Abstract

We present a new method for the continuous flow production of concentrated hyperpolarized xenon-129 (HP 129Xe) gas from a dilute xenon (Xe) gas mixture with high nuclear spin polarization. A low vapor pressure (i.e., high boiling-point) gas was introduced as an alternative to molecular nitrogen (N2), which is the conventional quenching gas for generating HP 129Xe via Rb-Xe spin-exchange optical-pumping (SEOP). In contrast to the generally used method of extraction by freezing Xe after the SEOP process, the quenching gas separated as a liquid at moderately low temperature so that Xe was maintained in its gaseous state, allowing the continuous delivery of highly polarized concentrated Xe gas. We selected isobutene as the candidate quenching gas and our method was demonstrated experimentally while comparing its performance with N2. Isobutene could be liquefied and removed from the Xe gas mixture using a cold trap, and the concentrated HP 129Xe gas exhibited a significantly enhanced nuclear magnetic resonance (NMR) signal. Although the system requires further optimization depending on the intended purpose, our approach presented here could provide a simple means for performing NMR or magnetic resonance imaging (MRI) measurements continuously using HP 129Xe with improved sensitivity.

Similar content being viewed by others

Introduction

Nuclear magnetic resonance (NMR) of hyperpolarized xenon-129 (HP 129Xe) atoms has been widely used in a variety of research areas, such as physics, chemistry, material science, and biomedical imaging1, 2. HP 129Xe gas is usually produced via a spin-exchange optical-pumping (SEOP) method, in which a hyperpolarized nuclear spin state is achieved based on the transfer of the angular momentum carried by photons from circularly polarized laser light3, 4. For this transfer process, an alkali metal (typically rubidium, Rb) is used as an intermediate. One of the two spin states of the valence electron of a vaporized Rb atom becomes populated abundantly by absorbing circularly polarized laser light with a wavelength matched to the Rb D1 transition (~795 nm). Through subsequent Rb-Xe interactions, such as binary collision between a spin-polarized Rb atom and a Xe atom or the formation of an Rb/Xe van der Waals molecular complex, the transfer of spin polarization from a Rb electron to the 129Xe nuclei occurs.

In order to obtain highly polarized 129Xe gas, two types of buffer gases are generally added to the Xe gas to promote efficient SEOP. The first, and the most important for optical pumping is to add a quenching gas such as molecular nitrogen (N2), which prevents the excited state of Rb atoms from re-radiating unpolarized photons, enabling the avoidance of radiation trapping. Nitrogen has a large quenching cross section5, 6 and a moderate spin destruction cross section for Rb (\({k}_{{\rm{SD}}}^{{\rm{Rb}}-{{\rm{N}}}_{2}}\) = 1.3 × 10−25 T 3 cm3 s−1 7, where T is the temperature in K) and, therefore, it is typically used as a quenching gas in SEOP, where several tens of kPa of N2 are added to Xe gas to provide sufficient quenching effect. A second buffer gas is added in order to broaden the absorption line of Rb to better match the spectral profile of the laser8. Generally, several hundreds of kPa of helium (He) are added to the Xe/N2 gas mixture for this purpose. Helium is chosen because it has the smallest spin destruction cross section for Rb (\({k}_{{\rm{SD}}}^{{\rm{Rb}}-{\rm{He}}}\) = 1.0 × 10−29 T 4.26 cm3 s−1 9) and, therefore, causes little loss of Rb spin polarization while broadening. Xe, in contrast, has a large spin destruction cross section for Rb (\({k}_{{\rm{SD}}}^{{\rm{Rb}}-{\rm{Xe}}}\) = 6.3 × 10−17(T-273.15)1.17 cm3 s−1 10) and, therefore, causes a significant loss of Rb spin polarization in condition with higher Xe number density, leading to a reduction in 129Xe nuclear spin polarization, P Xe. Based on these characteristics, a highly diluted Xe gas mixture composed of a small amount of Xe and N2, and a large amount of He gas has been used for generating highly polarized 129Xe gas8, 10,11,12,13.

The buffer gases needed for SEOP cause a side-effect of signal reduction through dilution of the Xe gas. By separating the HP 129Xe gas from the buffer gases, HP 129Xe gas can be concentrated. Because Xe freezes well above the boiling point of both N2 and He, the buffer gases can be removed by freezing out the Xe. At present, the only effective way to concentrate HP 129Xe for further use in NMR or magnetic resonance imaging (MRI) is freeze-thaw separation, in which Xe in the continuously flowing gas mixture is frozen and accumulated until it reaches a sufficient amount for use, and then the solid Xe is thawed to return it to a gaseous state8, 10, 11, 14, 15. The freeze-thaw approach, however, has some drawbacks, such as the accumulation of a sufficient quantity of solid HP 129Xe taking a considerable time (e.g., several tens of minutes). Although the longitudinal relaxation time T 1 of solid 129Xe at liquid N2 temperature in the presence of a magnetic field is reasonably long for accumulation16, it often results in an extra significant loss of P Xe in the process of solidification, accumulation, and volatilization of Xe, and this process complicates the system and its operation. Furthermore, this approach is not compatible with the continuous flow production of HP 129Xe gas because the Xe gas has to be stored in a solid state. Therefore, its use is limited to NMR or MRI experiments conducted in a batch mode.

Depending on the purpose, it is possible to forgo the cryogenic accumulation step to directly deliver highly or moderately dilute HP 129Xe mixtures to the target by continuous flow12, 17, 18 or stopped flow19,20,21,22,23. However, it is obvious that the use of fully concentrated 129Xe gas from highly dilute HP 129Xe mixture enables MRI applications with significantly increased signal intensity12. Most recently, Meersmann and coworkers demonstrated that molecular hydrogen (H2) can be used as a quenching gas in SEOP and it can be reactively removed via catalytic combustion for the purpose of purifying HP 83Kr as well as HP 129Xe after SEOP24. However, the continuous flow production of purified HP noble gas, to the best of our knowledge, has not been demonstrated previously.

The aim of this work is to develop a new method to concentrate HP 129Xe gas from a dilute Xe gas mixture using a new buffer gas for SEOP that is capable of continuously delivering highly spin polarized undiluted 129Xe gas for use in performing NMR or MRI measurement continuously with improved sensitivity. We reported a study on pulmonary functional imaging in mice using HP 129Xe generated using a system based on the concept described here25. In the present study, we focus on the basic aspects of the methodology based on a detailed analysis of Xe polarization, Rb polarization and Rb-Xe spin exchange process in the use of a new quenching gas comparing them with the conventional N2. Furthermore, we investigate the current shortcoming to improve the system by analyzing observed enhancement of MR signal strength and loss of polarization encountered in a concentration process of dilute Xe gas.

Results and Discussion

Selection of a quenching gas

Our proposal for concentrating HP 129Xe gas from a dilute Xe gas mixture was to use a high boiling point gas as a quenching gas that condenses at a higher temperature than Xe. In order to achieve this objective, the candidate quenching gas requires sufficient quenching ability, a higher boiling point than Xe, a small contribution to the spin destruction of Rb, and low chemical reactivity with highly reactive Rb. To quench the fluorescent emission, it is required to transfer the excitation energy of Rb atoms to kinetic energy of the quenching gas. Molecular gases with a chemical double bond possess a large quenching cross section and can effectively quench fluorescence through energy transfer into its vibrational mode6. Among the previously reported data regarding quenching cross section, a hydrocarbon gas ethylene (ethene, H2C=CH2) has a larger quenching cross section (σ(P 1/2 → S 1/2) = 139 Å2) than that of N2 (σ(P 1/2 → S 1/2) = 58 Å2)5, 6, and has a slightly higher boiling point (169.5 K) than Xe (165.0 K). Ethylene, however, was not suitable for our purpose because of the very small difference in boiling point, and, therefore, a gas with a substantially different boiling point was required in order to enhance the separation efficiency from Xe gas. In the present study, isobutene (2-methylpropene, H2C=C(CH3)2) was selected as the first candidate quenching gas because its boiling point is 266.2 K, which is over 100 K higher than Xe, and it has a chemical double bond favorable for effective quenching similar to N2 and ethylene.

Continuous flow production of concentrated HP 129Xe gas by isobutene condensation

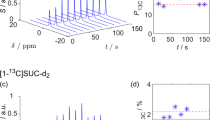

In order to demonstrate that Xe was concentrated continuously from the dilute Xe gas mixture, the 129Xe NMR signal was measured repeatedly from the continuously flowing Xe/isobutene gas mixture before and after condensing of isobutene. The Xe/isobutene gas mixture was flowed through a polarizer26 for hyperpolarization, a tubular spiral glassware as a cold trap (Fig. 1a), and an NMR tube in a 9.4-T superconducting magnet for measuring the 129Xe NMR signal. More details about the experimental set-up and NMR measurement are given in Methods section. Figure 1b shows a time course of the 129Xe signal-to-noise ratio (SNR) of the NMR spectrum measured during the continuous flow production of HP 129Xe using a binary gas mixture of Xe/isobutene before and after the concentration of HP 129Xe by application of the cold trap. Results from the Xe/N2 mixture are shown for comparison. For a dilute Xe/isobutene mixture without a cold trap, a stable HP 129Xe signal was observed continuously, although the SNR was slightly lower than that of the Xe/N2 mixture. For repeated acquisitions of 129Xe spectra, the spiral glass was put in a cold Dewar at after 150 s. Immediately after this, the 129Xe signal intensity began to increase, then increased further gradually with some fluctuations, and finally reached a steady state. The enhanced 129Xe signal continued to be measured with sufficient stability similar to the Xe/N2 mixture. Representative NMR spectra showing spectral enhancement by concentrating Xe are shown in Fig. 1c. After the measurement, it was confirmed that liquid isobutene was stored in the storage vessel attached to the lower side of the spiral glassware (Fig. 1d), and, therefore, isobutene had been removed from the Xe gas, and the concentrated Xe gave the enhanced signal.

Dynamics of 129Xe NMR signal enhancement by removing isobutene. (a) Diagram of the glassware for condensing and storing isobutene using a cold trap and schematic diagram of the production of concentrated HP 129Xe gas from the Xe/isobutene gas mixture. (b) Time course of SNR of 129Xe spectrum using gas mixtures with Xe/isobutene (diamonds) and Xe/N2 (rectangles). Spiral glass piping was immersed in a Dewar at the time point indicated by the black allow to trap isobutene at 203 K. The Xe fraction in both mixtures was f Xe,SEOP = 0.20. Gas flow rates of Xe, isobutene, and N2 were F Xe = 17, F ib = 69 and \({F}_{{{\rm{N}}}_{2}}\) = 69 sccm, respectively. (c) HP 129Xe NMR spectrum acquired from a Xe/N2 gas mixture (left) and a Xe/isobutene gas mixture recorded before (center) and after separation of isobutene using the cold trap (right). (d) Photograph of the liquid isobutene separated from Xe gas and stored in the storage vessel.

Comparison between isobutene and N2 as a quenching gas for Rb-Xe SEOP

In order to maximize a benefit from signal enhancement by concentrating HP 129Xe, it is important that the use of isobutene did not cause a significant loss of P Xe compared with using conventional N2. The influence of using isobutene as an alternative quenching gas to conventional N2 on P Xe was investigated by comparing with that of N2. The details of calculations of P Xe are given in Methods section. The P Xe for each diluted Xe gas mixture (i.e., Xe/isobutene or Xe/N2) was measured for the five conditions with the gas mixture. The Xe flow rate (F Xe) varied from 2.2 to 30 sccm (cubic centimeter per minute at standard temperature and pressure (STP)) whereas that of isobutene (F ib) or N2 \(({F}_{{{\rm{N}}}_{2}})\) was kept constant at 69 sccm; therefore, the volume fraction of Xe in the source gas mixture, f Xe,SEOP, ranged from 0.03 to 0.30 (Table 1). Figure 2a compares P Xe between isobutene and N2 in the gas mixture without a cold trap. Here, the volume fraction of Xe in the gas mixture at measurement region, f Xe,meas, was equal to that in the source gas mixture, f Xe,SEOP. When using the isobutene mixture, P Xe was 2–17% lower than that observed with the N2 mixture in these experimental conditions. A similar tendency between the two mixtures was observed for the dependence of P Xe on f Xe,SEOP; namely, P Xe increased with decreasing f Xe,SEOP because the lower Xe number density in SEOP process as is well-known.

Comparison between isobutene and N2 as the quenching gas for Rb-Xe SEOP. Plot of P Xe (a), P app (b), P Rb (c), γ SE (d), and τ SU (e) as a function of f Xe,SEOP for a Xe/N2 mixture (rectangles) and Xe/isobutene mixture (circles) without the separation procedure. The residency time of atoms in SEOP cell, τ cell, is also shown in (e). (f) Plot of the ratio of P Xe, P Rb, γ SE τ SU, and a factor of \(1-{e}^{-{\tau }_{{\rm{cell}}}/{\tau }_{{\rm{SU}}}}\) for isobutene mixture relative to those for N2 mixture as a function of f Xe,SEOP. Gas flow conditions used in these experiments were listed in Table 1.

In order to compare the 129Xe signal intensities in the various experimental conditions, the apparent polarization, P app, was defined as refs 19 and 20:

Details of P app are given in Methods section. The f Xe,SEOP dependence of P app was also observed to have a similar tendency between the two mixtures (Fig. 2b). Owing to a dilution effect, P app decreased with decreasing f Xe,SEOP even though P Xe increased.

The use of isobutene resulted in a slight loss of P Xe compared with N2. In order to understand how isobutene affects the Rb-Xe SEOP process and clarify the rationale of the polarization loss, we further analyzed the experimental data using a standard model of SEOP and compared several factors affecting P Xe between isobutene and N2 mixtures. The nuclear spin polarization of 129Xe at the output of the SEOP cell in the flow-though polarizer is given by ref. 27

where γ SE is the Rb-129Xe spin-exchange rate, which includes the contributions of spin exchange induced by Rb-Xe van der Waals molecules, \({\gamma }_{{\rm{SE}}}^{{\rm{vdW}}}\), and spin exchange caused by Rb-Xe binary collisions, \({\gamma }_{{\rm{SE}}}^{{\rm{BC}}}\), according to refs 10 and 27

where ξ j denotes the van der Waals-specific rate for each gas atom with density n j , and 〈σv〉 is the velocity averaged binary spin-exchange cross section. τ SU is the spin-up time constant defined as ref. 27

where ΓXe is the 129Xe spin relaxation rate, which is though to be dominated by wall relaxation8, 10. The wall relaxation rate is pressure independent and depends on the cell geometry (surface/volume) and its surface properties (paramagnetic impurities). 〈P Rb〉 is the volume-averaged Rb polarization in the cell. τ cell is the mean 129Xe residence time in the cell, which is related to the total flow rate, F tot, according to

where V cell is the cell volume and p cell is the total pressure of the gas in the cell. Among the two contributions to the Rb-Xe spin exchange, the formation and break up of Rb/Xe van der Waals molecular complex is affected by the difference in gas atoms or molecules, which is characterized by van der Waals specific rate, ξ j according to Eq. 3. We could estimate the ξ for isobutene as ξ ib = 2.61 × 103 s−1 (see Methods section) and found that the ξ ib is less than half of \({\xi }_{{{\rm{N}}}_{2}}\) (=5.70 × 103 s−1 28, 29). The low ξ results in low spin exchange rate, γ SE, which was 40–48% lower for isobutene mixture than for N2 mixture under our experimental conditions summarized in Table 1 (Fig. 2d). According to Eq. 2, P Xe reaches γ SE τ SU〈Rb〉 after a sufficiently long SEOP time compared to the spin up time, τ SU. Therefore, if ΓXe is sufficiently small compared to γ SE, the difference in γ SE has a small influence on P Xe. In our system, sufficiently small ΓXe was measured as 1.84 × 10−4 s−1 (see Methods section). Indeed, the γ SE τ SU was calculated as 0.986–0.987 for isobutene mixture and 0.992–0.993 for N2 mixture; therefore, the effect of the difference between two mixtures is less than 1% (Fig. 2f). The lower γ SE prolong the spin up time, τ SU, and requires longer residency time for P Xe to reach sufficiently high value. Since the nuclear spin polarization of 129Xe builds up with a time constant of τ SU according to Eq. 2, especially for the continuous flow system at a low cell pressure, we need to take into account that the residency time becomes short according to Eq. 5. The spin up time, τ SU, for isobutene was calculated as raged from 69.4 to 78.4 s and from 40.9 to 41.8 s for N2. Although these spin up times for both gas mixtures were shorter than τ cell (Fig. 2e), which was ranged from 76.1 to 105.8 s for our experimental condition (V cell = 848 cc, p cell = 15 kPa, and F tot ranging from 71.2 to 99.0 sccm), the SEOP time was insufficient for isobutene compared to N2 as a factor of \(1-{e}^{-{\tau }_{{\rm{cell}}}/{\tau }_{{\rm{SU}}}}\) for isobutene mixture (0.666–0.741) was ~20% lower than that for N2 mixture (0.838–0.925) (Fig. 2f).

Interestingly, in all experimental conditions, 〈P Rb〉 for isobutene mixture was 4–24% higher than that for N2 mixture (Fig. 2c,f). The Rb electron spin polarization at a position z in the SEOP cell along the laser propagation direction is given by refs 8, 10 and 27

where γ OP is the optical pumping rate, which is determined by the overlap of the frequency- and position-dependent laser intensity profile Φ(ν,z) and the alkali-metal D 1 absorption cross section σ s(ν) according to

ΓSD is the Rb spin polarization destruction rate, which can be attributed to spin depolarizing binary collisions with atoms in the gas mixture, the formation and breakup of Rb-Xe van der Waals molecules and radiation trapping19, 30:

where \({k}_{{\rm{S}}{\rm{D}}}^{{\rm{R}}{\rm{b}}-j}\) is the Rb spin-destruction cross section for Rb binary collisions with each gas atom with an atomic density n j . Therefore, the Rb polarization is limited by the Rb spin destruction processes characterized by a rate constant of ΓSD (Eq. 6). Since the difference in gases alters all the rate constants involved in these processes, the higher value of 〈P Rb〉 for isobutene mixture indicates that the isobutene has a valuable property of sufficiently small contribution to the spin destruction of Rb compared to N2. The optical pumping rate, γ OP includes the effects of pressure broadening of the Rb absorption line and shift of its central line by buffer gases. The pressure-broadening and shift coefficients for Rb have been measured for He, Xe and N2 and they are slightly different ranging from 18.0 to 18.9 GHz/amg for broadening and from −8.3 to 5.6 GHz/amg for shift31. Although the difference in gases may be less effective for the behavior of broadening and shift as reported for these three gases, the use of isobutene has a possibility to change the γ OP compared to the case of N2. In order to understand how isobutene affects spin destruction of Rb and optical pumping rate, further study is required, in which important physical quantities such as the absorption line broadening factor and each rate constant related to spin depolarizing binary collisions, van der Waals molecules and radiation trapping should be quantified. At this stage, our results suggested that isobutene seems to act as a quenching gas effectively because observed Rb polarization was higher than that for N2 mixture.

In terms of the reactivity of hydrocarbon gases coexisting with highly reactive Rb in the SEOP cell, Rb does not seem to readily react with saturated hydrocarbon gases such as methane21, 32, ethane32 and butane33. Any reaction also seems to be very slow for the unsaturated hydrocarbon isobutene used here. In fact, degradation of the SEOP cell using the isobutene mixture was adequately slow and at an acceptable level to complete in vivo experiments with a sufficient number of mice, e.g., 50 mice25.

Dependence of 129Xe signal enhancement on the volume fraction of Xe in the diluted gas mixture

In the same gas flow conditions as described in the previous section, the enhancement of 129Xe signal by removing isobutene was investigated. Figure 3a shows dependence of P app on f Xe,SEOP measured from concentrated Xe and that from diluted Xe using Xe/isobutene mixtures. Here f Xe,meas was different from f Xe,SEOP for the concentrated Xe because isobutene was removed from the source gas mixture. For all conditions, the removal of isobutene from Xe gas enabled P app to increase (i.e., the enhancement was due to the increase in f Xe,meas in Eq. 1). The highest value of P app = 11.9% was obtained at f Xe,SEOP = 0.20, whereas P app = 3.7% was observed for diluted Xe at f Xe,SEOP = 0.30.

Dependence of 129Xe signal enhancement on the Xe fraction in a dilute gas mixture. (a) Plot of P app as a function of f Xe,SEOP for a Xe/isobutene mixture. Data were obtained for a dilute Xe mixture without the separation (circles, the same data as shown in Fig. 2b) and for concentrated Xe after separation from isobutene at 196 K (diamonds). (b) Plot of enhancement factor ε as a function of f Xe,SEOP. Gas flow conditions used in these experiments were listed in Table 1. (c) Comparison of 129Xe signal enhancement between experimental results and ideal conditions. Asterisks: observed enhancement factor, which are the same data as shown in (b) solid line: ideal enhancement factor; dashed line: ideal enhancement factor including residual isobutene at 196 K; dotted line: fitted curve using Eq. 11 with f ib,res = 0.13. Inset shows the expanded plot of the main figure for clarify. (d) Plot of 129Xe polarization loss factor, LP, as a function of f Xe,SEOP. The flow rate of Xe is indicated above the plot. The plotted values were calculated using a relation of Eq. 10 with f ib,res = 0.13. The dotted line was drawn based on Eq. 13 using the values of α estimated from the fit as shown in c and f ib,res = 0.13.

In order to assess the effectiveness of concentrating Xe from the dilute Xe gas mixture, an enhancement factor, ε, was defined as the ratio of the amplitude of 129Xe signal obtained from concentrated Xe relative to that from diluted Xe with the same gas mixture used. Details about ε are given in the Methods section. The enhancement factor can be expressed by using the index P app as:

where P app,conc and P app,dil are the apparent polarization observed from concentrated Xe and diluted Xe, respectively. Figure 3b shows dependence of ε on f Xe,SEOP. The maximum enhancement factor of ε = 3.9 was observed at f Xe,SEOP = 0.11.

Although the 129Xe NMR signal was enhanced by the proposed method, the observed enhancement did not reach the value expected. From Eqs 1 and 9, the enhancement factor can be further rewritten as:

where P Xe,conc and P Xe,dil are the polarization for concentrated Xe and diluted Xe, respectively, and f ib,res is the fraction of residual isobutene in the gas mixture after the removal process. Note that P Xe,conc and P Xe,dil are the polarization observed in the measured region (i.e., in the NMR magnet) and, therefore, there is a possibility of a difference between them, although the polarization at the exit of the SEOP cell was the same for both concentrated and diluted conditions. According to Eq. 10, the specific relation ε = 1/f Xe,SEOP holds true in conditions that satisfy the following two assumptions: (I) isobutene is completely removed from the gas mixture by the cold trap (i.e., f ib,res = 0), and (II) the separation process has no influence on P Xe (i.e., P Xe,conc = P Xe,dil). In this ideal condition, it was expected that extremely high ε can be obtained at lower f Xe,SEOP. Figure 3c compares ε between the ideal (solid line) and the observed values (asterisks). At the lower f Xe,SEOP, the observed ε was far lower than the ideal one, whereas it was closer to the ideal one with increasing f Xe,SEOP (e.g., ε~33 and ε~1.7 at f Xe,SEOP = 0.03 for ideal case and measured value, respectively, whereas ε~3.3 and ε~2.4 at f Xe,SEOP = 0.30 for ideal case and measured value, respectively). The first assumption described above (I) was not established in our experiments. f ib,res can be estimated from the vapor pressure of isobutene, which is related to the cold trap temperature, and the total pressure at the separation region. The vapor pressure of isobutene at 196 K is ~2.0 kPa34, leaving 13% of isobutene in the gas mixture at 15 kPa total pressure, which was our experimental condition. This caused an increase in f ib,res from the ideal value of 0 to 0.13, and thus ε decreased 13% from the ideal one (Fig. 3c, dashed line). With regard to the second assumption above (II), there were three possible causes to induce a difference in P Xe between the concentrated and diluted conditions: (i) a reduction in 129Xe magnetization at the gas–liquid surface in the concentrated condition. The depolarization was expected when gaseous Xe atoms contact with a liquid surface, where an interaction occurs between the 129Xe atoms and 1H of the dense liquid isobutene molecules. In addition, an exchange phenomenon of Xe atoms between gaseous Xe and depolarized dissolved Xe caused a loss of gaseous Xe magnetization. (ii) A difference in relaxation time between concentrated and diluted conditions downstream of the separation region. Because Xe interacts with Xe in concentrated conditions whereas Xe interacts with both Xe and isobutene in diluted condition, the difference in gas composition could cause a difference in relaxation time. (iii) A difference in time needed for gas transport from the separation region to the measurement region. The reduced total flow rate due to the removal of isobutene could cause extra depolarization before the measurements. In order to analyze our experimental data in relation to these possibilities, ε was rewritten to include relaxation and flow rate:

with

where the suffixes “dil” and “conc” denote the parameters related to the diluted Xe gas mixture and concentrated Xe gas, respectively, F tot is the total flow rate downstream from the separation region, F ib,res is the flow rate of residual isobutene after the removal process, α is a constant involved in 129Xe relaxation, i denotes a site in which the relaxation occurs, T 1,i is the 129Xe T 1 at site i, V i is the volume at site i, and p i and p s are the total pressure of the gas at site i and standard-state pressure, respectively. The total flow rate was measured at ambient pressure. The depolarization effects described for (i) and (ii) were included in α conc and α dil in Eq. 11 as a difference in the number of sites, where the relaxation is occurred, and difference in the relaxation time. Details about the relationship between Eqs 10 and 11 are given in the Methods section. By fitting the observed ε to Eq. 11, α conc and α dil were estimated as 8.6 and 8.4 sccm, respectively, with a coefficient of determination of R 2 = 0.733 (Fig. 3c, dotted line). From these values, the degree of relaxation in the concentrated condition could be similar to that in diluted conditions. Here, we introduce a polarization loss factor (LP) defined as:

where a retained polarization fraction (RP) is a factor that describes the fraction of polarization retained when the gas passes through the buffer gas separation procedure and expressed using Eqs 10 and 11 (see also the Methods section for RP):

Figure 3d shows a plot of the LP as a function of f Xe,SEOP as well as F Xe. LP increased with decreasing f Xe,SEOP because of the reduced flow rate for the concentrated condition. Therefore, the discrepancy of ε between our experimental results and the ideal case could be mainly attributed to the reduced total flow rate because of the removal of isobutene described in (iii).

Requirements for improving the system

In order to improve the system and produce HP 129Xe gas with higher P app, LP needs to be minimized. Based on our results, higher F Xe was required to suppress the reduction in P Xe,conc (i.e. the increase in LP) and attain higher signal enhancement. In fact, it was confirmed experimentally that ε was improved by increasing F Xe because of the partial suppression of relaxation during the concentrated Xe gas transfer, as shown in Table 2, where the results using a 3% Xe/97% isobutene mixture with different total flow rates of F tot = 71.2 and F tot = 142.3 sccm (i.e. F Xe = 2.2 and F Xe = 4.3 sccm, respectively) were compared. In this case, LP was improved from 0.94 to 0.88. However the improved ε~3.4 was still far lower than that for the ideal value of ~33 because LP remained high value. Additionally, the achievable P Xe,dil was low for the higher flow rate because of the short residency time of Xe atoms in SEOP cell (τ cell = 53 s) compared to the spin up time of this mixture (τ SU = 78 s), resulting in low P app.

In order to further suppress the relaxation effect and obtain higher P app, it will be necessary to adopt much higher F Xe while keeping f Xe,SEOP low. By improving SEOP efficiency, the reduction in P Xe at the outlet of the SEOP cell caused by the increasing total flow rate may be suppressed. A simple solution could be to introduce spectrally line-narrowed laser diode array (LDA) to improve the absorption efficiency of Rb. The effectiveness of using the line-narrowed LDA to improve P Xe has been shown by other group19 and by our group as well for our own SEOP system35. Another approach to prevent P Xe,conc from reduction was to suppress depolarization during HP 129Xe gas transfer from the SEOP cell to the measurement region. For this purpose, the material or inner surface coating as well as the shape of all regions from the outlet of the SEOP cell to the measurement region and any effect of the magnetic field that the HP gas is passing through should be taken into account to prolong the relaxation time of 129Xe36,37,38. An additional requirement for improving this system is to optimize the temperature of the cold trap. In this study, isobutene was condensed and removed from Xe gas at only a single temperature around 195 K. At this temperature, ~13% of isobutene remained in the gas mixture, resulting in a reduction in the achievable Xe concentration. Lowering the cold trap temperature can reduce the vapor pressure of isobutene and could improve the separation efficiency.

Conclusion

We have demonstrated the continuous flow production of nearly pure HP 129Xe gas concentrated from dilute HP 129Xe gas mixture with higher P Xe, which could be realized using isobutene as a quenching gas in Rb-Xe SEOP. Useful properties of isobutene as a quenching gas for generating HP 129Xe was revealed by the comparison of several parameters related to SEOP with conventional N2. Utilizing the large difference in boiling point between isobutene and Xe, isobutene could be condensed and removed from HP 129Xe/isobutene gas mixture, resulting in enhancement of the 129Xe NMR signal owing to the increased concentration of Xe. By optimizing further the system for better performance, this approach could provide a simple means for performing NMR or MRI measurements continuously using HP 129Xe with extremely improved sensitivity in a wide range of research fields.

Methods

Polarizer

A schematic overview of the experimental setup is shown in Fig. 4, which is a modified system of our low-pressure and flow-through polarizer26. Approximately 0.5 g of Rb (EP grade, over 99.5% purity; Nacalai Tesque Inc., Kyoto, Japan) was deposited into a cylindrical Pyrex glass cell (6 cm diameter, 30 cm length). The SEOP cell was placed vertically in a fringe field of 12 mT near a vertical 9.4-T superconducting magnet and housed in an oven. The temperature of the oven was maintained at 383 K using a hot-air blower (CH-6056 HOTWIND S; Leister Technologies AG, Kaegiswil, Switzerland) to increase the Rb vapor pressure. Laser light from two fiber-coupled broadband LDA systems (FAP system, output power ~30 W, linewidth ~2 nm full width at half maximum (FWHM); DUO-FAP system, ~60 W and <6 nm FWHM; COHERENT Inc., CA, USA) were coupled via a transport glass fiber to the circular polarizing unit (COHERENT Inc.). Two circularly polarized beams output from the unit were emitted into the SEOP cell.

Natural abundance Xe (26.44% 129Xe; Air Liquide Japan Ltd., Tokyo, Japan), N2 (Air Liquide Japan Ltd.), and isobutene (Tokyo Chemical Industry Co., Ltd., Tokyo, Japan) were used. The gas flow rates were controlled independently using individual mass flow controllers (Model 3660, Kojima Instruments Inc, Kyoto, Japan) calibrated for each gas. By adjusting the each flow rate, we controlled the volume fraction of each gas in the gas mixture. Different gases from the outlets of the mass flow controllers were mixed, dried, and then passed into the SEOP cell. The SEOP process was conducted at a pressure of 15 kPa, which was monitored using a pressure gauge (Handy Manometer Model PG-100 102RP, Nidec Copal Electronics Corp., Tokyo, Japan). The resulting HP gas was compressed to atmospheric pressure using a diaphragm pump (LABPORT N86KV.18, KNF Neuberger GmbH, Freiburg, Germany) and delivered into a ϕ 10-mm NMR tube placed in an NMR probe via a polyethylene tube (1.4 mm inner diameter, 1.9 mm outer diameter; SP102, Natsume Seisakusho Co., Ltd., Tokyo, Japan). After passing through the NMR tube, the gas flow rate was checked by a water displacement method.

Gas separation

In order to separate isobutene from the Xe gas, a cold trap was introduced within the system, where isobutene gas was condensed, collected, and stored. The HP gas mixture exiting the SEOP cell was transferred into Pyrex tubular spiral glassware (Fig. 1a), where the gas mixture flowed around and down the spiral, deposited liquid isobutene, and exited up through the vertical return tube. The liquid isobutene dropped down through the spiral and entered a storage vessel placed on the lower side of the spiral. The glassware was cooled by immersing it in dry ice/methanol mixture in a Dewar and maintained at a constant temperature of around 195 K while being monitored using a thermocouple. This temperature was well below the boiling point of isobutene and well above that of Xe (the vapor pressures of isobutene and Xe at 195 K are ~2 kPa and ~428 kPa, respectively), allowing Xe gas to pass through.

Because the solubility of Xe and the relaxation rate of 129Xe in organic solvent both increase with decreasing temperature39, 40, the separation process was conducted at low pressure to suppress volume loss and polarization loss of 129Xe. That is, by reducing the partial pressure of Xe gas, the amount of Xe atoms dissolved into liquid isobutene can be reduced. In addition, shorter residence time of Xe gas in this region can suppress the polarization loss of gaseous 129Xe by coming in contact with 1H of liquid isobutene at the gas–liquid interface as well as by exchange phenomenon at the liquid surface with dissolved Xe, which relaxed by dipole–dipole interaction with 1H of liquid isobutene.

NMR measurement

All NMR measurements were performed in a vertical 9.4-T superconducting magnet (bore width 89 mm; Oxford Instruments plc., Oxford, UK) with a high-resolution NMR spectrometer, Agilent Unity INOVA 400WB with software VNMR 6.1 C installed (Agilent Technologies, Inc., Santa Clara, CA). A ϕ 10-mm NMR probe (Agilent Technologies, Inc.) tuned to the resonant frequency of 129Xe (110.6 MHz) was used for detection. The NMR signal of HP 129Xe was measured at room temperature with a pulse width of 1 μs, flip angle of 8°, spectral width of 49321.8 Hz, and 16384 data points, without accumulating multiple free induction decay (FID) transients. The FID was recorded repeatedly with a repetition interval of 5 s while the HP gas flowed continuously. The acquired FIDs were phase and baseline corrected and an exponential line broadening of 3 Hz was applied, and then, Fourier transformed to obtain NMR spectra. An SNR was calculated from each spectrum, in which a range from 50 ppm to 100 ppm (with respect to the 129Xe spectrum at 0 ppm) was set as the noise region. FWHM of the spectrum, ν FWHM, was also measured. These processing steps were carried out using VNMR 6.1 C software.

Polarization

To calculate the P Xe of HP 129Xe, the signal was compared with that measured for a standard sample of Xe gas at thermal equilibrium according to:

where suffixes p and e denote the parameters for hyperpolarized and thermal equilibrium state, respectively, and f Xe and NA are the fraction of Xe in the gas mixture and the number of FID accumulation, respectively. As the standard sample, a gas mixture of 50% Xe/50% O2 was enclosed at atmospheric pressure within a ϕ 10-mm NMR tube. O2 was included to promote the efficiency of FID accumulation by reducing 129Xe T 1 41. For the thermal equilibrium gas, 10,000 FID transients were accumulated with the same acquisition parameters as HP 129Xe except for a repetition interval of 3 s. Post-processing of the FID was performed in the same manner as HP 129Xe. 129Xe polarization at thermal equilibrium was calculated from Boltzmann’s distribution law for nuclei with spin I = 1/2 according to ref. 42:

where ħ = h/2π, γ, B 0, k B and T are Plank constant, gyromagnetic ratio of 129Xe nuclei, static magnetic field strength (B 0 = 9.4 T), Boltzmann constant, and temperature (typically T = 292 K), respectively. For HP 129Xe, ten P Xe,p calculated from repeatedly acquired spectra were averaged to give final values.

Enhancement factor

In order to assess the effectiveness of concentrating Xe from a dilute Xe gas mixture, an enhancement factor, ε, was defined as the ratio of the amplitude of the 129Xe signal, A, obtained from concentrated Xe relative to that from diluted Xe with the same gas mixture used. ε was calculated from SNR and ν FWHM of 129Xe spectra according to:

where the suffixes “dil” and “conc” denote the parameters related to experiments with diluted Xe gas mixture without a separation procedure and experiments with concentrated Xe gas by removing isobutene using a cold trap, respectively. The amplitude of the 129Xe NMR signal obtained from a Xe gas mixture was proportional to the 129Xe polarization, P Xe, and the number density of 129Xe in the gas mixture at the measurement region, n Xe,meas. In the present study, because the signal was measured at constant temperature and atmospheric pressure, n Xe,meas was only the function of a fraction of Xe in the gas mixture at the measurement region, f Xe,meas, and therefore:

For the diluted condition, f Xe,meas was equal to the fraction of Xe in the gas mixture in the SEOP region, f Xe,SEOP, whereas for the concentrated condition, f Xe,meas becomes 1 − f ib,res with f ib,res as a fraction of residual isobutene in the gas mixture after the removal process. Therefore, the enhancement factor can be expressed as Eq. 10.

Apparent polarization

In order to compare the 129Xe signal intensities between diluted and concentrated conditions for various gas mixtures, the fraction of Xe in the gas mixture needs to be taken into account together with the polarization of 129Xe17, 19, 20. Apparent polarization, P app, has been proposed by Meersmann and coworkers19, 20 in this regard as Eq. 1. P app is a measure of the polarization taking into account the fraction of Xe in the gas mixture and scaled to the polarization in pure HP 129Xe gas, allowing direct comparison of the signal intensity of dilute Xe gas mixture with that of pure Xe gas at polarization P Xe. By using the P app, the enhancement factor is also expressed as the ratio of apparent polarization as Eq. 9. The apparent polarization for the diluted condition, P app,dil, was calculated from a measured P Xe,dil and a setup condition of f Xe,SEOP as:

whereas that for the concentrated condition, P app,conc, was calculated from P app,dil and ε using relations of Eqs 10 and 18 as:

because P Xe,conc cannot be determined due to uncertainty of f ib,res.

Retained polarization fraction

In the experimental setup used in this study, Xe gas mixture polarized at the SEOP cell was transferred to the NMR tube in which the 129Xe NMR signal is measured. During this transfer process, the nuclear spin polarization of 129Xe was depolarized by various factors. This polarization loss was simply defined here as:

where P Xe,meas and P Xe,SEOP are 129Xe polarization at the measurement region and at the exit of the SEOP cell, respectively, i denotes a site in which the relaxation occurs, T 1,i and τ i are the longitudinal relaxation time of 129Xe at site i and the residence time of the gas mixture at site i, respectively. τ i is related to the total gas flow rate at STP, F tot, according to:

where V i is the volume at site i, and p i and p s are the total pressure of the gas at site i and standard-state pressure, respectively. The total gas flow rate is the sum of each flow rate for constituents included in the gas mixture, F j :

The fraction of each constituent in the gas mixture was defined as:

When the polarized gas mixture was transferred to the measurement region without separation procedure, the fraction of Xe in the gas mixture at the measurement region, f Xe,meas, was equal to that at the SEOP region, f Xe,SEOP:

where f k,SEOP is the fraction of buffer gases in the SEOP region. If the buffer gases were removed after the SEOP process, f Xe,meas would increase with the following relation:

where f k,res is the fraction of residual buffer gases in the mixture after the removal process, and has a value ranging from 0 to f k,SEOP. That is, if the buffer gases are removed completely from Xe gas, f Xe,meas becomes unity, whereas if the buffer gases are not removed at all, f Xe,meas = f Xe,SEOP, which is the same as for the case described in Eq. 24. A retained polarization factor (RP) was defined as a polarization obtained from concentrated Xe, P Xe,meas,conc, divided by that from diluted Xe mixture, P Xe,meas,dil. This index means a factor that describes the fraction of polarization retained when the gas passes through the buffer gas separation procedure, and is expressed by using relations of Eqs 20 and 21 as:

with:

Here we assumed that the P Xe,SEOP is the same value regardless of the use of the cold trap, because the SEOP process, and hence P Xe,SEOP, was assumed not to be affected by the separation process in the experiments. Therefore, from Eqs 23 to 26, Eq. 10 can be further rewritten as Eq. 11.

Estimation of van der Waals-specific rate for isobutene

In order to estimate a van der Waals-specific rate for isobutene, ξ ib, we conducted the following experiments. By using a gas mixture of single composition, 3% Xe/97% isobutene, the total flow rate dependence of P Xe were measured for the two pressures in SEOP cell of p cell = 15 kPa and p cell = 101 kPa. The total flow rate was varied ranging from 35.1 sccm to 285 sccm. The results were analyzed by using following equation. Including a relaxation effect during the transfer process from the output of the SEOP cell to the measurement region into Eq. 2 (see also Retained polarization section), we can express the 129Xe polarization at the measurement region as a function of total flow rate as follows:

with:

where α is the same definition as the one described in Eq. 26. The experimental data were fitted by using Eq. 27 with P 0 and \({\tau }_{{\rm{SU}}}^{-1}\) as fitting parameters. The α was also set as a fitting parameter for the data obtained from the experimental data at p cell = 101 kPa whereas α = 8.4 sccm was used for that at p cell = 15 kPa, which was measured as α dil as described in the previous section. The values of V cell = 848 cc was used in the analysis. The observed P Xe,meas and fitted curves are shown in Fig. 5, and the estimated values from the fit are listed in Table 3 (upper). The van der Waals-specific rate for isobutene and 129Xe spin relaxation rate can be calculated from the values of \({\tau }_{{\rm{SU}}}^{-1}\) for two cell pressures using relations of Eqs 3 and 4. In the calculation, literature values of ξ Xe and 〈σv〉, and the number densities of atoms calculated for our experimental condition listed in Table 3 (lower) were used. The estimated values were ξ ib = 2.61 × 103 s−1 and ΓXe = 1.84 × 10−4 s−1.

Dependence of P Xe on total gas flow rate using 3% Xe/97% isobutene mixture polarized at 15 kPa and 101 kPa. The experiments were performed without a separation procedure. The solid and dashed lines are the result of the fit using Eq. 27. The coefficient of determination of the fit was R 2 = 0.9991 for 15 kPa and 0.9998 for 101 kPa.

Data Availability

All data generated or analysed during this study are included in this published article.

References

Goodson, B. M. Nuclear magnetic resonance of laser-polarized noble gases in molecules, materials, and organisms. J. Magn. Reson. 155, 157–216 (2002).

Meersmann, T. & Brunner, E. (eds) New developments in NMR No. 4. Hyperpolarized xenon-129 magnetic resonance: concepts, production, techniques and applications (The Royal Society of Chemistry, London, 2015).

Happer, W. et al. Polarization of the nuclear spins of noble-gas atoms by spin exchange with optically pumped alkali-metal atoms. Phys. Rev. A 29, 3092–3110 (1984).

Walker, T. G. & Happer, W. Spin-exchange optical pumping of noble-gas nuclei. Rev. Mod. Phys. 69, 629–642 (1997).

Hrycyshyn, E. S. & Krause, L. Inerastic collosions between excited alkali atoms and molecules. VII. Sensitized fluorescence and quenching in mixtures of rubidium with H2, HD, D2, N2, CH4, CD4, C2H4, and C2H6. Can. J. Phys. 48, 2761 (1970).

Happer, W. Optical pumping. Rev. Mod. Phys. 44, 169–249 (1972).

Chen, W. C., Gentile, T. R., Walker, T. G. & Babcock, E. Spin-exchange optical pumping of 3He with Rb-K mixtures and pure K. Phys. Rev. A 75, 013416 (2007).

Driehuys, B. et al. High-volume production of laser-polarized 129Xe. Appl. Phys. Lett. 69, 1668–1670 (1996).

Baranga, A. B. A. et al. Polarization of 3He by spin exchange with optically pumped Rb and K vapors. Phys. Rev. Lett 80, 2801–2804 (1998).

Norquay, G., Parnell, S. R., Xu, X., Parra-Robles, J. & Wild, J. Optimized production of hyperpolarized 129Xe at 2 bars for in vivo lung magnetic resonance imaging. J. Appl. Phys. 113, 044908 (2013).

Ruset, I. C., Ketel, S. & Hersman, F. W. Optical pumping system desigh for large production of hyperpolarized 129Xe. Phys. Rev. Lett. 96, 053002 (2006).

Driehuys, B., Pollaro, J. & Cofer, G. P. In vivo MRI using real-time production of hyperpolarized 129Xe. Magn. Reson. Med. 60, 14–20 (2008).

Korchak, S. E., Kilian, W. & Mitschang, L. Configuration and performance of a mobile 129Xe polarizer. Appl. Magn. Reson. 44, 65–80 (2013).

Hersman, F. W. et al. Large production system for hyperpolarized 129Xe for human lung imaging studies. Acad. Radiol. 15, 683–692 (2008).

Schrank, G., Ma, Z., Schoeck, A. & Saam, B. Characterization of a low-pressure high-capacity 129Xe flow-through polarizer. Phys. Rev. A 80, 063424 (2009).

Kuzuma, N. N., Patton, B., Raman, K. & Happer, W. Fast nuclear spin relaxation in hyperpolarized solid 129Xe. Phys. Rev. Lett. 88, 147602 (2002).

Wakayama, T. et al. Hyperpolarized 129Xe MRI of the mouse lung at a low xenon concentration using a continuous flow-type hyperpolarizing system. J. Magn. Reson. Imaging 27, 777–784 (2008).

Hane, F. T. et al. In vivo detection of cucurbit[6]uril, a hyperpolarized xenon contrast agent for a xenon magnetic resonance imaging biosensor. Sci. Rep. 7, 41027 (2017).

Six, J. S., Hughes-Riley, T., Stupic, K. F., Pavlovskaya, G. E. & Meersmann, T. Pathway to cryogen free production of hyperpolarized krypton-83 and xenon-129. PLoS One 7, e49927 (2012).

Hughes-Riley, T. et al. Cryogenics free production of hyperpolarized 129Xe and 83Kr for biomedical MRI applications. J. Magn. Reson. 237, 23–33 (2013).

Stupic, K. F., Six, J. S., Olsen, M. D., Pavlovskaya, G. E. & Meersmann, T. Combustion resistance of the 129Xe hyperpolarized nuclear spin state. Phys. Chem. Chem. Phys. 15, 94–97 (2013).

Nikolaou, P. et al. Near-unity nuclear polarization with an open-source 129Xe hyperpolarizer for NMR and MRI. Proc. Natl. Acad. Sci. USA 110, 14150–14155 (2013).

Nikolaou, P. et al. Xena: An automated ‘open-source’ 129Xe hyperpolarizer for clinical use. Magn. Reson. Imaging 32, 541–550 (2014).

Rogers, N. J. et al. Molecular hydrogen and catalytic combustion in the production of hyperpolarized 83Kr and 129Xe MRI contrast agents. Proc. Natl. Acad. Sci. USA 113, 3164–3168 (2016).

Hodono, S. et al. Hyperpolarized 129Xe MRI using isobutene as a new quenching gas. NMR Biomed. 29, 1414–1419 (2016).

Imai, H., Fukutomi, J., Kimura, A. & Fujiwara, H. Effect of reduced pressure on the polarization of 129Xe in the production of hyperpolarized 129Xe gas: development of a simple continuous flow mode hyperpolarizing system working at pressures as low as 0.15 atm. Concepts. Magn. Reson., Part B 33B, 192–200 (2008).

Freeman, M. S., Emami, K. & Driehuys, B. Characterizing and modeling the efficiency limits in large-scale production of hyperpolarized 129Xe. Phys. Rev. A 90, 023406 (2014).

Rice, C. V. & Raftery, D. Rubidium-xenon spin exchange and relaxation rates measured at high pressure and high magnetic field. J. Chem. Phys. 117, 5632–5641 (2002).

Zeng, X. et al. Experimental determination of the rate constants for spin exchange between optically pumped K, Rb, and Cs atoms and 129Xe nuclei in alkali-metal-noble-gas van der Waals molecules. Phys. Rev. A 31, 260–278 (1985).

Fink, A., Baumer, D. & Brunner, E. Production of hyperpolarized xenon in a static pump cell: Numerical simulations and experiments. Phys. Rev. A 72, 053411 (2005).

Romalis, M. V., Miron, E. & Cates, G. D. Pressure broadening of Rb D 1 and D 2 lines by 3He, 4He, N2, and Xe: Line cores and near wings. Phys. Rev. A 56, 4569 (1997).

Zameroski, N. D., Rudolph, W., Hager, G. D. & Hostutler, D. A. A study of collisional quenching and radiation-trapping kinetics for Rb(5p) in the presence of methane and ethane using time-resolved fluorescence. J. Phys. B: At. Mol. Opt. Phys. 42, 245401 (2009).

Fujiwara, H., Imai, H., Iguchi, S., Yoshimura, H. & Kimura, A. Polarized xenon gas concentration method, polarized xenon gas manufacturing supply device, and MRI system. US patent US 8,624,594 B2 (January 7, 2014), European patent EP 2,309,283 B1(September 19, 2012).

McGarry, J. Correlation and prediction of the vapor pressures of pure liquids over large pressure ranges. Ind. Eng. Chem. Process. Des. Dev. 22, 313–322 (1983).

Imai, H., Kimura, A. & Fujiwara, H. Development and application of mouse imaging using hyperpolarized xenon. In Albert, M. & Hane, F. (eds) Hyperpolarized and inert gas MRI in research and medicine, chap. 8, 115–129 (Elsevier, Amsterdam, 2016).

Fujiwara, H. et al. Relaxation behavior of laser-polarized 129Xe gas: size dependency and wall effect of the T1 relaxation time in glass and gelatin bulbs. J. Magn. Reson. 150, 156–160 (2001).

Möller, H. E., Cleveland, Z. I. & Driehuys, B. Relaxation of hyperpolarized 129Xe in a deflating polymer bag. J. Magn. Reson. 212, 109–115 (2011).

Zheng, W., Cleveland, Z. I., Möller, H. E. & Driehuys, B. Gradient-induced longitudinal relaxation of hyperpolarized noble gases in the fringe fields of superconducting magnets used for magnetic resonance. J. Magn. Reson. 208, 284–290 (2011).

Ishikawa, K., Imai, H. & Takagi, Y. Magnetic resonance imaging of spin-polarization transfer of polarized Xe atoms dissolving into ethanol. J. Chem. Phys. 120, 7602–7606 (2004).

Ishikawa, K., Imai, H. & Takagi, Y. Spin relaxation of polarized Xe atoms stored in deuterated ethanol. Phys. Rev. A 70, 042712 (2004).

Jameson, C. J., Jameson, A. K. & Hwang, J. K. Nuclear spin relaxation by intermolecular magnetic dipole coupling in the gas phase: 129Xe in oxygen. J. Chem. Phys. 89, 4074–4081 (1988).

Stupic, K. F., Cleveland, Z. I., Pavlovskaya, G. E. & Meersmann, T. Hyperpolarized 131Xe NMR spectroscopy. J. Magn. Reson. 208, 58–69 (2011).

Killian, T. J. Thermionic phenomena caused by vapors of rubidium and potassium. Phys. Rev. 27, 578 (1926).

Cates, G. D. et al. Rb-129Xe spin-exchange rates due to binary and three-body collisions at high Xe pressures. Phys. Rev. A 45, 4631 (1992).

Jau, Y. Y., Kuzma, N. N. & Happer, W. Magnetic decoupling of 129Xe-Rb and 129Xe-Cs binary spin exchange. Phys. Rev. A 67, 022720 (2003).

Acknowledgements

This work was supported by JSPS KAKENHI Grant Number 15K01283.

Author information

Authors and Affiliations

Contributions

H.I. and H.F. proposed the concept, designed research, and developed the experimental setup. All authors performed the experiments. H.I. analyzed the results, prepared figures, and mainly wrote the paper. All authors discussed the results and reviewed/edited and commented the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Imai, H., Yoshimura, H., Kimura, A. et al. Continuous flow production of concentrated hyperpolarized xenon gas from a dilute xenon gas mixture by buffer gas condensation. Sci Rep 7, 7352 (2017). https://doi.org/10.1038/s41598-017-07695-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-07695-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.