Abstract

The area used for mineral extraction is a key indicator for understanding and mitigating the environmental impacts caused by the extractive sector. To date, worldwide data products on mineral extraction do not report the area used by mining activities. In this paper, we contribute to filling this gap by presenting a new data set of mining extents derived by visual interpretation of satellite images. We delineated mining areas within a 10 km buffer from the approximate geographical coordinates of more than six thousand active mining sites across the globe. The result is a global-scale data set consisting of 21,060 polygons that add up to 57,277 km2. The polygons cover all mining above-ground features that could be identified from the satellite images, including open cuts, tailings dams, waste rock dumps, water ponds, and processing infrastructure. The data set is available for download from https://doi.org/10.1594/PANGAEA.910894 and visualization at www.fineprint.global/viewer.

Measurement(s) | terrestrial mining |

Technology Type(s) | satellite imaging |

Sample Characteristic - Environment | land |

Sample Characteristic - Location | Earth (planet) |

Machine-accessible metadata file describing the reported data: https://doi.org/10.6084/m9.figshare.12594248

Similar content being viewed by others

Background & Summary

Global extraction of minerals grew at an unprecedented pace in the past decades, causing a wide range of social and environmental impacts around the world1,2,3. Growing demand for essential minerals and declining quality of ores4,5,6 lead to larger volumes of unused material extracted and disposed7, increasing appropriation of land8,9. The direct land used by mining is a crucial indicator of environmental pressure, which is closely associated with a range of negative impacts, including fragmentation and degradation of ecosystems and biodiversity loss10,11,12,13,14. Such an indicator supports the implementation and monitoring of several Sustainable Development Goals (SDGs), as mining impacts on biodiversity and ecosystem services can be reduced by limiting mining areas15. Data on land use of mining is also important to further develop land footprint indicators that inform about land required along global supply chains to satisfy final consumption of products16,17. Yet, to date information about mining areas worldwide is not available.

Databases on the global mining sector are regularly updated by national geological services, mining industries, associations, and information services18,19. These databases, however, focus on commodities production, not on land use or other environmental aspects. They include, for example, commodity classifications, produced volumes, and approximate location of the sites, but not their geographic extents. These data sources alone are therefore not sufficient for a comprehensive assessment of the impacts related to the direct land use of global mining.

Satellite images are an important source of information on mining extents complementing surveys and statistics. Visual interpretation of satellite images9, for example, has been applied to map the 295 most relevant mining sites in terms of commodities production across the world20,21. This approach is effective and precise but can be costly and time-intensive, therefore, posing challenges to producing comprehensive accounts of global mining areas. Alternatively, automated classification algorithms to monitor land-use changes have rapidly advanced due to the increasing availability of satellite images and computational infrastructure22,23,24,25,26. These developments have helped to map mining extents in many regions27,28,29,30,31. However, scaling automated classification is difficult, as current state-of-the-art algorithms require a large amount of labeled examples32, which are usually not available.

In this work, we contribute to filling this knowledge gap by presenting a new data set of mining extents derived by visual interpretation of satellite images. Our data set covers more than six thousand mining sites distributed across the entire globe. These mining sites have reported mineral extraction or activities between the years 2000 and 2017, according to the SNL Metals and Mining database19. Within these regions, we delineated the mining areas (i.e., drew polygons) by visual interpretation of several satellite data sources, including Google Satellite, Microsoft Bing Imagery and Sentinel-2 cloudless33. As a result, we derived a set of 21,060 polygons globally, covering a total area of 57,277 km2. The overall accuracy, calculated from 1,000 stratified random points is 88.4% (for details see the section on Technical Validation).

This novel data set can help improving environmental impact assessments of the global mining sector, for example, regarding mining-induced deforestation or fragmentation and degradation of ecosystems. It can also serve as a benchmark for further monitoring the temporal evolution of mining sites around the world and as training and validation data to support automated classification of mines using satellite images.

Methods

We produced the global-scale data set on mining areas by visual interpretation of satellite images. This remote sensing technique is precise but also costly and time-intensive. To make the visual interpretation viable on a global scale, we defined regions of interest (ROI) based on the SNL Metals and Mining database19. This was important to reduce the time spent inspecting the satellite images and delineating the mining extents. Automated post-processing was also applied to check and correct possible invalid polygon geometries34, for instance polygons with self-intersections.

Region of interest

We defined our ROI as a buffer around the geographical coordinates (georeferenced points) of active mines reported in the SNL Metals and Mining database19. The SNL database provides production information on more than 35,000 mines across the globe. Among many other variables, SNL reports the approximate geographic coordinates of the extraction sites, from which we selected all mines reporting activity (i.e., actual production or active status) at any time between the years 2000 and 2017. This subset added up to 6,021 mining locations extracting 76 different commodities, with a focus on coal, metal ores and industrial minerals. Note that many mines, particularly regarding metal ore extraction, report more than one commodity in the SNL database (see full list in Table 1).

The buffer around the selected SNL mines was necessary to increase the efficiency and systematize the interpretation of the satellite images. The radius of the buffer should be as small as possible and cover all mining ground features, including open cuts, tailings dams, waste rock piles, water ponds, and processing infrastructure. Besides, the size of the buffer should consider that the geographical coordinates reported in the SNL database can differ between 1 km and 3 km from the mines identified in satellite images10,14.

After inspecting a random selection of mines we found that a 10 km radius was adequate for our propose, i.e., covering all ground features related to the mines while minimizing the time spent on the visual interpretation of the images. The 10 km buffer was sufficient to cover most of the mining complexes spreading over several kilometers, including the largest mines in the world, which have an open cut extending over 4 km diameter.

Delineation of mines

The polygons were delineated by two trained experts using an open-source web application35 developed for this specific purpose. The web interface systematically displays buffers and markers with information about the mines. As background, the app offers three options of satellite layers: Google Satellite, Microsoft Bing Imagery, and Sentinel-2 cloudless33. Google Satellite and Microsoft Bing provide images with a spatial resolution finer than 5 m for many regions of the world. These images allow identifying ground features related to mines with high confidence9. However, these data sources do not cover the whole globe with the same spatial resolution and contain out-of-date images for some regions36. To fill this gap, we used the Sentinel-2 cloudless data product with a 10 m spatial resolution provided by EOX33. The Sentinel-2 cloudless provides a mosaic built from Sentinel-2 images taken during the years 2017 and 2018. Combining these data layers, the experts identified and delineated the ground features related to mining.

All three satellite data sources were visually inspected before delineating the polygons. The majority of the inspected locations had at least two sources of clear images (e.g., no cloud cover) and sufficient spatial resolution to identify mining features. Only very few locations lacked images with sufficient quality to draw the polygons, for example, due to cloud cover or low spatial resolution.

We used the source showing the largest mining extent for the delineation of the areas. This premise was taken because the largest extent of a mine is usually stable for several years as a long lifespan is intended due to economic reasons. Besides, mining areas generally increase and could only reduce through ecological restoration, which can take a long time37. These conjectures do not ensure the temporal consistency of all delineated extents but helped to capture the largest and most up-to-date extent of the mines according to the available satellite images within our ROI.

In some cases, the mining polygons can also extend beyond the ROI. Mining features intersecting the buffer borders were delineated to account for their full extent, even if they extend beyond the buffer limits. Moreover, the mining polygons can contain isolated patches with forest or other land covers, which do not necessarily represent any mining feature on the ground. These patches were included because we aim at accounting for the total area used by mining, including isolated spare areas that most probably cannot have other uses. The delineated polygons do not distinguish the different ground features within the mines, i.e., each polygon can cover several mining features (open cuts, tailings dams, waste rock dumps, etc). As a final product from the delineation we obtained a set of polygons covering the total land used by mining within the ROI.

Geoprocessing of data records

We applied geospatial and geometric operations to check and correct the raw data collection. This geoprocessing was performed to avoid double counting of mining areas, correct invalid geometries, and add attributes (variables) to the polygons. To avoid double-counting, we dissolved polygons that possibly overlapped or shared a common boundary, i.e., we merged them to form a single polygon. After that, we removed sliver polygons (unwanted small polygons) and invalid polygon geometries, producing a consistent set of polygons.

From this set of preprocessed polygons, we calculated the area of each feature and added information on the country where each polygon is located. We calculated the area in square kilometers by projecting each polygon to its respective Universal Transverse Mercator (UTM) zone. After that, a spatial join query acquired country name and ISO 3166-1 alpha-3 code from country’s administrative units geometries available from EUROSTAT38. The final set of polygons thus includes the geometries (polygons) covering the mining areas, their respective areas in square kilometers, country name, and ISO 3166-1 alpha-3 code of the corresponding country.

From the mining polygons we derived global grid data sets with the mining area at 30 arcsecond, 5 arcminute and 30 arcminute spatial resolution (approximately 1 × 1 km, 10 × 10 km and 50 × 50 km at the equator). This is useful because many modeling applications require standardized grid data39. The 30 arcsecond grid was derived from the percentage of area of the geometric intersection between each cell and the geometries of the mining polygons. These percentages were rounded to zero decimal digits to reduce the size of the data set. Therefore, the percentage of the cell covered by mine should be greater than 0.5% to be considered, i.e., approximately 0.5 ha at the equator. To obtain the gridded mining area, we estimated the area of each cell in square kilometers and multiplied with the percentage of mining cover per cell, resulting in a 30 arcsecond global grid indicating the mining area within each cell. The 5 arcminute and 30 arcminute grid resolutions were downsampled form the 30 arcsecond grid. All scripts used in the geoprocessing of data records are available with our open-source web application tool35.

Data Records

Our data records provide spatially explicit information on the direct land use of mining activities. The main data set consists of 21,060 mining polygons covering the extents of mining sites worldwide40. Grid data derived from the polygons is available at 30 arcsecond, 5 arcminute, and 30 arcminute spatial resolution, providing a ready-to-use data set for modeling purposes with the mining area in square kilometers per grid cell. All data records are available for download from PANGAEA (Data Publisher for Earth & Environmental Science) at https://doi.org/10.1594/PANGAEA.910894 and for visualization at https://www.fineprint.global/viewer.

Mining polygons

Figure 1 illustrates how the satellite images were used to delineate the mining extent. In this example, the area is used for coal mining in Mackenzie River, Queensland, Australia. The polygon in Fig. 1a was derived from the Sentinel-2 cloudless mosaic (Fig. 1b), which shows the largest extent of the mine among all three images sources. The Sentinel-2 cloudless mosaic is composed by images from the years 2017 and 201833 while Microsoft Bing (Fig. 1c) and Google Satellite (Fig. 1d) only offered out-of-date images for that location, respectively taken in July 2011 and December 2007. Nevertheless, all three data sources contributed to providing pieces of evidence of mining in the mapped area.

An example polygon delineated over a coal mine in Mackenzie River, Queensland, Australia. (a) Shows the delineated polygon in purple and (b) shows the Sentinel-2 cloudless mosaic composed by images from the year 201833 used to delineate the mining extent. (c) Shows a Microsoft Bing image from July 2011 and (d) a Google Satellite image from December 2007.

The delineated polygons cover all infrastructure and land cover types directly related to mining activities. This can produce large polygons, such as in the case of the Salar de Atacama, Chile. In that area, we delineated a polygon of approximately 1,354 km2, covering almost the whole nucleus of the salt flat, which extends over 1,360 km2 and is used as a source to extract lithium, boron, potassium, iodine, sodium chloride, and bischofite41. Figure 2 shows the delineated polygon extent and a detailed view of one of the mining plants. Some pipelines and wells are more than 10 km away from the core infrastructure of the mine. We decided to map the whole area because the mining plants, in fact, have brine pumping and monitoring wells spreading over the entire salt flat far beyond the actual evaporation ponds41. Alternative assumptions mapping only the evaporation ponds estimated an area of only 80.53 km2 in 201742. However, it is important to note that the case of Salar de Atacama was rather isolated; in most cases, no features such as pipelines and wells outside the main mining sites could be identified from the available satellite images.

Mine on the Salar de Atacama salt flat, Chile. The purple polygon on the left side was derived from the Sentinel-2 images shown in the background. The polygon covers all infrastructure spread over the salt flat, including water pipelines, wells, and the actual mining plants. The zoom boxes on the right side show Google Satellite images with a detailed view of water pipelines and wells over the salt flat as well as one of the mining plants.

In many cases, mines are located following the structure of mineral deposits, making it easy to map them from satellite images. We selected three mines to illustrate these large-scale concentrated activities (Fig. 3). The first example (Fig. 3a) shows the main open cut of the Carajás iron ore mine complex in the Brazilian Amazon, which is among the world’s largest iron ore mining operations43. Figure 3b shows the Batu Hijau copper-gold mine. Despite its large open cut, this mine does not use much area for unused material, as its tailings disposal takes place in the ocean44. The third example is the Super Pit gold mine in Australia, Fig. 3c. This mine is located in one of the largest gold producing regions in the world. In the case of these large mines, coordinates reported in the SNL database were accurate.

Contrasting to the above examples, in other regions the reported coordinates were of lower accuracy. Figure 4, for example, shows a large area with widely spread coal mining activities in East Kalimantan, Indonesia. The SNL database reports some mining locations in this region, however, they do not always spatially intersect the mining areas mapped from the satellite images. In these cases the predefined ROI (10 km buffer around the coordinates) was crucial to systematically map the extents of the mines.

Coal mining polygons in East Kalimantan, Indonesia, overplayed with the Sentinel-2 Cloudless images form the year 2019 provided by EOX33.

Overview of global mapped mining area

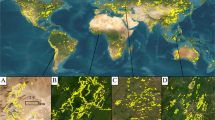

Figure 5 shows an overview of the geographical distribution of our mapped mining area across the globe. The map in the figure is projected to equal area Interrupted Goode Homolosine and resampled to a 50 × 50 km grid to facilitate visualization. From this figure we can see concentrations of mining areas in many regions, for example, in northern Chile mainly due to copper extraction and northeastern Australia and East Kalimantan in Indonesia because of coal mining.

A summary of our data aggregated by country shows that 51% of the mapped mining area is concentrated in only five countries: China, Australia, the United States, Russia, and Chile. Another ten countries account for 30%, and the remaining countries add up to 19% of the total mapped mining area (Fig. 6). These results show that mining areas are highly concentrated in only a few countries. However, it is worth mentioning that our polygons could be biased by the activities reported in the SNL database and could mask countries and commodities that are poorly reported. For instance, SNL data underestimates the quantities extracted in China for most metals and minerals compared to national accounts according to UNEP’s Global Material Flows Database2. For most African countries, however, SNL extraction of metals compares well to the national aggregates. One of the few exceptions is gold from the DR Congo, where SNL data sums up to less than 6 mt in the year 2017, while UNEP reports more than 10 mt of gold ore extraction.

Countries have different profiles regarding the spatial distribution of the mines. For example, China and Australia have similar figures on the mapped mining area, 6,567 km2, and 6,470 km2. However, they vary with respect to the number of identified polygons, 5,557 and 1,797, respectively. This discrepancy in the number of mining locations can be related to the high importance of the small-scale mining industry in China45,46, while Australia is characterized by fewer, large-scale mines19.

Figure 7 displays the relationship between the mapped area and the number of polygons on a country level. Most of the variation in mining area can be explained by a linear relationship to the number of polygons. Excluding China from the data set, a simple linear regression model reaches r2 = 0.90 (dashed line in Fig. 7). However, r2 drops to = 0.71 for the full data set including China (solid line in Fig. 7). A complete summary of the mining area mapped per county is shown in Table 2 and available from download with our data records40.

Our mining data set accounts for all land cover types related to mining that could be identified from the satellite images. However, it does not distinguish the different features within the polygons. For example, we could not separate mining from quarry, because this would require additional information other than the satellite images. Although our data set does not cover all existing mines, to date, it is the most comprehensive database on mining extents openly available. The data set can help filling existing gaps for spatially explicit mineral extraction assessments on a global scale. It opens up opportunities to improve environmental pressure and impact indicators of the mining sector and can support the development of automated systems to monitor mining sites worldwide.

Technical Validation

The mapped mining extents presented in this work can be subject to many sources of error, ranging from experts’ interpretation to the temporal availability and precision of the satellite images. The precision of the delineated mining borders can vary according to the satellite data source and the location. In general, the satellite sources used in this work provide sufficient spatial resolution and georeferencing accuracy to map mining areas9. Images available from Google Earth, for instance, have an overall positional root mean squared error (RMSE) of 39.7 m related to the reality on the ground47. Sentinel-2, on the other hand, has a RMSE below its pixel size (10 × 10 m)48. These errors are acceptable for global scale environmental assessments.

The visual interpretation of satellite images depends on the previous knowledge of the perceiving person. The ground features related to mining are not always easy to identify in the satellite images and can be subject to the judgment of the person that delineates a particular mine. For that reason, we obtained a second independent classification for a set of random points. We drew a set of 1,000 random points stratified49 between the area mapped as mine and those not mapped as mine (no-mine) within the region of interest (10 km buffer from the geographical coordinates). These validation points were inspected independently by experts that did not participate in the delineation of the mines. They classified these validation points as mine or no-mine based on the three satellite data sources without information whether or not the points were originally mapped as part of a mining areas. The validation points are also part of our data records40.

The overall agreement between the mapped areas and the validation points was 88.4%. Assuming that the validation points consist of a reference data set, we derived User’s (commission errors) and Producer’s (omission errors) accuracy (see Table 3). The User’s accuracy tells how well the classes in the map represent the reality on the ground; the Producer’s accuracy points how well a class has been mapped50. In our case the mapped mining areas have 97.5% User’s accuracy and 78.8% Producer’s accuracy, meaning that the mapped areas are highly reliable (less than 3% was incorrectly mapped as mining), but we missed some mining areas (the omission of mines was around 21.2%). The omission of mines also reflects a lower User’s accuracy of the no-mine class (82.2%).

An alternative way to visualize the accuracy of our data set is the Receiver Operating Characteristic (ROC probability curve). The graph in Fig. 8 displays the classification performance in terms of true positive and false positive. A discrete classifier (mine/no-mine) produces a point in the ROC curve. For our classification, the point is near the upper-left corner of the ROC curve, meaning that the classification performs well (a perfect classifier would reach the point 0, 1). Besides, the area under the curve (AUC) in Fig. 8 shows that our classification has 89.9% probability of correctly distinguishing between mine and no-mine.

Looking at the spatial distribution of the validation points, we found that half of the points with disagreement (i.e., 58 points) are located less than 50 m from the borders of the delineated polygons. On the other hand, of the points with an agreement (i.e., 884 points) only 16% are located closer than 50 m to the polygons’ borders. This shows that higher uncertainty lies on the borders of the delineated extents as it can be expected due to the use of several satellite data sources with different precision. These results also indicate that we have high confidence in the existence of mines within the mapped polygons.

Usage Notes

The global mining data set described here is available from PANGAEA under the license Creative Commons Attribution-ShareAlike 4.0 International (CC-BY-SA). The data records include the mining polygons, validation points, mining area grid, and a summary of the mining area per country.

1. The mining polygons and validation points are encoded in GeoPackage geographic data structures51, such as:

(a) the mining_polygons layer has five attributes:

-

ISO3_CODE: A string with the country’s ISO 3166-1 alpha-3 code

-

COUNTRY_NAME: A string with the country name in English

-

AREA: A number with the area of the feature in square kilometers

-

geom: A polygon geometry in geographical coordinates WGS84

-

fid: An integer with feature ID

(b) the validation_points layer has four attributes:

-

MAPPED: A string with the class derived from the mining polygons (“mine” or “no-mine”)

-

REFERENCE: A string with the validation class (“mine” or “no-mine”)

-

geom: A point geometry in geographical coordinates WGS84

-

fid: An integer with feature ID

2. The mining grids include a single layer (one band raster) encoded in Geographic Tagged Image File Format (GeoTIFF)52. Each grid cell over land has a float number (data type Float32) greater than or equal to zero representing the mining area in square kilometers; grid cells over water have no-data values. The grid is available in three spatial resolutions, 30 arcsecond, 5 arcminute, and 30 arcminute, extending from the longitude −180 to 180 degrees and from the latitude −90 to 90 degrees in the geographical reference system WGS84.

3. The summary of the mapped mining area per country derived from the mining polygons is available in Comma-separated values (CSV)53 format, including four attributes:

-

COUNTRY_NAME: A string with the country name in English

-

ISO3_CODE: A string with the country ISO3 code

-

AREA: A number with the area of the feature in square kilometers

-

N_FEATURES: An integer with the number of features per country

Our spatially explicit data records can be combined with other geographical data to perform further statistical analysis, for example, to test spatially stratified heterogeneity54 and non-stationarity of variables55,56. For that, users can open the data records using software that support Geographic Information System (GIS), including, QGIS57, R58, and Python59. Besides, we also provide a tool for visual analysis of the geographical data records at www.fineprint.global/viewer and a Web Map Service (WMS)60 accessible from www.fineprint.global/geoserver/wms.

Code availability

All the code and geoprocessing scripts used to produce the results of this paper are distributed under the GNU General Public License v3.0 (GPL-v3)61 from the repository www.github.com/fineprint-global/app-mining-area-polygonization35. The processing scripts were written in R58, Python59, and GDAL (Geospatial Data Abstraction Library62). The web application to delineate the polygons was written in R Shiny63 using a PostgreSQL64 database with PostGIS65 extension for storage. The full app setup uses Docker65 containers to facilitate management, portability, and reproducibility.

The web application supports the delineation of areas from the satellite images layers. It systematically displays the regions of interest (e.g., buffer around the mines) and several background options of satellite images, which the users can take into account to draw and edit polygons. Note that mining coordinates are not part of the web application and must be fed into the database by the user. To learn more about the application setup see www.github.com/fineprint-global/app-mining-area-polygonization. The current version of app provides image layers from Sentinel-2 Cloudless33, Google Satellite, and Microsoft Bing Imagery. Further sources of satellite images can be added to the application via WMS.

References

Giljum, S., Dittrich, M., Lieber, M. & Lutter, S. Global patterns of material flows and their socio-economic and environmental implications: A MFA study on all countries world-wide from 1980 to 2009. Resources 3, 319–339 (2014).

IRP, U. Global Resources Outlook 2019: Natural Resources for the Future we Want. A Report of the International Resource Panel. Report No. DTI/2226/NA (United Nations Environment Programme, 2019).

Krausmann, F., Schandl, H., Eisenmenger, N., Giljum, S. & Jackson, T. Material flow accounting: Measuring global material use for sustainable development. Ann. Rev. Env. Resour. 42, 647–675 (2017).

Calvo, G., Mudd, G., Valero, A. & Valero, A. Decreasing ore grades in global metallic mining: A theoretical issue or a global reality? Resources 5 (2016).

Prior, T., Giurco, D., Mudd, G., Mason, L. & Behrisch, J. Resource depletion, peak minerals and the implications for sustainable resource management. Glob. Environ. Change 22, 577–587 (2012).

West, J. Decreasing metal ore grades. J. Ind. Ecol. 15, 165–168 (2011).

Mudd, G. M. Global trends in gold mining: Towards quantifying environmental and resource sustainability. Resour. Policy 32, 42–56 (2007).

Sonter, L. J., Moran, C. J., Barrett, D. J. & Soares-Filho, B. S. Processes of land use change in mining regions. J. Clean. Prod. 84, 494–501 (2014).

Werner, T., Bebbington, A. & Gregory, G. Assessing impacts of mining: Recent contributions from GIS and remote sensing. Extract. Indus. Soc. 6, 993–1012 (2019).

Kobayashi, H., Watando, H. & Kakimoto, M. A global extent site-level analysis of land cover and protected area overlap with mining activities as an indicator of biodiversity pressure. J. Clean. Prod. 84, 459–468 (2014).

Sonter, L. J., Ali, S. H. & Watson, J. E. M. Mining and biodiversity: key issues and research needs in conservation science. Proc. Biol. Sci. 285 (2018).

Islam, K., Vilaysouk, X. & Murakami, S. Integrating remote sensing and life cycle assessment to quantify the environmental impacts of copper-silver-gold mining: A case study from laos. Resour. Conserv. Recy. 154, 104630 (2020).

Butt, N. et al. Biodiversity risks from fossil fuel extraction. Science 342, 425–426 (2013).

Murguía, D. I., Bringezu, S. & Schaldach, R. Global direct pressures on biodiversity by large-scale metal mining: Spatial distribution and implications for conservation. J. Eenviron. Manage. 180, 409–420 (2016).

Endl, A., Tost, M., Hitch, M., Moser, P. & Feiel, S. Europe’s mining innovation trends and their contribution to the sustainable development goals: Blind spots and strong points. Resour. Policy 101440 (2019).

Bruckner, M., Fischer, G., Tramberend, S. & Giljum, S. Measuring telecouplings in the global land system: A review and comparative evaluation of land footprint accounting methods. Ecol. Econ. 114, 11–21 (2015).

Schaffartzik, A. et al. Trading land: A review of approaches to accounting for upstream land requirements of traded products. J. Ind. Ecol. 19, 703–714 (2015).

USGS – United States Geological Survey. Mineral resources online spatial data, https://mrdata.usgs.gov/ (2018).

S&P Global Market Intelligence. SNL metals and mining database, https://www.spglobal.com/marketintelligence/en/campaigns/metals-mining (2018).

Murguía, D. I. & Bringezu, S. Measuring the specific land requirements of large-scale metal mines for iron, bauxite, copper, gold and silver. Prog. Ind. Ecol. 10, 264–285 (2016).

Werner, T. T. et al. Global-scale remote sensing of mine areas and analysis of factors explaining their extent. Glob. Environ. Change 60 (2020).

Mountrakis, G., Im, J. & Ogole, C. Support vector machines in remote sensing: A review. ISPRS J. Photogramm. 66, 247–259 (2011).

Belgiu, M. & Dragu, L. Random forest in remote sensing: A review of applications and future directions. ISPRS J. Photogramm. 114, 24–31 (2016).

Zhu, X. X. et al. Deep learning in remote sensing: A comprehensive review and list of resources. IEEE Geosc. Rem. Sen. M. 5, 8–36 (2017).

Wulder, M. A., Coops, N. C., Roy, D. P., White, J. C. & Hermosilla, T. Land cover 2.0. Int. J. Remote Sens. 39, 4254–4284 (2018).

Zhu, Z. et al. Benefits of the free and open Landsat data policy. Remote Sens. Environ. 224, 382–385 (2019).

Petropoulos, G. P., Partsinevelos, P. & Mitraka, Z. Change detection of surface mining activity and reclamation based on a machine learning approach of multi-temporal Landsat TM imagery. Geocarto Int. 28, 323–342 (2013).

LaJeunesse Connette, K. J. et al. Assessment of mining extent and expansion in Myanmar based on freely-available satellite imagery. Remote Sens. 8 (2016).

Yu, L. et al. Monitoring surface mining belts using multiple remote sensing datasets: A global perspective. Ore Geol. Rev. 101, 675–687 (2018).

Vasuki, Y. et al. The spatial-temporal patterns of land cover changes due to mining activities in the darling range, western australia: A visual analytics approach. Ore Geol. Rev. 108, 23–32 (2019).

Mukherjee, J., Mukherjee, J., Chakravarty, D. & Aikat, S. A novel index to detect opencast coal mine areas from Landsat 8 OLI/TIRS. IEEE J-STARS 12, 891–897 (2019).

Waldrop, M. M. News Feature: What are the limits of deep learning? PNAS 116, 1074–1077 (2019).

EOX IT Services GmbH. Sentinel-2 cloudless (contains modified Copernicus sentinel data 2017 and 2018), https://s2maps.eu (2018).

Pebesma, E. Simple Features for R: Standardized Support for Spatial Vector Data. R J. 10, 439–446 (2018).

Gutschlhofer, J. & Maus, V. Web application for mining area polygonization version 1.2. Zenodo https://doi.org/10.5281/zenodo.3691743 (2020).

Lesiv, M. et al. Characterizing the spatial and temporal availability of very high resolution satellite imagery in Google Earth and Microsoft Bing maps as a source of reference data. Land 7 (2018).

Bradshaw, A. Restoration of mined lands—using natural processes. Ecol. Eng. 8, 255–269 (1997).

EUROSTAT. Countries, 2016 - administrative units - dataset (generalised dataset derived from eurogeographics and UN-FAO GI data), https://ec.europa.eu/eurostat/cache/GISCO/distribution/v2/countries/ (2018).

Amatulli, G. et al. A suite of global, cross-scale topographic variables for environmental and biodiversity modeling. Sci. Data 5, 180040 (2018).

Maus, V. et al. Global-scale mining polygons (version 1). Pangaea https://doi.org/10.1594/PANGAEA.910894 (2020).

Marazuela, M., Vázquez-Suñé, E., Ayora, C., García-Gil, A. & Palma, T. The effect of brine pumping on the natural hydrodynamics of the Salar de Atacama: The damping capacity of salt flats. Sci. Total Environ. 654, 1118–1131 (2019).

Liu, W., Agusdinata, D. B. & Myint, S. W. Spatiotemporal patterns of lithium mining and environmental degradation in the Atacama Salt Flat, Chile. Int. J. Appl. Earth Obs. 80, 145–156 (2019).

Hansen, K. Brazil’s Carajás mines, NASA Earth Observatory, https://earthobservatory.nasa.gov/images/144457/brazils-carajas-mines (2018).

Mining Technology. Batu Hijau copper-gold mine, Indonesia, https://www.mining-technology.com/projects/batu/ (2020).

Shen, L. & Gunson, A. J. The role of artisanal and small-scale mining in China’s economy. J. Clean. Prod. 14, 427–435 (2006).

Shen, L., Dai, T. & Gunson, A. J. Small-scale mining in China: Assessing recent advances in the policy and regulatory framework. Resour. Policy 34, 150–157 (2009).

Potere, D. Horizontal positional accuracy of Google Earth’s high-resolution imagery archive. Sensors 8, 7973–7981 (2008).

Vajsová B & Åstrand, P. J. New sensors benchmark report on Sentinel-2A sensor over Maussane test site for CAP purposes. Report No. EUR 27674EN (Publications Office of the European Union, 2015).

Cochran, W. G. Sampling Techniques. Series in Probability and Statistics (Wiley, 1977), 3 edn.

Olofsson, P. et al. Good practices for estimating area and assessing accuracy of land change. Remote Sens. Environ. 148, 42–57 (2014).

OGC – Open Geospatial Consortium. GeoPackage Encoding Standard, https://www.geopackage.org/ (2005).

OGC – Open Geospatial Consortium. Geographic tagged image file format (GeoTIFF), https://www.ogc.org/standards/geotiff (2019).

The Internet Society. RFC 4180: Common format and MIME type for comma-separated values (CSV). https://tools.ietf.org/html/rfc4180 (2005).

Wang, J.-F., Zhang, T.-L. & Fu, B.-J. A measure of spatial stratified heterogeneity. Ecol. Indic. 67, 250–256 (2016).

Brunsdon, C., Fotheringham, A. S. & Charlton, M. E. Geographically weighted regression: A method for exploring spatial nonstationarity. Geogr. Anal. 28, 281–298 (1996).

Brunsdon, C., Fotheringham, S. & Charlton, M. Geographically weighted regression. J. R. Stat. Soc., Ser. D Stat. 47, 431–443 (1998).

QGIS Development Team. QGIS geographic information system, version 3.12.0. Open Source Geospatial Foundation, https://www.qgis.org (2020).

R Core Team. R: A language and environment for statistical computing, version 3.6.1. Foundation for Statistical Computing, Vienna, Austria, https://www.R-project.org (2019).

Python Core Team. Python: A dynamic, open source programming language, version 2.7.17. Python Software Foundation, https://www.python.org (2019).

OGC – Open Geospatial Consortium. Web map service interface standard (WMS), https://www.ogc.org/standards/wms (2020).

GNU general public license, version 3. Free Software Foundation, https://www.gnu.org/licenses/gpl-3.0.en.html (2019).

GDAL/OGR contributors. GDAL/OGR geospatial data abstraction software library, version 2.4.2. Open Source Geospatial Foundation, https://gdal.org (2019).

Chang, W., Cheng, J., Allaire, J., Xie, Y. & McPherson, J. Shiny: Web Application Framework for R, version 1.3.2, https://CRAN.R-project.org/package=shiny (2019)

The PostgreSQL Global Development Group. PostgreSQl: an open source object-relational database system, version 11.6, https://www.postgresql.org/ (2019).

PostGIS Team. PostGIS: a spatial database extender for PostgreSQL object relational database, version 2.5.4. Open Source Geospatial Foundation, https://postgis.net (2019).

Acknowledgements

This work was supported by the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme grant number 725525.

Author information

Authors and Affiliations

Contributions

Victor Maus – conceptualization, experiment design, data collection, data revision, and writing the manuscript. Stefan Giljum – conceptualization, data validation, and writing the manuscript. Jakob Gutschlhofer – experiment design, scripting and web application development. Dieison Morozoli da Silva – data collection and revision. Michael Probst – data collection and revision. Sidnei Luís Bohn Gass – data validation. Sebastian Luckeneder – compiling mining data and data validation. Mirko Lieber – experiment design and data revision. Ian McCallum – data validation and accuracy assessment.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

The Creative Commons Public Domain Dedication waiver http://creativecommons.org/publicdomain/zero/1.0/ applies to the metadata files associated with this article.

About this article

Cite this article

Maus, V., Giljum, S., Gutschlhofer, J. et al. A global-scale data set of mining areas. Sci Data 7, 289 (2020). https://doi.org/10.1038/s41597-020-00624-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41597-020-00624-w

This article is cited by

-

A combined compost, dolomite, and endophyte addition is more effective than single amendments for improving phytorestoration of metal contaminated mine tailings

Plant and Soil (2024)

-

Patterns of infringement, risk, and impact driven by coal mining permits in Indonesia

Ambio (2024)

-

Metataxonomy of acid mine drainage microbiomes from the Santa Catarina Carboniferous Basin (Southern Brazil)

Extremophiles (2024)

-

Global Patterns of Metal and Other Element Enrichment in Bog and Fen Peatlands

Archives of Environmental Contamination and Toxicology (2024)

-

Global mining footprint mapped from high-resolution satellite imagery

Communications Earth & Environment (2023)