Abstract

Heterogeneous TiO2@Nb2O5 composites, in which TiO2 nanoparticles were evenly embedded on ultrathin Nb2O5 nanosheets, were used as anode materials for LIBs and demonstrated high capacities and excellent rate capability. For instance, this material displayed large capacities of 166.3 and 129.1 mA h g−1 at current densities of 1 A g−1 after 100 cycles and 5 A g−1 after 300 cycles, respectively.

Similar content being viewed by others

Introduction

To meet the demand for large application of lithium-ion batteries (LIBs) in the field of hybrid electric vehicles and electric vehicles, development of electrode materials with high capacity and superior rate capability is urgent1,2,3. Over the past few decades, TiO2 have been considered as an alternative anode material for LIBs because of chemical stability, safety, environmental friendliness as well as a negligible volume change in Li-ion intercalation4,5,6,7,8. In particular, nanostructured TiO2, with short electron/ion diffusion distance and high surface area, exhibit enhanced lithium-ion intercalation properties9,10,11,12. Notably, ultrafine TiO2 with several nanometers can reveal pseudocapacitance storage process as well as lithium intercalation process, resulting in an increase of the total amount of Li storage and improved rate capability13, 14. However, nanostructured TiO2 are prone to suffer from server aggregation which dramatically diminishes its rate performances and cycling stabilities.

Dispersion of nanosized TiO2 onto other materials with a large surface area is one of the strategies to overcome the above drawback of TiO2, because they can efficiently inhibit aggregation of TiO2. Conventionally, carbonaceous materials have been considered as excellent supports for TiO2 because of its excellent electronic conductivity. Thus, TiO2@carbon composite nanofibers15, TiO2/carbon nanotubes16 and TiO2-mesoporous carbon nanocomposites17 have been explored for lithium storage. Among these carbonaceous materials, the graphene with a two-dimensional structure appears particularly promising to improve the electrochemical performance of TiO2 composite materials and served as a support for nanostructured TiO2 due to its superior electrical conductivity, large surface area and excellent structural flexibility18,19,20,21,22,23,24. For examples, Wang et al. used anionic sulfate surfactants to synthesize TiO2-graphene hybrid, which showed improved electrochemical performance25. Zhang et al. reported a simple one-step hydrothermal method toward in situ growth of mesoporous TiO2 on 3D-graphene aerogels, which displayed a reversible capacity of 99 mA h g−1 at a high rate of 5000 mA g−1 26. Nevertheless, a homogenous dispersion of TiO2 nanoparticles onto graphene remains a challenge because of intrinsic incompatibility of graphene with inorganic components18, 27,28,29. On the other hand, graphene barely contribute to the capacity in operating potential windows of TiO2 (in the range of 1.0 between 3.0 V vs. Li+/Li). Therefore, it is highly desirable to develop other materials as supports for nanosized TiO2 deposition. Kim et al. reported that TiO2 nanoparticles were uniformly assembled onto high-conductivity indium tin oxide nanowire arrays, which exhibited a large capacity of more than 200 mA h g−1 at a 60 C rate30. Gu et al. reported that Ag nanowires/mesoporous TiO2 delivered a reversible capacity of ~160 mA h g−1 after 230 cycles at a current density of 1 C31.

In the present work, heterogeneous TiO2@Nb2O5 composites, in which TiO2 nanoparticles were evenly embedded on ultrathin Nb2O5 nanosheets, were successfully synthesized for the first time. Furthermore, this composite was used as an anode for LIBs and delivered high reversible capacities and superior rate capability.

Results

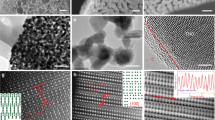

The morphology and structure of TiO2@Nb2O5 composites are firstly characterized by SEM and TEM, respectively. A SEM image in Fig. 1a gives us a full view of the obtained TiO2@Nb2O5 composites, in which uniform sheet-like morphology with thin thickness can be observed. Unlike pure Nb2O5 nanosheets (Figure S1), the surface of TiO2@Nb2O5 composites appeared rough (Fig. 1b). It is noteworthy that the thickness of these nanosheets was larger than that of pure Nb2O5 nanosheets. The surface difference of TiO2@Nb2O5 composites and Nb2O5 nanosheets indicates that TiO2 nanoparticles were embedded on Nb2O5 nanosheets. Apart from the uniform TiO2@Nb2O5 composites, single TiO2 nanoparticles are not observed. TEM images in Fig. 1c shows that the whole surface of Nb2O5 nanosheets was covered with TiO2 nanoparticles, and further confirms that TiO2@Nb2O5 heterogeneous structure can be formed. In a HRTEM image of TiO2@Nb2O5 composites in Fig. 1d, it can be found that the size of TiO2 nanoparticles was about 5 nm, which is smaller than that of pure TiO2 nanoparticles (Figure S1f). To investigate the chemical composition of the TiO2@Nb2O5 composites, EDX analysis was carried out and the result is depicted in Figure S3. Strong O, Ti and Nb signals can be observed and ICP-OES results (Table S1) showed that the atomic ratio of Nb to Ti was 0.44. At the same time, STEM image and the corresponding elemental mappings O, Ti and Nb were performed to investigate the distribution of TiO2 nanoparticles in the Nb2O5 nanosheets. As shown in Fig. 1e, TiO2 nanoparticles were evenly embedded on the surface of Nb2O5 nanosheets.

AFM measurement was performanced to determine the thicknesses of Nb2O5 nanosheets and TiO2@Nb2O5 composites. As shown in Fig. 2, the thicknesses of Nb2O5 nanosheets and TiO2@Nb2O5 composites were about 4.5 and 16 nm, respectively, further indicating that the size of TiO2 nanoparticles was about 6 nm. On the other hand, it can be clearly found that the surface of Nb2O5 nanosheets appeared smooth, while the surface of TiO2@Nb2O5 composites was rough. The AFM results were in good agreement with SEM and TEM results.

Figure 3 shows the XRD patterns of TiO2@Nb2O5 composites. The diffraction peaks can be indexed to the mixed of monoclinic Nb2O5 (JCPDS 43-1042) and anatase TiO2 (JCPDS 21-1272). Furthermore, Raman spectra of TiO2 nanoparticles, Nb2O5 nanosheets and TiO2@Nb2O5 composites were also recorded and the results are presented in Figure S2. Raman spectrum of TiO2@Nb2O5 composites exhibited the characteristic peaks of anatase TiO2 and weak peaks of Nb2O5, which is consistent with the XRD result.

To investigate the Brunauer-Emmett-Teller (BET) surface area and porous structure of TiO2@Nb2O5 composites, N2 adsorption-desorption isotherms of this material was measured and the results are depicted in Fig. 4. Similar to Nb2O5 nanosheets (Figure S5b), TiO2@Nb2O5 composites exhibited a type-IV isotherm with a type-H3 hysteresis loop, indicating that TiO2@Nb2O5 composites maintain sheet-like morphology. However, it is noteworthy that the range of hysteresis loop for TiO2@Nb2O5 composites is larger than that of Nb2O5 nanosheets (Figure S5b), which can be ascribed to the slight aggregation of TiO2 nanoparticles on the surface of Nb2O5 nanosheets. The BET surface area of TiO2 nanoparticles, Nb2O5 nanosheets and TiO2@Nb2O5 composites are 85.6, 99.8 and 134.6 m2 g−1, respectively. Homogeneous dispersion of TiO2 nanoparticles onto Nb2O5 nanosheets increased the thickness of these composites and inhibited aggregation of nanosheets. On the other hand, the structure of TiO2 nanoparticles embedded on nanosheets prevents the undesirable aggregation. Therefore, TiO2@Nb2O5 composites show an inconspicuous BJH pore size (Fig. 4b), which is different to that of Nb2O5 nanosheets (inset in Figure S5b) or TiO2 nanoparticles (inset in Figure S5a).

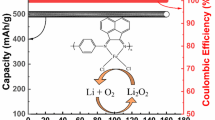

Figure 5a shows CV curves of TiO2@Nb2O5 composites at a scan rate of 0.5 mV s−1 in range of 1.0–3.0 V. All cathodic and anodic peaks can be ascribed to the mixed of monoclinic Nb2O5 and anatase TiO2. Several broad cathodic and anodic peaks in the potential range of 1.1–2.2 V can be observed, which are similar to those of other Nb2O5 32,33,34,35,36. In addition, TiO2@Nb2O5 composites also shows representative CV curves of anatase TiO2, in which two well-defined cathodic and anodic peaks at ~1.7 and 2.0 V can be clearly observed, respectively. The electrochemical performance of TiO2@Nb2O5 composites was evaluated by galvanostatic charge-discharge cycling at different current densities. Fig. 5b shows the charge-discharge voltage profiles of TiO2@Nb2O5 composites electrode in the 1st and 2nd cycle at a current density of 1 A g−1. Interestingly, TiO2@Nb2O5 composites also displayed sloping charge-discharge profiles, which was very similar to that of Nb2O5 nanosheets (Figure S7a). Namely, the two typical voltage plateaus of TiO2 cannot be observed in charge-discharge voltage profiles of TiO2@Nb2O5 composites. This might be ascribed to the effect of particle size of TiO2 on the galvanostatic charge-discharge process13. Comparison with Nb2O5 nanosheets (Figure S7a) or TiO2 nanoparticles (Figure S7b), TiO2@Nb2O5 composites delivered a superior initial discharge and charge capacities of 216.8 and 174.3 mA h g−1 with a high Coulombic efficiency of 80.4%. The first irreversible capacity loss can be attributed to some irreversible side reactions inside the electrode materials37.

As shown in Fig. 6, TiO2@Nb2O5 composites exhibited high reversible capacities of 166.3 mA h g−1 after 100 cycles at 1 A g−1 and 129.1 mA h g−1 after 300 cycles at 5 A g−1, respectively. In addition, the Coulombic efficiency rapidly increased to nearly 100% after first several cycles. On the other hand, the rate capability of TiO2 nanoparticles, Nb2O5 nanosheets and TiO2@Nb2O5 composites were evaluated and the results were shown in Fig. 6c and Figure S9. It is clear that TiO2@Nb2O5 composites exhibited a significantly improved rate capability over TiO2 nanoparticles or Nb2O5 nanosheets. The capacities of 194.9, 184.8, 173.2, 161.8, 149.3 and 136.0 mA h g−1 were achieved for TiO2@Nb2O5 composites at 0.1, 0.2, 0.5, 1, 2 and 5 A g−1, respectively. When the current density was back to 0.2 A g−1, the capacity of 177.1 mA h g−1 was obtained after 50 cycles.

It is well known that Nb2O5 is a kind of pseudocapacitative materials32,33,34. At the same time, TiO2 with small size also shows a pseudocapacitative behavior12, 13. To further authenticate the pseudocapacitive feature in TiO2@Nb2O5 composites, CV curves with different scan rates in cathodic process were presented in Fig. 7a. The total stored charge can be separated into three componets: the Faradaic contribution from the Li+ ion intercalation process, pseudocapacitance and nonFaradaic contribution from the double layer effect. The differnet storage mechanisms can be determined by investigating the change of the peak current (i) with the scan rate (ν) according to the following equation 1 13:

where both a and b are adjustable parameters. When the b value is about 0.5, it implies that Li+ ion intercalation process is a dominant process; while the b value is close to 1, it indicates that stored charge mostly come from the surface capacitive effect. As shown in Fig. 7b, the fitting b values at the voltages of 1.3, 1.5, 1.9, 2.1 and 2.3 V were 0.90, 0.87, 0.85, 0.92 and 0.83, respectively, which are very close to 1 and suggest that the lithium storage process is mostly dominated by the pseudocapacitative contributions. It’s worth noting that the fitting b value of 0.75 at the voltage of 1.7 V was relatively low, which implied the current comes primarily from Li+ ion intercalation and pseudocapacitative process. The high performance of TiO2@Nb2O5 composites would be mainly related to this pseudocapacitive storage process.

Discussion

In the present work, heterogeneous TiO2@Nb2O5 composites show high capacities at high-rate over TiO2@carbonaceous materials, as listed in Table 1. The excellent performance of TiO2@Nb2O5 composites can be attributed to the synergistic effects of nanostructured TiO2 and Nb2O5 as following: (i) TiO2@Nb2O5 composites with a surface area as large as 134.6 m2 g−1 can enhance the contact between the electrolyte and the electrode; (ii) nanosheet-like Nb2O5 as a support can buffer aggregation of TiO2 nanoparticles, and TiO2 nanoparticles embedded on Nb2O5 nanosheets offer a short diffusion distance and more surface storage sites for Li+ ions, thus promoting fast and reversible lithium intercalation/deintercalation into/from electrode and enhanced capacity; (iii) pseudocapacitive behavior of Nb2O5 nanosheets can deliver a high reversible capacity at high current densities32, 33, 38.

In summary, a two-step synthetic route was firstly developed for synthesizing heterogeneous TiO2@Nb2O5 composites, in which TiO2 nanoparticles were evenly embedded on the surface of ultrathin Nb2O5 nanosheets. When used as anode material for lithium-ion batteries, it showed high capacities and superior rate capability in comparison to pure TiO2 nanoparticles or Nb2O5 nanosheets due to their synergistic effects as following: The composite with a large surface area can enhance the contact between the active material and the electrolyte; the aggregation of TiO2 nanoparticles can be buffered on the surface of Nb2O5 nanosheets; TiO2 nanoparticles embedded on Nb2O5 nanosheets offer a short diffusion distance and more surface storage sites for Li+ ions; pseudocapacitive behavior of Nb2O5 can deliver a high reversible capacity at high current densities. Therefore, such heterogeneous nanostructure has a great potential application in field of photocatalysis, Li/Na-ion batteries and supercapacitors.

Methods

Synthesis of Nb2O5 nanosheets, TiO2 nanoparticles and TiO2@Nb2O5 composites

6 g of urea was dissolved in 30 mL of ethylene glycol (EG). After stirring for 10 min, 0.25 g of niobium (V) oxalate hydrate was added into above solution under stirring, and then the resulting solution was transferred into Teflon coated stainless steel with a capacity of 50 mL. The autoclave was kept at 200 °C for 2 days and then naturally cooled to room temperature. The white product was harvested via centrifugation, washed thoroughly with ethanol for several times and dried in an oven at 70 °C overnight. To obtain Nb2O5 nanosheets, the above white product was annealed at 500 °C in air for 2 h with a heating rate of 2 °C min−1.

For the synthesis of TiO2@Nb2O5 composites, the 50 mg of as-prepared Nb2O5 nanosheets were added into a 50 mL Teflon container with pre-filled with 30 mL ethylene glycol (EG) under stirring. After stirring for 3 h, 0.2 mL of titanium isopropoxide (TTIP) was dropwise added into the above suspension. After stirring for another 3 h, 4.0 g of urea was dissolved in above solution under stirring to form a white solution which was transferred into Teflon coated stainless steel. The autoclave was kept at 180 °C for 24 h and naturally cooled to room temperature. The white product was separated by centrifugation, washed with ethanol for several times and dried in an oven at 70 °C overnight. The resulting product was annealed at 400 °C in air for 2 h with a heating rate of 2 °C min−1 and TiO2@Nb2O5 composites were obtained.

TiO2 nanoparticles were synthesized following the same procedure of TiO2@Nb2O5 composites except for the addition of Nb2O5 nanosheets.

Characterizations

X-ray diffraction (XRD) patterns of products were recorded on a Rigaku Ultima IV X-ray diffractomator by using CuKα radiation. Scanning electron microscopy (SEM, Hitachi S4800 instrument) and transmission electron microscopy (TEM, FEI F20 S-TWIN instrument) were applied for the determination of products morphology and composition. The STEM mapping is TEM-based STEM and a voltage of 200 KV was used for the mapping. Atomic Force Microscope (AFM, Agilent Technologies) was used to determine the thickness and morphology of products. The Raman spectra were recorded in a Renishaw inVai Raman microscope with a 532 nm laser. N2 adsorption-desorption was performed on a Micromeritics ASAP 2020 instrument (Micromeritics, Norcross, GA, USA). BET surface area of the obtained samples were measure by nitrogen adsorption and desorption isotherms at 77 K after the samples were degassed under vacuum at 220 °C for 6 h. The pore size distributions of the samples were analyzed by using the BJH methods. The contents of Nb2O5 and TiO2 in the prepared composites were determined by PerkinElmer Optima 8000 inductively coupled plasma optical emission spectrometry (ICP-OES).

Electrochemical measurements

The electrochemical performance of all products was performed using 2025-type coin cells with two-electrodes. First, the resulting products were admixed with polyvinylidene fluoride (PVDF) binder and acetylene black carbon in a weight ratio of 7:2:1 to form a slurry which was coated on copper foil circular flakes and dried at 110 °C in a vacuum overnight. Copper foils coated active materials were used as working electrodes and Lithium foils were used as the counter electrodes. The electrolyte was 1 M LiPF6 in a 1:1:1 (volume ratio) mixture of ethylene carbonate (EC), ethylene methyl carbonate (EMC) and dimethyl carbonate (DMC). Celgard2400 (America) microporous polypropylene membrane was used as the separator. Cell assembly was carried out in a glove box filled with highly pure argon gas (O2 and H2O levels <1 ppm). Cyclic voltammetry (CV) and charge-discharge tests of all electrodes were performed using an electrochemical workstation (CHI 600 C) and Land automatic batteries tester (Land, CT 2001A, Wuhan, China), respectively. The specific capacities of TiO2@Nb2O5 were calculated based on the weight of the composites.

References

Tarascon, J. M. & Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001).

Goodenough, J. B. & Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 22, 587–603 (2001).

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Zhu, G. N., Wang, Y. G. & Xia, Y. Y. Ti-based compounds as anode materials for Li-ion batteries. Energy Environ. Sci. 5, 6652–6667 (2012).

Huang, S. Y., Kavan, L., Exnar, I. & Gratzel, M. Rocking chair lithium battery based on nanocrystalline TiO2 (anatase). J. Electrochem. Soc. 142, L142–L144 (1995).

Su, X. et al. Advanced titania nanostructures and composites for lithium ion battery. J. Mater. Sci. 47, 2519–2534 (2012).

Wu, Q. et al. Ultrathin anatase TiO2 nanosheets embedded with TiO2-B nanodomains for lithium-ion storage: capacity enhancement by phase boundaries. Adv. Energy Mater. 5, 1401756 (2015).

Zhang, R. Y., Elzatahry, A. A., Al-Deyab, S. S. & Zhao, D. Y. Mesoporous titania: From synthesis to application. Nano Today 7, 344–366 (2012).

Hu, Y. S., Kienle, L., Guo, Y. G. & Maier, J. High lithium electroactivity of nanometer-sized rutile TiO2. Adv. Mater. 18, 1421 (2006).

Arico, A. S., Bruce, P., Scrosati, B., Tarascon, J. M. & Van Schalkwijk, W. Nanostructured materials for advanced energy conversion and storage devices. Nat Mater. 4, 366–377 (2005).

Bruce, P. G., Scrosati, B. & Tarascon, J. M. Nanomaterials for rechargeable lithium batteries. Angew. Chem. Int. Ed. 47, 2930–2946 (2008).

Jiang, C. H. et al. Particle size dependence of the lithium storage capability and high rate performance of nanocrystalline anatase TiO2 electrode. J. Power Sources 166, 239–243 (2007).

Wang, J., Polleux, J., Lim, J. & Dunn, B. Pseudocapacitive contributions to electrochemical energy storage in TiO2 (anatase) nanoparticles. J. Phys. Chem. C 111, 14925–14931 (2007).

Zhu, K., Wang, Q., Kim, J. H., Pesaran, A. A. & Frank, A. J. Pseudocapacitive lithium-ion storage in oriented anatase TiO2 nanotube arrays. J. Phys. Chem. C 116, 11895–11899 (2012).

Yang, Z. X. et al. Synthesis of uniform TiO2@carbon composite nanofibers as anode for lithium ion batteries with enhanced electrochemical performance. J. Mater. Chem. 22, 5848–5854 (2012).

Wang, J., Ran, R., Tade, M. O. & Shao, Z. Self-assembled mesoporous TiO2/carbon nanotube composite with a three-dimensional conducting nanonetwork as a high-rate anode material for lithium-ion battery. J. Power Sources 254, 18–28 (2014).

Chang, P. Y., Huang, C. H. & Doong, R. A. Ordered mesoporous carbon-TiO2 materials for improved electrochemical performance of lithium ion battery. Carbon 50, 4259–4268 (2012).

Yang, S., Feng, X. & Müllen, K. Sandwich-like, graphene-based titania nanosheets with high surface area for fast lithium storage. Adv. Mater. 23, 3575–3579 (2011).

Ding, S. et al. Graphene-supported anatase TiO2 nanosheets for fast lithium storage. Chem. Commun. 47, 5780–5782 (2011).

Li, W. et al. Sol-gel design strategy for ultradispersed TiO2 nanoparticles on graphene for high-performance lithium ion batteries. J. Am. Chem. Soc. 135, 18300–18303 (2013).

Li, N. et al. Battery performance and photocatalytic activity of mesoporous anatase TiO2 nanospheres/graphene composites by template-free self-assembly. Adv. Funct. Mater. 21, 1717–1722 (2011).

Xin, X., Zhou, X., Wu, J., Yao, X. & Liu, Z. Scalable synthesis of TiO2/graphene nanostructured composite with high-rate performance for lithium ion batteries. ACS Nano 6, 11035–11043 (2012).

Zhang, X. et al. Electrospun TiO2-graphene composite nanofibers as a highly durable insertion anode for lithium ion batteries. J. Phys. Chem. C 116, 14780–14788 (2012).

Mo, R. W., Lei, Z. Y., Sun, K. N. & Rooney, D. Facile synthesis of anatase TiO2 quantum- dot/graphene nanosheet composites with enhanced electrochemical performance for lithium-ion batteries. Adv. Mater. 26, 2084–2088 (2014).

Wang, D. H. et al. Self-assembled TiO2-graphene hybrid nanostructures for enhanced Li-ion insertion. ACS Nano 3, 907–914 (2009).

Qiu, B., Xing, M. & Zhang, J. Mesoporous TiO2 nanocrystals grown in situ on graphene aerogels for high photocatalysis and lithium-ion batteries. J. Am. Chem. Soc. 136, 5852–5855 (2014).

Yang, S. et al. Fabrication of cobalt and cobalt oxide/graphene composites: towards high-performance anode materials for lithium ion batteries. ChemSusChem 3, 236–239 (2010).

Yoo, E. et al. Large reversible Li storage of graphene nanosheet families for use in rechargeable lithium ion batteries. Nano Letters 8, 2277–2282 (2008).

Yang, S., Feng, X., Ivanovici, S. & Müllen, K. Fabrication of graphene-encapsulated oxide nanoparticles: towards high-performance anode materials for lithium storage. Angew. Chem. Int. Ed. 49, 8408–8411 (2010).

Park, K. S. et al. Long-term, high-rate lithium storage capabilities of TiO2 nanostructured electrodes using 3D self-supported indium tin oxide conducting nanowire arrays. Energy Environ. Sci. 4, 1796–1801 (2011).

Qu, G., Geng, H., Guo, J., Zheng, J. & Gu, H. Facile synthesis of Ag nanowires/mesoporous TiO2 core-shell nanocables with improved properties for lithium storage. New J. Chem. 39, 7889–7894 (2015).

Kim, J. W., Augustyn, V. & Dunn, B. The effect of crystallinity on the rapid pseudocapacitive response of Nb2O5. Adv. Energy Mater. 2, 141–148 (2012).

Augustyn, V. et al. High-rate electrochemical energy storage through Li+ intercalation pseudocapacitance. Nat Mater. 12, 518–522 (2013).

Lubimtsev, A. A., Kent, P. R. C., Sumpter, B. G. & Ganesh, P. Understanding the origin of high-rate intercalation pseudocapacitance in Nb2O5 crystals. J. Mater. Chem. A 1, 14951–14956 (2013).

Lim, E. et al. Facile synthesis of Nb2O5@carbon core-shell nanocrystals with controlled crystalline structure for high-power anodes in hybrid supercapacitors. ACS Nano 9, 7497–7505 (2015).

Liu, M. N., Yan, C. & Zhang, Y. G. Fabrication of Nb2O5 nanosheets for high-rate lithium ion storage applications. Sci Rep 5, 6 (2016).

Kim, G. et al. TiO2 nanodisks designed for Li-ion batteries: a novel strategy for obtaining an ultrathin and high surface area anode material at the ice interface. Energy Environ. Sci. 6, 2932–2938 (2013).

Rahman, M. M. et al. A vein-like nanoporous network of Nb2O5 with a higher lithium intercalation discharge cut-off voltage. J. Mater. Chem. A 1, 11019–11025 (2013).

Shen, L. et al. Three-dimensional coherent titania–mesoporous carbon nanocomposite and its lithium-ion storage properties. ACS Appl. Mater. Interfaces 4, 2985–2992 (2012).

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (NSFC U1505241).

Author information

Authors and Affiliations

Contributions

Y.B.L. and M.D.W. proposed and designed the experiments. Y.B.L. and L.W.L. carried out the synthetic experiments and conducted the characterization. Y.B.L. and W.F.Z. performed the HRTEM, SEM characterization and structural analysis. Y.B.L. and M.D.W. analysed the data. Y.B.L. and M.D.W. wrote the manuscript. All the authors participated in discussions of the research.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, Y., Lin, L., Zhang, W. et al. Heterogeneous TiO2@Nb2O5 composite as a high-performance anode for lithium-ion batteries. Sci Rep 7, 7204 (2017). https://doi.org/10.1038/s41598-017-07562-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-07562-5

This article is cited by

-

Nanoscale niobium oxides anode for electrochemical lithium and sodium storage: a review of recent improvements

Journal of Nanostructure in Chemistry (2021)

-

Synthesis of a novel hexagonal porous TT-Nb2O5 via solid state reaction for high-performance lithium ion battery anodes

Journal of Central South University (2020)

-

Hierarchical bicomponent TiO2 hollow spheres as a new high-capacity anode material for lithium-ion batteries

Journal of Materials Science (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.