Abstract

The preparation of a specially modified titanium dioxide/zirconium oxide (TiO2/ZrO2) composite and its subsequent application using a unique method are described. Specifically, after the whole surface of the composite was covered with a very thin layer of water, solar light was irradiated onto it. This method is unique because the reduction of CO2 was performed in air (gas phase). The light source was real solar light. In this study, novel composites comprising nanometre-sized TiO2 and micrometre-sized zirconium oxide (ZrO2) increased the amount of reduced CO2. And, suitable weight ratio of TiO2/ZrO2 was 6/4-5/5. Thin water layer on the composite offered catalytic-reaction medium, and, catalytic-reaction cite existed at interface of TiO2 and ZrO2 particles, and, this reaction was catalytic reaction enhanced by photocatalytic effect. A large amount of reduced products (maximum: approximately 300 μmol/(g·300 s) of formaldehyde and methanol)was obtained under only 300 s of irradiation of solar light.

Similar content being viewed by others

Introduction

The CO2 concentration in the atmosphere is gradually increasing. Temperature of atmosphere is rising continuously1. Research into methods for converting CO2 into low-molecular-weight organic compounds is extremely important because this research can not only reduce the concentration of CO2 in the atmosphere but also can convert the CO2 into useful organic compounds. Reported methods for reducing CO2 include the use of photo-catalysts or photo-electrodes2,3. Sato et al. succeeded in converting CO2 into organic compound (formic acid (HCOOH)) under irradiation of solar simulated light4. This report was probably most advanced one in this field on that time (2011). But, the reduced product was small(approximately 1 μmole/4 h cm2 under irradiation intensity 1 sun (AM 1.5)). In recent times, many reports in regard to converting CO2 into organic compounds with special photo-catalysts under solar light or visible light irradiation have been proposed5,6,7,8,9. However, their reduced products were small, too. Moreover, there are excellent review literatures10,11,12. With regarded to large reaction products, Zhao et al. reported that total organic carbon (TOC) yield of N-TNT(Nitrogen-doped TiO2 nanotube) 500 (post-heating 500 °C) was 1453.0 μmol/g-cat. in 100 ml 0.1 N NaOH aqueous solution with a visible-light of 500 W tungsten-halogen lamp13.

And, Wang et al. reported Pt-TiO2 nanostructured films via versatile gas-phase deposition method (unique one-dimensional structure of TiO2 single crystals coated with ultrafine Pt nanoparticles (0.5–2 nm)) and maximum Methane (CH4) yield of 1361 μmol/g-cat./h with 400 W-Xe lamp (accumulated intensity of 19.6 mW/cm2 in the effective UV range (250–388 nm))14.

On the other hand, in catalytic field, commercial methanol producing process have established, the process is commercially in operation with Cu/ZnO/Al2O3 or Cu/ZnO/Cr2O3 catalyst by using of CO2-H2 system under high temperature and high pressure. CO2 and H2 are those obtained by another industrial processes.

Millar et al. reported importance regarding to interface of particles that constructed catalyst15,16. However, on the catalytic fields, there are no ideas of using CO2 in the air and of using solar light as energy source.

Therefore, no report in which a very large amount of organic compounds has been generated by reducing CO2 with inexpensive catalyst in air under irradiation of solar light at room temperature and atmospheric pressure in both photocatalytic and catalytic fields is founded.

The aim of this research is obtaining large amount of low-molecular- weight organic compounds by the original method under irradiation of real solar light.

In relation to this research, Fujishima et al. reported the photo-catalyst effect of TiO2 17. Specifically, irradiation with UV light generates electrons (e−) and holes (h+) in TiO2. The electrons provide the reduction driving force, and the holes provide the oxidation driving force. In 1979, Inoue and Fujishima et al. reported the reduction of CO2 to formaldehyde (HCHO) and methanol (CH3OH) under irradiation with high-energy UV light using a TiO2 photocatalyst18. Later, Sato et al. reported the generation of H2 and O2 using wet Pt/TiO2 under irradiation by light with energy equal to the band-gap energy of TiO2 (1980)19,20. Moreover, they demonstrated that H2 and O2 were generated by the splitting of H2O added. Author also started this study to obtain desirable result by the photocatalytic reaction.

In this report, following items were studied.

First: Ascertaining whether the thin water layer on the surface of composites is essential.

Second: Consideration of preparing method (Effect of press on preparing method of composites)

Third: Dependence of quantity of reduced products on TiO2/ZrO2 ratios. (TiO2/ZrO2 ratios were changed between 10/0 and 0/10).

Forth: Measurements of quantity of reduced products under irradiation of real solar light (at TiO2/ZrO2 = 1/1).

Fifth: Proving the water layer on the surface of composites.

Sixth: Discussion regarding with macro mechanism (hypothesis) through which the large quantity reduced product can be obtained.

Experiments

The author devised composites consisting of nanometre-sized TiO2 particles and micrometre-sized zirconium oxide (ZrO2) particles and applied them using an original method. First, particles or molecules adsorbed onto the composite surface were removed by the elimination of static electricity using an ion blower. Next, after the composites were cooled in a refrigerator for more than 20 h, they were placed into a transparent gas-barrier plastic bag with high-temperature and high-humidity room air.

Cooling in a refrigerator enabled the whole surface of the composite to be covered with a very thin layer of water via the condensation of water vapour in the air to reproduce Sato’s condition (wet condition). The reduction of CO2 did not occur until the thin water layer condensed onto the composite’s surface. This method is unique because the reduction of CO2 is performed in air (or more precisely, in the air phase via a very thin water layer). Moreover, this method increases the efficiency of the light irradiation because real solar light is directly irradiated onto the composites.

In this study, the TiO2/ZrO2 composites greatly increased the amount of reduced CO2 product. The composite exhibited a particulate morphology. In this report, CO2 was reduced under real solar light without the use of platinum as a co-catalyst.

The new photo-catalyst composites are composed of two types of inorganic compounds (a,b) that were combined and pressed together. The first inorganic compound (a) is characterized by nanometre-sized anatase TiO2 photo-catalyst particles, and the other inorganic compound (b) is composed of micrometre-sized ZrO2 particles. The weight ratio (TiO2/ZrO2) of the composites is mainly 1:1. The use of such a large amount of additive (ZrO2) is unique. After (a) and (b) were pressed to form the composites (c), the composites (c) were scattered onto an electric conducting material such as a copper plate. The copper plate can facilitate the transfer of electrons and holes from one composite to the other. Then, the composites and Cu plate were held in a glass laboratory dish (the glass laboratory dish containing the composites and Cu plate is hereafter referred to as the test unit).

Figure 1 shows SEM image of the composite with water vapour condensed on its surface and with the thin water layer evaporated away (SEM: JAPAN ELECTRONIC Co. Ltd., JSM-5310LV). Image “a” shows that numerous nanometre-sized TiO2 particles are present on the top layer of the composite, and the core of the composite is composed of micrometre-sized ZrO2 particle. Image “b” shows a higher-magnification (20,000×) SEM image of the surface of the composites shown in image “a” of Fig. 1. Pores of various sizes are present in the nanometre-sized TiO2 layer. The CO2 in the air can penetrate the pores and reach the water layer existing at the surface of the ZrO2 particles.

Magnification SEM image of the composite. (a) Low-magnification SEM image of the composite. This image is a low-magnification (2000×) micrograph of typical composite particle. (b) High-magnification SEM image of the composite. This image is a high-magnification (20,000×) image of the surface shown in “a” of Fig. 1.

Figure 2 shows a photograph of the experiment under irradiation by real solar light. Experiments were performed during the Japanese summer season, which provides high temperatures and high humidity. During irradiation, the test unit was placed into a transparent gas-barrier plastic bag with 1000 ml of air. The bag transfers solar light and contains the produced organic compounds. The bag allows both the concentration of organic compounds and the inner volume to be measured after solar-light irradiation. After irradiation, the concentration of formaldehyde and methanol in the bag was measured using gas-detecting tubes.

Photograph taken during the experiment. (c) Gas-barrier plastic bag; (d) test unit; (e) composites (TiO2:ZrO2 = 1:1); (f) solar-energy-detecting instrument (UNIMETER); (g) solar-energy-detecting sensor. The composites in the test unit were irradiated through the gas-barrier plastic bag. The only light source was real solar light.

A gas-barrier plastic bag through which CO2 molecules can penetrate but not oxygen (O2) or nitrogen molecules (N2) was used. When the amount of CO2 in the bag is decreased by the reduction of CO2, the CO2 in the air outside of the bag diffuses into the bag because of the concentration gradient. Therefore, the concentration (in ppm) of the total reduced products exceeding the CO2 concentration in the atmosphere (approximately 400 ppm) is not contradictory.

The experiments were conducted in Funabashi in the Chiba prefecture of Japan (lat. 35° 70′ N and long. 140° 02′ E).

Additionally, the author performed several weight measurements 5–8 min after removing the test unit from the refrigerator. The weight of the test unit increased by 70–110 mg because of the condensation of water vapour (ambient air conditions: 30.9 °C in temperature and 65% in humidity −30.0 °C in temperature and 90% in humidity).

Results

In the subsequent description, the term “dry conditions” refers to experiments in which the test unit was not cooled in a refrigerator, whereas the term “wet conditions” refers to experiments in which the test unit was cooled in a refrigerator, resulting in the formation of a thin water layer on the composites. The term “the dry conditions” refers to condition that the formation of a thin water layer on the composites was not generated.

Table 1 show the experimental conditions and Table 2 show the experimental results of experimental No. 1-7. And, Table 3 show the experimental conditions and Table 4 show the experimental results of experimental No. 8-25. Hence, Tables 1 and 2 make a pair, and, Tables 3 and 4 also make a pair.

-

The results in Group A of Tables 1 and 2 show that no reduced product was obtained under dry conditions. By contrast, reduced products were obtained under wet conditions. Therefore, wet conditions are essential.

Moreover, Group A shows the following results

-

Under dry conditions with TiO2 only, no products reduced by the photo-catalyst were detected (Tables 1 and 2, No. 1).

That is, reduction driving force of TiO2 photo-catalyst is not enough to reduce the CO2.

-

Under wet conditions with TiO2 only, reduced products were probably obtained by a catalytic- reaction (Tables 1 and 2, No. 2).

-

Under dark (no light irradiation) and wet conditions, the TiO2/ZrO2 composite produced methanol, which is clearly a catalytic- reaction (Tables 1 and 2, No. 4).

-

Tables 1 and 2, No. 5 shows result of blank test, that is, formaldehyde and methanol were not generated from the plastic bag under irradiation of solar light.

On the amount of reduction products, very large deference was showed between No. 6 and No. 7. No. 6 was prepared with strong press during mixing, whereas, No. 7 was prepared with no press (only mixing). On the surface of composites with press during mixing, large amount of interface between TiO2 particles and ZrO2 ones are formed, whereas, in the case of no press, the interface exist at only contact point between TiO2 particles and ZrO2 ones. Therefore, possible explanation is that reaction cites exist at the interface. And, this result supports that reaction of this research is catalytic one.

Incidentally, standard method of this report is strong press during mixing.

(c) Dependence of quantity of reduced products on TiO2/ZrO2 ratios

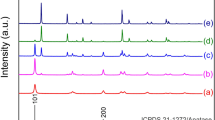

Figure 3 shows plots of formaldehyde and methanol products (μmol/(g·300 s)) against ZrO2 weight % in the TiO2/ZrO2 composite that correspond to the results in Group C of Tables 3 and 4. Figure 3 shows volcano plots, and, peak was at TiO2/ZrO2 = 6/4−5/5. In left side of the peak, reduced products increased with increasing of ZrO2, and, in right side of the peak, decreased with decreasing of TiO2. This shows that activating effect of ZrO2 increased in left side of the peak, by contrast, photocatalytic effort of TiO2 decreased in right side of the peak. (Band gap of ZrO2 is 5.0 eV, whereas, maximum energy of solar light is equal to 4.1 eV (1240/300 nm in wavelength). Band gap of ZrO2 is larger than maximum energy of solar light. Therefore, photocatalytic effect of ZrO2 does not occur).

Figure 3 Moreover, interface of TiO2 particle and ZrO2 one increases with increasing of ZrO2. Increasing of interface increased the reaction products.

This result agrees with the description of b) in this section

Group D of Tables 3 and 4 show the results obtained when the composites were used. The results indicate that CO2 was reduced under real solar light and that formaldehyde and methanol were obtained in every experiment. A large amount of reduced products (maximum: approximately 300 μmol/(g·300 s) of formaldehyde and methanol)was obtained. These reaction also is catalytic one at the interface of TiO2 particle and ZrO2 one, because composites were prepared with author’s standard method (mix and press). And, Turnover number (reduction products (mole/h)/catalyst (mole)) was equal to 1.7.

Figure 4 shows plots of formaldehyde and methanol products (μmol/(g·300 s)) as a function of the irradiation intensity of solar light (mW/cm2). These plots reveal that the formaldehyde yield increased rapidly with increasing irradiation energy of solar light. By contrast, the amount of methanol gradually increased with increasing irradiation intensity of solar light. This shows that CO2 reducing reaction was enhanced strongly by the photocatalytic effort.

Figure 4 (e) Evidence of the generation of the thin water layer

In this report, thin water layer on the surface of composites is most important.

As this water layer is very thin, transparent, liquid and not-flat, visualization of water layer was difficult. Thus, below mentioned considerations were performed.

-

As described at the end part of the Experiments section, the weight of the test unit increased 70–110 mg, 5–8 min after being removed from the refrigerator. This weight gain certainly includes water-vapour condensation on the surfaces of the composites, the Cu plate and the glass laboratory dish. However, this weight gain also provides indirect evidence of the formation of a thin condensed water layer on the composites because the surface area of the composites is markedly larger than the surface areas of the other materials; i.e., this weight gain would be dominated by the weight gain on the composite surface.

-

Electric conductivities of two kinds of composites were measured under dry and wet conditions.

The composites were TiO2/ZrO2/NaCl (weight ratio) = 4.5/4.5/1 and 4/4/2.

In the case of wet condition, each composite (0.2 g) was scattered in glass laboratory dish, held in the refrigerator for 20–24 h. They were measured in atmosphere 5 min after being removed from refrigerator.

Atmosphere conditions were 26–28 °C in temperature and 73–77% in humidity, respectively. They were measured by HORIBA COMPACT CONDUCTIVITY METER B-771.

The measuring results were

-

TiO2/ZrO2/NaCl = 4.5/4.5/1: conductivity 80 μS (atmosphere: 27.9 °C 73%)

-

TiO2/ZrO2/NaCl = 4.5/4.5/1: conductivity 95 μS (atmosphere: 27.8 °C 74%)

-

TiO2/ZrO2/NaCl = 4/4/2: conductivity 160 μS (atmosphere: 26.1 °C 76%)

-

TiO2/ZrO2/NaCl = 4/4/2: conductivity 250 μS (atmosphere: 27.8 °C 77%)

In contrast to these, in the dry condition, no conductivities of two kinds of composites were detected (electric conductivities were 0 μS).

Therefore, in the case of wet condition, surface of composites were covered with continuous water layer by condensation of water vapour, NaCl dissolved and dissociated in the water layer. Then, the conductivity was generated. This result shows existence of the water layer on the surface of composites.

-

If the water layer is not formed, the TiO2/ZrO2 composite’s surface is dry. As dry TiO2 photo-catalyst particles exhibit only strong oxidation activity, no reduced products are produced under UV light irradiation. (Author dispose gas in the bag after the formaldehyde and methanol were returned to CO2 by the oxidation effect of dry TiO2 particles.) But large amount of reduced products actually generated. This also evidences the existing of water layer on the surface of the composites by the condensation of water vapour.

(f) The role of ZrO2

ZrO2 have affinity to both acid and base21. Further, ZrO2 strongly support for hydrogenation of CO and CO2 as a carrier22,23,24,25. Therefore, ZrO2 provably have moderate adsorption force with carbonyl group. And, ZrO2 probably adsorbs carbonyl group on the surface physically and transport adsorbing species to the interface of TiO2 particle and ZrO2 one.

It was shown from Fig. 3 that adding of ZrO2 largely increased the reduced products. From these results, the use of ZrO2 was essential for obtaining large amounts of reduced products.

The measuring results were

Discussion

CO2 molecules dissolve in the thin layer of water on the composites. Part of the dissolved CO2 in the thin water layer generates carbonic acid26 (equation (1)):

The equilibrium constant (Kh) for this reaction is small (1.7 × 10−3 at 25 °C). Furthermore, H2CO3 dissociates, as described by equations (2) and (3)27,28:

where pK*a1 and pKa2 are the apparent acid-dissociation constant and acid-dissociation constant, respectively.

The reaction formulas that include CO3 2−, HCHO and CH3OH are shown as equations (4) and (5); the standard electrode potentials E0 are also shown for these equations29:

The standard electrode potential E0 is related to the standard Gibbs energy transition by following equation:

In equation (6), E0 is positive; therefore, ∆G0 is negative because nF is positive. As ∆G0 is negative, the reactions in equations (4) and (5) proceed towards the right to achieve equilibrium if the energy exceeds the activation energy. Catalysts are known to remarkably decrease the activation energy. Thus, equations (4) and (5) through which carbonic ions are reduced are not photocatalytic but catalytic reaction.

CO3 2− is converted into HCHO and CH3OH; then, HCHO and CH3OH volatilize from the thin water layer. As the equilibrium (equations (4) and (5)) is disrupted, equations (4) and (5) proceed towards the right to maintain equilibrium, thereby decreasing the concentration of CO3 2−. To maintain the equilibria of equations (1), (2) and (3), CO2 dissolves and dissociates and new CO3 2− is generated. The generation of HCHO and CH3OH therefore continues.

These reactions together form a chain reaction, and the reaction from volatilization to the next volatilization is cyclic. Moreover, the thin water layer accelerates this cycle by the facile volatilization of HCHO and CH3OH. After the cycle completes, the next cycle continues until the water layer disappears. A large amount of reduced products are obtained. In equation (3), the CO3 2−(aq) concentration is extremely small. However, the aforementioned cyclic reaction can compensate for the low concentration of CO3 2−.

Author calculated vapour pressure (p) of formaldehyde and methanol by Antoine’s formula.

(Vapour pressure of water: p = 9.2 Torr at 10 °C and 17.5 Torr at 20 °C)30

These results show a relation of formaldehyde > methanol > water.

This result (formaldehyde > ethanol) was in agreement with order of the quantity of reduced products (formaldehyde > ethanol).

The solar light that reaches ground is greater than 300 nm in wavelength. The TiO2 photo-catalyst absorbs light less than 380 nm in wavelength. Therefore, the available wavelength range is only 300–380 nm. The energy of the light in this range is estimated to be approximately 3–4% of the entire solar energy.

However, solar energy of 3–4% is useful. Both e− and h+ are generated by the TiO2 photo-catalyst.

In this report, the author used only TiO2, not Pt/TiO2. Therefore, the reaction schemes are based on the report of Fujishima et al.17:

At oxidation sites on the TiO2 surface: H2O + 2 h+ → 1/2 O2 + 2H+

At reduction sites on the TiO2 surface: 2 e− generate the reduction driving force

H+ and e− can be used as those in equation (4) and (5).

Reduction driving force of electron generated by TiO2 photo-catalyst is not enough to reduce the CO2 directly. However, as the reduction driving force (−0.52 eV with respect to SHE31,32) is stronger than that of normal electrons, and, high energy e− ions can move to the interface of TiO2 particle and ZrO2 one. And, the catalytic reducing reaction can be enhanced by the strong reduction driving force of e− ions at the interface. Figure 4 showed that products yield of formaldehyde and methanol largely increased with increasing irradiation intensity of solar light. Increasing of irradiation intensity offers increasing numbers of high energy electron, thus, catalytic reducing reaction was enhanced.

From results and discussion, possible macro mechanism is following

-

1.

Dissolve and dissociate of CO2 in air into the thin water layer on the surface of composite, and generation of CO3 2− ions in the thin water layer.

-

2.

Physical adsorbing of CO3 2− ion to the ZrO2 surface.

-

3.

Movement of adsorbing species to the interface of TiO2 particle and ZrO2 one.

-

4.

Catalytic reducing reaction of adsorbing species at the interface.

High energy e− generated by TiO2 photocatalytic effect strongly accelerates the catalytic reducing reaction.

-

5.

Desorption of reduced products (low-molecular-weight organic compounds) from the interface into thin water layer.

-

6.

Evaporation of reduced products (low-molecular-weight organic compounds) from the water thin layer into air.

-

7.

Repeating of 1–6.

Conclusion

In this study, the thin water layer noted by Sato et al. splits to provide H+ ions because of the TiO2 photo-catalyst and provides a reaction medium for the catalytic reduction of CO2.

Thin water layer on the composite surface (wet condition) is essential, and, author’s method is catalytic reaction enhanced by the TiO2 photo-catalyst. This method is new approach upon which nobody could hit. Moreover, the fact that a large amount of reduced products was obtained from CO2 and H2O in air under irradiation of only real solar light at room temperature and atmosphere pressure is a novel and important finding.

Methods

Preparation of the composites (c)

In the case of TiO2/ZrO2 = 1/1, procedure is following.

First, 0.5 g of nanometre-sized anatase TiO2 particles (a) (TAYKA Co. Ltd., AMT100, nominal particle size: 6 nm) and 0.5 g of special-grade ZrO2 particles (b) (KANTO KAGAKU Co. Ltd., purity: 99.9%, particle size: 10–15 μm) were placed into a small ceramic pot and mixed uniformly. They were then forcefully pressed and agglomerated at room temperature to form the composites (c).

Experimental procedure

Next, 0.2 g of the composites (c) was scattered uniformly onto a copper plate, which was placed in a glass laboratory dish (inner diameter: 56 mm). The assembly with (c) scattered on the Cu plate in a glass laboratory dish is referred to as the test unit.

Initially, particles or molecules adsorbed onto the composites surface were removed by eliminating static electricity using an ion blower (AZ ONE Co. Ltd., Ion Blower AS-18). The blowing time was 1 h in the strong-wind mode. (Without the use of the ion blower, the test unit must be kept in a refrigerator for 2–3 days).

After the test unit was kept for more than 20 h in a refrigerator (inner temperature of the refrigerator: 1–5 °C), it was removed and placed into a transparent gas-barrier plastic bag (OKURA KOGYO Co. Ltd., OE-4, 200 × 300 mm2). The bag was heat-sealed at its entrance. Urethane tape (1 × 1 cm2) was adhered to the outside surface of the bag. After the air in the bag was removed using a plastic syringe, new air was injected into the bag. The needle of the syringe was inserted though the urethane tape to avoid leaving a small hole after the needle was removed. The inner volume of the bag was 1000 ml. The bag was then placed on the ground facing the sun.

The injected air was at a sufficient temperature and humidity. With the using of 0.2 g of the composites (c), the desired temperature and humidity were approximately 30 °C and 60–80%, respectively. Too much quantity of water layer by condensation of water vapour considerably decreased the reduced products, for instance, in the case of 95–100% in humidity.

After irradiation by real solar light through the bag for 0.5 h or 10 min or 300 s, the concentrations (ppm) of formaldehyde and methanol were measured by a gas-detecting tube (GASTEC Co. Ltd., tube No. 91 M (measuring range: 8–20 ppm, 20–2000 ppm, and 2000–6400 ppm; three measuring ranges were available by altering the suction volume) and Tube No. 111L (measuring range: 20–40 ppm and 40–1000 ppm; two measuring ranges are available by altering the suction volume)). The tubes were inserted one by one thorough the plastic tape adhered to the outside surface of the bag, and the concentrations were measured; after the tubes were removed, the remaining hole was immediately sealed with another piece of tape. The inner volume of the bag was measured by extracting the gas with the plastic syringe. The measured concentrations (ppm) of both formaldehyde and methanol were then corrected for temperature and expressed in terms of μmol/g:

where, c is the gas concentration (ppm), V is the inner volume after irradiation (ml), and g is the mass of composite (c) used (g).

The intensity of the UV light (mW/cm2) with a wavelength of 365 nm was measured using a UNIMETER (USHIO Co. Ltd., UIT-201 and UVD-365PD) during the irradiation of solar light during each experiment; the measurements were performed near the point where the composites were placed in the bag. The intensity was measured every 5 min (Experiment Nos 1–4 and Nos 17–25) or every 1 min (Experiment Nos 5–16). In the case of experiment Nos 17–25, the intensity was measured at the start and the end of irradiation. And, average of each experiment was calculated.

References

Medhaug, I., Stolpe, M. B., Fischer, E. M. & Knutti, R. Reconciling controversies about the ‘global warming hiatus’. Nature 545, 41–47 (2017).

Iizuka, K., Wato, T., Miseki, Y., Saito, K. & Kudo, A. Photocatalytic reduction of carbon dioxide over Ag cocatalyst-lorded ALa4Ti4O15 (A = Ca, Sr, and Ba) using water as a reducind reagent. J. Am. Chem.Soc. 133, 20863–20868 (2011).

Deguchi, M., Yotsuhashi, S., Hashiba, H., Yamada, Y. & Ohkawa, K. Enhanced capability of photoelectrochemical CO2 conversion system using an AlGaN/GaN photoelectrode. Jpn.J. Appl. Phys. 52, 08JF07-1-5 (2013).

Sato, S. et al. Selective CO2 conversion to formate conjugated with H2O oxidation utilizing semiconductor/complex hybrid photocatalysts. J. Am. Chem. Soc. 133, 15240–15243 (2011).

Li, X. et al. Adsorption of CO2 on heterostructure CdS(Bi2S3)/TiO2 nanotube photocatalysts and their photocatalytic activities in the reduction of to methanol under visible light irradiation. Chem. Eng. J. 180, 151–158 (2012).

Tahir, M., Tahir, B. & Amin, N. A. S. Gold- nanoparticle-modified TiO2 nanowires for plasmon- enhanced photocatalytic CO2 reduction with H2 under visible light irradiation. Appl. Surf. Sci. 356, 1289–1299 (2015).

Sim, L. C., Leong, K. H., Saravanan, P. & Ibrahim, S. Rapid thermal reduced graphene oxide/Pt-TiO2 nanotube arrays for enhanced visible-light-driven photocatalytic reduction of CO2. Appl. Surf. Sci. 358, 122–129 (2015).

Ong, W.-L., Tan, L.-L., Chai, S.-P. & Yong, S.-T. Heterojunction engineering of graphitic carbon nitride (g-C3N4) via Pt loading with improved daylight-induced photocatalytic reduction of carbon dioxide to methane. Dalton Trans. 44, 1249–1257 (2015).

Wang, W., Xu, D., Cheng, B., Yu, J. & Jiang, C. Hybrid carbon@TiO2 hollow spheres with enhanced photocatalytic CO2 reduction activity. J.Mater.Chem. A. 5, 5020–5029 (2017).

Low, J., Cheng, B. & Yu, J. Surface modification and enhanced photocatalytic CO2 reduction performance of TiO2: a review. Appl. Surf. Sci. 392, 658–685 (2017).

Nikokavoura, A. & Trapalis, C. Alternative photocatalysts to TiO2 for the photocatalytic reduction of CO2. Appl. Surf. Sci. 391, 149–174 (2017).

Yuan, L. & Xu, Y.-J. Photocatalytic conversion of CO2 into value –added and renewable fuels. Appl. Surf. Sci. 342, 154–167 (2015).

Zhao, Z., Fan, J., Wang, J. & Li, R. Effect of heating temperature on photocatalytic reduction of CO2 by N-TiO2 nanotube catalyst. Catalysis Communications. 21, 32–37 (2012).

Wang, W.-N. et al. Size and Structure Matter: Enhanced CO2 protoreduction efficiency by size-resolved ultrafine Pt nanoparticles on TiO2 single crystals. J.Am.Chem.Soc. 134, 11276–11281 (2012).

Graeme, J., Millar, G. J., Colin, H. & Rochester, C. H. Evidence for the Adsorption of Molecules at Special Sites located at Copper/Zink Oxide Interfaces Part2.-A fourier-transform infrared spectroscopy study of Methanol adsorption on reduced and oxidised Cu/ZnO/SiO2 catalysts. J.Chem.Soc.Faraday Trans. 88(15), 2257–2261 (1992).

Millar, G. J. & Rochester, C. H. A combined temperature-programmed reaction spectroscopy and fourier-transform infrared spectroscopy study of CO2-H2 and CO-CO2-H2 interactions with model ZnO/SiO2,Cu/SiO2 and Cu/ZnO/SiO2 Methanol-synthesis catalysts. J.Chem.Soc. Faraday Trans. 88(14), 2085–2093 (1992).

Fujishima, A. & Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 238, 37–38 (1972).

Inoue, T., Fujishima, A., Konishi, S. & Honda, K. Photoelectrocatalytic reduction of carbon dioxide in aqueous suspensions of semiconductor powders. Nature 277, 637–638 (1979).

Sato, S. & White, J. M. Photodecomposition of water over Pt/TiO2 catalysis. Chem.Phys.Lett. 72, 83–86 (1980).

Ohtani, B. Revisiting the original works related to titania photocatalysis: A review of papers in the early stage of photocatalysis studies. Electrochemistry 82(6), 14–425 (2014).

Xu, B.-Q., Yamaguti, T. & Tanabe, K. Acid-base bifunctional behaviour of ZrO2 in dual adsorption of CO2 and NH3. Chem. Lett., 1663–1666 (1988).

Iizuka, T., Tanaka, Y. & Tanabe, K. Hydrogenation of CO and CO2 over Rhodium catalysts supported on various metal oxides. J.Catal. 76, 1–8 (1982).

Tsunoda, T., Ogasawara, H., Komiyama, M., Ozawa, S. & Ogino, Y. Alcohol formation in CO hydrogenation over supported Rhenium. Chem. Lett., 819–822 (1981).

Ichikawa, M. Catalysis by supported metal crystallites from carbonyl clusters. Catalytic ethanol synthesis from CO and H2 under atmospheric pressure over supported Rhodium crystallites prepared from Rh carbonyl clusters deposited on TiO2, ZrO2, and La2O3. Bull. Chem. Soc.Jpn. 51(8), 2273–2277 (1978).

Lisitsyn, A. S., Kuznetsov, V. L. & Yermakov, Y. I. Hydrogenation of carbon monoxide, Catalysis prepared by pyrolysis of Co2(CO8) on various oxide supports. React. Kinet. Catal. Lett. 14(4), 445–450 (1980).

Welch, M. J., Lipton, J. F. & Seck, J. A. Tracer studies with radioactive oxygen-15. Exchange between carbon dioxide and water. J. Phys.Chem. 73, 3351–3356 (1969).

IWANAMI RIKAGAKU JITEN (Iwanami Dictionary of physical sciences) 5th edn Vol.2 (ed. M. Nagakura et al.) Item: carbonic acid, 813 (Iwatani bookshop, 1998).

Lower, S. K. Carbonate equilibria in nature waters. A Chem1 Reference Text of Simon Fraser University, Chem1 Environmental Chemistry. Tables 3, 4 (1999) Available at: www.chem.1com/acad/webtext/pdf/c3carb.pdf (Accessed: 26th September 2017).

KAGAKU BINRAN fundamental II(Chemical comprehensive reference guide Fundamental II) 5th edn Vol.1 (ed. Japan Chemical Institute) Ch. 13, II-581 (Maruzen Co. Ltd., 2004).

KAGAKU BINRAN fundamental II (Chemical comprehensive reference guide Fundamental II) 5th edn.Vol.1 (ed. Japan Chemical Institute) Ch. 9, Table 9.55II-182 (Maruzen Co. Ltd., 2004).

Fujishima, A., Rao, T. N. & Tryk, D. A. Titanium dioxide photocatalysis. J.Photochem.Photobio.C: Photochemistry Reviews 1, 1–21 (2000).

Phattalung, S., N., Limpijumnong, S. & Yu, J. Passivated co-doping approach to bandgap narrowing of titanium dioxide with enhanced photocatalytic activity. Appl. Cat. B:Environmental 200, 1–9 (2017).

Acknowledgements

The author thanks TAYKA Co., Ltd for providing the nanometre-sized TiO2 particles approximately 15 years ago. Furthermore, the author acknowledges Wikipedia for information on dissolving and dissociating CO2 with water.

Author information

Authors and Affiliations

Contributions

I.M. performed all work.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moriya, I. Converting of CO2 into low-molecular-weight organic compounds with the TiO2/ZrO2 composites under solar irradiation. Sci Rep 7, 14446 (2017). https://doi.org/10.1038/s41598-017-14683-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-14683-4

This article is cited by

-

Converting N2 molecules into NH3 with TiO2/Fe3O4 composite covered with a thin water layer under ambient condition

Scientific Reports (2023)

-

Preparation of graphdiyne-doped TiO2/SiO2 composite for enhanced photocatalytic activity

Journal of Nanoparticle Research (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.