Abstract

The development of highly active and cost-effective catalysts based on noble metal free oxygen electro-catalysis is critical to energy storage and conversion devices. Herein, we highlight a plasma-treated Bi0.1(Ba0.5Sr0.5)0.9Co0.8Fe0.2O3−δ perovskite (denoted as P-Bi0.1BSCF) as a promising catalyst for oxygen evolution reaction (OER) in alkaline media. H2/Ar plasma engraving could significantly increase electrochemically active O22−/O− concentration and tune the electronic structure of Co ions efficiently, and consequently tailor the intrinsic electrocatalytic ability for OER. Of note, P-Bi0.1BSCF, with unique crystalline core/amorphous shell structure, exhibits an enhanced intrinsic OER activity and higher stability than the noble metal IrO2 catalyst, which outperforms most of the reported perovskite catalysts. The present work provides new insights into exploring efficient catalysts for OER, and it suggests that, in addition to the extensively applied for surface treatment of various catalysts such as carbons and metal oxides, the plasma engraved perovskite materials also exhibits great potential as precious metal-free catalysts.

Similar content being viewed by others

Introduction

The pursuit of highly active and cost-effective catalysts is of prime significance for sustainable energy conversion and storage in order to develop renewable energy production. Implementing these emerging clean energy solutions, such as water splitting, direct solar and metal air batteries et al., highly relies on a variety of electrocatalytic reactions, such as oxygen evolution reaction (OER). Given that OER is in general impeded by its intrinsically sluggish kinetics due to a multistep four electron process, and consequently requires a considerable overpotential relative to its thermodynamic potential of 1.23 V vs. reversible hydrogen electrode (RHE). To address this, precious metal-based materials, e.g. RuO2 and IrO2, are currently employed as the efficient state-of-art OER catalysts1. However, high cost, low abundance as well as poor durability during long term operation badly hinder their widespread application.

Over these years, a tremendous number of alternatives based on non-precious metals materials have been intensively explored, including oxides (hydroxides)2,3,4,5, carbon (carbon based hybrid)6,7, metal oxides/carbon composite catalysts8,9,10, chalcogenides11,12 and phosphates13,14. Among these candidates, perovskite oxides have drawn much attention as competitive electrocatalysts due to their flexible states of transition metals, fascinating oxygen ion mobility and exchange kinetics, and unique tailorable properties15,16,17. For example, Suntivich et al.18,19 reported that Ba0.5Sr0.5Co0.8Fe0.2O3 (BSCF) perovskite provided a higher intrinsic OER activity in alkaline solution comparable to commercial IrO2 electrocatalyst, A site of Ba/Sr displays the fastest oxygen transport kinetics, while the Co-rich compositions on the B site offers faster oxygen exchange kinetic. The rational design of B-site transition metal ratio could tune the eg orbital filling (σ*-orbital occupation), and thus benefited OER process18.

Although BSCF is known to have superior intrinsic activity, large particle sizes rendered from traditional bottom-up method18 limit their large-scale practical application due to low gravimetric mass activity. The poor stability caused by surface amorphization of BSCF particles under OER conditions is another tough issue for industrial application20. It is known that the surface area could be increased through a nanostructure strategy or surface modification, while the stability of perovskites could be improved by intrinsic methods resort such as chemical substitution or electronic configuration modification. Jung et al.19 introduced a nano-sized Lax(Ba0.5Sr0.5)1−xCo0.8Fe0.2O3 with superior activity and stability, where the electronic states was managed by chemical substitution of A-site cations with lanthanum and particle growth was controlled by sintered temperature. Ln(Ba0.5Sr0.5)0.5Co0.8Fe0.2O3 (Ln = Nd, Sm, Gd)21 and Pr0.5(Ba0.5Sr0.5)0.5Co0.8Fe0.2O322 have also been developed as highly active catalysts base on A-site chemical substitution strategy.

In this work, we highlight a feasibility of Bi introduced into A site of BSCF lattice (Bi0.1(Ba0.5Sr0.5)0.9Co0.8Fe0.2O3−δ, denoted as Bi0.1BSCF) to modify the electronic structure of perovskites. As known, bismuth oxide is usually used as an oxygen-ion conducting electrolyte in solid oxide fuel cells. Bi could also be introduced to A site of BSCF perovskite and tailor oxygen electrocatalysis ability23. Furthermore, surface modification is another effective strategy to improve the activity and durability of electrocatalysts. It is reported that the cold plasma process is an efficient approach for surface modification and functionalization, which can generate roughed surface, surface vacancies, defects and other active functional groups24,25,26,27,28. Therefore, for the first time, we propose the pollution-free and facile plasma modification on perovskite oxides to tailor the near-surface structure. The optimized 5% H2/Ar plasma-treated Bi0.1BSCF catalyst, which denoted as P-Bi0.1BSCF, demonstrates a higher intrinsic activity and durability towards OER, relative to the well-known BSCF perovskite as well as commercial IrO2 catalyst. An electrochemically active amorphous layer created by plasma engraving is achieved, and its effect is furthermore elaborated for OER.

Methods

Catalysts synthesis

Ba0.5Sr0.5Co0.8Fe0.2O3 and Bi0.1(Ba0.5Sr0.5)0.9Co0.8Fe0.2O3−δ (denoted as BSCF and Bi0.1BSCF, respectively) perovskite oxides were synthesized by using a EDTA-citrate sol-gel process17. Briefly, the starting materials of Ba(NO3)2, Sr(NO3)2·4H2O, Bi(NO3)3·6H2O, Fe(NO3)3·9H2O, and Co(NO3)2·6H2O (Sinopharm Chemical Reagent Co., Ltd.) were mixed in deionized water in accordance with their stoichiometric amounts, employing EDTA and citric acid as chelating agents. With the introduction of aqueous ammonium hydroxide solution (NH3, 28%, Sinopharm Chemical Reagent Co., Ltd.) into above solution, the pH value was tuned at ~7. Such solution was stirred and then heated at 100 °C to yield a gel, then calcination at 250 °C overnight to form a solid precursor. The solid precursor of BSCF was sintered in air at 1000 °C, whereas Bi0.1BSCF was calcined in air at 850 °C for 4 h to obtain the powders. The commercial IrO2 (99.5%, Aladdin Industrial Corporation) catalysts was studied for comparison.

The freshly-prepared Bi0.1BSCF catalyst was subsequently conducted via a plasma cleaner (MING HENG, PDC-MG) with a gas flow of air, Ar or 5% H2/Ar for the plasma ignition (commercial 13.56 MHz RF source). Different irradiation time (0 min, 2 min, 3 min, 5 min and 8 min) with powers of ~130 W and pressure of 90 Pa was applied during plasma process. The optimized 5% H2/Ar plasma-treated Bi0.1BSCF for 3 min was used for detailed studies, which denoted as P-Bi0.1BSCF.

Materials characterization

Phase structures of the as-prepared catalyst powders were determined by XRD on Bruker (D8 Focus, Cu Kα radiation). Program FullProf was employed for the diffraction refinement. SEM images were performed on a SU-8010 SEM, whereas high resolution TEM images equipped with EDS were conducted on a Tecnai G2 F20 U-TWIN TEM. XPS measurements of the catalysts were carried out on a Kratos Axis Ultra DLD instrument. The obtained XPS spectra were calibrated by referencing C 1 s to 284.6 eV, and simulated using the XPSPEAK41 software. We analyzed the specific surface areas by Brunauer Emmet Teller (BET) system with N2 as the adsorptive medium. Approximately 2.0 g samples were weighed and degassed at 250 °C for 4 h before nitrogen physisorption at the temperature of liquid nitrogen (77 K). The ability of perovskites to adsorb OH− after exposure to water (100% humidity) at room temperature for 2 h was estimated from the Fourier transform infrared spectra (FTIR, Nicolet iS50, Thermo Scientific America). Oxygen temperature programmed desorption (O2-TPD) measurement was surveyed to analysis the oxygen desorption properties.

Electrochemical evaluation

The as-prepared BSCF, Bi0.1BSCF, P-Bi0.1BSCF and commercial IrO2 (~5 μm, Sigma Aldrich 99.9%) catalysts were, respectively, ground in mortar to disperse well. The mixture, including 40 mg perovskite catalyst, 8 mg Ketjen black (KB, EC-600JD), 5 mL ethanol and 0.25 mL 5 wt.% Nafion solution were ultrasonicating to obtain a homogeneous ink. A 2 μL catalyst ink was then deposited onto the polished glassy carbon electrode surface with a uniform loading of ~0.2832 mg cmdisk−2 (~0.2266 mgcatalyst cmdisk−2). Electrodes containing IrO2 were also prepared with a similar loading of 0.2587 mg cmdisk−2. The OER electrochemical characteristics were conducted in N2-saturated 0.1 M KOH electrolyte with a standard three electrode cell configuration (Pine Research Instrumentation). 1 M Hg/Hg2Cl2 electrode and platinum sheet were applied as the reference and the counter electrode, respectively. The potentials in this work were iR corrected, where the value of R is the ohmic electrolyte resistance via high frequency AC impedance. Cyclic voltammetry (CV) curves for OER were recorded on the rotating disk electrode from 1.3 to 2.0 V vs. RHE at 1600 rpm, with the scan rate of 10 mV s−1.

Results and Discussion

Fig.1a,b show the Rietveld refined powder XRD pattern of pristine Ba0.5Sr0.5Co0.8Fe0.2O3 and Bi0.1(Ba0.5Sr0.5)0.9Co0.8Fe0.2O3−δ (denoted as BSCF and Bi0.1BSCF, respectively). Upon Rietveld refinements, the fitted lattice parameters of BSCF and Bi0.1BSCF are summarized in Table S1 (ESI). One can see that both BSCF and Bi0.1BSCF present a cubic perovskite structure with the space group of Pm-3m. Schematic representation of A-site doping perovskite structure of Bi0.1BSCF is described in Figure S1 (ESI). The phase structure of Bi0.1BSCF in this study agrees well with the reported literature23. The typical diffraction peak (110) of Bi0.1BSCF moves to a higher angle compared to pristine BSCF, indicating that the introduction of Bi into BSCF lattice causes lattice contraction. This might be attributed to the substitution of the larger Sr2+ (0.158 nm) and Ba2+ (0.175 nm) ions by smaller Bi3+ (0.124 nm). Additionally, upon XRD analysis (Fig. 1c), no obvious structural change of P-Bi0.1BSCF is observed after plasma treatment for 3 min using 5% H2/Ar as the generating gas.

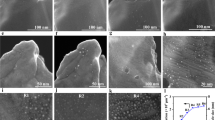

Shown in Fig. 2 is the SEM morphology of the as-prepared BSCF, Bi0.1BSCF, and P-Bi0.1BSCF catalysts. It is clearly seen that the particle size of Bi0.1BSCF is 0.5~1 um (Fig. 2c,d) and is smaller than that of initial BSCF (Fig. 2a,b), which is probably due to its much lower sintering temperature. Accordingly, Bi0.1BSCF has a larger surface area of 3.0771 m2 g−1, which is 4.3 times larger than that of BSCF (0.7132 m2 g−1) as estimated via BET method (Fig. S2, ESI). Although the SEM morphology of P-Bi0.1BSCF does not change obviously after 5% H2/Ar plasma engraving (Fig. 2e,f), the BET surface area of P-Bi0.1BSCF increase by 14% compared to the freshly prepared Bi0.1BSCF. This demonstrates that the plasma treatment could engrave the surface of Bi0.1BSCF perovskite and thereby increase the specific surface area.

To further investigate the crystalline structural change of BSCF after Bi-doping and plasma treatment, HR-TEM are performed on BSCF, Bi0.1BSCF and P-Bi0.1BSCF catalysts, as shown in Fig. 3. The cubic perovskite structure of BSCF and Bi0.1BSCF is also confirmed by Fourier transformed pattern. The lattice diffraction fringes in Fig. 3b are 0.397 and 0.176 nm, which are well indexed to the (100)BSCF and (021)BSCF interplanar spacing, respectively. In the case of Bi0.1BSCF, the lattice diffraction fringes in Fig. 3d is 0.395 nm, which agrees well with the (100) interplanar spacing. One can see that the surfaces of BSCF and Bi0.1BSCF particles are highly crystalline with little amorphous region. After exposure in 5% H2/Ar-plasma for 3 min, the perovskite structure of P-Bi0.1BSCF is still observed in Fig. 3f (d (110) spacing of 0.281 nm). Together with XRD characterization of plasma-engraved Bi0.1BSCF, the results reveal that no crystalline changes after plasma treatment. In addition, STEM and the corresponding EDS mapping analysis suggests that the elements of P-Bi0.1BSCF are uniformly distributed without surface segregation phenomenon after plasma engraving process. Moreover, it is apparent that P-Bi0.1BSCF displays a unique core-shell structure, a disordered amorphous shell with a thickness of approximately 8–10 nm is generated after plasma modification. Similar phenomenon is reported by Li and his co-workers that the TiO2 nanosheets shows a crystalline TiO2 core/amorphous TiO2−δ shell structure via NH3-plasma surface modification with oxygen deficient on shell region29.

Figure 4a presents the CV curves of pristine BSCF, Bi0.1BSCF and P-Bi0.1BSCF catalysts under the OER potential window. Similar measurements are performed on the IrO2 and KB for comparison. The catalytic activity contribution of KB is subtracted according to the composition of electrode. The performance of commercial IrO2 catalyst is comparable to that reported elsewhere30,31. The CV of Bi0.1BSCF shows a comparably lower onset potential (1.49V) and a higher current density than the IrO2 and BSCF catalyst, indicating a better OER catalytic activity of Bi0.1BSCF. After plasma engraving, P-Bi0.1BSCF catalyst manifests an apparent enhancement in OER activity with a significantly improved current density. The optimized processing parameters for plasma engraving is 5% H2/Ar working atmosphere only for 3 min (Fig. S3, ESI). Moreover, P-Bi0.1BSCF catalyst exhibits a quite small overpotential (η) at a current density of 10 mA cmdisk−2 of 370 mV, which is superior to that of Bi0.1BSCF (411 mV), BSCF (525 mV), and IrO2 (464 mV). Notably, the overpotential of P-Bi0.1BSCF favorably outperforms the reported perovskite-based OER catalysts21,32,33,34,35,36,37,38,39, e.g. BaCo0.7Fe0.2Sn0.1O3−δ (410 mV)36, SrNb0.1Co0.7Fe0.2O3−δ (SNCF) (500 mV)39 summarized in Table S2 (ESI).

(a) Cyclic voltamograms of the BSCF, Bi0.1BSCF, P-Bi0.1BSCF, IrO2, and KB in 0.1 M KOH at 1600 rpm. (b) Tafel plots of these catalysts. (c) OER mass activity (MA) and specific activity (SA) at an overpotential of 0.4 V. (d) Degradation of electrochemical performance of as-prepared catalysts, inset: LSV curves of P-Bi0.1BSCF at 2nd, 200th, 400th and 600th cycles.

Corresponding Tafel plots of the investigated samples are compared in Fig. 4b to evaluate the kinetics performance of OER. The Tafel slopes are 68, 74, 87, and 78 mV dec−1 for P-Bi0.1BSCF, Bi0.1BSCF, BSCF, and IrO2, respectively. Furthermore, the mass activity (MA) and specific activity (SA) are illustrated to evaluate the intrinsic activity, as shown in Fig. 4c. For instance, at an overpotential of 0.4 V, P-Bi0.1BSCF displays 8.9 times higher MA and 2.7 times higher SA relative to BSCF, respectively. The results confirm the positive contribution from the Bi-dopant and plasma engraving to the intrinsic activity. In addition,

The durability of electrocatalysts is another vital parameter for OER. In current study, we performed continuous CV curves for P-Bi0.1BSCF, Bi0.1BSCF, BSCF, and commercial IrO2 catalysts for 600 cycles, as shown in Fig. 4d. BSCF and IrO2 show a 25% and 27% reduction of its 2nd activity over 600 cycles, respectively, and the poor stability of BSCF results from the leaching of A site cations to the alkaline medium20. In contrast to BSCF, only 10% and 12% reduction is observed in the Bi0.1BSCF and P-Bi0.1BSCF catalysts under the same condition, respectively. The TEM image of post-OER P-Bi0.1BSCF in Fig. S4 shows that the structure of P-Bi0.1BSCF is maintained and the thickness of amorphous shell did not change much after continuous CV tests compared to as-synthesized P-Bi0.1BSCF. In addition, the XPS spectra before and after long-term OER testing shows that the oxidation state of Bi3+ does not change40,41 (Fig. S5), which also reveals the durability of P-Bi0.1BSCF catalyst.

To understand the source responsible for the excellent OER activity of P-Bi0.1BSCF, the surface state of BSCF, Bi0.1BSCF and P-Bi0.1BSCF catalysts is intensively studied by XPS analysis. The O1s XPS spectra for BSCF, Bi0.1BSCF and P-Bi0.1BSCF is deconvoluted to four characteristic peaks (Fig. 5a). The first one at a lower binding energy (529.6 eV) represents the lattice oxygen (O2−), followed by the surface oxidative oxygen O22−/O− (530.5 eV), hydroxyl groups OH− or adsorbed O2 (531.5 eV), and adsorbed molecular H2O of the oxide surface (532.9 eV)42. The relative content of the lattice and surface oxygen species derived is listed in Table S3 (ESI). The content of surface oxidative oxygen O22−/O− increases from 35.68% with BCSF to 42.17% with Bi0.1BSCF. Moreover, the O22−/O− concentration is further increased to ~49.23% by plasma engraving, indicating the existence of abundant active oxygen species on the amorphous region of P-Bi0.1BSCF oxide surface. Importantly, the electrochemically active O22−/O− are proved to be beneficial for catalyzing OER43,44. Also, the highly oxidative oxygen species on the surface are reported to be closely relevant to the oxygen vacancies45, and surface oxygen vacancies play a key role for perovskite oxides in catalyzing OER46. It reveals that the plasma engraving could create more electrochemical active sites on the amorphous shell. The similar phenomenon of surface amorphization and simultaneous increased activity for efficiently electro-catalyzing OER is also found in other catalysts47,48,49,50.

The core-level spectra of Co 2p & Ba 3d for these three catalysts are presented in Fig. 5b. The overlapping between Co 2p and Ba 3d spectra makes it different to identify the surface Co valence by peak fitting, while the Co oxidation state could be inferred from the shift of peak position. Compared to BSCF, the positions of Co peaks for the Bi0.1BSCF shift to lower binding energies, suggesting that the surface valence of Co slightly decrease owing to high valence Bi-substitution. After 5% H2/Ar plasma engraved, the two main peaks of P-Bi0.1BSCF shift to higher binding energies obviously, which indicates the presence of surface cobalt in a higher oxidation state. It is reported that the high valence of Co could also play a positive role in the improvement of OER activity51. No distinctive variation was observed in the Fe state of catalyst surface (Fig. 5c). On the basis of the XPS results, the increased O22−/O− concentration together with electronic structure tuning of Co induced by plasma engraving might be responsible to the enhancement in OER performance.

The redox property of BSCF, Bi0.1BSCF, and P-Bi0.1BSCF is studied by O2-TPD, as shown in Fig. 6a. The desorption peak of the Bi0.1BSCF catalyst, associated with the reduction of Co iron, occur at approximately 251 °C, which is lower than that of BSCF (275 °C). It’s worth noting that, after 5% H2/Ar plasma engraved, the desorption temperature of P-Bi0.1BSCF catalyst reduce remarkably to nearly 198 °C, this indicates an excellent oxygen desorption capability35 and reflects a higher oxygen surface exchange ability for P-Bi0.1BSCF perovskite. The result is consistent with the EIS analysis that P-Bi0.1BSCF has better ionic and charge transfer abilities. Besides O2 desorption capability, the P-Bi0.1BSCF catalyst also shows good OH− adsorption. As observed by FTIR spectroscopy (Fig. 6b), a broad IR band centers at approximately 3466 cm−1 appeared, which corresponds to H-bonded OH− stretching vibration52. Obviously, Bi0.1BSCF exhibited a stronger OH− absorption ability than initial BSCF, and the OH− absorption ability is further improved via plasma treatment. According to the adsorbate evolution mechanism53, OH− absorption on the active sites of perovskites is the prerequisite for OER, and thereby the large OH− absorption can continually offer raw materials for the following OER process36. Due to the complex interplay between oxygen deficiency and surface-active redox centre of perovskite oxides, detailed mechanistic insights into the OER electrocatalysis of P-Bi0.1BSCF materials in alkaline media are currently limited. Nevertheless, with the superior activity, stability and cost-effectiveness, Bi0.1BSCF promises a novel precious-metal-free catalyst for the alkaline OER, and plasma engraving proved to be a facile and effective surface modification method to further improve the activity.

Conclusion

In summary, a plasma engraving strategy is, for the first time, proposed for the surface modification of perovskite materials towards electrocatalyzing OER. After 5% H2/Ar plasma engraving only for 3 min, an amorphous layer with abundant electrochemical active oxygen species is generated on Bi0.1BSCF perovskite surface. Moreover, the increased oxygen surface exchange ability and OH- absorption ability of P-Bi0.1BSCF are achieved. Owing to the unique properties via Bi-doping as well as plasma engraving, P-Bi0.1BSCF exhibits a fast kinetics process with a small Tafel slope of 68 mV dec−1 and high stability for OER, that is superior to most of the state-of-the-art perovskite-based electrocatalysts. The foregoing results open a new avenue for engineering perovskite oxides via plasma method for highly efficient OER, which is promising for a variety of electrochemical energy storage applications.

References

Jiao, Y., Zheng, Y., Jaroniec, M. & Qiao, S. Z. Design of electrocatalysts for oxygen- and hydrogen-involving energy conversion reactions. Chemical Society Reviews 44, 2060–2086 (2015).

Wang, Y. et al. Reduced Mesoporous Co3O4 Nanowires as Efficient Water Oxidation Electrocatalysts and Supercapacitor Electrodes. Advanced Energy. Materials 4, 1400696 (2014).

Han, L., Dong, S. & Wang, E. Transition-Metal (Co, Ni, and Fe)-Based Electrocatalysts for the Water Oxidation Reaction. Advanced Materials 28, 9266–9291 (2016).

Zhang, Z. et al. Durable oxygen evolution reaction of one dimensional spinel CoFe2O4 nanofibers fabricated by electrospinning. Rsc Advances 8, 5338–5343 (2018).

Zhang, Z. et al. Boosting Overall Water Splitting via FeOOH Nanoflake-Decorated PrBa0.5Sr0.5Co2O5+ delta Nanorods. Acs Applied Materials & Interfaces 10, 38032–38041 (2018).

Zhao, Y., Nakamura, R., Kamiya, K., Nakanishi, S. & Hashimoto, K. Nitrogen-doped carbon nanomaterials as non-metal electrocatalysts for water oxidation. Nature Communications 4, 2390 (2013).

Mao, S., Wen, Z., Huang, T., Hou, Y. & Chen, J. High-performance bi-functional electrocatalysts of 3D crumpled graphene-cobalt oxide nanohybrids for oxygen reduction and evolution reactions. Energy & Environmental Science 7, 609–616 (2014).

Su, Y. et al. Cobalt nanoparticles embedded in N-doped carbon as an efficient bifunctional electrocatalyst for oxygen reduction and evolution reactions. Nanoscale 6, 15080–15089 (2014).

Wang, H. et al. Cobalt ion-coordinated self-assembly synthesis of nitrogen-doped ordered mesoporous carbon nanosheets for efficiently catalyzing oxygen reduction. Nanoscale 9, 15534–15541 (2017).

Han, X. et al. Ultrasensitive Iron-Triggered Nanosized Fe-CoOOH Integrated with Graphene for Highly Efficient Oxygen Evolution. Advanced Energy. Materials 7, 1602148 (2017).

Qiao, X., Jin, J., Fan, H., Li, Y. & Liao, S. In situ growth of cobalt sulfide hollow nanospheres embedded in nitrogen and sulfur co-doped graphene nanoholes as a highly active electrocatalyst for oxygen reduction and evolution. Journal of Materials Chemistry A 5, 12354–12360 (2017).

Zhang, Y. et al. Nanostructured Metal Chalcogenides for Energy Storage and Electrocatalysis. Advanced Functional Materials 27, 1702317 (2017).

Zhang, X. et al. Ni(OH)(2)-Fe2P hybrid nanoarray for alkaline hydrogen evolution reaction with superior activity. Chemical Communications 54, 1201–1204 (2018).

Fu, S. et al. Ultrafine and highly disordered Ni2Fe1 nanofoams enabled highly efficient oxygen evolution reaction in alkaline electrolyte. Nano Energy 44, 319–326 (2018).

Zhu, L., Ran, R., Tade, M., Wang, W. & Shao, Z. Perovskite materials in energy storage and conversion. Asia-Pacific Journal of Chemical Engineering 11, 338–369 (2016).

Chen, D., Chen, C., Baiyee, Z. M., Shao, Z. & Ciucci, F. Nonstoichiometric Oxides as Low-Cost and Highly-Efficient Oxygen Reduction/Evolution Catalysts for Low-Temperature Electrochemical Devices. Chemical Reviews 115, 9869–9921 (2015).

Gong, C. et al. Atomic layered deposition iron oxide on perovskite LaNiO3 as an efficient and robust bi-functional catalyst for lithium oxygen batteries. Electrochimica Acta 281, 338–347 (2018).

Suntivich, J., May, K. J., Gasteiger, H. A., Goodenough, J. B. & Shao-Horn, Y. A Perovskite Oxide Optimized for Oxygen Evolution Catalysis from Molecular Orbital Principles. Science 334, 1383–1385 (2011).

Jung, J.-I. et al. Optimizing nanoparticle perovskite for bifunctional oxygen electrocatalysis. Energy & Environmental Science 9, 176–183 (2016).

May, K. J. et al. Influence of Oxygen Evolution during Water Oxidation on the Surface of Perovskite Oxide Catalysts. Journal of Physical Chemistry Letters 3, 3264–3270 (2012).

Kim, N.-I. et al. Highly active and durable nitrogen doped-reduced graphene oxide/double perovskite bifunctional hybrid catalysts. Journal of Materials Chemistry A 5, 13019–13031 (2017).

Xu, X. et al. A Perovskite Electrocatalyst for Efficient Hydrogen Evolution Reaction. Advanced Materials 28, 6442–6448 (2016).

Liu, Y., Ran, R., Tade, M. O. & Shao, Z. Structure, sinterability, chemical stability and conductivity of proton-conducting BaZr0.6M0.2Y0.2O3-delta electrolyte membranes: The effect of the M dopant. J. Membr. Sci. 467, 100–108 (2014).

Zhong, W. et al. Air plasma etching towards rich active sites in Fe/N-porous carbon for the oxygen reduction reaction with superior catalytic performance. Journal of Materials Chemistry A 5, 16605–16610 (2017).

Liu, Z. et al. In Situ Exfoliated, Edge-Rich, Oxygen-Functionalized Graphene from Carbon Fibers for Oxygen Electrocatalysis. Advanced Materials 29, 1606207 (2017).

Wang, Y. et al. Layered Double Hydroxide Nanosheets with Multiple Vacancies Obtained by Dry Exfoliation as Highly Efficient Oxygen Evolution Electrocatalysts. Angewandte Chemie-International Edition 56, 5867–5871 (2017).

Xu, L. et al. Plasma-Engraved Co3O4 Nanosheets with Oxygen Vacancies and High Surface Area for the Oxygen Evolution Reaction. Angewandte Chemie-International Edition 55, 5277–5281 (2016).

Bharti, B., Kumar, S., Lee, H.-N. & Kumar, R. Formation of oxygen vacancies and Ti3+ state in TiO2 thin film and enhanced optical properties by air plasma treatment. Scientific Reports 6, 32355 (2016).

Li, B. et al. Highly Efficient Low-Temperature Plasma-Assisted Modification of TiO2 Nanosheets with Exposed {001} Facets for Enhanced Visible-Light Photocatalytic Activity. Chemistry-a European Journal 20, 14763–14770 (2014).

Wang, M. et al. Oxidizing Vacancies in Nitrogen-Doped Carbon Enhance Air-Cathode Activity. Advanced materials (Deerfield Beach, Fla.), e1803339-e1803339 (2018).

Bu, Y. et al. A Highly Efficient and Robust Cation Ordered Perovskite Oxide as a Bifunctional Catalyst for Rechargeable Zinc-Air Batteries. Acs Nano 11, 11594–11601 (2017).

Zhang, D. et al. Active LaNi1-xFexO3 bifunctional catalysts for air cathodes in alkaline media. Journal of Materials Chemistry A 3, 9421–9426 (2015).

Park, H. W. et al. Electrospun porous nanorod perovskite oxide/nitrogen-doped graphene composite as a bi-functional catalyst for metal air batteries. Nano Energy 10, 192–200 (2014).

Yu, J. et al. Activity and Stability of Ruddlesden-Popper-Type Lan + 1NinO3n + 1 (n = 1, 2, 3, and infinity) Electrocatalysts for Oxygen Reduction and Evolution Reactions in Alkaline Media. Chemistry-a European Journal 22, 2719–2727 (2016).

Sun, H. et al. B-Site Cation Ordered Double Perovskites as Efficient and Stable Electrocatalysts for Oxygen Evolution Reaction. Chemistry-a European Journal 23, 5722–5728 (2017).

Xu, X. et al. Co-doping Strategy for Developing Perovskite Oxides as Highly Efficient Electrocatalysts for Oxygen Evolution Reaction. Advanced. Science 3, 1500187 (2016).

Zhou, S. et al. Engineering electrocatalytic activity in nanosized perovskite cobaltite through surface spin-state transition. Nature Communications 7, 11510 (2016).

Zhu, Y. et al. Enhancing Electrocatalytic Activity of Perovskite Oxides by Tuning Cation Deficiency for Oxygen Reduction and Evolution Reactions. Chemistry of Materials 28, 1691–1697 (2016).

Zhu, Y. et al. SrNb0.1Co0.7Fe0.2O3-delta Perovskite as a Next-Generation Electrocatalyst for Oxygen Evolution in Alkaline Solution. Angewandte Chemie-International Edition 54, 3897–3901 (2015).

Lee, C. W. et al. Selective Electrochemical Production of Formate from Carbon Dioxide with Bismuth-Based Catalysts in an Aqueous Electrolyte. Acs. Catalysis 8, 931–937 (2018).

Zhang, Z. et al. Rational Design of Bi Nanoparticles for Efficient Electrochemical CO2 Reduction: The Elucidation of Size and Surface Condition Effects. Acs Catalysis 6, 6255–6264 (2016).

Zhu, Y. et al. A High-Performance Electrocatalyst for Oxygen Evolution Reaction: LiCo0.8Fe0.2O2. Advanced Materials 27, 7150–+ (2015).

Liu, R., Liang, F., Zhou, W., Yang, Y. & Zhu, Z. Calcium-doped lanthanum nickelate layered perovskite and nickel oxide nano-hybrid for highly efficient water oxidation. Nano Energy 12, 115–122 (2015).

Jung, J.-I., Jeong, H. Y., Lee, J.-S., Kim, M. G. & Cho, J. A Bifunctional Perovskite Catalyst for Oxygen Reduction and Evolution. Angewandte Chemie-International Edition 53, 4582–4586 (2014).

Zhu, J. et al. Perovskite Oxides: Preparation, Characterizations, and Applications in Heterogeneous Catalysis. Acs Catalysis 4, 2917–2940 (2014).

Li, Z. et al. Engineering phosphorus-doped LaFeO3-δ perovskite oxide as robust bifunctional oxygen electrocatalysts in alkaline solutions. Nano Energy 47, 199–209 (2018).

Gerken, J. B. et al. Electrochemical Water Oxidation with Cobalt-Based Electrocatalysts from pH 0–14: The Thermodynamic Basis for Catalyst Structure, Stability, and Activity. Journal of the American Chemical Society 133, 14431–14442 (2011).

Risch, M. et al. Nickel-oxido structure of a water-oxidizing catalyst film. Chemical Communications 47, 11912–11914 (2011).

Zaharieva, I. et al. Synthetic manganese-calcium oxides mimic the water-oxidizing complex of photosynthesis functionally and structurally. Energy & Environmental Science 4, 2400–2408 (2011).

Liang, H. et al. Amorphous NiFe-OH/NiFeP Electrocatalyst Fabricated at Low Temperature for Water Oxidation Applications. Acs Energy Letters 2, 1035–1042 (2017).

Mefford, J. T. et al. Water electrolysis on La1-xSrxCoO3-delta perovskite electrocatalysts. Nature Communications 7, 11053 (2016).

Zou, X. et al. Efficient oxygen evolution reaction catalyzed by low-density Ni-doped Co3O4 nanomaterials derived from metal-embedded graphitic C3N4. Chemical Communications 49, 7522–7524 (2013).

Rong, X., Parolin, J. & Kolpak, A. M. A Fundamental Relationship between Reaction Mechanism and Stability in Metal Oxide Catalysts for Oxygen Evolution. Acs. Catalysis 6, 1153–1158 (2016).

Acknowledgements

The project was supported by the National Natural Science Foundation of China (Grant No. 21401171 and Grant No. 51402266).

Author information

Authors and Affiliations

Contributions

B.B. He conceived and designed the research. J. Sun and Z.H. Zhang carried out the electrochemical tests. Y.S. Gong performed the BET measurements. B.B. He wrote the manuscript with the help of H.W. Wang, L. Zhao and R. Wang. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sun, J., Zhang, Z., Gong, Y. et al. Plasma engraved Bi0.1(Ba0.5Sr0.5)0.9Co0.8Fe0.2O3−δ perovskite for highly active and durable oxygen evolution. Sci Rep 9, 4210 (2019). https://doi.org/10.1038/s41598-019-40972-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-40972-1

This article is cited by

-

Investigation of oxygen evolution reaction performance of silver doped Ba0.5Sr0.5Co0.8Fe0.2O3-δ perovskite structure

Journal of Applied Electrochemistry (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.