire propagation and are easier to be controlled at early stage. Ignition under constant1,2,3,4,5,6,7,8 and time-increasing9,10,11,12,13,14,15,16,17,18,19 HFs gained much attention and have been studied extensively in the literature, including empirical models1,5,6,13,15, analytical4,7,8,9,10,12,17,18 and numerical models2,3,11,20,21,22,23. However, the time-decreasing HF, which may result from a moving-away flame in forest fire, high temperature smoke during cooling process in compartment fire before flashover or irradiative heater after power outage24, is barely concerned and the ignition behaviors of the imposed materials are not adequately understood.

Under constant HF, the pioneers did some remarkable works to reveal the ignition mechanism, such as the classical ignition theory1,25 in which pyrolysis and the dependence of thermal parameters on temperature were neglected. Critical temperature was used in these models. Based on this original theory, other researchers improved the model when dealing with some influential aspects, such as the surface heat loss26,27, porosity of materials and the mass transfer of the yielded gas in solid28,29,30,31, grain orientation of wood32, ambient pressure and oxygen concentration30,31,33,34,35, air flow velocity on surface36, generated char layer37, melting behaviors38, gravity39, in-depth absorption of thermal radiation2,3,4,7, optical and radiative properties of semitransparent materials40,41. In order to introduce the critical mass flux into analytical model, Lautenberger8 and Snegirev42 used a power law function and Frank-Kamenetskii decomposition43 respectively to replace the Arrhenius pyrolysis rate and derived explicit expressions for ignition time. Some remarkable works aiming at providing insight into the thermal degradation of solid utilizing multi-component Arrhenius expressions were implemented through TGA, DSC, MCC and cone calorimetry44,45,46,47. Constant HF was applied in these studies owing to the fact that this condition is comparatively easier to conduct using standard experimental apparatus at bench scale tests. However, the materials received HF frequently varies with a propagating flame, growth or decline of fires.

While under time-increasing HF, Lamorlette18 discussed an approach to determine the analytical solutions, including power law and polynomial HFs. Didomizio10 experimentally and numerically studied the ignition of wood under fourth-order HF. Vermesi12,13 investigated the ignition of PMMA and wood under parabolic HF by the FPA. Also, a numerical solver Gpyro21 was employed to implement the simulation. Yang14 and Ji15 designed a linearly increasing HF in their tests to explore the ignition of wood species. An integral model was developed to analyze the experimental data. Later, Zhai17 extended Yang and Ji’s works to exponential HF. In all these studies, critical temperature and critical mass flux were commonly used for analytical and numerical models, respectively. Reszka9 studied the ignition time of solid under time-dependent HF in forest fire, and found that the ignition time can be correlated with the total absorbed energy before ignition. Nonetheless, critical mass flux which is believed to be a more reasonable ignition criterion is barely studied under the time-varying HF in these models. Bilbao24 examined the ignition behaviors of wood under time-decreasing HF in his experiment by turning off the power supply of the heater once the predetermined initial HF was reached. A numerical model was introduced in that study to estimate the ignition time. However, no analytical work was provided and the detailed information of the decreasing heat flux was avoided by using an average heat flux before ignition.

In this study, the ignition of PMMA under linearly and quadratically decreasing HFs is investigated analytically. Critical mass flux is utilized to obtain an explicit expression for ignition time with consideration of pyrolysis within solid. Also, transient mass flux is studied in this work. A previously developed numerical model23 is employed to validate the proposed model. The capability of the numerical model has been validated through experimental measurements, including the surface temperatures and mass loss rates of several charring and non-charring polymers under constant incident heat flux, and good agreement is found. Furthermore, parametric study is implemented to analyze the dependence of ignition time prediction on ignition criterion.

Theoretical Analysis

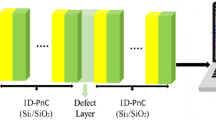

Considering a thermally thick PMMA imposed to a time-decreasing HF, the one-dimensional heat transfer in solid is illustrated in Fig. 1. Relatively low HF, lower than 80 kW/m2 4, is focused in this study and only surface absorption of radiation, corresponding to opaque materials, is utilized instead of in-depth absorption. This is because Jiang7, Vermesi12, Beaulieu5, Bal3,41, Delichatsios4 and Boulet40 found surface absorption dominates the heat absorption process even for translucent materials under low HF, whereas in-depth absorption plays a more important role as HF increases. Surface heat loss including convection and reradiation is neglected in this study for simplification. The time-decreasing HF is expressed as:

where \(\dot{q^{\prime\prime} }\) is the transient HF, \({\dot{q}^{\prime\prime} }_{0}\) is the initial HF, a and b are rational constants. Defining a relative temperature:

where T and T0 are the transient and initial temperatures, respectively. The energy conservation equation in solid, initial and boundary conditions can be written as:

where t is time, α is the thermal diffusivity, \(\alpha =k/\rho {C}_{p}\), k is thermal conductivity, \(\rho \) is the density, Cp is the specific heat and x is the spatial variable. Equation (3) can be further decomposed as:

θ1 and θ2 are the solutions of constant and time-increasing HF scenarios, respectively. θ2 was derived in ref.19. θ1 is equivalent to θ2 when \(a={\dot{q^{\prime\prime} }}_{0}\), \(b=0\). Consequently, the solution of θ can be obtained as:

After defining a dimensionless variable \(\xi =x/{\delta }_{c}\) where \({\delta }_{c}=2\sqrt{\alpha t}\), Eq. (6) can be rewritten as:

Equation (6) or (7) is the transient in-depth temperature in solid. Some researchers tried to integrate the pyrolysis reaction into analytical models by invoking some approximations. For instance, Lautenberger8 replaced the pyrolysis rate by a power law function, and Snegirev42 used the Frank-Kamenetskii decomposition to simplify the Arrhenius function. However, all these works were conducted under constant HF. In this section, we extend Lautenberger’s8 study from constant to time-decreasing boundary condition. Both linearly and quadratically decreasing HFs are examined.

Linearly decreasing heat flux

The total transient mass flux of a thermally thick solid subjected to an incident HF can be expressed as19:

where \(\dot{m}^{\prime\prime} \) is mass flux, Z is the pre-exponential factor and Ta is the activation temperature. As the approximation results in ref.8, the pyrolysis rate can be replaced by a power law function when the pyrolysis temperature is between 250 °C and 450 °C and the Ta ranges from 10000 K to 30000 K:

where A and B are constants, T1 and T2 are characteristic temperatures. For linearly decreasing HF, b = 1, Eq. (7) can be rewritten as:

Noticing that

Rearranging Eqs (12–14) and (9), the total mass flux at linearly decreasing HF condition, Eq. (8) can be expressed as:

In order to further simplify Eq. (15), the same exponential approximation in ref.19 where the excellent accuracy of this approximation was verified, is utilized as follow:

Combining Eqs (16) and (17), Eq. (15) can be rewritten as:

Unfortunately, Eq. (18) cannot be integrated analytically. Another approximation is introduced to simplify Eq. (18):

The reliability of this assumption is validated in Fig. 2. Although the approximate curves deviate more greatly as \(\xi \) increases, they agree well with the exact solutions near the high temperature surface where the pyrolysis reaction contributes the most of the mass flux. Accordingly, the transient mass flux can be expressed as:

Ignition occurs only if the maximum mass flux is greater than the critical mass flux, \({\dot{m}^{\prime\prime} }_{\max ,1}\ge {\dot{m}^{\prime\prime} }_{cri}\). Based on Eq. (20), it can be derived that:

where \({T}_{ig,1}^{\ast }\) is the equivalent ignition temperature under linearly decreasing HF. Equation (22) is an implicit expression because \({\theta }_{ig,1}^{\ast }\) actually is a function of tmax,1. However, a characteristic value of tmax,1 = 20 s is used in Eq. (23) to obtain an explicit result. When tmax,1 changes from 10 s to 50 s, \({(1/\sqrt{{t}_{\max ,1}})}^{1/B}\) varies from 0.95 to 0.92 and this small discrepancy can be neglected. Solving Eq. (22), the ignition range of a can be calculated as:

The ignition time at the critical condition can be expressed as:

If a is larger than acri,1, no ignition is observed. When \({\dot{m}^{\prime\prime} }_{{\rm{\max }},1} > {\dot{m}^{\prime\prime} }_{cri}\), at ignition time we can get:

Consequently, the ignition time can be calculated based on Cardano’s formula for cubic equation:

Although Eq. (27) provides an exact solution for ignition time, it is a relatively complicated correlation. An approximate method is introduced here to simplify the ignition time expression. Noticing that when \(a < {a}_{cri,1}\), the ignition time is slightly less than the value obtained under constant HF. A reasonable approximation is to substitute the tig,1 in brackets of Eq. (26) for the average value of tig,const and tig,cri,1. Combining Eq. (25) and the correlation under constant hear flux:

Equation (26) can be approximately rewritten as:

Quadratically decreasing heat flux

Noticing that

Under quadratically decreasing HF, the mass flux can be expressed according to Eqs (7–9), (13) and (31):

Another exponential approximation in ref.19 is employed to simplify Eq. (32):

Based on Eqs (16) and (33), Eq. (32) can be simplified as:

Being similar to the simplification process from Eqs (18) to (19), another approximation is invoked to simplify Eq. (34):

The reliability of this assumption is validated in Fig. 3 and the agreement is good especially in the vicinity of the high temperature surface. After integrating Eq. (35), the mass flux can be consequently expressed as:

Comparison of the expressions in the square brackets of Eq. (34).

Similarly, the occurrence of ignition requires \({\dot{m}^{\prime\prime} }_{{\rm{\max }},2}\ge {\dot{m}^{\prime\prime} }_{cri}\) which results in the following expression through Eq. (36):

The ignition range of a can be calculated as:

Similar to Eq. (25), the ignition time at the critical condition can be expressed as:

If \(a > {a}_{cri,2}\), no ignition takes place. When \(a < {a}_{cri,2}\), at ignition time Eq. (36) can be written as:

Similar to Eq. (30), the ignition time can be approximately solved as:

Numerical Model

A previously developed numerical model23 was used to validate the established analytical model and experimental results. Both surface and in-depth absorptions and their combination were considered in the numerical model. The energy and mass conservation equations and decomposition rate in solid are:

where r and \(\tau \) denote the reflectivity, absorptivity of top surface, Sv is the rate of volatiles generation in solid, ΔHv is the heat of decomposition, Cg is specific heat of gas, \(\dot{m}^{\prime\prime} \) is the mass flux in the controlled volume, Z is pre-exponential factor, E is activation energy and R is ideal gas constant. \(\tau =0\) denotes in-depth absorption and \(\tau ={1}-r\) means surface absorption. When \(\tau \in (0,1-r)\), both exist. The initial and boundary conditions are:

where L denotes the thickness of sample. Although temperature-dependent thermal parameters were considered in this numerical model, constant values at ambient temperature were used for comparison with analytical model. More detailed information about the numerical model can be found in ref.23. The simulation time, spatial and time steps are 500 s, 0.05 mm and 0.2 s, respectively. In order to verify the thermally thick assumption, 30 and 50 mm thick sample cases were also simulated. Little discrepancy of the in-depth temperature was found between the two cases. Therefore, 30 mm thickness was used in this study to save the simulation time.

Results and Discussion

PMMA is selected for computation to validate the proposed analytical model in this section. The thermophysics, chemical kinetics and other relevant parameters of PMMA are listed in Table 1.

Surface temperature

The exact solutions of surface temperature can be expressed based on Eqs (7), (13), (14) and (31) for linearly and quadratically decreasing HFs:

The comparison of surface temperature of PMMA between the developed analytical model and simulation results is illustrated in Fig. 4. acri is crucial for ignition and the ranges of a used in Fig. 4 are in the vicinity of acri. The calculated values of acri through critical mass loss rate under the initial HFs of 50 and 70 kW/m2 are listed in Table 2. For fixed \({\dot{m}^{\prime\prime} }_{cri}\), acri,1 and acri,2 are proportional to \({\dot{q^{\prime\prime} }}_{0}^{3}\) and \({\dot{q^{\prime\prime} }}_{0}^{5}\), respectively, based on Eqs (24) and (40), and thus acri increases with increasing initial HF. When \(a\le {a}_{cri}\), ignition occurs in air and the established flame would affect the surface temperature. However, the purpose of this section is to verify the capability of the analytical model. Therefore, the heating is assumed to be conducted in anaerobic environment and no ignition is examined in Fig. 4.

Comparison of surface temperature of PMMA between analytical and numerical models: (a) Linearly decreasing HF; (b) Quadratically decreasing HF. Solid symbols: numerical results at \({\dot{q^{\prime\prime} }}_{0}=50\,kW/{m}^{2}\); Hollow symbols: numerical results at \({\dot{q^{\prime\prime} }}_{0}=70\,kW/{m}^{2}\); Thick solid curves: analytical results at \({\dot{q^{\prime\prime} }}_{0}=50\,kW/{m}^{2}\); Thin solid curves: analytical results at \({\dot{q^{\prime\prime} }}_{0}=70\,kW/{m}^{2}\). The value of a increases in the direction of the arrow.

As expected, the surface temperature gets higher as a decreases. When pyrolysis is considered in numerical model. The exact analytical solutions fit the simulation results relatively well, but still some discrepancy is observed in Fig. 4. Especially in the range near the peak value, the analytical model deviates from the numerical results most. This divergence is caused by the gasification heat absorbed during pyrolysis in the numerical model. A small portion of the absorbed energy is consumed in the thermal degradation to evaporate the condensed solid. However, in the analytical model all the energy is assumed to heat the thermally inert material. Consequently, the analytical curves are slightly higher than the numerical ones. In the early and late stages, the lower surface temperature leading to a weaker pyrolysis rate results in a better agreement. The maximum discrepancy of surface temperature caused by the thermal degradation in Fig. 4 between the analytical and numerical models is less than 20 K.

Transient mass flux

Transient mass flux reflects the generation rate of volatiles and determines the subsequent ignition. Figure 5 demonstrates the comparison of mass flux of PMMA under linearly and quadratically decreasing HFs without considering the ignition effect. Also, acri listed in Table 1 can be calculated through Eqs (25) and (41). The value of a used in analytical and numerical models in Fig. 5 spans the ignition and no-ignition domains. The resultant peak values higher and lower than the critical mass flux, 2.42 g/m2 s, imply the ignition and no-ignition scenarios, respectively. The developed analytical model fits the simulation results reasonably well except the peak values in low a cases. This disagreement is also attributed to the temperature related pyrolysis rate. Higher temperature resulting from lower a vaule would enhance the thermal degradation and consume more absorbed energy during the gasification. While with higher a values, the agreement is good. Although the disagreement of peak values is significant in the ignition cases, the prediction of ignition time is barely affected since the agreement at critical mass flux, 2.42 g/m2 s, is good during the increasing phase of the curves in Fig. 5. Predictably, this distinction of peak value would induce the maximal error of ignition time in the critical case, a = acri, which will also be demonstrated later.

Comparison of transient mass flux of PMMA between analytical and numerical models: (a) Linearly decreasing HF; (b) Quadratically decreasing HF. Solid symbols: numerical results at \({\dot{q^{\prime\prime} }}_{0}=50\,kW/{m}^{2}\); Hollow symbols: numerical results at \({\dot{q^{\prime\prime} }}_{0}=70\,kW/{m}^{2}\); Thick solid curves: analytical results at \({\dot{q^{\prime\prime} }}_{0}=50\,kW/{m}^{2}\); Thin solid curves: analytical results at \({\dot{q^{\prime\prime} }}_{0}=70\,kW/{m}^{2}\). The value of a increases in the direction of the arrow.

Ignition time

Figure 6 shows the predicted ignition time of PMMA under linearly and quadratically decreasing HFs through analytical and numerical models. Under linearly decreasing HF, Fig. 6 (a), Eq. (27) provides good agreement with the numerical simulation by solving the cubic equation even though several approximations are invoked, including Eqs (9), (16), (17), (19) and (23). Without solving the cubic and quintic equations, the approximate analytical solutions, Eqs (30) and (43), provide linear correlations between \({t}_{ig}^{-0.5}\) and a for both linearly and quadratically decreasing HFs. In Fig. 6, the straight lines agree well with the numerical simulation until acri. When a approaches acri, \({t}_{ig}^{-0.5}\) decreases sharply. However, the ignition time at acri can be attained through Eqs (25) and (41).

Parametric Study of Critical Mass Flux

Critical mass flux is a determinant input parameter in analytical and numerical ignition models for specified materials. The objective of this section is to investigate the influence of ignition criteria on ignition time.

Although the critical mass flux of PMMA used in Section 3.3 is 2.42 g/m2 s, it is hard to be measured accurately in the tests and it is sensitive to the experimental condition. Therefore, utilization of a valid range of this parameter may be a more practicable choice. The reported critical mass flux ranges of PMMA by Bal3 and Vermesi12 are 1.82–3.75 and 1.9–3.2 g/m2 s, respectively. However, a larger range, 1–8 g/m2 s is used in this study to examine its influence on ignition time. The equivalent ignition temperatures of PMMA, \({T}_{ig}^{\ast }\), are calculated through Eqs (23) and (39), and the values are listed in Table 3 for the focused two types of HFs. \({T}_{ig}^{\ast }\) is independent of \({\dot{q^{\prime\prime} }}_{0}\) and increases with \({\dot{m}^{\prime\prime} }_{cri}\) because it is proportional to \({\dot{m}}_{cri}^{^{\prime\prime} 1/B}\) in Eqs (23) and (39). All these values are lower than Tig, 655.1 K. Furthermore, the values of acri of PMMA computed through Eqs (24) and (40) using critical mass flux are given in Table 4. Not surprisingly, for fixed initial HF acri decreases with increasing \({\dot{m}^{\prime\prime} }_{cri}\), indicating that lower acri is prerequisite to heat the solid to higher temperature and generate more volatiles. acri also increases with initial HF because \({a}_{cri,1}\propto {\dot{q}}_{0}^{^{\prime\prime} 3}\) and \({a}_{cri,2}\propto {\dot{q}}_{0}^{^{\prime\prime} 5}\) for linearly and quadratically decreasing HFs, respectively.

Figure 7 shows the influence of \({\dot{m}^{\prime\prime} }_{cri}\) on \({t}_{ig}^{-0.5}\) of PMMA with initial HFs of 50 and 70 kW/m2. The agreement between analytical and numerical results in this figure is not very good but acceptable because several additional approximations are employed when considering thermal degradation reaction within solid. As a getting closed to acri, the discrepancy gets larger. This is caused by the fact that the induced error by invoking the approximations approaches a climax when a = acri, which has been interpreted in the end of Section 3.2. As shown in Fig. 7, the critical mass flux has significant effect on the ignition time.

Conclusions

An approximate analytical model is established in this study to investigate the ignition of solids exposed to a time-decreasing incident HF. Critical mass flux is used in the model to calculate the surface temperature, transient mass flux and ignition time based on the exactly obtained in-depth temperature. Linearly and quadratically decreasing HFs are focused. An approximation methodology is proposed to simplify the complicated expressions during the derivation. The reliability of the developed model is verified by comparison with a numerical model employing PMMA as the reference material.

For time-decreasing HF, \(\dot{q^{\prime\prime} }={\dot{q^{\prime\prime} }}_{0}-a{t}^{b}\), a must be lower than a critical value, acri, to ensure the ignition occurrence. This acri is proportional to \({\dot{q}}_{0}^{^{\prime\prime} 3}\) and \({\dot{q}}_{0}^{^{\prime\prime} 5}\) for linearly and quadratically decreasing HFs, respectively. A linear dependence is found between \({t}_{ig}^{-0.5}\) and \(a\). Also, \({t}_{ig}^{-0.5}\) under time-decreasing HF is correlated with the ignition time under constant HF. An equivalent ignition temperature, \({T}_{ig}^{\ast }\), which is identical to Tig, is found to keep the ignition time expression similar to the one in critical temperature case. \({T}_{ig}^{\ast }\) is independent of \({\dot{q^{\prime\prime} }}_{0}\) but is proportional to \({\dot{m}}_{cri}^{^{\prime\prime} 1/B}\). The accuracy of the proposed model is good for high values of a and decreases as a gets lower when predicting the transient mass flux. However, this increased inaccuracy does not compromise the capability of ignition time prediction. The error induced by invoking the approximations gets larger as a approaching acri. According to the parametric study, critical mass flux has great effect on the ignition time prediction.

Although only linearly and quadratically decreasing HFs are studied in this work, the derivation procedure and the approximation method can be extended to other time-decreasing HF scenarios. The main criticism of this work is the negligence of the surface heat loss. The temperature-dependent heat loss in boundary condition would greatly complicate the derivation, and thus more future studies are needed to solve this issue. Meanwhile, in-depth absorption of thermal radiation within infrared translucent solids and the corresponding heat transfer and ignition problems also deserve more attention.

References

Lawson, D. I. & Simms, D. L. The ignition of wood by radiation. Br. J. Appl. Phys. 3, 288–292 (1952).

Staggs, J. The effects of gas-phase and in-depth radiation absorption on ignition and steady burning rate of PMMA. Combust. Flame 161, 3229–3236 (2014).

Bal, N. & Rein, G. Numerical investigation of the ignition delay time of a translucent solid at high radiant heat fluxes. Combust. Flame 158, 1109–1116 (2011).

Delichatsios, M. A. & Zhang, J. An alternative way for the ignition times for solids with radiation absorption in-depth by simple asymptotic solutions. Fire Mater. 36, 41–47 (2012).

Beaulieu, P. A. & Dembsey, N. A. Flammability characteristics at applied heat flux levels up to 200 kW/m2. Fire Mater. 32, 61–86 (2008).

Kashiwagi, T. Experimental observation of radiative ignition mechanisms. Combust. Flame 34, 231–244 (1979).

Jiang, F., De Ris, J. L. & Khan, M. M. Absorption of thermal energy in PMMA by in-depth radiation. Fire Safety J. 44, 106–112 (2009).

Lautenberger, C. & Fernandez-Pello, C. A. Approximate analytical solutions for the transient mass loss rate and piloted ignition time of a radiatively heated solid in the high heat flux limit. Fire Safety Sci. 8, 445–456 (2005).

Reszka, P., Borowiec, P., Steinhaus, T. & Torero, J. L. A methodology for the estimation of ignition delay times in forest fire modelling. Combust. Flame 159, 3652–3657 (2012).

Didomizio, M. J., Mulherin, P. & Weckman, E. J. Ignition of wood under time-varying radiant exposures. Fire Safety J. 82, 131–144 (2016).

Leventon, I. T., Li, J. & Stoliarov, S. I. A flame spread simulation based on a comprehensive solid pyrolysis model coupled with a detailed empirical flame structure representation. Combust. Flame 162, 3884–3895 (2015).

Vermesi, I. et al. Pyrolysis and ignition of a polymer by transient irradiation. Combust. Flame 163, 31–41 (2016).

Vermesi, I., Didomizio, M. J., Richter, F., Weckman, E. J. & Rein, G. Pyrolysis and spontaneous ignition of wood under transient irradiation: Experiments and a-priori predictions. Fire Safety J. 91, 218–225 (2017).

Yang, L., Guo, Z., Zhou, Y. & Fan, W. The influence of different external heating ways on pyrolysis and spontaneous ignition of some woods. J. Anal. Appl. Pyrol. 78, 40–45 (2007).

Cui, C., Jiang, S. & He, X. Experimental study on the location of gas drainage pipeline leak using cellular automata. J. Loss Prevent. Proc. 56, 68–77 (2018).

Ji, J., Cheng, Y., Yang, L., Guo, Z. & Fan, W. An integral model for wood auto-ignition under variable heat flux. J. Fire Sci. 24, 413–425 (2006).

Zhai, C., Gong, J., Zhou, X., Peng, F. & Yang, L. Pyrolysis and spontaneous ignition of wood under time-dependent heat flux. J. Anal. Appl. Pyrol. 125, 100–108 (2017).

Lamorlette, A. Analytical modeling of solid material ignition under a radiant heat flux coming from a spreading fire front. J. Thermal Sci. Eng. Appl. 6, 044501 (2014).

Gong, J. et al. Approximate analytical solutions for transient mass flux and ignition time of solid combustibles exposed to time-varying heat flux. Fuel 211, 676–687 (2018).

McGrattan, K. et al. Fire dynamics simulator (version 6) technical reference guide, national institute of standards and technology special publication 1018-6. Mathematical Model 1 (2013).

Lautenberger, C. A. & Fernandez-Pello, C. Generalized pyrolysis model for combustible solids. Fire Safety J. 44, 819–839 (2009).

Stoliarov, S. I., Leventon, I. T. & Lyon, R. E. Two-dimensional model of burning for pyrolyzable solids. Fire Mater. 38, 391–408 (2014).

Gong, J., Chen, Y., Jiang, J., Yang, L. & Li, J. A numerical study of thermal degradation of polymers: surface and in-depth absorption. Appl. Therm. Eng. 106, 1366–1379 (2016).

Bilbao, R. et al. A model for the prediction of the thermal degradation and ignition of wood under constant and variable heat flux. J. Anal. Appl. Pyrol. 62, 63–82 (2002).

Simms, D. L. Experiments on the Ignition of cellulosic materials by thermal radiation. Combust. Flame 5, 369–375 (1961).

Delichatsios, M. A. & Chen, Y. Asymptotic, approximate, and numerical solutions for the heatup and pyrolysis of materials including reradiation losses. Combust. Flame 92, 292–307 (1993).

Delichatsios, M. A., Panagiotou, T. & Kiley, F. The use of time to ignition data for characterizing the thermal inertia and the minimum (critical) heat flux for ignition or pyrolysis. Combust. Flame 84, 323–332 (1991).

Kung, H. A mathematical model of wood pyrolysis. Combust. Flame 18, 185–95 (1972).

Kashiwagi, T. A radiation ignition model of a solid fuel. Combust. Flame 8, 225–236 (1974).

Wang, Y. et al. Experiment study of the altitude effects on spontaneous ignition characteristics of wood. Fuel 89, 1029–1034 (2010).

Dai, J. et al. Experimental and modeling study of atmospheric pressure effects on ignition of pine wood at different altitudes. Energ. Fuel 24, 609–615 (2010).

Spearpoint, M. J. & Quintiere, J. G. Predicting the piloted ignition of wood in the cone calorimeter using an integral model-effect of species, grain orientation and heat flux. Fire Safety J. 36, 391–415 (2001).

McAllister, S., Fernandez-Pello, C., Urban, D. & Ruff, G. The combined effect of pressure and oxygen concentration on piloted ignition of a solid combustible. Combust. Flame 157, 1753–1759 (2010).

Nakamura, Y. & Aoki, A. Irradiated ignition of solid materials in reduced pressure atmosphere with various oxygen concentrations - for fire safety in space habitats. Adv. Space Res. 41, 777–782 (2008).

Delichatsios, M. A. Piloted ignition times, critical heat fluxes and mass loss rates at reduced oxygen atmospheres. Fire Safety J. 40, 197–212 (2005).

McAllister, S. Critical mass flux for flaming ignition of wet wood. Fire Safety J. 61, 200–206 (2013).

Wasan, S. R., Rauwoens, P., Vierendeels, J. & Merci, B. An enthalpy-based pyrolysis model for charring and non-charring materials in case of fire. Combust. Flame 157, 715–734 (2010).

Nayagam, V., Balasubramaniam, R. & Williams, F. A. Diffusion flames over a melting polymer disk in von kármán swirling flows. Combust. Flame 156, 1698–1704 (2009).

Fereres, S., Fernandez-Pello, C., Urban, D. L. & Ruff, G. A. Identifying the roles of reduced gravity and pressure on the piloted ignition of solid combustibles. Combust. Flame 162, 1136–1143 (2015).

Boulet, P. et al. Optical and radiative properties of clear PMMA samples exposed to a radiant heat flux. Int. J. Therm. Sci. 82, 1–8 (2014).

Bal, N. et al. Experimental study of radiative heat transfer in a translucent fuel sample exposed to different spectral sources. Int. J. Heat Mass Tran. 61, 742–748 (2013).

Snegirev, A., Kuznetsov, E. & Markus, E. Coupled analytical approach to predict piloted flaming ignition of non-charring polymers. Fire Safety J. 93, 74–83 (2017).

Frank-Kamenetskii, D. A. Diffusion and heat transfer in chemical kinetics. Plenum Press (1969).

Li, J. & Stoliarov, S. I. Measurement of kinetics and thermodynamics of the thermal degradation for non-charring polymers. Combust. Flame 160, 1287–1297 (2013).

Ding, Y., Stanislav, S. I. & Kraemer, R. H. Pyrolysis model development for a polymeric material containing multiple flame retardants: Relationship between heat release rate and material composition. Combust. Flame 202, 43–57 (2019).

Ding, Y., Kwon, K., Stoliarov, S. I. & Kraemer, R. H. Development of a semi-global reaction mechanism for thermal decomposition of a polymer containing reactive flame retardant. P. Combust. Inst. 37, 4247–4255 (2019).

Park, W. H. & Yoon, K. B. Optimization of pyrolysis properties using TGA and cone calorimeter test. J. Therm. Sci. 22, 168–173 (2013).

Li, J., Gong, J. & Stoliarov, S. I. Gasification experiments for pyrolysis model parameterization and validation. Int. J. Heat Mass Transfer. 77, 738–744 (2014).

Acknowledgements

This work is supported by the National Key R D Program of China, grant number 2017YFD0600106-4; Nanjing Forest Police College Pre-research Project, grant number LGY201801; Qing Lan Project, the Priority Academic Program Development of Jiangsu Higher Education Institutions of China; National Natural Science Foundation of China, grant number 31872705. The authors gratefully appreciate all these supports.

Author information

Authors and Affiliations

Contributions

Draft Preparation, Chunjie Zhai; Writing-Review & Editing, Qingbin Zhan, Shuifeng Zhang and Yue Wang; Supervision, Siyu Zhang and Shuren Yao; Project Administration, Siyu Zhang and Chunjie Zhai.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhai, C., Zhang, S., Yao, S. et al. Analytical study on ignition time of PMMA exposed to time-decreasing thermal radiation using critical mass flux. Sci Rep 9, 11958 (2019). https://doi.org/10.1038/s41598-019-48411-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-48411-x

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.