Abstract

Up to now, a very few catalysts have been developed approaching the heterogeneous catalytic degradation of Eosin Y and Chromotrope 2R dyes (Acid Red 29). The present study provides a complete perspective of recyclable nanocomposite Au(Salen)@CC for catalytic degradation of hazardous water pollutant dyes viz., Eosin Y & Chromotrope 2R using mild reaction conditions. New gold Salen complex doped carbon nanocomposite Au(Salen)@CC was developed by easy methodology using nano carbon cage (CC) prepared from low-priced Pyrolysis fuel oil (PFO) residue based Pitch. The UV-Vis adsorption spectroscopy results of Eosin Y and Chromotrope 2R dyes indicated complete degradation into acidic compounds which can be further mineralized to CO2 and H2O under mild reaction conditions. The heterogeneous catalyst recycled and reused successfully for four repeated experiments without loss in its adequate performance. This new sustainable and eco-friendly catalyst delivered significant degradation activity compared to existing reports and it can be further utilized for new multifunctional applications such as, radiopharmaceutical activities, heterogeneous catalysis and chiral resolution.

Similar content being viewed by others

Introduction

Dyes and pigments have ubiquitous presence in modern industries such as, textile, leather, food, paper and plastic industries. The discharged effluent of these factories is evidently contaminated and critically hazardous because of its adverse outcome on the environment and society. Countermeasure of this dye-associated waste has been greater field of exploration now a day. A red fluorescent dye from xanthene family, Eosin Y, has been normally utilized in several applications such as, semiconductor’s sensitizer1 biological stain, laser dye, fluorescent research, nanocomposite preparation and polymerization process2. Eosin Y has stability, resilience, and light absorptivity3. The extensive use of Eosin Y in sensitizing industries3 and as biological stain in biomedical research laboratories and for diagnostic intention4, cause carcinogenic exposure as dye waste due to its benzene and pyran rings as well as carboxyl group. Eosin Y affects surroundings by direct discharging into wastewater due to its toxic nature and its intense color. Chromotrope 2R (Acid Red 29) is one of the azo dyes consist of azo group (−N = N−), as chromophore group with aromatic structure having, −OH and –SO3H functional groups. Azo pigment also creates water contamination and serious environmental problem due to its carcinogenic, poisonous and harmful properties5,6,7,8,9.

Organic water contaminants are either moderately decomposed by using an oxidizing agent into biodegradable intermediates/important chemicals or complete mineralization into innocuous inorganic compounds such as CO2, H2O and inorganic salts, which remain in the aqueous phase. Further, the intermediates are broken down into simpler, easily treatable materials before they are released into the environment. The ultimate products usually reside of low molecular weight oxygenated molecules like acetic acid, propionic acid, ethanol etc10. Currently, a variety of techniques are being used for the removal or degradation of dyes from pollutant water, e.g. adsorption, coagulation, oxidation, reduction, microbiological, photo-catalysis and biotechnology. These techniques declined to remove or destroy pollutant completely, but it offered few drawbacks such as incomplete removal, high consumption of chemical reagent, expensive, slow and generation of toxic secondary contaminants11. Modified titanium dioxide (TiO2) is possibly most practiced photocatalyst for determining environmental issues specially wastewater purification4, 12. However, the TiO2 based photocatalysis experienced few fundamental technical hurdles that pauses its industrialization, i.e. limited utilization of visible light, small adsorption scope for hydrophobic pollutants, high aggregation tendency and recovery of the TiO2 composite after successive catalytic cycle11. The ability of biological treatment processes for decolorization of industrial effluents has limitations in that it is affected by the concentration, non-biodegradable toxic and inhibitory nature, alkalinity and elevated temperature of the dye effluents.

Salen Schiff base-transition metal complexes and their composites have been broadly researched due to its potential use as a promising catalyst in a wide range of organic transformations13. Hydrogen peroxide is a powerful and environment friendly oxidizing agents since the product of its degradation are H2O and O2 14. Sodium borohydride (NaBH4) is widely used in catalytic reduction method of dyes15. Though activated carbon composite demonstrates its potential to remove the dyes, the high initial cost of carbon, coupled with problems associated with regeneration/reuse necessitates search for other developments. Owing to these reasons chemical oxidation-reduction methods are preferred. Various advanced oxidation/reduction processes of pollutant treatment have been modernized with low-cost, ecofriendlyness and high efficiency to reconcile the developing demand of direct wastewater treatment.

Very few reports have been published dealing with Eosin Y and Chromotrope 2R by catalytic degradation methods. Reusable, inexpensive and eco-friendly organic metal carbon nanocomposite have numerous supplementary combined features of organic moiety, metal and carbon base along with the potential for tuning the activity and selectively of nanocomposites. Combination of hetero atoms into porous carbon framework can engender active sites and most transition metals have been doped into porous nanocomposite. Transition metal nanocomposites have revealed huge importance over last decade because of their potential in applications as a solid catalyst, adsorbent, sensor, electrode, energy storage or its host16. To expand better awareness of the possibility of this treatment, herein, we report the development of new heterogeneous catalyst of Au(III) Salen complex onto carbon cage prepared from pyrolysis fuel oil based Pitch residue using a new and eco-friendly approach for the catalytic degradation of Eosin Y and Chromotrope 2R dyes. Gold Salen complex doped carbon nanocomposite Au(Salen)@CC has promise for the degradation of dyes under mild conditions (Eosin Y: room temperature (25 °C); Chromotrope 2R: 50 °C and atmospheric pressure) using environmentally friendly oxidant (H2O2) for Chromotrope 2R and reductant NaBH4 for Eosin Y. This sustainable catalyst has immense prospective for the application of cleaning organic dye polluted water and it can be further utilized for new multifunctional applications as well.

Results

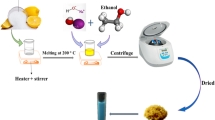

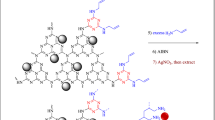

The organic-inorganic hybrid nanocomposite materials CC, CCO, CCONa and Au(Salen)@CC were synthesized by simple template method using nanosilicaball (NSB) followed by air oxidation and NaOH treatment and easy deposition of gold Salen complex on hierarchical CC, respectively (Fig. 1). All the composites and products were characterized by physico-chemical characterization methods.

Powder X-ray diffraction analysis

The wide angle XRD profile of CC showed two peaks with lower intensity corresponding to graphite type reflections from the (002) and (100) planes which were correspond to 2θ value 25.3° and 42.7°, respectively (Fig. 2), which were assigned to porous carbon17,18,19. Upon Salen complex of gold deposition in CC, XRD of the Au(Salen)@CC showed four new peaks at 2θ = 38.1°, 44.3°, 64.5° and 77.5°, which resembled to reflections of gold planes (111), (200) (220) and (311), respectively19. Some supplementary diffractions peaks of sodium metal planes observed at 2θ value 25.6°, 26.5°, 27.2°, 29.8°, 30.1°, 32.8° and 33.9°18. Though, the low-angle XRD of CCO, CCONa, Au(Salen)@CC did not show any characteristic peak (Fig. S5, supplementary information).

Nitrogen adsorption–desorption study

The BET surface area of NSB and CC was 163 m2/g and 212 m2/g, respectively. CC was oxidized with a mixture of nitrogen and air (with 5% O2) to CC, the surface areas of CCO was 224 m2/g. The surface hydroxyl groups triggering and gold Salen complex incorporation to CCO, the surface area of CCONa and Au(Salen)@CC observed to 258 and 239 m2/g, respectively. An increase in the pore diameter from 71 to 162 Å was observed from NSB to CC. Upon oxidation and impregnation, the values decreased further for CCO: 16; CCONa: 16; and Au(Salne)@CC: 17 Å with respect to CC. The pore volume of NSB and CC was 0.290 cm3/g and 0.857 cm3/g, respectively. The pore volume of CCO, CCONa and Au(Salen)@CC also increased to 0.869, 1.003 and 1.002 cm3/g, respectively (Table S1 and Fig. S1, supplementary information).

13C CP-MAS NMR analysis

The presence of organic metal complex in Au(Salen)@CC 1 was further monitored by solid state 13C CP-MAS NMR. It showed broad peaks in aromatic and aliphatic regions (58–189 δ ppm) (Fig. S4, supplementary information).

TEM and SEM analysis

The TEM images of the CCO, CCONa and Au(Salen)@CC carbon materials are shown in Fig. 3. The Scanning electron microscopy image of the CC, CCO, CCONa and Au(Salen)@CC are shown in Fig. S7 (Supplementary information).

Thermogravimetric analysis

TGA revealed minute weight losses of approximately 4.70 and 4.68% from 21 to 800 °C for CCO and CCONa, respectively. The loading of organic moiety in Au(Salen)@CC was found to be 13.95% as determined from the weight loss measured by thermo-gravimetric analysis carried out in the temperature range between 27 to 800 °C (Fig. S8, supplementary information).

Catalytic activity study

The Fig. 4 shows UV-vis spectra of Eosin Y degradation by Au(Salen)@CC. The spectrum of Eosin Y showed major absorbance band at 514 nm. It clearly indicates that in Eosin Y reduction in the presence of NaBH4, the intensity of absorbance peak became weaker as the reduction continued and totally disappeared after 50 min. We have also investigated oxidative degradation of Chromotrope 2R dye using Gold Salen complex doped carbon nanocomposite. The UV-vis measurement spectrum of chromotrope 2R is shown in Fig. 5. The spectrum of Chromotrope 2R exhibits major absorbance at 508 nm. When the catalyst was introduced to oxidation of Chromotrope 2R/H2O2 mixture, the reaction slowly loss in the absorbance of the dye was observed after 55 min.

Discussion

The gold Salen complex doped carbon nanocomposite Au(Salen)@CC was developed by easy methodology using nano carbon cage (CC) prepared from low-priced pyrolysis fuel oil (PFO) residue based Pitch. All the composites and products were fully characterized by X-ray diffraction (XRD), 13C cross polarized magic angle spinning (CP-MAS) NMR, thermo-gravimetric analysis (TGA), N2 adsorption–desorption isotherm, scanning electron microscopy (SEM), transmission electron microscope (TEM), Gas chromatography mass spectrometry (GCMS), Liquid chromatography mass spectroscopy (LCMS) and Fourier transform-infrared (FT-IR). The detailed characterizations are given in supplementary information. UV-Vis spectroscopy was used for catalytic study of hazardous dyes and GCMS for identification of degraded products.

In powder X-ray diffraction analysis, the two broad peaks observed in the diffraction patterns of CC indicate that the crystallinity in the porous carbons is relatively small19. Four new peaks of Au(Salen)@CC designate the association of gold Salen complex verified the presence of gold complex in CC 20. Additional diffractions peaks supported the presence of sodium metal planes (JCPDS No. 011173 and 772082) are labeled in Fig. 2 21. Metal incorporation has a considerable influence on the structural regularity of the CC materials17, 22. Recycled Au(Salen)@CC catalyst also shown identical XRD pattern after completion of catalytic cycle. It revealed that the heterogeneous catalyst Au(Salen)@CC was retained and stable under catalytic degradation condition (Fig. S8, supplementary information). In nitrogen adsorption study, the porosity of the carbons was generated by the release of small molecules during carbonization of the carbon precursors and the removal of the nano sized silica particles. Therefore, the different pore parameters of the immobilized CC and its precursors can be explained by the thermal stability of the CC and it remained intact after multiple treatment and immobilization (Table S1 and Fig. S1). 13C CP-MAS NMR analysis showed broad peaks in aromatic and aliphatic regions (58–189 δ ppm) corresponding to carbons originating from Salen complex immobilized on CC (Fig. S4, supplementary information). The presence of organic metal complex in Au(Salen)@CC 1 was further confirmed by solid state 13C CP-MAS NMR. SEM image of CC has shown uniform hollow cores of hierarchically porous CC while images of CCO, CCONa and Au(Salen)@CC have shown well ordered nanoporous structure with the pores distributed consistently in the carbons. During the template synthesis process and thermal and chemical treatments, the hierarchically type framework of CC and Au(Salen)@CC is well-replicated and retained their well arranged hollow morphology (Fig. S7, supplementary information). Transmission electron microscopy image CCO has consistent nanoporous cores of hierarchically porous CC. The TEM images CCONa and Au(Salen)@CC have shown well retained nanoporous structure with the well pores distributed uniformly in the carbons upon thermo-chemical treatment (Fig. 3). Thermogravimetric analysis gives characteristic weight loss which shows the loading of organic moiety in Au(Salen)@CC (Fig. S8, supplementary information).

In Eosin Y degradation using Au(Salen)@CC as catalyst suggests that the benzene and pyran rings containing carboxyl group of Eosin Y destroyed and decomposed into simpler acid components which gradually will decay into its mineral components. GC-MS analysis could identify four products such as, 2-(2-formylphenyl)-2-carboxylate, 2-(2-3,6-dihydro-2H-pyran-4-yl)phenyl)2-carboxylate, 3,5-dibromocyclohex-5-ene-1,2,4-trione and (1Z,4E)-1,5-dibromo-3((Z)-2carboxyvinyl)-6-oxohexa-1,4-dien-2-olate. On the basis of degradation products, possible mechanism was suggested for catalytic degradation of Eosin Y (Figs S9 and S10, supplementary information)4. These four intermediate products undergo degradation to give malonic acid and oxalic acid which can be further mineralized to CO2 and H2O. As a result, Au(Salen)@CC can be used to decompose dye Eosin Y. Our research findings revealed that Au(Salen)@CC catalyst is more reliable and efficient compared to available literature reports4. We found 98.68% decomposition of Eosin Y within 50 min at normal pressure and room temperature, while recently practiced TiO2 based photocatalyst gave 96% degradation of Eosin Y under visible light irradiation for 180 min4. Decomposition reaction of Chromotrope 2R results into some active acid species due to degradation of aromatic structure containing azo group (−N = N−), −OH and –SO3H9, 23. GC-MS could identify oxalacetic acid, malonic acid, oxalic and oxamic acid as the final products that are mineralized to CO2 (Fig. S11, supplementary information)24. Equally, 98.78% degradation of Chromotrope 2R was achieved using Au(Salen)@CC catalyst within 55 min compared to report based on decomposition of the dye using Fenton process9. Our catalytic technique is simple, effective, and recyclable and requires very less time for complete degradation of dyes.

Besides, we have also conducted the catalyst optimization study by varying the amount of catalyst for the degradation of Eosin Y and Chromotrope 2R (Table 1). In case of both the dyes, when the catalyst load was increased from 1, 3, 5, 8, 10 g L−1 in different five experiments, the total conversation experienced reasonable enhancement. Required time for complete degradation of Eosin Y was 90, 70, 50, 50, and 50 min at catalyst amount 1, 3, 5, 8, 10 g L−1, respectively. Similarly, observed reaction completion time of Chromotrope 2R was 80, 70, 55, 55 and 55 min at catalyst load 1, 3, 5, 8, 10 g L−1, respectively. Thus, the optimum catalyst amount was found to be 5 g L−1, which produced maximum conversion in most favorable time of 50 and 55 min for Eosin Y and Chromotrope 2R, respectively. The UV-Vis spectra of catalyst optimization study were summarized Figs S12 to S21 in supplementary information.

An attempt was made to recycle the catalyst, Au(Salen)@CC, after catalytic degradation of Eosin Y and Chromotrope 2R under optimized reaction conditions (Eosin Y: 2.7 × 10−4 mol L−1, 100 mL; NaBH4: 6.8 × 10−4 mol L−1, 0.025 g; Chromotrope 2R: 2.7 × 10−4 mol L−1, 50 mL; H2O2: 10−4 mol L−1, 50 mL; catalyst load: 5 gL−1; temperature: 25 °C (Eosin Y reaction) and 50 °C (Chromotrope 2R reaction). The aim was to evaluate the catalyst stability in degradation reaction, a basic necessity for its application at industrial scale. After the first catalytic reaction, the used Au(Salen)@CC catalyst was separated by filtration and the nanocomposite was thoroughly washed with distilled water. The resultant nanocomposite was dried overnight in vacuum desiccators at 100 °C and this revived Au(Salen)@CC catalyst was reused directly as a catalyst in the successive catalytic reaction. Four catalytic runs were carried out using the same catalyst with no observable loss of performance.

In conclusion, newly developed gold Salen doped carbon nanocomposite, Au(Salen)@CC, have potential functions in catalysis owing to their outstanding organic-inorganic hybrid physicochemical properties. The sustainable catalyst acts as a dynamic heterogeneous catalyst for catalytic decomposition of hazardous water pollutant dyes viz., Eosin Y and Chromotrope 2R. The complete degradation of Eosin Y and Chromotrope 2R dyes into acidic compounds was accomplished which can be further mineralized to CO2 and H2O under mild reaction conditions, it is more environmentally responsive and acceptable compared to earlier literature reports. The recyclability of eco-friendly catalyst is another advantage of the catalytic degradation process. The study is in progress towards the development of new applications such as energy storage and labeling of gold radioisotope for radiopharmaceutical activity.

Methods

Materials

Reagents and solvents such as ethanol, sodium hydroxide, hydrogen peroxide, Eosin Y (Dae-Jung Chemicals & Metals Co. Ltd., Korea), sodium borohydride, tetraethylorthosilicate, ethylenediamine (Aldrich, USA), hydrofluoric acid (J. T. Baker, USA), Chromotrope 2R, 3,5-di-tert-butyl-2-hydroxybenzaldehyde (Alfa Aesa, UK), and hydrogen tetrachloroaurate (III) hydrate (HAucl4) (Kojima Chemicals Co. Ltd, Japan) were employed as obtained. Petroleum residue pyrolysis fuel oil (PFO) was recieved from Yeocheon Naphtha Cracking Center (YNCC, South Korea). PFO based Pitch, Nano silica ball (NSB) and carbon cage (CC) were prepared according to the method reported previously using PFO based pitch residue25. All the solvents were purified by known method26.

Characterization of materials

The characterization of Au(Salen)@CC, its precursors were fully accomplished by powder X–ray diffraction (PXRD, Phillips X’pert MPD diffractometer, Almelo, The Netherlands) in the low angle and high angle 2θ spectrum (0.5–10 and 10–80). 1H and 13C NMR were carried out by 500 and 125 MHz NMR spectrometer (Jeol, JNM-ECA500, Japan). Cross polarized magic angle spinning (CP-MAS) 13C NMR was used for the identification of Au(Salen)@CC catalyst (Agilent Unity Infinity Solid State 200 MHz NMR, USA). Fourier transform infrared spectroscopy (FT-IR, Perkin–Elmer Spectrometer, Massachusetts, USA) was conducted using a KBr pellet facility. Microanalysis of the compounds was accomplished by CHN analyzer (CE instruments, UK) and the percentage of gold associated with CC were measured by inductively coupled plasma optical emission spectroscopy (ICP-OES, JY Ultima 2CHR). The thermal strength of the carbon nanocomposite was discovered by thermogravimetric analysis (TGA, SDT600, TA instrument, USA). The BET surface area was performed by nitrogen adsorption-desorption data determined at 77 K adopting volumetric adsorption technique (Micromeritics ASAP-2010, USA). The micro-structural assessment of these nanocomposite were probed by scanning electron microscopy (SEM, LEO–1430, VP, UK) and transmission electron microscopy (TEM, JEM 2011, Jeol Corporation, Japan). The high performance liquid chromatography mass spectroscopy (LCMS, Agilent Technology, 6120 quadrupole LC/MS, USA) and gas chromatography mass spectroscopy (GCMS, HP-6890 MASS-5973, USA) were used for the identification synthesized compounds and degraded products. The complete degradation of Eosin-Y and Chromotrope-2R dyes was monitored by UV–vis spectroscopy (Varian Cary 4000, USA).

Preparation of CCO and CCONa

The prepared petroleum pitch based carbon cage (CC) was oxidized with a mixture of nitrogen and air (with 5% O2) at 698 K for 10 h to obtain CCO. The surface hydroxyl groups of CCO were triggered by refluxing it with an aqueous solution of 0.1 N NaOH for an hour (Fig. 1). A sharp decrease in the pH value of the mixture from 13 to 10 was examined. This linking agent CCONa was washed with distilled water prior to constant pH = 8 and then dried at 393 K in an oven under vacuum27.

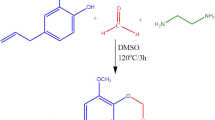

Synthesis of Salen ligand 4

The Salen ligand used for the development of Au(Salen)@CC catalyst was synthesized by following procedure adapted from our group’s earlier report28. First, a mixture of 3,5-di-tert-butyl-2-hydroxybenzaldehyde 2 (23.40 g, 99.83 mmol) and ethylenediamine 3 (0.40 ml 5.9745 mmol) was refluxed for 6 h in 30 mL of ethanol (Fig. 1). The formation of compound 4 was observed by TLC analysis. The final solution was concentrated by rotary evaporator after cooling. The yellow color residue was washed with cool ethanol and dried in vacuum. Salen ligand 4 was purified by silica gel column chromatography. Yield 24.25 g (98%). 1H NMR (500 MHz, CDCl3): δ 13.63 [s, 2 H, OH], 8.38 [s, 2 H, NCH], 7.36 [d, J = 2.46, 2 H of Ar], 7.25 [CDCl3] 7.06 [d, J = 2.45, 2 H of Ar], 3.91 [s, 4 H, CH 2 ], 1.43 [s, 18 H, CCH 3 ] and 1.28 [d, J = 0.74, 18 H, CCH 3 ] (Fig. S2). 13C NMR (125 MHz, CDCl3): δ 168 [C of Imine], 158 [C of Ar], 140 [C of Ar], 137 [C of Ar], 127 [C of Ar], 126 [C of Ar], 118 [C of Ar], 60 [CH2N], 35 [CCH3], 34 [CCH3], 32 [CH3] and 30 [CH3] (Fig. S3). Elemental analysis (Found) C: 77.84, H: 10.00, N: 5.65% (C/N = 13.78, C/H = 7.78). LCMS: m/z = 493.5 [M + H]+, 492.4 [M]+. FTIR (KBr): 2958, 2907, 2869, 2591, 1630, 1594, 1440, 1391, 1361, 1272, 1203, 1172, 1131, 1042, 974, 879, 849, 829, 773 and 710 cm−1.

Synthesis of gold Salen complex 5

The gold (III) Salen complex was synthesized by refluxing an ethanolic solution of equimolar quantities of hydrogen tetrachloroaurate (III) hydrate (5 g in 50 mL, 14.71 mmol) and ligand 4 (7.25 g, 14.71 mmol, MW 492.37). The above mixture was refluxed for 4 h under steady stirring condition (Fig. 1). Finally, a large amount of pinkish gray solid was formed. The material was filtered and washed extensively with dry ethanol (3 × 5 mL) and dried air to afford the respective gold (III) Salen complex 5. Yield 3.16 g (30%). LCMS: m/z = 723.4 [M]+. FTIR (KBr): 2978, 2912, 2802, 2744, 2710, 2676, 2573, 2519, 2418, 2279, 2056, 1601, 1487, 1344, 1085, 1034, and 820 cm−1.

Preparation of gold Salen doped carbon nanocomposite Au(Salen)@CC

Functionalization of Salen complex 5 with treated carbon cage CCONa was achieved by following method. Activated CCONa (5.0 g) nanocomposite was refluxed with an ethanolic solution of 1.38 mmol of gold (III) Salen complex 5 (1.0 g) for 12 h (Fig. 1). The prepared nanocomposite was washed and purified by Soxhlet extraction process with dry ethanol for 8 h. Gold Salen complex immobilized on carbon cage was vacuum dried in an oven overnight at 110 °C. Yield: 5.903 gm. 13C CP-MAS NMR (12 KHz): δ 58–189 (broad peak, C of Salen complex). Elemental analysis (Found) C: 78.68, H: 1.19, N: 2.18%. Elemental analysis and ICP results showed that Au(Salen)@CC contained > 78 wt% carbon and 2.99 wt% Au after compound 5 immobilization on CC, respectively. Solid reflectance UV-Vis: 220, 280, 340 nm. FTIR (KBr): 3450, 2917, 2803, 2677, 2347, 2058, 1600, 1502, 1086 and 1034 cm−1.

Catalytic reduction of Eosin Y and oxidation of Chromotrope 2R dyes

Catalytic degradation of Eosin Y and Chromotrope 2R dyes was executed in a glass reactor attached with a condenser. The reduction reaction of Eosin Y was carried out under typical conditions, by combining Eosin Y (100 mL, 2.7 × 10−4 mol L−1), NaBH4 (0.025 g, 6.8 × 10−4 mol L−1) with the catalyst Au(Salen)@CC (5 g L−1). The reaction mixture was stirred with 180 rpm rate for 50 min at room temperature (25 °C) and normal pressure. The oxidation reaction of Chromotrope 2R was carried out with 50 mL Chromotrope 2R (2.7 × 10−4 mol L−1), 50 mL H2O2 (10−4 mol L−1) using 5 g L−1 Au(Salen)@CC catalyst for 55 min at 50 °C temperature, normal pressure, and 180 rpm rate. After the completion of reaction, the catalyst, Au(Salen)@CC, was separated by centrifugation. The complete degradation of Eosin Y and Chromotrope 2R was monitored using UV–visible spectroscopy (at maximum adsorption wavelength of 514 nm and 508 nm for Eosin Y and Chromotrope 2R, respectively. GCMS was used for product identification. After each reaction run was completed, the products were extracted with chloroform by mixing equal volumes of the product mixture and chloroform. The solution was sonicated for several minutes allowed to settle down layers. 0.6 μL of the extracted layer of the mixures were investigated by GC-MS. In GC-MS, the temperature of injection was 250 °C. The starting temperature was preserved at 50 °C for 5 min and then raised to 180 °C at 10 °C min−1 rate, retained at present temperature for 5 min, then increased to 250 °C at 10 °C min−1 rate, and again retained at this temperature for 5 min.

References

Chowdhury, P., Athapaththu, S., Elkamel, A. & Ray, A. K. Visible-solar-light-driven photo-reduction and removal of cadmium ion with Eosin Y sensitized TiO2 in aqueous solution of triethanolamine. Sep. Purif. Technol. 174, 109–115 (2017).

Arbeloa, E. M., Previtali, C. M. & Bertolotti, S. G. Photochemical study of eosin-Y with PAMAM dendrimers in aqueous solution. J. Lumin. 180, 369–375 (2016).

Nagaya, S. et al. Crystal structure and photoelectric conversion properties of eosinY adsorbing ZnO films prepared by electroless deposition. Appl. Catal. B. Environ. 189, 51–55 (2016).

Vignesh, K., Suganthi, A., Rajarajan, M. & Sakthivadivel, R. Visible light assisted photodecolorization of eosin-Y in aqueous solution using hesperidin modified TiO2 nanoparticles. Appl. Surf. Sci. 258, 4592–4600 (2012).

Robinson, T., McMullan, G., Marchant, R. & Nigam, P. Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Bioresourse Technol. 77, 247–255 (2001).

Kunz, A., Peralta-Zamora, P. & Durán, S. G. M. N. New tendencies on textile effluent treatment. Quim. Nova 25, 78–82 (2002).

Umbuzeiro, G. A. et al. The contribution of azo dyes to the mutagenic activity of the Cristais river. Chemosphere 60, 55–64 (2005).

Sharma, K. P. et al. A comparative study on characterization of textile wastewaters (untreated and treated) toxicity by chemical and biological tests. Chemosphere 69, 48–54 (2007).

Almeida, L. C. et al. Electrochemical mineralization of the azo dye Acid Red 29 (Chromotrope 2R) by photoelectro-Fenton process. Chemosphere 89, 751–758 (2012).

Mayani, S. V., Mayani, V. J., & Bhattacharyya K. G. Phenol and its analogues in water: sources, environmental fate, effects and treatment, In chemistry of phenolic compounds; State of the art (ed. Baruah, J. B.), Chapter 13, 181–202 (Nova Science Publishers Inc., New York, USA, 2011).

Dong, H. et al. An overview on limitations of TiO2-based particles for photocatalytic degradation of organic pollutants and the corresponding countermeasures. Water Res. 79, 128–146 (2015).

Wang, W., Silva, C. G. & Faria, J. L. Photocatalytic degradation of Chromotrope 2R using nanocrystalline TiO2/activated-carbon composite catalysts. Appl. Catal. B. Environ. 70, 470–478 (2007).

Abdi, S. H. R., Kureshy, R. I., Khan, N. H., Mayani, V. J. & Bajaj, H. C. Dimeric & polymeric chiral Schiff base complexes and supported BINOL complexes as potential recyclable catalysts in asymmetric kinetic resolution and C–C bond formation reactions. Catal. Surv. Asia 13, 104–131 (2009).

Goti, A., & Cardona, F. Hydrogen peroxide in green oxidation reactions: Recent catalytic processes, green chemical reactions, Part of the series NATO science for peace and security series, 191–212, (Springer Netherlands, 2008).

Sahiner, N., Sagbas, S. & Aktas, N. Very fast catalytic reduction of 4-nitrophenol, methylene blue and eosin Y in natural waters using green chemistry: p(tannic acid)-Cu ionic liquid composites. RSC Adv. 5, 18183–18195 (2015).

Mayani, V. J., Mayani, S. V. & Kim, S. W. Simple preparation of tungsten supported carbon nanoreactors for specific applications: adsorption, catalysis and electrochemical activity. Appl. Surf. Sci. 345, 433–439 (2015).

Kao, L. H. & Hsu, T. C. Silica template synthesis of ordered mesoporous carbon thick films with 35-nm pore size from mesophase pitch solution. Mater. Lett. 62, 695–698 (2008).

Guo, X., Liu, X., Xu, B. & Dou, T. Synthesis and characterization of carbon sphere-silica core–shell structure and hollow silica spheres. Colloids Surf A 345, 141–146 (2009).

Teng, H. & Weng, T. Transformation of mesophase pitch into different carbons by heat treatment and KOH etching. Micropor. Mesopor. Mater. 50, 53–60 (2001).

Mayani, V. J., Mayani, S. V. & Kim, S. W. Development of nanocarbon gold composite for heterogeneous catalytic oxidation. Mater. Lett. 87, 90–93 (2012).

Yuan, Z., Si, L. & Zhu, X. Three-dimensional hard carbon matrix for sodium-ion battery anode with superior-rate performance and ultralong cycle life. J. Mater. Chem. A 46, 23403–23411 (2015).

Yang, G. W. et al. Controllable deposition of Ag nanoparticles on carbon nanotubes as a catalyst for hydrazine oxidation. Carbon 46, 747–752 (2008).

Salem, I. A., El-Ghamry, H. A. & El-Ghobashy, M. A. Application of montmorillonite–Cu(II)ethylenediamine catalyst for the decolorization of Chromotrope 2R with H2O2 in aqueous solution. Spectrochimica Acta Part A: Mol. Biomol. Spectroscopy 139, 130–137 (2015).

Qamar, M., Saquib, M. & Muneer, M. Titanium dioxide mediated photocatalytic degradation of two selected azo dye derivatives, chrysoidine R and acid red 29 (chromotrope 2R), in aqueous suspensions. Desalination 186, 255–271 (2005).

Mayani, S. V., Mayani, V. J., Park, S. K. & Kim, S. W. Synthesis and characterization of metal incorporated composite carbon materials from pyrolysis fuel oil. Mater. Lett. 82, 120–123 (2012).

Perrin, D. D., Armarego, W. L. F., & Perrin, D. R. Purification of Laboratory Chemicals, (Pergamon, New York, 1981).

Silva, A. R., Freire, C. & Castro, B. Jacobsen catalyst anchored onto an activated carbon as an enantioselective heterogeneous catalyst for the epoxidation of alkenes. Carbon 42, 3027–3030 (2004).

Kureshy, R. I. et al. Encapsulation of a chiral MnIII(salen) complex in ordered mesoporous silicas: an approach towards heterogenizing asymmetric epoxidation catalysts for non-functionalized alkenes. Tetrahedron Asymmetry 16, 3562–3569 (2005).

Acknowledgements

“This research was supported by Nuclear R&D Program through National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning (2015M2A2A4A02043268 and 2017R1D1A1B03035589) and Dongguk University research fund, Republic of Korea”.

Author information

Authors and Affiliations

Contributions

V.J.M. designed the project and developed gold-Salen-carbon nanocomposite and its characterization. S.V.M. accomplished the heterogeneous catalytic degradation study, catalyst optimization & recycling activity and degradation products identification. V.J.M. and S.V.M. wrote the main manuscript. S.W.K. managed the chemicals and characterization. All the authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mayani, V.J., Mayani, S.V. & Kim, S.W. A Sustainable Nanocomposite Au(Salen)@CC for Catalytic Degradation of Eosin Y and Chromotrope 2R Dyes. Sci Rep 7, 7239 (2017). https://doi.org/10.1038/s41598-017-07707-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-07707-6

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.