Abstract

Response surface methodology (RSM) including three variables was performed to optimize the extraction parameters of Astragalus cicer L. polysaccharides (ACPs). The influence of different drying techniques on the physicochemical properties and antioxidant abilities of ACPs were evaluated. The ACPs were dried with hot air (HD), vacuum (VD) and freeze drying (FD) methods. The optimal conditions for ACPs extraction were as follows: water to raw material ratio of 25 mL/g, extraction time of 61 min and temperature of 75 °C. Under these parameters, an ACPs yield of 10.97% was obtained. HPLC analysis showed that the monosaccharide compositions of the three ACPs dried with HD, VD or FD techniques were identical. The three ACPs exhibited antioxidant abilities in a concentration-dependent manner. ACPs dried with the FD method (FD-ACPs) had the best antioxidant activities, which might be related to their smaller molecular weight and higher uronic acid content. At the determined concentration of 1 mg/mL, the ferric reducing power, and DPPH and ABTS free radical scavenging capacities of FD-ACPs were 0.762, 75.30% and 99.21%, respectively. Therefore, FD was a good choice for the drying of Astragalus cicer L. polysaccharides.

Similar content being viewed by others

Introduction

Astragalus L., the largest genus in the family of Leguminosae with approximately 2500–3000 species, is widely distributed throughout the temperate regions of the world1. Several species of Astragalus L. are considered to have potential anhidrotic, diuresis, antidote and tonic effects2. Certain species of Astragalus L. are also used for the treatment of nephritides, mellitus, leucocythemia and metrocarcinoma3. Many studies have been carried out using compounds such as flavones, saponins, alkaloids, polysaccharides, sterols or phenols from various species of Astragalus L4.

Polysaccharides, a type of carbohydrate polymer macromolecule, are important bioactive constituents in plants. A number of biological functions of polysaccharides, such as antioxidant, antivirus, immunoregulation, hypoglycemic activity and blood fat reduction have been reported5,6. The development and utilization of Astragalus cicer L. are both connected with the extraction efficiency of polysaccharides from its tissue. Nevertheless, there have not yet been studies regarding the extraction conditions of Astragalus cicer L. polysaccharides (ACPs). In general, water extraction technology is the most common method used for extracting polysaccharides from plant tissue because of its safety and low cost. However, the various conditions of water extraction technologies can lead to differences in yield, purity, physicochemical properties and biological activities of the extracted polysaccharides. Response surface methodology (RSM) is a commonly used procedure for optimizing the extraction parameters of polysaccharides. One type of RSM, the Box-Behnken Design (BBD), has been widely used in the optimization of the extraction procedure because it dramatically reduces the number of experimental trails, saving time and decreasing expenses.

Drying techniques have significant effects on the physicochemical characteristics and bioactivities of the resulting polysaccharides7. Hot air drying (HD), freeze drying (FD) and vacuum drying (VD) are commonly used techniques for drying polysaccharides. Each technique has advantages, such as the easy accessibility and low cost of HD, the vacuum environment, which prevents the oxidation reaction of polysaccharides during VD, and the vacuum and freeze conditions, which protect the biological activities of polysaccharides during FD. However, significant changes of physicochemical properties and activities of polysaccharides may appear when using the high temperature of HD and VD8. One disadvantage of FD is the higher energy consumption during the drying process due to refrigeration and deoxygenation conditions. At present, there are no available data regarding the selection of drying methods of ACPs.

This study was therefore designed to optimize the extraction conditions of ACPs using the RSM methodology and to determine the physicochemical characteristics and antioxidant properties of ACPs as influenced by the different drying techniques. The physicochemical characteristics of the ACPs investigated were chemical composition, moisture content, pH, relative viscosity, solubility, molecular weight and monosaccharide composition. The antioxidant properties of ACPs were evaluated based on the determination of scavenging activities against DPPH and ABTS free radicals, as well as ferric reducing power.

Results and Discussion

Effect of water to raw material ratio on ACPs yield

The ACPs yield from different water to raw material ratios from 10 to 30 mL/g is shown in Fig. 1A. As the water to raw material ratio increased from 10 to 25 mL/g, the ACPs yield increased from 6.87% to 9.98% (P < 0.05). However, the ACPs yield did not significantly increase at the water to raw material ratio of 30 mL/g compared to 25 mL/g (P > 0.05). The reason for this might be due to the concentration difference between the Astragalus cicer L. tissue and the extraction solvent9. The solution amount from Astragalus cicer L. tissue increased with the water to raw material ratio increase. Nevertheless, with a further increase in the water to raw material ratio, the amount of extracted ACPs did not significantly improve because of the increasing diffusion distance of ACPs from plant tissue10. Therefore, 25 mL/g was used as the water to raw material ratio in subsequent RSM experiments.

Effect of extraction time on ACPs yield

Extraction time is one of the main factors to optimize for polysaccharide extraction conditions11. The ACPs yield from different extraction times ranging from 40 to 80 min is shown in Fig. 1B. As the extraction time increased from 40 to 60 min, the ACPs yield increased from 7.11% to 10.16% (P < 0.05). However, a further lengthening of extraction time (70 and 80 min) resulted in a slight reduction in ACPs yield compared with the extraction time of 60 min. This phenomenon might be explained by the degradation of ACPs during a long extraction time at high temperatures12. Therefore, an extraction time of between 50 and 70 min was used in subsequent RSM experiments.

Effect of extraction temperature on ACPs yield

Extraction temperature is another routine factor that requires optimization in the extraction of polysaccharides. The ACPs yield from different extraction temperatures (60 to 100 °C) is presented in Fig. 1C. A significant increase (from 7.97% to 10.81%) in the extraction yield of ACPs was found when the extracting temperature was in the range of 60 to 70 °C (P < 0.05). However, a further increase in temperature (80, 90 and 100 °C) caused a significant reduction in ACPs yield compared with the extraction temperature at 70 °C (P < 0.05). This might be due to an increased capacity of the solvent to solubilize the polysaccharides from Astragalus cicer L. tissue, with a concomitant decrease in the viscosity of the sample solution when the temperature rose, improving the ACPs yield. However, the ACPs structure might be destroyed when using too high of an extraction temperature13. Therefore, the temperature range of 60 to 80 °C was selected for use in subsequent RSM experiments.

Box-Behnken design of ACPs extraction

BBD is useful for RSM because it is based on single factor experiments and provides a scale of experimental variables and avoids excessive preliminary experiments. According to the single-factor experiment results, 17 runs of three variables were performed to determine the optimum extraction conditions for ACPs. The three variables were water to raw material ratio encoded as X1, extraction time encoded as X2 and extraction temperature encoded as X3. The designed experimental parameters and ACPs yields (from 7.24% to 10.85%) are shown in Table 1. By performing a multiple regression analysis of the experimental values, equation (1) of the response model for ACPs yield (Y) was obtained as follows:

The ANOVA analysis of the response surface model for ACPs extraction is presented in Table 2. The regression model was significant (P < 0.0001), and the lack of fit was insignificant (P = 0.9043), indicating that the model was adequate to predict the ACPs yield. The determination coefficient (R2) of 0.9988 suggested that only 0.12% of the variation could not be explained by the regression model. As presented in Table 2, the cross-product coefficient of X1 X 2 was significant (P < 0.05). The linear coefficients of X1, X2 and X3, cross-product coefficient of X1 X 3, and quadratic coefficients of X12, X22 and X32 were highly significant (P < 0.01). The other term coefficient (X2 X 3) was not significant (P > 0.05). Therefore, X1, X2 and X3 designed in this study were significant parameters that influenced ACPs yield.

Response surface plots are used to visually evaluate the interactions of variables on the ACPs yield14. The pattern of the 2-dimensional (2D) contour plot (elliptical, selliform or circular) indicates the different interactions between two variables. Elliptical or selliform 2D plots indicate significant interactions between two variables, while circular 2D plots indicate non-significant interactions between two variables. As shown in Fig. 2, the 2D plot of X1 and X2 (Fig. 2B) was elliptical, suggesting that the interaction between these two variables is significant (P < 0.05). A similar significance for the interaction between X1 and X3 is shown in Fig. 2D (P < 0.05). The 2D plot of X2 and X3 (Fig. 2F) was circular, suggesting that the interaction between these two variables is non-significant (P > 0.05).

It could be concluded from the regression model that the optimum extraction conditions of ACPs were X1 = 25.39 mL/g, X2 = 60.95 min, and X3 = 75.07 °C. The predicted ACPs yield was 11.02%. To facilitate convenient operation, X1 = 25 mL/g, X2 = 61 min, and X3 = 75 °C were used for ACPs extraction. The verification experiment was performed, and the actual ACPs yield was found to be 10.97 ± 0.13% (n = 3).

Effects of drying techniques on physicochemical characteristics of ACPs

The yield and activities of polysaccharides are related to dehydration methods and temperature, because polysaccharides from different plant sources possess different denaturation temperatures. In this study, ACPs were dried using three different techniques (HD, VD and FD). ACPs dried with HD method were termed HD-ACPs, VD-ACPs were obtained by VD technology, and ACPs dried with FD method were termed FD-ACPs. The activities of polysaccharides are influenced by many characteristics, such as their chemical composition, monosaccharide composition and molecular weight15. Therefore, these parameters were determined for the ACPs obtained by the three drying methods in this study.

The chemical composition of ACPs dried using the three methods is listed in Table 3. The yields of the ACPs were 10.65% for FD-ACPs, 9.75% for HD-ACPs and 9.91% for VD-ACPs. The total polysaccharides content of HD-ACPs, VD-ACPs and FD-ACPs were 52.48%, 55.43% and 58.90%, respectively. The protein content of HD-ACPs, VD-ACPs and FD-ACPs were 0.88%, 0.83% and 0.91% with a uronic acid content of 2.49%, 2.52% and 2.71%, respectively. Good correlation between the uronic acid content and the antioxidant ability of tea polysaccharides was reported by Chen et al.16. FD-ACPs possessed the highest uronic acid content among the three dried ACPs, which might be related to the higher temperature in the HD and VD conditions.

Moisture content is an important property of polysaccharides. As shown in Table 3, the moisture content of HD-ACPs, VD-ACPs and FD-ACPs was 8.13%, 8.27% and 8.33%, respectively (P > 0.05). Low moisture content suggests that ACPs have the potential to be widely used in the food processing field. The pH of HD-ACPs, VD-ACPs and FD-ACPs was determined to be 7.19, 7.17 and 7.22, respectively (P > 0.05). The relative viscosities (to deionized water) of HD-ACPs, VD-ACPs and FD-ACPs increased from 1.01 to 1.13. As the temperature increased, the time for ACPs to dissolve gradually decreased (Fig. 3). ACPs dried with the freeze method showed the shortest dissolving time, which might be related to the loose structure of FD-ACPs.

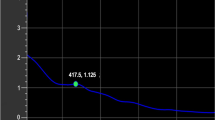

In general, the molecular weights of polysaccharides extracted from plants are highly dispersed. The molecular weight distribution of the ACPs is presented in Fig. 4. When the ACPs were dried by hot air, two distinct groups were found, possessing the molecular weights of 356.95 × 104 Da and 2243.48 Da. VD-ACPs also showed two distinct groups with molecular weights of 314.34 × 104 Da and 2243.48 Da. When ACPs were freeze dried, the molecular weight distribution showed two distinct groups with the molecular weights of 276.82 × 104 Da and 1975.70 Da. The molecular weights of the three ACPs obtained by HD, VD, and FD techniques were different, which might be related to the intermolecular aggregation of ACPs during different drying processes. VD-ACPs and HD-ACPs showed higher molecular weights, which suggests that the polysaccharides molecules aggregate easily at relative high temperature. A portion of the hydration layer was removed during the drying process, which destroyed the polysaccharide structure and resulted in aggregation17. The molecular weight of FD-ACPs was smaller than that of VD-ACPs or HD-ACPs. Generally, polysaccharides with smaller molecular weights show better activities compared to the polysaccharides with larger molecular weights, which might be due to the polysaccharides with lower molecular weights being able to pass through biological membranes without the restriction of the immune system in the body18.

The monosaccharide analysis showed that HD-ACPs, VD-ACPs and FD-ACPs were composed of rhamnose, galacturonic acid, glucose, galactose and arabinose. The molar ratios of the five monosaccharides in HD-ACPs were 1.22, 1.00, 11.98, 10.48 and 3.62. VD-ACPs consisted of the five monosaccharides with the molar ratios of 1.12, 1.00, 11.71, 10.75 and 3.56. FD-ACPs were composed of the five monosaccharides with the molar ratios of 1.22, 1.00, 11.64, 10.51 and 3.74. The monosaccharide analysis results indicated the homogeneity of the three ACPs.

Effects of drying techniques on antioxidant activities of ACPs

Many different in vitro methods have been used to determine the antioxidant activities of polysaccharides. The DPPH free radical is one kind of stable radical being used for assessing the antioxidant properties of polysaccharides19. The DPPH free radical scavenging activity assay is based on the reduction of DPPH ethanol solution in the presence of a hydrogen donating antioxidant, resulting in the formation of the non-radical form of DPPH-H. The assay can accommodate many samples in a short period and is sensitive enough to detect active ingredients at low concentrations20. ABTS radicals can react with antioxidants through the acceptance of a hydrogen atom or an electron18. The ABTS radical scavenging activity assay was shown to be simple and quick, and has been extensively used to evaluate the antioxidant activity of biological samples7. The ion Fe3+ can activate the reaction of lipid peroxidation in the human body21. Ferric reducing power serves as a significant potential index of antioxidant activity. In the reaction system, the addition of the antioxidant substance reduces the Fe3+ in the potassium ferricyanide to the Fe2+ form and is monitored by the formation of Prussian Blue at 700 nm. Therefore, the ferric reducing power can directly reflect the donation of electrons or hydrogen, and has been widely used to investigate the antioxidant activities of natural compounds18.

In Fig. 5A, the DPPH radical scavenging abilities of the three ACPs can be found in a quadratic concentration-dependent pattern (P < 0.05). FD-ACPs showed stronger DPPH radical scavenging activities compared to HD-ACPs or VD-ACPs (P < 0.05) at each concentration from 0.05 to 1 mg/mL. This might be related to differences in chemical composition, such as total polysaccharides and uronic acid content among the three dried ACPs. The scavenging activities were 70.27%, 73.30% and 75.30% for HD-ACPs, VD-ACPs and FD-ACPs, respectively, at a concentration of 1 mg/mL. ACPs (from 0.2 to 1 mg/mL) dried with the three techniques showed higher scavenging activities than vitamin C (P < 0.05), suggesting that ACPs may be donors of electrons or hydrogen to eliminate the free radical DPPH.

As shown in Fig. 5B, the ABTS radical scavenging power of FD-ACPs was stronger than ACPs dried with either the HD or VD methods (P < 0.05). Hydroxyl groups are important for polysaccharides to exhibit ABTS radical scavenging activity18. Nevertheless, oxidation of hydroxyl groups occurred under the presence of oxygen during hot air drying. Therefore, HD-ACPs showed lower ABTS radical scavenging power compared to the other two ACPs. FD-ACPs (1 mg/mL) had an ABTS scavenging activity of 99.21 ± 2.33%, and the scavenging abilities of the three ACPs (1 mg/mL) reached the scavenging levels of vitamin C (P < 0.05).

As shown in Fig. 5C, ACPs dried with the three methods presented a nicely linear relationship to the determination concentration (R2 > 0.99, P < 0.05) in their ferric reducing powers. Ferric reducing powers of all the ACPs increased with elevated concentration, which suggests that ACPs could terminate the radical chain reactions. FD-ACPs showed stronger ferric reducing powers compared to HD-ACPs or VD-ACPs (P < 0.05) in each determination concentration from 0.2 to 1 mg/mL. The ferric reducing powers of ACPs were significantly lower compared to vitamin C (P < 0.05). FD-ACPs (1 mg/mL) had a reducing power of 0.762. Nevertheless, garlic22 and Hohenbuehelia serotina18 polysaccharides (10 mg/mL) showed a reducing power of approximately 0.5. The ferric reducing powers of polysaccharides were related to their molecular weights23. The polysaccharides with smaller molecular weights showed better ferric reducing powers than the polysaccharides with larger molecular weights due to the more exposed reducing ends in the smaller polysaccharides24. Therefore, the high ferric reducing power of FD-ACPs might be related to its lower molecular weight among the three ACPs.

The antioxidant activity of polysaccharides was associated with their chemical composition, monosaccharide composition and molecular weight25. The higher antioxidant activity of FD-ACPs might be due to its higher content of uronic acid and lower molecular weight. In the polysaccharides, the existence of uronic acid groups could trigger the hydrogen atom of the anomeric carbon26. It has been reported that the higher the content of galacturonic acid, the stronger the antioxidant activity of the polysaccharides27. According to correlation analysis, a higher uronic acid content and lower molecular weight correlated to a higher antioxidant activity of polysaccharides from Dioscorea hemsleyi28. The lower molecular weight of Grifola frondosa polysaccharides extracted by combined enzyme enzymolysis rather than by boiling water played an important role in their higher antioxidant activities29. An explanation for this molecular weight-antioxidant activity relationship is that, at an equal mass concentration, lower molecular weight polysaccharides may provide a larger number of hydroxyl groups for antioxidant action12. The low molecular weight polysaccharides have more opportunities to come into contact with free radicals because of their increased water solubility and larger surface area30.

In conclusion, RSM was performed to obtain ACPs extracting parameters. The ACPs yield was significantly affected by different variables (P < 0.05). The optimal conditions in which to extract ACPs were determined to be a water to raw material ratio of 25 mL/g, an extraction time of 61 min and an extraction temperature of 75 °C, affording an ACPs yield of 10.97%. The three ACPs dried with different methods showed homogeneity in the monosaccharide composition. FD-ACPs had the highest solubility, the lowest molecular weight and the highest antioxidant activity. The high antioxidant activity of FD-ACPs might be related to its higher content of uronic acid and lower molecular weight. Therefore, the freeze-drying method was found to be the preferred technology to dry Astragalus cicer L. polysaccharides. Further work is essential to determine the antioxidant activities in vivo and the potential antioxidant mechanism of ACPs.

Materials and Methods

Plant and chemicals

Astragalus cicer L. in bloom stage was obtained from Jilin Agricultural University (Changchun, Jilin, China). The plant materials were dehydrated (50 °C) and crushed into powders (1 mm). The lipids of the powders were removed by soaking in ethanol (85%, v/v) for one day. The insoluble substance was dehydrated at 50 °C and prepared for polysaccharide extraction. DPPH, ABTS, vitamin C and monosaccharide standard were obtained from Sigma (St. Louis, MO, USA). Other chemicals were analytically pure reagents.

ACPs extraction

ACPs were extracted by distilled water based on the designed conditions. The extract was centrifuged for 15 min (3000 rpm), then one-quarter volume of the primary supernatant was obtained by vacuum concentration at 60 °C. The starch fraction in the concentrated solution was removed by α-amylase at 60 °C. Four times the volume of ethanol was mixed with the concentrated extraction solution to precipitate the ACPs (4 °C, 12 h). Subsequently, the precipitates were obtained by centrifugation at 3000 rpm for 15 min, and washed successively with ether, absolute ethanol and acetone. The extracts were dissolved with distilled water and protein was removed with the Sevag reagent (chloroform: normal butanol, 4:1, v/v) method. After dialysis (MWCO 1400 Da, Union Carbide) of the extraction solution, the ACPs were obtained by freeze drying. The ACPs yield was calculated with the following equation (2):

where WACPs and Wsample are the weights of ACPs and Astragalus cicer L. powder used, respectively.

Design of Box-Behnken

A single-factor experiment was first designed to evaluate the variable range for ACPs extraction. Each Astragalus cicer L. powder material was extracted with deionized water based on the designed variables including X1, X2 and X3 according to the ACPs extraction process mentioned above. The BBD of ACPs yield (Y) was then carried out. As shown in Table 1, the design was made up of 17 experimental runs. The three levels of each variable were coded as −1, 0 and + 1. A second-order polynomial mode (3) was used to optimize the extraction conditions of the ACPs as follows:

where Y is the dependent variable (ACPs yield); X ij is the interaction term; X i 2 is the quadratic term; A0, A i , A ii and A ij represent the coefficients of the intercept term, the linear term, the quadratic term, and the interaction term of two variables, respectively; and X i and X j are variables.

Drying process of ACPs

ACPs were extracted under the optimum conditions according to the BBD. The ACPs extracts were dehydrated with three different techniques (HD, VD and FD) until the weights became constant. HD was performed using a drying oven (101–2-BS, Shanghai Yuejin Medical Instrument Co., LTD, Shanghai, China) at 50 °C, and the dried polysaccharides were termed HD-ACPs. VD was carried out in a vacuum drying chamber (DZF, Shanghai Longyue Instrument Equipment Co., LTD, Shanghai, China) at 50 °C, and the dried polysaccharides were termed VD-ACPs. FD was carried out in a lyophilizer (SCIENTZ-12N, Ningbo Scientz Biotechnology Co., LTD, Ningbo, China) at −70 °C, and the resulting polysaccharides were termed FD-ACPs.

Physicochemical properties of ACPs

Chemical composition parameters, including the total polysaccharide, uronic acid and protein content of the ACPs were analyzed using colorimetry methods. The total polysaccharide content in the ACPs was determined with the phenol-sulfate method31. The uronic acid content was determined with the m-hydroxybiphenyl method32, and protein content was determined using Bradford’s method33. The moisture content was determined based on the report of Kong et al.34.

A pH meter was used to determine the pH values of the ACPs at the concentration of 2 mg/mL. The relative viscosity of ACPs (10 mg/mL) to deionized water was determined using a rotation viscometer (NDJ-8S, Shanghai Jitai Electronic Technology Co., LTD, Shanghai, China) at 25 °C. The solubility of ACPs was measured at 20, 40, 60, 80, and 100 °C according to the method as described by Shang et al.7.

Before determining the molecular weight distribution of the polysaccharides obtained by the three drying methods, the ACPs samples were initially purified by using a DEAE-52 cellulose column (3.5 cm × 20 cm), and eluted first with deionized water, then with a linear gradient (0 to 1 mol/L) of NaCl at a flow rate of 2 mL/min. The fractions (8 mL/tube) were collected automatically, and the polysaccharide content of each tube was determined with the phenol-sulfate method31. Fractions (one fraction eluting with distilled water) containing carbohydrates were collected and concentrated to measure the molecular weight of ACPs by gel filtration chromatography on a Sepharose CL-6B column (2.6 cm × 100 cm). A series of dextrans (T-10, T-40, T-70, T-500) were used as calibration standards. The eluent was deionized water (0.9 mL/min), and 4.05 mL fractions were collected per tube. The polysaccharide content of each tube was determined using the phenol-sulfate method31.

The monosaccharide composition of the ACPs obtained by the three drying methods was determined using high-performance liquid chromatographic (HPLC) by following methods as described previously35 with minor modifications. ACPs samples (2 mg) were hydrolyzed with 0.5 mL trifluoroacetic acid (TFA, 2 mol/L) in a sealed flask filled with N2 at 120 °C for 2 h. After hydrolysis, the excess TFA in the system was removed by repeated co-evaporation with ethanol at 45 °C. The dry hydrolysate samples of ACPs or monosaccharide standards were then added to a 0.5 mL methanol solution of 1-phenyl-3-methyl-5-pyrazolone (PMP, 0.5 mol/L) and 0.5 mL NaOH (0.3 mol/L) for derivatization at 70 °C for 30 min. The mixed solution was then centrifuged (10 000 rpm) for 5 min. The supernatant was mixed with 0.05 mL HCl (0.3 mol/L), and the reaction mixture was extracted with chloroform to remove excess PMP. The aqueous layer was filtered with a 0.22 μm membrane and used for analysis of the monosaccharide composition of ACPs by a Shimadzu 2010AHT HPLC system (SHIMADZU, Kyoto, Japan). The HPLC system was equipped with a UV detector (245 nm) and an Amethyst C18 column (4.6 mm × 250 mm, 5 μm, Sepax, Delaware, USA). The mobile phase was a mixture of phosphate buffered saline (PBS, 0.1 mol/L, pH 7) and acetonitrile (80:20, v/v) with a flow rate of 1 mL/min. The column was kept at 25 °C, and the injection volume was 10 μL.

Measurement of antioxidant activities of ACPs

The DPPH radical scavenging activity of ACPs was assessed based on a literature procedure with some modifications36. In brief, the DPPH solution (0.1 mM in ethanol, 1 mL) was added into 3 mL ACPs solution (dissolved in distilled water) at different concentrations (0.05, 0.075, 0.1, 0.2, 0.4, 0.6, 0.8 and 1.0 mg/mL). The mixture was kept in the dark for 30 min, and then the absorbance of the reaction mixture was determined at 517 nm. Vitamin C served as the positive control. The scavenging activity of ACPs against DPPH radical was evaluated by the followed equation (4):

where A0 is the control absorbance (water instead of the ACPs solution); A1 is the absorbance of the ACPs; and A2 is the absorbance of the combined reaction reagents, except that the DPPH solution is replaced with ethanol.

The scavenging activity of ACPs against ABTS radical was evaluated with a literature method with some modifications37. Vitamin C served as the positive control. The ABTS radical cation was produced by the reaction between ABTS solution (5 mL, 7 mM) and K2S2O8 aqueous solution (1 mL, 15 mM) for 12 h in the dark. The ABTS radical cation solution was then diluted with deionized water to obtain an absorbance of 0.70 ± 0.02 at 734 nm. The ABTS radical cation solution (3 mL) was added into 0.75 mL ACPs solution (dissolved in distilled water) at different concentrations (0.05, 0.1, 0.2, 0.4, 0.6, 0.8, 1.0 and 1.2 mg/mL). After reaction for 15 min, the absorbance at 734 nm was determined. The scavenging activity of ACPs against ABTS radical was evaluated by the followed equation (5):

where A0 is the absorbance of the control (ACPs solution was replaced with water); A1 is the absorbance of the ACPs solution; and A2 is the absorbance of all the reaction reagents, except that the ABTS solution is replaced with distilled water.

The ferric reducing power of ACPs was determined according to procedures included in the literature38,39. Vitamin C was used as the positive control. ACPs in distilled water (1.5 mL) were mixed with sodium phosphate buffer (1.5 mL, 0.2 M, pH 6.6) and potassium ferricyanide solution (1.5 mL, 1%, w/v). After incubation at 50 °C for 20 min, the mixture was quickly cooled. Trichloroacetic acid (1.5 mL, 10%, w/v) was added to the mixture, and the mixture was centrifuged at 3000 rpm for 10 min. The supernatant (1.5 mL) was mixed with deionized water (1.5 mL) and ferric chloride (0.3 mL, 0.1%, w/v). After 10 min, the absorbance was determined at 700 nm. The ferric reducing power of ACPs was evaluated by the equation as described by Shang et al.7.

Statistical analysis

All measurements were repeated in triplicate. The values were subjected to one-way ANOVA using SPSS software (19.0). Significant difference of the results was evaluated by Duncan post hoc test, and the differences were regarded as significant and highly significant when the P-values were less than 0.05 and 0.01, respectively. The curve estimation procedure was used to estimate the influence of ACPs on the antioxidant capacities.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Lim, D. H. et al. Effect of Astragalus sinicus L. seed extract on antioxidant activity. Journal of Industrial Engineering Chemistry 17, 510–516 (2011).

Niu, Y. G. et al. Structural analysis and bioactivity of a polysaccharide from the roots of Astragalus membranaceus (Fisch) Bge. var. mongolicus (Bge.) Hsiao. Food Chemistry 128, 620–626 (2011).

Sun, L. M. et al. Chemical constituents from Astragalus ernestii. Chinese Journal of Natural Medicines 9, 0038–0041 (2011).

Boual, Z. et al. Mediterranean semi-arid plant Astragalus armatus as a source of bioactive galactomannan. Bioactive Carbohydrates and Dietary Fibre 5, 10–18 (2015).

Kozarski, M. et al. Antioxidative and immunomodulating activities of polysaccharide extracts of the medicinal mushroom Agaricus bisporus, Agaricus brasiliensis, Ganoderma lucidum and Phellinus linteus. Food Chemistry 129, 1667–1675 (2011).

Kang, M. C. et al. In vitro and in vivo antioxidant activities of polysaccharide purified from aloe vera (Aloe barbadensis) gel. Carbohydrate Polymers 99, 365–371 (2014).

Shang, H. M. et al. Extraction optimization and influences of drying methods on antioxidant activities of polysaccharide from cup plant (Silphium perfoliatum L.). PLoS ONE 12, e0183001, https://doi.org/10.1371/journal.pone.0183001 (2017).

Zhao, Q. S. et al. Effect of drying methods on physicochemical properties and antioxidant activities of wolfberry (Lycium barbarum) polysaccharide. Carbohydrate Polymers 127, 176–181 (2015).

Zheng, Q., Ren, D. Y., Yang, N. N. & Yang, X. B. Optimization for ultrasound-assisted extraction of polysaccharides with chemical composition and antioxidant activity from the Artemisia sphaerocephala Krasch seeds. International Journal of Biological Macromolecules 91, 856–866 (2016).

Ying, Z., Han, X. X. & Li, J. R. Ultrasound-assisted extraction of polysaccharides from mulberry leaves. Food Chemistry 127, 1273–1279 (2011).

Ye, Z. P. et al. Box–Behnken design for extraction optimization, characterization and in vitro antioxidant activity of Cicer arietinum L. hull polysaccharides. Carbohydrate Polymers 147, 354–364 (2016).

Chen, R. Z. et al. Extraction, isolation, characterization and antioxidant activity of polysaccharides from Astragalus membranaceus. Industrial Crops and Products 77, 434–443 (2015).

Thirugnanasambandham, K., Sivakumar, V. & Maran, J. P. Microwave-assisted extraction of polysaccharides from mulberry leaves. International Journal of Biological Macromolecules 72, 1–5 (2015).

Liu, Z. G. et al. Optimization of polysaccharides from Lycium ruthenicum fruit using RSM and its anti-oxidant activity. International Journal of Biological Macromolecules 61, 127–134 (2013).

Wu, Z. Effect of different drying methods on chemical composition and bioactivity of finger citron polysaccharides. International Journal of Biological Macromolecules 76, 218–223 (2015).

Chen, H. X., Zhang, M., Qu, Z. S. & Xie, B. J. Antioxidant activities of different fractions of polysaccharide conjugates from green tea (Camellia Sinensis). Food Chemistry 106, 559–563 (2008).

Ma, L. S., Chen, H. X., Zhu, W. C. & Wang, Z. S. Effect of different drying methods on physicochemical properties and antioxidant activities of polysaccharides extracted from mushroom Inonotus obliquus. Food Research International 50, 633–640 (2013).

Li, X. Y., Wang, L., Wang, Y. & Xiong, Z. H. Effect of drying method on physicochemical properties and antioxidant activities of Hohenbuehelia serotina polysaccharides. Process Biochemistry 51, 1100–1108 (2016).

Xiong, S. L. et al. Antioxidant and immune regulatory activity of different polysaccharide fractions from tuber of Ophiopogon japonicas. Carbohydrate Polymers 86, 1273–1280 (2011).

Fan, L. P., Li, J. W., Deng, K. Q. & Ai, L. Z. Effects of drying methods on the antioxidant activities of polysaccharides extracted from Ganoderma lucidum. Carbohydrate Polymers 87, 1849–1854 (2012).

Wang, N. N. et al. Antioxidant property of water-soluble polysaccharides from Poria cocos Wolf using different extraction methods. International Journal of Biological Macromolecules 83, 103–110 (2016).

Pan, S. K. & Wu, S. J. Cellulase-assisted extraction and antioxidant activity of the polysaccharides from garlic. Carbohydrate Polymers 111, 606–609 (2014).

Wang, W. et al. Optimization of extraction, characterization and antioxidant activity of polysaccharides from Brassica rapa L. International Journal of Biological Macromolecules 82, 979–988 (2016).

Qi, H. M. et al. Antioxidant activity of different molecular weight sulfated polysaccharides from Ulva pertusa Kjellm (Chlorophyta). Journal of Applied Phycology 17, 527–534 (2005).

Chen, R. Z. et al. Antioxidant and immunobiological activity of water-soluble polysaccharide fractions purified from Acanthopanax senticosu. Food Chemistry 127, 434–440 (2011).

Wang, J. L. et al. Sulfated modification, characterization and structure-antioxidant relationships of Artemisia sphaerocephala polysaccharides. Carbohydrate Polymers 81, 897–905 (2010).

Asker, M. M. S., Mahmoud, M. G. & Ibrahim, G. S. Structural characterization and biological activity of acidic polysaccharide fractions isolated from Bacillus polymyxa NRC-A. Journal of Applied Sciences Research 3, 1170–1177 (2007).

Zhao, C. C. et al. The effect of different extraction techniques on property and bioactivity of polysaccharide from Dioscorea hemsleyi. International Journal of Biological Macromolecules 102, 847–856 (2017).

Fan, Y. N. et al. Physical characteristics and antioxidant effect of polysaccharides extracted by boiling water and enzymolysis from Grifola frondosa. International Journal of Biological Macromolecules 48, 798–803 (2011).

Zhang, Z. S., Wang, X. M., Liu, C. B. & Li, J. F. The degradation, antioxidant and antimutagenic activity of the mucilage polysaccharide from Dioscorea opposita. Carbohydrate Polymers 150, 227–231 (2016).

Dubois, M. et al. Colorimetric method for determination of sugars and related substances. Analytical Chemistry 28, 350–356 (1956).

Blumenkrantz, N. & Asboe-Hansen, G. New method for quantitative determination of uronic acids. Analytical Chemistry 54, 484–489 (1973).

Bradford, M. M. A rapid and sensitive method for the quantification of microgram quantities of protein, utilizing the principle of protein–dye binding. Analytical Chemistry 72, 248–254 (1976).

Kong, L. S. et al. Physicochemical characterization of the polysaccharide from Bletilla striata: Effect of drying method. Carbohydrate Polymers 125, 1–8 (2015).

Chai, Y. Y. & Zhao, M. Purification, characterization and anti-proliferation activities of polysaccharides extracted from Viscum coloratum (Kom.) Nakai. Carbohydrate Polymers 149, 121–130 (2016).

Kumar, C. S., Sivakumar, M. & Ruckmani, K. Microwave-assisted extraction of polysaccharides from Cyphomandra betacea and its biological activities. International Journal of Biological Macromolecules 92, 682–693 (2016).

Re, R. et al. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biology and Medicine 26, 1231–1237 (1999).

Jing, Y. S. et al. Structural characterization and biological activities of a novel polysaccharide from cultured Cordycep smilitaris and its sulfated derivative. Journal of Agricultural and Food Chemistry 63, 3464–3471 (2015).

Tan, L. H. et al. Antioxidant activity and optimization of extraction of polysaccharide from the roots of Dipsacus asperoides. International Journal of Biological Macromolecules 81, 332–339 (2015).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 31601972) and the Project funded by China Postdoctoral Science Foundation (No. 2017M621224).

Author information

Authors and Affiliations

Contributions

All authors have reviewed the manuscript. H.M.S. and H.Z.Z. designed the research. H.M.S., M.H.W. and R.L. performed the experiments. H.M.S., M.Y.D. and H.X.W. drafted the paper.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shang, H., Wang, M., Li, R. et al. Extraction condition optimization and effects of drying methods on physicochemical properties and antioxidant activities of polysaccharides from Astragalus cicer L.. Sci Rep 8, 3359 (2018). https://doi.org/10.1038/s41598-018-21295-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-21295-z

This article is cited by

-

Structural Characterization and Functional Studies of Exopolysaccharide by Native Lacticaseibacillus rhamnosus P14 Isolated from the Moroccan Region

Current Microbiology (2024)

-

Pharmacological Properties of Preparations Based on Astragalus Extract (Review)

Pharmaceutical Chemistry Journal (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.