Abstract

The negative replica of biomorphic TiO2 with nano-holes structure has been effectively fabricated directly from nano-nipple arrays structure of cicada wings by using a simple, low-cost and highly effective sol-gel ultrasonic method. The nano-holes array structure was well maintained after calcination in air at 500 °C. The Ag nanoparticles (10 nm–25 nm) were homogeneously decorated on the surface and to the side wall of nano-holes structure. It was observed that the biomorphic Ag-TiO2 showed remarkable photocatalytic activity by degradation of methyl blue (MB) under UV-vis light irradiation. The biomorphic Ag-TiO2 with nano-holes structure showed superior photocatalytic activity compared to the biomorphic TiO2 and commercial Degussa P25. This high-performance photocatalytic activity of the biomorphic Ag-TiO2 may be attributed to the nano-holes structure, localized surface plasmon resonance (LSPR) property of the Ag nanoparticles, and enhanced electron-hole separation. Moreover, the biomorphic Ag-TiO2 showed more absorption capability in the visible wavelength range. This work provides a new insight to design such a structure which may lead to a range of novel applications.

Similar content being viewed by others

Introduction

Photolysis of organic containments has paid a great attention in environmental cleaning and water purification1,2,3,4,5. TiO2 has been extensively used as a photocatalytic material due to its significant photostability, environmentally friendliness, high chemical stability, non-toxicity and low-cost6. It has potential applications in decomposition of organic pollutants7,8 water splitting9 and photo energy conversion10, etc. However, owing to their wide band gap (i.e., 3.2 eV for anatase and 3.0 eV for rutile), TiO2 absorb mainly UV light which is only 4% of the entire solar spectrum on earth11. Therefore, several techniques have been applied to exploit most of the energy spectrum (visible region) which is about 40% of the total energy12. These techniques involved doping of TiO2 with metallic or nonmetallic elements11, sensitizing TiO2 with a second photoactive component such as ruthenium complex13, quantum dots14, organic dyes15, and narrow bandgap semiconductors16. Even though the above-mentioned methods partially enhance the photocatalytic property of TiO2, yet still it limits their efficiency due to the thermal instability, lower redox potential of the photo-generated electrons and reduced electron-hole separation11. Moreover, it has been also reported that different micro-nano structures significantly enhances the light harvesting and photocatalytic property of TiO2 such as nanotube arrays17, ordered mesoporous structure18, micro-hole arrays19, inverse opal structures20. To improve light absorption, these structures allow the incident light through cavities and reduces the optical loss due to the multiple light scattering and reflection. However, it’s very challenging for new technology to design and produce such effective nano-architectures with high symmetry, while one can easily find these architectures in nature.

In fact, nature provides us an astonishing variety of structures from biological system such as periodic structure of butterfly wings21,22, cicada wings23,24, green leaves25,26, the sea-mouse spines27 and the insects compound eyes28. Among these biological prototypes, cicada wing is one of the most promising template due to its highly ordered hexagonal nano-nipple arrays structure, which plays an important role in reducing light reflection over a broad range of visible wavelength24. Chitin, a crystalline polymer with a high Young’s modulus of 7–9 GPa and high molecular weight, is the most important component of the cicada wing, and has a key role in preserving the original nanostructure of the wing surface29. Therefore, on large scale existing of these two dimensional nano-nipple arrays structure of cicada wing was found to be a most useful natural biotemplate during the replication process. Many researchers have made different approaches to replicate the negative replica of cicada wings nano-structure such as metal deposition30, nanoimprint lithography31,32, and low-surface-energy resin33. Guoyong et al. prepared the negative replica of Au directly from cicada template and then used it as a mold to fabricate the positive replica of PMMA (polymethyl methacrylate)30. Xinyue and Guoming et al. also produced the negative polymeric replica from cicada wings which shows better optical performance32,33. However, these synthetic methods are expensive and the low thermal stability of polymers limits their applications for outdoor uses. Therefore, in this study we used a simple and inexpensive sol-gel ultrasonic method to replicate one of the most interesting semiconductor titanium dioxide (TiO2) with nano-holes array structure which was further decorated with Ag nanoparticles to exhibit the better performance of photocatalytic activity under the UV-Vis light source.

Nowadays, noble metal nanoparticles have been used to enhance the photocatalytic performance of TiO2 under the visible light irradiation. These noble nanoparticles strongly connect with the light due to their excitation of surface plasmon resonance (SPR) and enhanced light harvesting property of nanocomposite34. The size, shape, composition, and the nature of the metallic nanostructure strongly affect the intensity and frequency of SPR which make it possible to design plasmonic nanostructures that interact with whole solar spectrum35,36. Moreover, the slow photon effect could also significantly enhance the photocatalytic performance due to the strong interaction of light with matter. The slow photon effect was raised from the reduced group velocity which increase the optical path of light wave and improves the light harvesting capability of the solar spectrum11. The inverse opal structure of wideband semiconductor TiO2 and ZnO showed better performance of photocatalytic activity owing to the slow photon effect37,38. Among the noble metals, Ag has attracted special attention due to inexpensive, non-toxic and easy preparation methods compared to the other noble metals. Therefore, the decoration of Ag nanoparticles on the surface of TiO2 composite has become a great interest. The Ag nanoparticles on the surface of TiO2 has been used to effectively maximize the photocatalytic reaction. The Fermi level of these Ag nanoparticles is below the conduction band of TiO2 which can play a role of electron scavenging centers to separate the electron-hole pair, and drastically increase the photocatalytic performance of TiO2 39. For example, different research works have shown the photocatalytic activity of Ag-TiO2 nanocomposite such as thin films40, nanowires41, nanorods42 and Ag modified TiO2 nanoparticles43. However, there is still some considerable difficulties due to the complicated experimental procedures and complex structural fabrication. The Ag nanoparticle was also deposited on surface of TiO2 photocatalysts via photochemical reduction through UV light irradiation44. This method was easy and inexpensive, but the weak bonding force between Ag and TiO2 and aggregation of Ag on surface of TiO2 decreased the light absorption as well as charge transfer rate. Besides, the photocatalytic performance of Ag-TiO2 was mostly studied only under the UV light illumination. Therefore, it was vital to fabricate Ag-TiO2 with strong bonding between Ag nanoparticles and TiO2 and to show a significant photocatalytic activity under UV-Vis light irradiation.

Herein, we fabricated biomorphic Ag-TiO2 with nano-holes array structure directly from cicada wings nanostructure after high calcination using a simple and inexpensive sol-gel ultrasonic method. Owing to the strong connection of SPR with in situ biomorphic TiO2, Ag nanoparticles effectively degrade MB under UV-Vis light irradiation.

Results and Discussion

In this work, black cicada was selected as the biological prototype due to its nano-nipple arrays structure on the surface of wing. It can be seen that the cicada wings are mostly transparent excluding some supporting veins and edge regions with cross-sectional thicknesses of 60−150 μm45. Figure 1a shows a photograph of the black cicada wing. The transparent wing section consist of nano-nipple arrays structure as shown by SEM images in Fig. 1b,c. It can be seen that the nano-nipple arrays on entire wing surface were arranged in highly order. The average separation distance between center to center (160 nm), basal diameter (140 nm), and height (210 nm) of the nano- nipple arrays are shown in Fig. 1c and its inset. It has been proved that these kind of subwavelength structures not only favors to the excellent antireflection property but also shows low adhesion, superhydrophobicity and self-cleaning properties46. Figure 1d,e shows the negative replica of biomorphic TiO2 with nano-holes structure after high calcination in air at 500 °C. The nano-holes arrays were uniformly distributed after complete removal of biotemplate. The biomorphic TiO2 effectively replicated the negative structure of cicada wing and maintained both the size and shape. The average structural parameters of the negative nano-holes arrays were found to be 220 nm in depth, 120 nm in diameter and 275 nm in central distance. These values indicate that a little distortion has been occurred after direct replication of nanostructures of cicada wing at high calcination.

(a) A photograph of the black cicada wing (b) Low magnified SEM image of the highly ordered nano-nipple arrays structure (c) Highly magnified side view SEM image of nano-nipple arrays structure. (d) Top view SEM image of negative replica of the biomorphic TiO2. (e) Highly magnified side view SEM image of the biomorphic TiO2.

As it is well known that the wing membrane of cicada wing is mainly composed of chitin, protein and wax component. Therefore, the wings were pretreated with 8% NaOH to remove inorganic salts from the surface of wings. After this modification, the precursor sol can easily flow into the internal structure of the wing and the final obtained replica well preserve the nanostructure of the original wings. The possible detail mechanism for the replication process of TiO2 is given below,

The reaction between TiCl4 and ethanol produces metallic chloroethoxide precursors [TiCl4−x (OEt)], with x ≈ 2 as shown in equation (1)47:

when water was added to the solution, the initial chloro-alkoxide complex TiCl2 (EtO)2 was modified through hydrolysis of the inorganic moieties which produce in situ ethanol and HCl as shown by equation (2). The maximum concentration of local HCl in the final solutions hampers inorganic polymerization and can extend inorganic polymerization from several minutes to days, and thus increase the stability of the sols:

Therefore, the hydrolysis and a small extent of condensation in these highly acidic condition make it possible to prepare the initial TiCl4/EtOH/H2O/template solutions48. The cicada wings surface with hydroxy groups can easily diffuse the gel inside nanostructures. Here, the HCl produced in situ can be eliminated by the evaporation process, allowing an extended inorganic condensation. When the reaction was agitated through ultrasound, the solutes homogeneously dispersed in the solution, catalyze the hydrolysis and condensation of the Titania precursor to TiO2. And thus, an intact sol particles layer is formed on the surface of wings after being taken out from precursor solution. Finally, the negative replica of biomorphic TiO2 with nano-holes array structure was produced after high calcination.

Figure 2 shows the SEM images of the negative replica of biomorphic Ag-TiO2 with nano-holes array structure. From Fig. 2a, it can be clearly seen that the biomorphic Ag-TiO2 with nano-holes array structure were uniformly distributed and there were no obvious defects. The Ag nanoparticles with a size of 10–25 nm were uniformly dispersed on the surface of biomorphic TiO2 as shown in Fig. 2b,c. It was obvious that the Ag nanoparticles were not only deposited on the surface of biomorphic TiO2 but also to the side wall of the nano-holes (Fig. 2d). As such, there is no aggregation of Ag nanoparticles to block the nano-holes of the obtained biomorphic Ag-TiO2 samples. A small cluster shown in the SEM images (Fig. 2b,d) might be due to the some impurity. The average depth, diameter and center to center distance of the nano-holes array were 220 nm, 110 nm, 275 respectively, as shown in Fig. 2c,d. These parameters show that the negative replica of original cicada wing was inherited to a great extent after high calcination. A shrinkage of 21% was observed in the diameter of the nano-holes compared to the basal diameter of the original wing. On the other hand, deformation of 41% and 3.6% was observed in the size of central spacing and depth of nano-holes structure, respectively. The shrinkage and deformation happened due to the high calcination temperature and uneven coating. It has been previously shown that the nanostructure morphology can be affected under high calcination temperatures23.

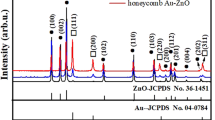

Figure 3 shows the XRD patterns of the biomorphic TiO2 and biomorphic Ag-TiO2. The diffraction peaks of anatase phase was centered at 2θ = 25.28, 37.80, 48.04, 53.89, 55.06, 62.68, 68.76, 70.30 and 75.02° which correspond to the (101), (004), (200), (105), (211), (204) (116), (220) and (215) planes. A small peak of rutile phase was also observed at 2θ = 27.44 corresponding to (110) plane due to the high calcination temperature. The diffraction peaks of Ag were not very obvious because the (111) plane of Ag at 2θ = 37.80 were overlapped to the diffraction peaks of biomorphic TiO2 (004) planes49. The diffraction peaks of biomorphic TiO2 were not disturbed by the deposition of Ag nanoparticles as shown in Fig. 3. This shows that the Ag elements did not enter into the crystal lattice of TiO2 50.

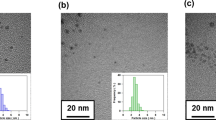

The detail morphology and microstructure of the biomorphic Ag-TiO2 was further investigated by TEM. From Fig. 4a, it can be clearly seen that the negative replica of TiO2 with nano-holes structure was well maintained after high calcination. The Ag nanoparticles were homogeneously deposited on the surface and to the side wall of nano-holes structure of biomorphic TiO2, which is in well agreement to the SEM results. The high-resolution transmission electron microscopy (HRTEM) image of the biomorphic Ag-TiO2 was shown in Fig. 4b to investigate the heterojunctions between Ag and biomorphic TiO2. It was observed that the lattice fringe with a space of 0.35 nm corresponds to the (101) lattice plane of anatase TiO2, while the interlayer space of 0.23 belonging to the (111) cubic face plane of Ag. Figure 4c shows the selected area electron diffraction (SAED) pattern of biomorphic Ag-TiO2. The diffraction rings clearly present the mixed phase of anatase TiO2 and cubic Ag. The diffraction rings indexed with (111) and (002) faces corresponds to the metallic Ag.

The surface area and porous structure of the biomorphic TiO2 and biomorphic Ag-TiO2 was determined by analysis of N2 adsorption/desorption isotherms as shown in Fig. 5. For both samples, a typical type IV isotherm with apparent hysteresis loops was detected in the relative pressure (P/Po) range of 0.45–1.0 (Fig. 5a). The upturn hysteresis loop confirms the existence of mesoporous structure of biomorphic TiO2 and biomorphic Ag-TiO2. The Brunauer-Emmet-Teller (BET) surface areas of biomorphic TiO2 and Ag-TiO2 were 33.0291 m²/g and 17.0921 m²/g, respectively. The lower surface area of the biomorphic Ag-TiO2 was due to the deposition of Ag nano-particles onto the surface of biomorphic TiO2. It has been previously shown that lower surface area of the three dimensional Ag-TiO2 nano-architecture was due to the deposition of Ag nano-particles which covered some mesopores and interstitial space of the TiO2 network49. The average pore diameters and the average pore volumes from the Barrett-Joyner-Halenda (BJH) desorption analysis for biomorphic TiO2 and Ag-TiO2 were 7.44 nm, 10.82 nm and 0.070231 cm³/g, 0.076065 cm³/g respectively. The pore size distribution curve in Fig. 5b confirm the mesopores.

Figure 6 depicts the UV-vis absorption spectra of the P25, biomorphic TiO2 and biomorphic Ag-TiO2. It can be seen that the commercial P25 shows a photoresponse in the ultraviolet region only and there is a very low absorption in the visible wavelength range. But, the biomorphic TiO2 with nano-holes structure shows a bit more visible response compared to the commercial P25 powder. Whereas, the deposition of Ag nanoparticles onto the surface as well as to the side wall of the nano-holes structure prominently increases the visible light absorption compared to both biomorphic TiO2 and P25. It has been shown theoretically that the more absorption of light in the visible wavelength range owing to the SPR originated from the Ag nanoparticles in the Ag-TiO2 samples51. Therefore, it is quite possible that the biomorphic Ag-TiO2 with nano-holes structure may implicate excellent photocatalytic activity due to the high absorption in the visible wavelength range.

The photocatalytic activities of the samples were evaluated by decomposing MB dye under UV-vis light irradiation, as shown in Fig. 7. The photocatalytic performances of biomorphic Ag-TiO2, biomorphic TiO2 and nonporous commercial powder P25 were measured under the same condition as shown in Fig. 7a. Here, the rate of change of concentration (C/Co) was calculated with respect to time under UV-vis light irradiation (where Co is the initial concentration of MB and C is the concentration at reaction time t). It can be clearly seen that the biomorphic Ag-TiO2 with nano-holes structure shows highest photocatalytic activity and completely degraded MB after 15 minutes. As it is apparent, the biomorphic TiO2 and P25 shows much lower photocatalytic activity than that of biomorphic Ag-TiO2. Moreover, the average decomposition rate of biomorphic Ag-TiO2 (0.50 min−1) was higher than that of biomorphic TiO2 (0.18 min−1) and P25 (0.07 min−1) as shown in Fig. 7b. The high-performance photocatalytic activity of biomorphic Ag-TiO2 may be attributed to the Schottky barriers which can be formed between Ag and biomorphic TiO2 with nano-holes and improves the electron-hole separation52. Another reason for the better photocatalytic performance of Ag-TiO2 with nano-holes structure is the enhanced LSPR intensity of Ag nanoparticles which in turn increase the absorption of light. The biomorphic TiO2 with nano-holes structure shows little photocatalysis of MB because pure TiO2 barely absorb visible light. The low performance of the P25 with high specific area (53 m2 g−1)53 was due to the absence of nano-holes structure compared to the biomorphic TiO2 and biomorphic Ag-TiO2. Therefore, the deposition of Ag nanoparticles on the surface of biomorphic TiO2 offer more active sites for the photocatalytic process.

Conclusion

We have successfully fabricated negative replica of biomorphic Ag-TiO2 with nano-holes structure from cicada wings by using a simple and low cost sol-gel ultrasonic method. The biomorphic Ag-TiO2 effectively inherited the negative structure of cicada wing after high calcination at 500 °C. The homogeneous dispersion of Ag nanoparticles onto the surface and inside the nano-holes structure of TiO2 enhanced the photocatalytic performance by degradation of MB in the UV-vis region, which can be attributed to the LSPR property of Ag nanoparticles and enhanced electron-hole separation. The biomorphic Ag-TiO2 showed higher photocatalytic activity compared to the biomorphic TiO2 and P25. Therefore, this simple synthetic method is expected to open up fabrication strategies of such nano-hole structure materials which can find important applications in environmental and energy technologies.

Experimental

Synthesis of biomorphic TiO2

Cicadas (Cryptotympana atrata Fabricius) were obtained from Shanghai Natural Wild-Insect Kingdom Co., Ltd. Analytical grade reagent, NaOH, AgNO3, NaBH4, absolute ethanol, titanium chloride(TiCl4), surfactant (TritonX-100) were provided by Shanghai chemical company. The cicada wings were firstly cleaned by water and ethanol three times each, and then dried in air. The cleaned wing were then pretreated by 8% NaOH solution and kept in water kettle for 3 hour at 40 °C. To prepare the precursor solution, firstly the 11 ml of deionized water was added with 35 ml of ethanol. After that 1 ml of TiCl4 was slowly added to the ethanol-water solution and keep at stirred for 1 h, while adding TritonX-100 dropwise in the precursor solution. The pretreated wings were then immersed carefully into the precursor solution and sonicated at room temperature for 2.5 h by high-intensity ultrasonic irradiation (20 kHz, 100 W cm−2). After ultrasonication, these wings were kept in the precursor solution for 5 h to solidify it, and then taken out, cleaned with ethanol and dried in air at room temperature. Finally, the wings were put on the glass slides and calcined at 500 °C for 2 h in air to eradicate the organic template, leaving behind biomorphic TiO2 with nano-holes structure. The schematic illustration for this synthetic process is shown in Fig. 8.

Synthesis of biomorphic Ag-TiO2

The 55 mg of biomorphic TiO2 was added to the 30 ml of AgNO3 (20 mM) solution and vigorously mixed on magnetic stirrer for 1 h. After that, the precipitation was separated from the solution and washed with ethanol three times. The obtained precipitation was then reacted with 200 NaBH4 solution, followed by a filtration and dried in air for 60 °C to get the biomorphic Ag-TiO2.

Characterization

The surface morphology of cicada wing, biomorphic TiO2 and biomorphic Ag-TiO2 were characterized by scanning electron microscopy (SEM; JSM-6700F, JEOL, Japan). X-ray diffraction patterns (XRD; CuKα, Bruker-AXS) with λ = 0.15406 nm of the samples were recorded from 10° to 80°. Transmission electron microscopy (TEM) images, high-resolution transmission electron microscopy (HRTEM) images and selected area electron diffraction (SAED) images were obtained on a JEOL JEM-2100F TEM. The specific surface area and pore size distribution of the samples were measured on a Micromeritics ASAP 2020 at 77 k. In the spectral range of 200 to 800 nm, the absorption spectra of the samples were measured on Varian Cary UV-vis-NIR spectrophotometer.

Photocatalytic degradation of MB

The photocatalytic degradation of MB was performed under the UV-vis light irradiation (Xenon lamp, PLS-SXE 300/300UV, 10A). The photocatalytic reaction was maintained at room temperature by using fixed cooling fan in the light source to avoid any thermal catalytic effect. 30 mg of the as-prepared samples were mixed in 30 ml of MB aqueous solution (30 mg/l) and kept on magnetic stirring for 30 min in the dark to achieve the adsorption-desorption equilibrium among water, MB and photocatalyst. After equilibrium, the reaction system was exposed to the UV-vis light to assess the photocatalytic degradation. After each 15 min, 3 ml of solution was taken out from the reaction system and centrifuged to get clear liquid. The absorption spectra of the supernatants were recorded on 25 lambda UV-vis spectrometer.

References

Ansari, S. A. & Cho, M. H. Growth of three-dimensional flower-like SnS2 on gC3 N4 sheets as an efficient visible-light photocatalyst, photoelectrode, and electrochemical supercapacitance material. Sustainable Energy & Fuels 1, 510–519 (2017).

Ansari, S. A., Ansari, S., Foaud, H. & Cho, M. H. Facile and sustainable synthesis of carbon-doped ZnO nanostructures towards the superior visible light photocatalytic performance. New Journal of Chemistry 41, 9314–9320 (2017).

Ansari, S. A., Ansari, M. O. & Cho, M. H. Facile and scale up synthesis of red phosphorus-graphitic carbon nitride heterostructures for energy and environment applications. Scientific reports 6, 27713 (2016).

Ansari, S. A., Khan, Z., Ansari, M. O. & Cho, M. H. Earth-abundant stable elemental semiconductor red phosphorus-based hybrids for environmental remediation and energy storage applications. RSC Advances 6, 44616–44629 (2016).

Ansari, S. A., Ansari, M. S. & Cho, M. H. Metal free earth abundant elemental red phosphorus: a new class of visible light photocatalyst and photoelectrode materials. Physical Chemistry Chemical Physics 18, 3921–3928 (2016).

Gao, M., Zhu, L., Ong, W. L., Wang, J. & Ho, G. W. Structural design of TiO2-based photocatalyst for H2 production and degradation applications. Catalysis Science & Technology 5, 4703–4726 (2015).

Sun, P. et al. Photocatalyst of organic pollutants decomposition: TiO2/glass fiber cloth composites. Catalysis Today 274, 2–7 (2016).

Ansari, S. A. & Cho, M. H. Highly visible light responsive, narrow band gap TiO2 nanoparticles modified by elemental red phosphorus for photocatalysis and photoelectrochemical applications. Scientific reports 6, 25405 (2016).

Zhang, X., Liu, Y., Lee, S. T., Yang, S. & Kang, Z. Coupling surface plasmon resonance of gold nanoparticles with slow-photon-effect of TiO2 photonic crystals for synergistically enhanced photoelectrochemical water splitting. Energy & Environmental Science 7, 1409–1419 (2014).

Etgar, L. et al. High efficiency quantum dot heterojunction solar cell using anatase (001) TiO2 nanosheets. Advanced Materials 24, 2202–2206 (2012).

Liu, J. et al. Slow Photons for Photocatalysis and Photovoltaics. Advanced Materials (2017).

Hayden, S. C., Allam, N. K. & El-Sayed, M. A. TiO2 nanotube/CdS hybrid electrodes: extraordinary enhancement in the inactivation of Escherichia coli. Journal of the American Chemical Society 132, 14406–14408 (2010).

Wang, Z.-S. et al. A highly efficient solar cell made from a dye-modified ZnO-covered TiO2 nanoporous electrode. Chemistry of Materials 13, 678–682 (2001).

Hensel, J., Wang, G., Li, Y. & Zhang, J. Z. Synergistic effect of CdSe quantum dot sensitization and nitrogen doping of TiO2 nanostructures for photoelectrochemical solar hydrogen generation. Nano letters 10, 478–483 (2010).

Hagfeldt, A., Boschloo, G., Sun, L., Kloo, L. & Pettersson, H. Dye-sensitized solar cells. Chemical reviews 110, 6595–6663 (2010).

Rawal, S. B., Bera, S., Lee, D., Jang, D. J. & Lee, W. I. Design of visible-light photocatalysts by coupling of narrow bandgap semiconductors and TiO2 : effect of their relative energy band positions on the photocatalytic efficiency. Catalysis Science & Technology 3, 1822–1830 (2013).

Roy, P., Berger, S. & Schmuki, P. TiO2 nanotubes: synthesis and applications. Angewandte Chemie International Edition 50, 2904–2939 (2011).

Li, W., Wu, Z., Wang, J., Elzatahry, A. A. & Zhao, D. A perspective on mesoporous TiO2 materials. Chemistry of Materials 26, 287–298 (2013).

Liu, H. et al. Hydrogen evolution via sunlight water splitting on an artificial butterfly wing architecture. Physical Chemistry Chemical Physics 13, 10872–10876 (2011).

Yang, X. Y. et al. Hierarchically porous materials: synthesis strategies and structure design. Chemical Society Reviews 46, 481–558 (2017).

Wang, Y. et al. Surface plasmon resonance of gold nanocrystals coupled with slow-photon-effect of biomorphic TiO2 photonic crystals for enhanced photocatalysis under visible-light. Catalysis Today 274, 15–21 (2016).

Zhu, S. et al. Fe2 O3/TiO2 photocatalyst of hierarchical structure for H2 production from water under visible light irradiation. Microporous and Mesoporous Materials 190, 10–16 (2014).

Zada, I. et al. Angle dependent antireflection property of TiO2 inspired by cicada wings. Applied Physics Letters 109, 153701 (2016).

Huang, Y. F., Jen, Y. J., Chen, L. C., Chen, K. H. & Chattopadhyay, S. Design for approaching cicada-wing reflectance in low-and high-index biomimetic nanostructures. ACS nano 9, 301–311 (2015).

Li, X. et al. Enhanced Light‐Harvesting and Photocatalytic Properties in Morph‐TiO2 from Green‐Leaf Biotemplates. Advanced Functional Materials 19, 45–56 (2009).

Zhou, H. et al. Artificial inorganic leafs for efficient photochemical hydrogen production inspired by natural photosynthesis. Advanced Materials 22, 951–956 (2010).

Parker, A. R., McPhedran, R. C., McKenzie, D. R., Botten, L. C. & Nicorovici, N. Photonic engineering. Aphrodite’s iridescence. Nature 409, 36–37 (2001).

Kwon, Y. W. et al. Flexible Near-Field Nanopatterning with Ultrathin, Conformal Phase Masks on Nonplanar Substrates for Biomimetic Hierarchical Photonic Structures. ACS nano 10, 4609–4617 (2016).

Vincent, J. F. & Wegst, U. G. Design and mechanical properties of insect cuticle. Arthropod structure & development 33, 187–199 (2004).

Xie, G. et al. The fabrication of subwavelength anti-reflective nanostructures using a bio-template. Nanotechnology 19, 095605 (2008).

Hong, S. H., Hwang, J. & Lee, H. Replication of cicada wing’s nano-patterns by hot embossing and UV nanoimprinting. Nanotechnology 20, 385303 (2009).

Zhang, G., Zhang, J., Xie, G., Liu, Z. & Shao, H. Cicada wings: a stamp from nature for nanoimprint lithography. Small 2, 1440–1443 (2006).

Zhang, X. et al. Integration of antireflection and light diffraction in nature: a strategy for light trapping. Journal of Materials Chemistry A 1, 10607–10611 (2013).

Hou, W. & Cronin, S. B. A review of surface plasmon resonance‐enhanced photocatalysis. Advanced Functional Materials 23, 1612–1619 (2013).

Rycenga, M. et al. Controlling the synthesis and assembly of silver nanostructures for plasmonic applications. Chemical reviews 111, 3669–3712 (2011).

Xia, Y., Xiong, Y., Lim, B. & Skrabalak, S. E. Cover Picture: Shape‐Controlled Synthesis of Metal Nanocrystals: Simple Chemistry Meets Complex Physics? Angewandte Chemie International Edition 48, 1–1 (2009).

Wu, M. et al. High photocatalytic activity enhancement of titania inverse opal films by slow photon effect induced strong light absorption. Journal of Materials Chemistry A 1, 15491–15500 (2013).

Liu, J. et al. Tracing the slow photon effect in a ZnO inverse opal film for photocatalytic activity enhancement. Journal of Materials Chemistry A 2, 5051–5059 (2014).

Sung-Suh, H. M., Choi, J. R., Hah, H. J., Koo, S. M. & Bae, Y. C. Comparison of Ag deposition effects on the photocatalytic activity of nanoparticulate TiO2 under visible and UV light irradiation. Journal of Photochemistry and Photobiology A: Chemistry 163, 37–44 (2004).

Naoi, K., Ohko, Y. & Tatsuma, T. TiO2 films loaded with silver nanoparticles: control of multicolor photochromic behavior. Journal of the American Chemical Society 126, 3664–3668 (2004).

Chen, S. & Carroll, D. L. Synthesis and characterization of truncated triangular silver nanoplates. Nano letters 2, 1003–1007 (2002).

Cozzoli, P. D. et al. Photocatalytic synthesis of silver nanoparticles stabilized by TiO2 nanorods: A semiconductor/metal nanocomposite in homogeneous nonpolar solution. Journal of the American Chemical Society 126, 3868–3879 (2004).

Tada, H., Ishida, T., Takao, A. & Ito, S. Drastic enhancement of TiO2-photocatalyzed reduction of nitrobenzene by loading Ag clusters. Langmuir 20, 7898–7900 (2004).

Liu, J. et al. Reversibly phototunable TiO2 photonic crystal modulated by Ag nanoparticles’ oxidation/reduction. Applied Physics Letters 98, 023110 (2011).

Morikawa, J. et al. Nanostructured Antireflective and Thermoisolative Cicada Wings. Langmuir 32, 4698–4703 (2016).

Nishimoto, S. & Bhushan, B. Bioinspired self-cleaning surfaces with superhydrophobicity, superoleophobicity, and superhydrophilicity. Rsc Advances 3, 671–690 (2013).

Mao, L. et al. Sonochemical fabrication of mesoporous TiO2 inside diatom frustules for photocatalyst. Ultrasonics sonochemistry 21, 527–534 (2014).

Zhu, S. et al. A simple and effective approach towards biomimetic replication of photonic structures from butterfly wings. Nanotechnology 20, 315303 (2009).

Zhang, W. et al. Three-dimensional ordered macroporous nano-architecture and its enhancing effects on Raman detection sensitivity for Eosin Y molecules. Materials & Design 119, 456–463 (2017).

Lu, R. et al. A 3D-SERS substrate with high stability: Silicon nanowire arrays decorated by silver nanoparticles. CrystEngComm 15, 6207–6212 (2013).

Li, J., Xu, J., Dai, W.-L. & Fan, K. Dependence of Ag deposition methods on the photocatalytic activity and surface state of TiO2 with twistlike helix structure. The Journal of Physical Chemistry C 113, 8343–8349 (2009).

Chen, Z. et al. Inverse opal structured Ag/TiO2 plasmonic photocatalyst prepared by pulsed current deposition and its enhanced visible light photocatalytic activity. Journal of Materials Chemistry A 2, 824–832 (2014).

Yang, Q. et al. Hierarchical TiO2 photonic crystal spheres prepared by spray drying for highly efficient photocatalysis. Journal of Materials Chemistry A 1, 541–547 (2013).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (no. 51572169, no.51772187), Shanghai Rising-Star Program (16QA1402400), Shanghai Science and Technology Committee (15ZR1422400, 16520710900 and 17ZR1441400), and the National Key Research and Development Program of China (No. 2016YFB0701201). Supported by the 111 Project (Grant No. B16032).

Author information

Authors and Affiliations

Contributions

Imran Zada, Wang Zhang contributed equally to this work and collected the experimental data. Wangshu Zheng and Yuying Zhu attended the preparation of the materials. Zhijian Zhang, Jianzhong Zhang and Di Zhang contributed to the result analysis. Muhammad Imtiaz and Waseem Abbas contributed to the writing of manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zada, I., Zhang, W., Zheng, W. et al. The highly efficient photocatalytic and light harvesting property of Ag-TiO2 with negative nano-holes structure inspired from cicada wings. Sci Rep 7, 17277 (2017). https://doi.org/10.1038/s41598-017-17479-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-17479-8

This article is cited by

-

Modification of the Properties of Titanium Carbide MXene by Ag Doping via Ion Implantation for Quantum Dot-Sensitized Solar Cell Applications

Journal of Electronic Materials (2024)

-

Plasmon enfolded TiO2 hierarchical photoanode: fabrication and the performance evaluation as liquid-based dye-sensitized solar cell

Journal of Materials Science: Materials in Electronics (2022)

-

Synthesis of Ag2O Coated TiO2 Nanoparticles by Sonochemically Activated Methods for Enhanced Photocatalytic Activities

Topics in Catalysis (2020)

-

Facile in-situ growth of Ag/TiO2 nanoparticles on polydopamine modified bamboo with excellent mildew-proofing

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.