Abstract

Soft magnetic materials (SMMs) serve in electrical applications and sustainable energy supply, allowing magnetic flux variation in response to changes in applied magnetic field, at low energy loss1. The electrification of transport, households and manufacturing leads to an increase in energy consumption owing to hysteresis losses2. Therefore, minimizing coercivity, which scales these losses, is crucial3. Yet meeting this target alone is not enough: SMMs in electrical engines must withstand severe mechanical loads; that is, the alloys need high strength and ductility4. This is a fundamental design challenge, as most methods that enhance strength introduce stress fields that can pin magnetic domains, thus increasing coercivity and hysteresis losses5. Here we introduce an approach to overcome this dilemma. We have designed a Fe–Co–Ni–Ta–Al multicomponent alloy (MCA) with ferromagnetic matrix and paramagnetic coherent nanoparticles (about 91 nm in size and around 55% volume fraction). They impede dislocation motion, enhancing strength and ductility. Their small size, low coherency stress and small magnetostatic energy create an interaction volume below the magnetic domain wall width, leading to minimal domain wall pinning, thus maintaining the soft magnetic properties. The alloy has a tensile strength of 1,336 MPa at 54% tensile elongation, extremely low coercivity of 78 A m−1 (less than 1 Oe), moderate saturation magnetization of 100 A m2 kg−1 and high electrical resistivity of 103 μΩ cm.

Similar content being viewed by others

Main

Lowest possible coercivity and highest possible electrical resistivity are primary goals for SMMs, to reduce hysteresis-related and eddy-current-related energy losses, noise and the associated material damage1,2,3. Also, new SMMs with higher strength and ductility are needed, to operate under mechanically demanding loading conditions for safety-critical parts in transport and energy4. High strength and ductility also serve as measures for many other mechanical properties, such as high hardness5 and fracture toughness6. This multi-property profile creates a fundamental dilemma. The mechanical strength of metallic materials is produced by lattice defects and their elastic interactions with linear lattice faults that carry inelastic deformation, referred to as dislocations. However, the defects also interact with the magnetic domain walls and pin them. The loss in domain wall motion increases coercivity, so that the materials lose their soft magnetic features. Therefore, current SMMs follow the design rule of avoiding lattice defects to minimize coercivity7. On the other hand, increasing the mechanical strength of an alloy requires enhancing its internal stress level through defects such as dislocations, grain boundaries and precipitates8. This means that the task of making soft magnets mechanically strong is a trade-off between two mutually exclusive design strategies, namely, mechanical strength versus unaffected domain wall motion.

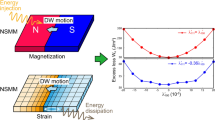

The theory of the grain size dependence of coercivity9 shows its proportionality to the sixth power of the grain size for the case of nanocrystalline materials, a relation that can also be applied to particles10. Current design of SMMs has thus focused on using small particles (less than 15 nm)10,11 and grain sizes (less than 100 nm)12,13,14. According to magnetic strain theory, the coercivity depends on the energy required to displace domain walls to overcome lattice barriers15. Here we introduce particles into a multicomponent massive solid solution matrix and increase their size from the commonly used range of 5–15 nm to 90–100 nm. With that, the internal stress level and the overall elastic coherency misfit energy are reduced through the smaller specific surface area (total surface area per unit of volume) of the particles, caused by the coarsening. We then propose that the particle design must follow four main rules. First, minimal pinning of domain walls requires a well-tuned and well-controlled particle size distribution with optimum balance between the decrease in specific surface area and the increase in magnetostatic energy during particle coarsening. Second, the particle size must remain smaller than the domain wall width to prevent strong pinning, that is, strong resistance against spin rotation8. Third, the chemical composition and crystal structure of the particles determine their saturation magnetization; therefore, antiferromagnetic elements are usually excluded. Fourth, strengthening of the alloys is determined by the interaction between dislocations and particles and by the friction forces exerted on dislocations in the massive solid solution matrix. Thus, intrinsically strong intermetallic particles with minimal lattice misfit are targeted. These require high forces for dislocation cutting (providing strength), but repeated cutting by ensuing dislocations emitted by the same source shear them with gradual ease along the remaining and gradually reducing particle cross sections (providing ductility).

These different mechanism considerations had to be translated into a corresponding compositional alloy design concept. This is mainly guided by the requirement for (1) a ferromagnetic matrix with (2) high solid solution contribution and components that trigger the formation of (3) strong and stable intermetallic phases with (4) small lattice misfit relative to the matrix. These considerations have led us to the non-equiatomic iron–nickel–cobalt–tantalum–aluminium (Fe32.6Ni27.7Co27.7Ta5.0Al7.0 (at.%)) MCA. We synthesized the material in a vacuum induction melting furnace, followed by conventional hot rolling and homogenization (details of the processing procedures and chemical compositions are provided in Methods). Through further isothermal heat treatments (1–100 h at 1,173 K), we prepared samples with different average particle sizes, ranging from 24 ± 15 nm to 255 ± 49 nm (edge length is used to characterize the topological particle size). The particles have L12 structure and complex composition, as presented in detail below.

Microstructure analysis

Figure 1 shows the structural characterization of the MCA with medium particle size (M-MCA, in which ‘M’ stands for medium particle size) after annealing at 1,173 K for 5 h. The M-MCA shows an average grain size of 85.3 ± 25.6 μm (excluding annealing twin boundaries) according to electron backscatter diffraction (EBSD) analysis shown in Fig. 1a. The electron channelling contrast imaging (ECCI) analysis shows that the L12 particles have a high number density (7.2 ± 0.2) × 1020 m−3 and a large volume fraction (55 ± 1%) in homogeneous distribution within the face-centred cubic (fcc) matrix (Fig. 1b). The lattice misfit (0.48%) between the fcc matrix and the L12 particles has been calculated using their lattice parameters acquired from the X-ray diffraction (XRD) patterns (Fig. 1c) by Rietveld simulation. Such a small lattice mismatch reduces the driving forces for further coarsening and the uniform dispersion prevents plastic localization at high strength16. The central beam dark-field (DF) transmission electron microscopy (TEM) analysis shows that the average size of the L12 particles is 90.8 ± 35.8 nm (Fig. 1d). The corresponding selected-area electron diffraction (see inset of Fig. 1d) and high-resolution (HR)-TEM (Extended Data Fig. 1d) confirm the high coherency between the particles and the matrix.

a, EBSD inverse pole figure map showing the equiaxed grains of the fcc matrix. The black lines highlight the high-angle grain/twin boundaries. b, ECC image featuring the high-density uniformly distributed L12 particles in the grain interiors and heterogeneous particles at the grain boundaries. c, Measured and simulated XRD patterns showing the phase structures. d, Centred DF-TEM image of the L12 particles obtained using the (011) superlattice spot (see inset). e, 3D reconstruction map of a typical APT tip showing the cuboidal L12 particles embedded in the fcc matrix. The L12–fcc interfaces are highlighted using isocomposition surfaces containing 25 at.% Fe. f, 1D compositional profiles computed along the cylinder region in e (marked by the black arrow), showing the compositional changes across several interfaces. Error bars refer to the standard deviations of the counting statistics in each bin of the profiles.

The elemental partitioning between the L12 precipitates and fcc solid solution matrix is characterized by atom probe tomography (APT). Figure 1e shows the 3D distribution of the volume investigated by APT, highlighted by a set of isosurfaces delineating regions containing more than 25 at.% Fe. Figure 1f shows the 1D compositional profiles acquired along the cylinder in Fig. 1e. The profiles show that Fe partitions into the fcc matrix (36 at.%), whereas the L12 particles are enriched in Ni (40 at.%), Ta (13 at.%) and Al (9 at.%). The compositions of the fcc and L12 phases were determined by averaging over three APT datasets (including ten L12 particles) as Fe36Co28Ni26Al7Ta3 and Ni40Co26Ta13Fe12Al9 (at.%), respectively.

Apart from these intragranular nanoparticles, we also observed two types of grain boundary variants: (1) coarse grain boundary particles (160.2 ± 55.3 nm) with the same crystal structure and composition as those inside the grains (Extended Data Fig. 1a–c) and (2) incoherent particles with a minor fraction (less than 0.3%) at the triple points of the grains with different structure (cubic Fd-3m, Fig. 1c) and composition (Ta40Co26Fe20Ni11Al3 (at.%), Extended Data Fig. 1e). These two types of particle are promoted by the high diffusion rate along the grain boundaries.

Mechanical properties

The current strategy of tuning the particle size also allows overcoming the strength–ductility trade-off, which is notable for advanced alloys with gigapascal-level strength. Figure 2a shows the tensile stress–strain curves of the M-MCA at room temperature (red curve). The yield strength (σy) is 904 ± 11 MPa, with an ultimate tensile strength (σUTS) of 1,336 ± 21 MPa and an elongation at fracture (εf) up to 53.6 ± 1.5%, averaged from four tests. Accordingly, the M-MCA has a high σUTS × εf value of 71.6 GPa%. To show the improvement in strength and ductility achieved by the well-controlled particle size distribution, the mechanical response of a material variant with identical chemical composition, that is, Fe32Co28Ni28Ta5Al7 (at.%), but smaller particle size (S-MCA, annealed for 1 h, producing an average particle size of 24 nm), larger particle size (L-MCA, annealed for 100 h, average particle size of 255 nm) and the particle-free Fe35Co30Ni30Ta5 (at.%) alloy11 are also presented in Fig. 2a.

a, Typical engineering stress–strain curves measured at room temperature, together with the average values for ultimate tensile strength (σUTS) and elongation at fracture (εf). b, Strain-hardening rate/true stress–true strain curves. The insets show the macroscopic image (top inset; scale bar, 1 cm) of the tensile sample and the corresponding fracture morphology (bottom inset; scale bar, 5 μm), in which a typical ductile fracture with fine dimples is observed. c, Substructure evolution as a function of global strain observed after interrupted tensile tests: EBSD-KAM maps showing the distributions of deformation-induced misorientations (top images; scale bar, 50 μm), in which εT stands for the global true strain; ECCI analysis (middle images; scale bar, 100 nm) showing the evolution of microbands; the shearing of L12 particles is highlighted by red arrows; schematics (bottom images) illustrating the microband refinement in the M-MCA during plastic straining.

Compared with the single-phase Fe35Co30Ni30Ta5 (at.%) alloy with a relatively low value of σy of 501 MPa (ref. 11), the notable increase in yield strength of the M-MCA can be attributed to the precipitation strengthening of the L12 particles with a high volume fraction (55%). Especially, such an improvement in the strength of the M-MCA is achieved at no expense of ductility, which is fundamentally different from the case of the S-MCA, in which a pronounced loss in ductility is observed with increasing strength. The good ductility is correlated with the high work-hardening capability, as shown in Fig. 2b. Further increase of particle size at longer annealing time (100 h) in the L-MCA leads to the decrease of ductility (53%) and σUTS (14%) as compared with those of the M-MCA. This is related to the mechanical weakness, strain localization and embrittlement in the particle-free zone adjacent to the grain boundary caused by solute depletion (Extended Data Fig. 2a). This interfacial weakening has been confirmed by the associated fracture morphologies, with typical ductile fracture with fine dimples in the M-MCA material (see Fig. 2b inset) and intergranular fracture in the L-MCA material (Extended Data Fig. 2b).

To unravel the mechanisms responsible for the marked improvement in the strength–ductility combination of the M-MCA, we studied its deformation substructures using EBSD kernel average misorientation (KAM) analysis and ECCI at different hardening stages (Fig. 2c). In principle, high strength requires to impede dislocation movement, whereas good ductility needs mobility of dislocations and new production of dislocations17. At the early deformation stage, the M-MCA deforms by planar dislocation glide on {111} planes (Extended Data Fig. 3a–c), as commonly observed in fcc alloys18. The dislocations extend through the grains. Corresponding pile-up configurations at the grain boundaries are shown by the higher KAM values (for example, at εT = 5%; see KAM maps in Fig. 2c). The relatively large grain size (85.3 μm) of the current M-MCA enables higher mobility of dislocations compared with most of the previously reported strong MCAs that had smaller grain size19,20,21 (around 10 μm). Further straining refines the crystallographically aligned microbands and facilitates the shearing of L12 particles (for example, at εT = 15%; see ECC images in Fig. 2c). The quantification of the evolution of the average microband spacing shows a microband refinement process during straining (Extended Data Fig. 3d). The gradually reduced microband spacing causes higher passing stress and, thus, enhanced strain hardening. This has been proposed to explain the good strength–ductility combinations in high-manganese steels22 and MCAs23. Hence, the observed dynamic microband refinement and particle shearing are the prevalent deformation mechanisms in the current MCAs. No Orowan looping was observed, even when increasing the average particle size up to 255 nm for the L-MCA (Extended Data Fig. 2c), as the average particle spacing remains far below the critical value (3,094 nm, see Methods) for the activation of dislocation bowing around particles, a mechanism referred to as Orowan effect. Furthermore, the stress required for shearing particles in the M-MCA with a medium particle size (91 nm) with high volume fraction (55%) is 2.2 times larger than that for the S-MCA with a smaller particle size (24 nm) with low volume fraction (43 ± 1%) (see Extended Data Table 1). Therefore, the high critical shear stress required for cutting the L12 particles and the dynamic microband refinement during plastic deformation lead to the strong strain-hardening capacity of the M-MCA.

Magnetic properties

Figure 3a,b shows the magnetic properties of the MCAs. All alloys show typical soft ferromagnetic behaviour. The M-MCA shows an excellent combination of extremely low coercivity (Hc) of 78 ± 3 A m−1 (less than 1 Oe) and moderate saturation magnetization (Ms) of 100.2 ± 0.2 A m2 kg−1. We identified a higher Ms for the alloy variant with larger average particle size (see inset in Fig. 3a). The reason for this is the change in intrinsic magnetic behaviour, as indicated by the higher Curie temperature (Tc), shown by the thermomagnetic curves (Extended Data Fig. 4a). Two distinct changes of the slope, indicating two ferromagnetic phases, are observed in the S-MCA. By contrast, only one sharp drop is observed in the M-MCA and L-MCA materials, indicating the presence of only one ferromagnetic phase. This is further confirmed by measuring the magnetic behaviour of the MCAs at elevated temperatures (Extended Data Fig. 4b). Considering that both the fcc and L12 phases contain high concentrations of ferromagnetic elements, we investigated their individual magnetic response through casting both phases as separate bulk samples with their respective nominal compositions acquired previously from APT analysis (see Methods for details). The results show that the L12 bulk phase is paramagnetic, whereas the fcc matrix is ferromagnetic in the M-MCA (Extended Data Fig. 4c). Owing to different partitioning, the magnetic behaviour of the L12 phase varies from ferromagnetic in the S-MCA material variant to paramagnetic in the M-MCA and L-MCA materials. The mechanism behind this transition is the change in the intrinsic spin alignment, which is related to the change in chemical composition (Extended Data Fig. 5) and ordering during annealing. The overall increase in saturation magnetization of the MCAs as a function of particle coarsening is attributed to the change in fcc matrix composition owing to elemental partitioning (Extended Data Fig. 5), that is, specifically to the resultant higher concentration of (Fe+Co) in the fcc matrix. This effect enhances the total average magnetic moment per formula unit and leads to a higher Ms.

a, Hysteresis loops (M/H) acquired up to ±800 kA m−1. The magnetic-field-sweeping rate is 1 kA m−1. The inset shows the enlarged view of the increase in saturation magnetization with particle coarsening. b, M/H curves measured at a rate of 0.1 kA m−1 between ±50 kA m−1, showing the extremely low coercivity. c, MOKE microscopy observation, in longitudinal contrast, showing the magnetization process. The applied magnetic field is horizontal to the viewing plane. d, Statistical particle size distribution of all the MCAs under different isothermal heat treatment conditions (1–100 h at 1,173 K). The inset shows the evolution of particle size by ECCI probing.

To gain further insight into the mechanism behind the magnetic response of the M-MCA, we investigated the domain structure using magneto-optical Kerr effect (MOKE) microscopy (Fig. 3c) under different applied magnetic field strengths. Starting from the AC demagnetized state to an applied field of 40 kA m−1, the nucleation of magnetic domains is uniformly distributed within the grain. Further increasing the applied field (155 kA m−1) leads to domain wall movement and growth of energetically favourable domains. The domains grow unaffected inside the grains but get impeded at grain and twin boundaries (Extended Data Fig. 6). Figure 3d summarizes the statistically averaged particle size distribution with respect to the coercivity of all the MCA samples at different annealed states. The data are acquired by developing an automated processing protocol, as shown in Extended Data Fig. 7. The coercivity first decreases from 763 A m−1 (S-MCA, average particle size 24 nm) to 78 A m−1 (M-MCA, average particle size 91 nm) and then increases to 1,745 A m−1 (L-MCA, average particle size 255 nm). Both the average particle size and the grain size increase monotonously with increasing annealing time (Extended Data Table 1). Because the grain size of the MCAs material is above the critical single-domain size, its coercivity decreases with grain coarsening, following the model for the grain size dependence of the coercivity as Hc ∝ 1/D (in which D is the grain size)13. However, the magnitude of the decrease in coercivity owing to grain coarsening according to the model is negligible compared with the experimentally observed values: the difference according to the model calculation between the S-MCA and M-MCA material variants is 2 A m−1, but the experimentally observed difference is 775 A m−1. Accordingly, the energy required for the irreversible displacement of domain walls within the grain is the determining effect for the extremely low coercivity.

Therefore, the notable decrease in coercivity at the early particle coarsening stage (\(\le \)91 nm) is attributed to the gradual reduction of the overall coherency stresses between matrix and particles, owing to their average size increase. More specifically, the values of the specific surface area × integrated lattice misfit decrease from 1.09 × 106 m−1 in the S-MCA material to 4.08 × 105 m−1 in the M-MCA material. The dislocation density in the matrix decreases from 1.50 × 1014 m−2 in the S-MCA material to 9.32 × 1013 m−2 in the M-MCA material when increasing the annealing time from 1 h to 5 h (see Methods). The reduction in dislocation density lowers the associated elastic distortion fields that can pin the domain walls. Although the elastic distortion and dislocation density decrease with particle coarsening, the coercivity of the L-MCA material increases. Two main mechanisms are proposed to explain this. First, the average particle size and the associated strain field in the L-MCA becomes larger than the domain wall width (δw), leading to domain wall pinning. The L-MCA has a δw of 117 nm and a much larger average particle size of 255 nm, whereas the average particle size of the M-MCA is 91 nm, which is below its δw of 112 nm (see Methods). Second, the increased magnetostatic energy (Es) associated with the paramagnetic particles causes a stronger individual pinning effect of each particle on the domain wall motion. More specifically, the Es of the L-MCA is estimated to be 23 times larger than that of the M-MCA (see Methods). When considering only particle size, it should be noted that, for the M-MCA, the coherent particles distributed along the grain boundaries with an average size (160 nm) above the δw (112 nm) are expected to have a stronger pinning effect on the domain walls than those in the grain interiors (91 nm). However, these coarser particles occupy only a small fraction (1.2 ± 0.2% in M-MCA), hence, with a negligible effect on domain wall motion.

These considerations show that the nanoscale size distribution of the particles must be carefully controlled to minimize their pinning effect on domain wall movement, which determines the coercivity of the alloy. This is achieved here by an optimal balance between the release of structural defects (for example, interfacial elastic distortion, dislocation density) just down to a level required to maintain high mechanical strength and the increase of the pinning effect from the magnetostatic energy, while keeping the particle size below the domain wall width during particle coarsening.

Overview of several property profiles

To highlight the good combination of mechanical and magnetic properties of the M-MCA with optimal particle size, we compare it with existing SMMs in an Ashby plot showing the σUTS × εf values against the Hc (Fig. 4a). This comparison shows that the σUTS × εf value of the new M-MCA material outperforms all other SMMs. Notably, the Hc of the new material is lower than that of all Fe–Ni (refs. 24,25) alloys and other MCAs26,27,28,29,30,31,32,33,34,35,36,37, comparable with that of Fe–Si (ref. 38), Fe–Co (refs. 39,40) alloys and pure Fe (ref. 41). Amorphous and nanocrystalline soft magnetic alloys42,43,44,45 can show ultralow Hc (less than 10 A m−1) and high mechanical strength, yet their limited ductility, damage tolerance and workability prohibit their application in cases in which the load path changes or high stresses, forming or machining are applied. A radar plot comparing the various soft magnetic and mechanical properties of the current M-MCA with several typical commercial SMMs is shown in Extended Data Fig. 8. Although the saturation induction (Bs) of the current M-MCA is not comparable with that of typical commercial SMMs (Extended Data Fig. 9), it has higher electrical resistivity (ρ) (103 ± 0.8 μΩ cm, see Extended Data Fig. 10), a feature that makes it suited for applications with AC conditions. The high ρ of the M-MCA is expected to be derived from the high resistance to electron movement from the larger lattice distortion46. Figure 4b compares the σUTS × εf values versus the grain size of the M-MCA material with recently reported strong and ductile MCAs16,19,20,21,47,48,49,50. The analysis shows that the current alloy reaches high values of σUTS × εf even without the substantial contribution from grain boundaries, confirming the notable strengthening effect provided by the nanoparticles and the massive solid solution.

a, Ashby map compiling room-temperature ultimate tensile strength (σUTS) × elongation at fracture (εf) and intrinsic coercivity compared with other SMMs, such as Fe–Ni (refs. 24,25), Fe–Si (refs. 38), Fe–Co (refs. 39,40), Fe (ref. 41), amorphous alloys42,43,44,45 and established MCAs26,27,28,29,30,31,32,33,34,35,36,37. b, Ashby map showing σUTS × εf values versus average grain size compared with data for other strong and ductile MCAs16,19,20,21,47,48,49,50. am, amorphous alloys.

Conclusions

In summary, we have developed a material that unifies so far mutually exclusive properties, namely, high mechanical strength (1,336 MPa), high tensile ductility (54%), low coercivity (78 A m−1), moderate saturation magnetization (100 A m2 kg−1) and high resistivity (103 μΩ cm). We realized this in a new class of bulk SMMs through a nanoparticle dispersion with well-controlled size (91 nm), magnetic properties, coherency strain, strength and interface energy. The design strategy is opposite to that generally applied in conventional SMM design. Instead of using the smallest microstructure features (particle size <15 nm) to avoid magnetic wall pinning as in conventional SMMs, we have chosen a relatively coarse particle dispersion with tuned particle/matrix interfacial coherency stresses and paramagnetic properties to minimize magnetic pinning of domain walls on the one hand (soft magnetism) and maximize interaction strength with dislocations on the other (strength and ductility).

The infinite composition space of MCAs allows realizing materials with good combinations of soft magnetic and mechanical properties. The new alloy design approach allows for tailoring SMMs for magnetic parts exposed to severe mechanical loads, be it from manufacturing and/or during service, for which conventional SMMs are mechanically too soft or too brittle. Future efforts on developing advanced magnetic MCAs could target variants with further improved soft magnetic properties (for example, higher magnetic saturation) while preserving their outstanding mechanical properties, at lower alloy costs, and use high-throughput experiments combined with computational techniques, for example, machine learning, to accelerate the discovery of new alloy variants.

Methods

Materials preparation

The bulk MCA ingot with a predetermined nominal composition of Fe32.6Co27.7Ni27.7Ta5.0Al7.0 (at.%) was first cast in a vacuum induction furnace using pure metallic ingredients (purity higher than 99.8 wt.%) under high-purity argon (Ar) atmosphere. The as-cast ingot with dimension 40 mm × 60 mm × 20 mm (length × width × thickness) was then hot rolled at 1,473 K to an engineering thickness reduction of 50% (final thickness 10 mm). After hot rolling, the alloy sheets were then homogenized at 1,473 K for 10 min in Ar atmosphere, followed by water quenching. To obtain a wide size distribution of the particles, further isothermal heat treatments were conducted at 1,173 K, lasting from 1 h up to 100 h (1 h, 2 h, 5 h, 20 h, 50 h and 100 h) in Ar atmosphere and followed by water quenching. The exact chemical composition of the MCA measured by wet-chemical analysis is Fe32.0Co28.0Ni28.1Ta4.7Al7.2 (at.%), which is close to the predesigned composition. In addition, the bulk ingots (50 g) with compositions identical to that of the fcc (Fe36Co28Ni26Al7Ta3 (at.%)) matrix phase and the L12 particle (Ni40Co26Ta13Fe12Al9 (at.%)) in the M-MCA derived from the APT analysis were also cast, respectively, by arc melting under Ar atmosphere. The ingots were remelted six times to achieve chemical homogeneity.

Analytical methods

XRD measurements were carried out in an X-ray system (Diffractometer D8 Advance A25-X1) with Co Kα radiation (λ = 1.78897 Å, 35 kV and 40 mA). EBSD characterizations were conducted in a ZEISS Crossbeam focused ion beam scanning electron microscope at 15 kV. ECCI characterizations were performed using a ZEISS MERLIN high-resolution field-emission electron microscope at 30 kV. TEM analysis including selected-area electron diffraction was conducted in a JEOL JEM-2100 at 200 kV. Scanning transmission electron microscopy (STEM) images were collected using a probe-corrected Titan Themis 60-300 (Thermo Fisher Scientific) microscope. To modify the Z-contrast characteristics of the imaging mode, high-angle annular dark-field (HAADF) micrographswith a convergence angle of 23.8 mrad were acquired at 300 kV. The resulting collection angle ranges from 73 mrad to 200 mrad. Further energy-dispersive X-ray spectroscopy (EDS) analysis was conducted using Thermo Fisher Scientific’s Super-X windowless EDS detector at an acceleration voltage of 300 kV. APT experiments were performed in a local electrode atom probe (LEAP 5000 XR) from Cameca Instruments Inc. and analysed with commercial AP Suite software (v6.1). A pulse frequency of 125 kHz, a pulse energy of 40 pJ and a temperature of 60 K was used. The detection rate was kept at a frequency of 1 ion per 100 pulses.

Mechanical response measurements

Room-temperature uniaxial tensile tests were performed using flat tensile specimens at an initial strain rate of 1 × 10−3 s−1. The tensile specimens were machined along the rolling direction from the alloy sheets by electrical discharge machining. The specimens with a total length of 60 mm, a gauge length of 30 mm, a gauge width of 5 mm and a thickness of 2 mm were used to investigate the bulk tensile properties. Further, smaller tensile specimens with a total length of 20 mm, a gauge length of 10 mm, a gauge width of 2 mm and a thickness of 1 mm were used to measure the local strain evolution by the digital image correlation method. At least four specimens for each condition were tested to confirm reproducibility. Further, to clarify the relation between global strain–stress behaviour and microstructure evolution, we also conducted interrupted tensile tests on different global true strains (that is, 5%, 15% and 25%), and the microstructures in the middle part of the deformed regions were then characterized accordingly.

Magnetic response measurements

The magnetic response was evaluated using the Quantum Design Magnetic Property Measurement System (MPMS) equipped with a standard Vibrating Sample Magnetometry (VSM) option. Cuboid specimens of dimensions 3 mm × 3 mm × 1 mm (length × width × thickness) were used for the measurements. The hysteresis loops M(H) were performed in an external magnetic field of ±800 kA m−1 at a magnetic field-sweeping rate of 1 kA m−1 at 10 K, 300 K, 500 K and 800 K, respectively. The temperature dependence of magnetization M(T) analysis was carried out under an applied field of 40 kA m−1 from 10 K to 1,000 K with a temperature-sweeping rate of 10 K min−1.

The magnetic domain patterns were characterized by a MOKE ZEISS microscope (Axio Imager.D2m). The domain wall movement was captured under an applied magnetic field of ±155 kA m−1. Before the measurement, a background image was collected as a reference in the AC demagnetized state. The images acquired at different applied fields were enhanced by subtracting the background image using KerrLab software.

Physical response measurements

The electrical resistivity response was evaluated using the Quantum Design Physical Property Measurement System (PPMS) equipped with an Electrical Transport Option (ETO) option. Cuboid specimens of dimensions 6 mm × 2 mm × 1 mm (length × width × thickness) were used for the measurements. The resistivity ρ values are calculated by:

in which R is the reported resistance, A is the cross-sectional area through which the current is passed and l is the voltage lead separation. The resistance value of each measurement is obtained by averaging those from 100 times of current passing. At least three specimens for each condition were tested.

Thermodynamic calculations

The equilibrium compositions of the fcc matrix and L12 particles in the Fe32Co28Ni28Ta5All7 (at.%) alloy at 1,173 K were calculated using the Thermo-Calc software (v.2022a) equipped with the High Entropy Alloys database TCHEA v.4.2. The calculated equilibrium compositions for the fcc and L12 phases in the Fe32Co28Ni28Ta5Al7 (at.%) alloy are Fe36Co31Ni23Ta4Al6 and Ni63Ta13Fe6Co3Al15 (at.%), respectively.

Estimation of particle size (edge length)

The size distribution is statistically analysed by applying a batch image-processing protocol with several 2D-projected ECC images of all the MCA samples at different annealed states (Extended Data Fig. 7). The average particle size (edge length) of the L12 particles is estimated by:

in which d is the average particle size, Si is related to the area of each particle acquired from the 2D-projected ECC images by the batch image-processing protocol and i is the total particle number. The particle size of the M-MCA is also characterized by DF-TEM (Fig. 1d) and bright-field TEM (Extended Data Fig. 1). The TEM results fit well with the value acquired by ECC images.

Estimation of interfacial coherency stress

The coherency stress at the L12–fcc interface is determined by integrating the lattice misfit across the interface as:

in which \({S}_{{\rm{L}}{1}_{2}/{\rm{fcc}}}\) is the L12–fcc interface area related to the average particle size (d), the volume fraction of the L12 particles (f) and the overall volume (V) as follows:

δx is the varying lattice misfit as a function of distance (x) from the L12–fcc interface determined by the following equation:

\({a}_{x}^{{\rm{L}}{1}_{2}}\) and \({a}_{x}^{{\rm{fcc}}}\) are the lattice parameters of the L12 and fcc phases at the interfacial region, respectively. Such values were calculated using the L12–fcc interfacial chemical compositions acquired from the APT datasets with Vegard’s relation51:

in which \({a}_{0}^{{\rm{L}}{1}_{2}}\) and \({a}_{0}^{{\rm{fcc}}}\) are the average lattice parameters for the L12 particles and the fcc matrix, respectively, derived from the Rietveld simulation based on the XRD measurements, as shown in Extended Data Table 1. \({\varGamma }_{i}^{{\rm{L}}{1}_{2}}\) and \({\varGamma }_{i}^{{\rm{fcc}}}\) are the Vegard coefficients for the L12 and fcc phases, respectively, obtained from the ordered Ni3Al phase and the disordered fcc phase in the Ni-base superalloys52, as shown in Extended Data Table 2. Note that the above-calculated lattice misfit δl represents the theoretical unconstrained state. This can be related to the constrained misfit (ε) by elasticity theory as below53:

The estimated interfacial constrained misfit value is 1.09 × 106, 4.08 × 105 and 1.96 × 105 for the S-MCA, M-MCA and L-MCA, respectively. Therefore, the marked decrease in the interfacial coherency stress is expected to play an essential role in releasing the pinning effect on domain wall movement with particle coarsening for the MCAs with particle size below the domain wall width.

Estimation of dislocation density

The dislocation density (ρ) in the fcc matrix can be calculated through the Williamson–Smallman relationship as54:

in which εs is microstrain, D is crystallite size acquired from the XRD profiles (Extended Data Table 1) and b is the Burgers vector (for fcc structure, \(b=\sqrt{2}/2\times {a}_{{\rm{fcc}}}\))55. The dislocation density in the fcc matrix is thus estimated to be 1.50 × 1014 m−2, 9.32 × 1013 m−2 and 5.38 × 1013 m−2 for the S-MCA, M-MCA and L-MCA, respectively. On the basis of the above estimation, the considerable improvement in the coercivity also derives from the decrease of dislocation density in the fcc matrix.

Estimation of particle shearing stress

On the basis of the experimental observation (Fig. 2c and Extended Data Fig. 2c), particle shearing is the primary deformation mechanism in the investigated MCAs. The strengthening contribution of particle shearing (Δτ) is estimated according to56:

in which 2λ is the mean spacing of the particles, \(2\lambda \approx \sqrt{\frac{2}{f}}\cdot d\), d is the average particle size, f is the volume fraction of the particles shown in Extended Data Table 1 and F is the force exerted on the particles. The shearing strength is expressed as:

by using the relation F ∝ d3/2 and introducing constant k. The effect of particle strengthening of the M-MCA is then estimated to be two times larger than that of the S-MCA (\(\Delta {\tau }_{{\rm{M}}-{\rm{M}}{\rm{C}}{\rm{A}}}/\Delta {\tau }_{{\rm{S}}-{\rm{M}}{\rm{C}}{\rm{A}}}=\frac{k\sqrt{{f}_{{\rm{M}}-{\rm{M}}{\rm{C}}{\rm{A}}}{\cdot r}_{{\rm{M}}-{\rm{M}}{\rm{C}}{\rm{A}}}}}{k\sqrt{{f}_{{\rm{S}}-{\rm{M}}{\rm{C}}{\rm{A}}\cdot }{r}_{{\rm{S}}-{\rm{M}}{\rm{C}}{\rm{A}}}}}\)).

When considering the volume fraction of the particles to be constant, the mean spacing of the particles increases with increasing particle size. As a result, the force required for shearing particles increases until the Orowan mechanism is activated, that is, dislocations bowing the particles becomes easier than shearing. The critical mean spacing of the particles is determined by56:

G = 84 GPa is the adopted shear modulus57. Consequently, the critical mean spacing of the particles is calculated as 3,094.3 nm. However, in the current MCAs, the volume fraction of the L12 phase is not constant even after annealing at 1,173 K for 100 h. This is because the alloys have not yet reached the thermodynamical equilibrium state, as indicated by both thermodynamic calculations and APT analysis (Extended Data Fig. 5).

Estimation of magnetostatic energy

The magnetostatic energy (Es) determines the coercive force that interacts between the paramagnetic particles (for M-MCA and L-MCA) and domain wall movement according to the formula38:

in which μ0 = 4π × 10−7 H m−1 is the permeability of vacuum, d is the average particle size and Ms is the saturation magnetization of the fcc matrix. For the M-MCA and L-MCA, in which the L12 phase is paramagnetic (Extended Data Fig. 4), the Ms of the fcc matrix is considered as the overall Ms of the alloy. The values of Es markedly increase with increasing particle size, that is, it varies from 1.57 × 10−24 (M-MCA) to 3.65 × 10−23 (L-MCA). The notable increase in magnetostatic energy results in a strong magnetic pinning effect.

Estimation of domain wall width

Strong pinning arises and results in the deterioration of coercivity when the microstructure defects have a comparable dimension to the domain wall thickness (δw). As a result, the estimation of the δw to help understand the extremely low coercivity in the current work is given by58,59:

in which Aex = kBTc/2a0 is the exchange stiffness, kB = 1.380649 × 10−23 J K−1 is Boltzmann’s constant and Tc and a0 are the Curie temperature and lattice parameter of the fcc matrix, respectively (Extended Data Fig. 4d and Extended Data Table 1). K1 is the first magnetocrystalline anisotropy constant. The value of K1 (M-MCA) is taken from the Co–Fe system60,61based on the composition of the fcc matrix (Fig. 1f) as 10.4 kJ m−3 (Al and Ta are non-ferromagnetic elements that do not show any magnetic moment, the chemical composition of the fcc phase Fe36Co28Ni26Al7Ta3 (at.%), in the M-MCA is thus considered as Co31(Fe+Ni)69 (at.%)). The domain wall thickness of the M-MCA is therefore estimated to be 112 nm. Similarly, the domain wall thicknesses of the S-MCA and L-MCA are calculated as 103 nm and 117 nm, respectively.

Data availability

Data and codes are available from the authors.

References

Silveyra, J. M. et al. Soft magnetic materials for a sustainable and electrified world. Science 362, eaao0195 (2018).

Krings, A. et al. Soft magnetic material status and trends in electric machines. IEEE Trans. Ind. Electron. 64, 2405–2414 (2017).

Gutfleisch, O. et al. Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv. Mater. 23, 821–842 (2011).

Henke, M. et al. Challenges and opportunities of very light high-performance electric drives for aviation. Energies 11, 344 (2018).

Zhang, P. et al. General relationship between strength and hardness. Mater. Sci. Eng. A 529, 62–73 (2011).

Hofmann, D. et al. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 451, 1085–1089 (2008).

Hasegawa, T. et al. Conversion of FeCo from soft to hard magnetic material by lattice engineering and nanopatterning. Sci. Rep. 7, 13125 (2017).

Cullity, B. D. & Graham, C. D. Introduction to Magnetic Materials 2nd edn (Wiley-IEEE Press, 2008).

Herzer, G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 26, 1397–1402 (1990).

Ma, Y. et al. A novel soft-magnetic B2-based multiprincipal-element alloy with a uniform distribution of coherent body-centered-cubic nanoprecipitates. Adv. Mater. 33, 2006723 (2021).

Han, L. et al. Ultrastrong and ductile soft magnetic high-entropy alloys via coherent ordered nanoprecipitates. Adv. Mater. 33, 2102139 (2021).

Fu, Z. et al. Exceptional combination of soft magnetic and mechanical properties in a heterostructured high-entropy composite. Appl. Mater. Today 15, 590–598 (2019).

Herzer, G. Grain structure and magnetism of nanocrystalline ferromagnets. IEEE Trans. Magn. 25, 3327–3329 (1989).

Osaka, T. et al. A soft magnetic CoNiFe film with high saturation magnetic flux density and low coercivity. Nature 392, 796–798 (1998).

Miyazaki, T. & Jin, H. The Physics of Ferromagnetism (Springer, 2012).

Yang, T. et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 362, 933–937 (2018).

Tolansky, S. Dislocations. Nature 209, 1058–1059 (1966).

Pande, C. S. & Hazzledine, P. M. Dislocation arrays in Cu-Al alloys. II. Philos. Mag. 24, 1393–1410 (1971).

Yang, T. et al. Ultrahigh-strength and ductile superlattice alloys with nanoscale disordered interfaces. Science 369, 427–432 (2020).

Luo, H. et al. A strong and ductile medium-entropy alloy resists hydrogen embrittlement and corrosion. Nat. Commun. 11, 3081 (2020).

Wang, Z. et al. Ultrastrong lightweight compositionally complex steels via dual-nanoprecipitation. Sci. Adv. 6, eaba9543 (2020).

Welsch, E. et al. Strain hardening by dynamic slip band refinement in a high-Mn lightweight steel. Acta Mater. 116, 188–199 (2016).

Wang, Z. et al. The effect of carbon on the microstructures, mechanical properties, and deformation mechanisms of thermo-mechanically treated Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys. Acta Mater. 126, 346–360 (2017).

Christenson, T. R. et al. Mechanical and metallographic characterization of LIGA fabricated nickel and 80%Ni-20%Fe permalloy. MRS Online Proc. Libr. 518, 185–190 (1998).

Yekta, P. V. et al. Magnetic and mechanical properties of cold-rolled permalloy. J. Magn. Magn. Mater. 468, 155–163 (2018).

Zhang, Y. et al. High-entropy alloys with high saturation magnetization, electrical resistivity and malleability. Sci. Rep. 3, 1455 (2013).

Körmann, F. et al. “Treasure maps” for magnetic high-entropy-alloys from theory and experiment. Appl. Phys. Lett. 107, 142404 (2015).

Li, P. et al. A ductile high entropy alloy with attractive magnetic properties. J. Alloys Compd. 694, 55–60 (2017).

Zuo, T. T. et al. Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy. J. Magn. Magn. Mater. 371, 60–68 (2014).

Wang, Y. P. et al. Solid solution or intermetallics in a high-entropy alloy. Adv. Eng. Mater. 11, 641–644 (2009).

Zhang, K. B. et al. Annealing on the structure and properties evolution of the CoCrFeNiCuAl high-entropy alloy. J. Alloys Compd. 502, 295–299 (2010).

Ma, S. G. & Zhang, Y. Effect of Nb addition on the microstructure and properties of AlCoCrFeNi high-entropy alloy. Mater. Sci. Eng. A 532, 480–486 (2012).

Zhang, K. & Fu, Z. Effects of annealing treatment on properties of CoCrFeNiTiAlx multi-component alloys. Intermetallics 28, 34–39 (2012).

Na, S. M. et al. Room-temperature ferromagnetic transitions and the temperature dependence of magnetic behaviors in FeCoNiCr-based high-entropy alloys. AIP Adv. 8, 056412 (2018).

Duan, H. et al. Al addition effect on structure and magnetic properties in high BS Fe-Cu-Si-B alloys. Mater. Res. Bull. 111, 289–293 (2019).

Zhang, H. et al. A novel FeCoNiCr0.2Si0.2 high entropy alloy with an excellent balance of mechanical and soft magnetic properties. J. Magn. Magn. Mater. 478, 116–121 (2019).

Zuo, T. et al. Novel high entropy alloys of FexCo1-xNiMnGa with excellent soft magnetic properties. Intermetallics 100, 1–8 (2018).

Chen, C. W. Magnetism and Metallurgy of Soft Magnetic Materials (Dover, 2013).

George, E. P. et al. Mechanical properties of soft magnetic FeCo alloys. Mater. Sci. Eng. A 329, 325–333 (2002).

Bozorth, R. M. Ferromagnetism (Wiley, 1993).

Pepperhoff, W. & Acet, M. Constitution and Magnetism of Iron and its Alloys (Springer, 2001).

Inoue, A. et al. Cobalt-based bulk glassy alloy with ultrahigh strength and soft magnetic properties. Nat. Mater. 2, 661–663 (2003).

Inoue, A. et al. Ultra-high strength above 5000 MPa and soft magnetic properties of Co–Fe–Ta–B bulk glassy alloys. Acta Mater. 52, 1631–1637 (2004).

Lin, C. Y. et al. Fe–Y–M–B (M = Nb or Ta) bulk metallic glasses with ultrahigh strength and good soft magnetic properties. J. Phys. D Appl. Phys. 40, 310–314 (2007).

Shen, B. et al. Superhigh strength and good soft-magnetic properties of (Fe,Co)–B–Si–Nb bulk glassy alloys with high glass-forming ability. Appl. Phys. Lett. 85, 4911–4913 (2004).

Yan, X. & Zhang, Y. Functional properties and promising applications of high entropy alloys. Scr. Mater. 187, 188–193 (2020).

Li, Z. et al. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227–230 (2016).

Du, X. H. et al. Dual heterogeneous structures lead to ultrahigh strength and uniform ductility in a Co-Cr-Ni medium-entropy alloy. Nat. Commun. 11, 2390 (2020).

Gludovatz, B. et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1158 (2014).

Otto, F. et al. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 61, 5743–5755 (2013).

Mishima, Y. et al. Lattice parameters of Ni(γ), Ni3Al(γ′) and Ni3Ga(γ′) solid solutions with additions of transition and B-subgroup elements. Acta Metall. 33, 1161–1169 (1985).

Okamoto, H. et al. in ASM Handbook Volume 3: Alloy Phase Diagrams (eds Okamoto, H., Schlesinger, M. E. & Mueller, E. M.) (ASM International, 1991).

Nembach, E. & Neite, G. Precipitation hardening of superalloys by ordered γ′-particles. Prog. Mater. Sci. 29, 177–319 (1985).

Williamson, G. K. & Hall, W. H. X-ray line broadening from filed aluminium and wolfram. L’elargissement des raies de rayons x obtenues des limailles d’aluminium et de tungstene. Die verbreiterung der roentgeninterferenzlinien von aluminium- und wolframspaenen. Acta Metall. 1, 22–31 (1953).

Callister, W. D. Jr. & Rethwisch, D. G. Fundamentals of Materials Science and Engineering: An Integrated Approach 5th edn (Wiley, 2018).

Rösler, J., Bäker, M. & Harders, H. Mechanical Behaviour of Engineering Materials: Metals, Ceramics, Polymers, and Composites (Springer, 2007).

Wu, Z. et al. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 81, 428–441 (2014).

Néel, L. Bases d’une nouvelle théorie générale du champ coercitif. Ann. Univ. Grenoble. 22, 299–343 (1946).

Pfeifer, F. & Radeloff, C. Soft magnetic Ni-Fe and Co-Fe alloys - some physical and metallurgical aspects. J. Magn. Magn. Mater. 19, 190–207 (1980).

McKeehan, L. W. Ferromagnetic anisotropy in nickel-cobalt-iron crystals at various temperatures. Phys. Rev. 51, 136–139 (1937).

Shin, J. W. Magnetic properties of iron-cobalt single crystals. Phys. Rev. 46, 139–142 (1934).

Bradski, G. Dr. Dobb’s Journal: Software Tools for the Professional Programmer. Vol. 25, pp 120–123 (2000).

Sundar, R. S. & Deevi, S. C. Soft magnetic FeCo alloys: alloy development, processing, and properties. Int. Mater. Rev. 50, 157–192 (2005).

Zhou, K. X. et al. FeCoNiAlSi high entropy alloys with exceptional fundamental and application-oriented magnetism. Intermetallics 122, 106801 (2020).

Zhao, C. et al. Effect of strong magnetic field on the microstructure and mechanical-magnetic properties of AlCoCrFeNi high-entropy alloy. J. Alloys Compd. 820, 153407 (2020).

Wu, Z. et al. The AC soft magnetic properties of FeCoNixCuAl (1.0 ≤ x ≤ 1.75) high-entropy alloys. Materials 12, 4222 (2019).

Acknowledgements

The support of G. Dehm at the Max-Planck-Institut für Eisenforschung is gratefully acknowledged. L.H. acknowledges the financial support from the China Scholarship Council (201906370028). Z.L. acknowledges the National Natural Science Foundation of China (51971248) and the Hunan Special Funding for the Construction of Innovative Province (2019RS1001). O.G. acknowledges the Deutsche Forschungsgemeinschaft (405553726, TRR 270).

Funding

Open access funding provided by Max Planck Society.

Author information

Authors and Affiliations

Contributions

L.H., Z.L. and D.R. designed the research project; L.H., N.J.P. and F.M. characterized the alloys; L.H., I.R.S.F., Y.W. and B.G. analysed the data; L.H., Z.L., O.G. and D.R. conceptualized the paper; all authors contributed to the discussion of the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Todd Monson and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Extended data

is available for this paper at https://doi.org/10.1038/s41586-022-04935-3.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 STEM-HAADF micrographs and corresponding STEM-EDS analysis showing the structure and chemical composition of the particles with different morphologies.

a, Overview of a STEM lamella showing the variation in particle morphology near the grain boundary. b, Enlarged view (red frame in a) showing particles inside the grains and along the GBs as well as their respective EDS elemental maps. c, Enlarged view (orange frame in a) illustrating a heterogeneous non-coherent particle at the triple junction of GBs and its EDS elemental maps. d, Atomically resolved HAADF-STEM micrographs and fast Fourier transforms of representative matrix and particle regions, indicating that the particles (ordered, bright) are coherent with the matrix (disordered, dark). The micrographs were obtained along the [011] zone axis. e, Comparison of the average chemical composition of different particles and the matrix determined by the EDS mapping. GB, grain boundary.

Extended Data Fig. 2 Deformation mechanisms of the investigated MCAs.

a, ECC images of the S-MCA and L-MCA. The formation of the particle-free zone can be identified in the L-MCA. b, Fracture surface morphologies of the L-MCA. The enlarged view shows the presence of intergranular fracture at the triple junction of GBs with dimpled topology at one side of the grain facets. c, ECCI analysis showing the microbands and the shearing of the particles in the S-MCA and L-MCA.

Extended Data Fig. 3 Evolution of the microband refinement.

a–c, ECCI analysis showing the evolution of microbands with increasing local strain (εloc) at 10%, 30% and 80%, respectively. d, Quantification of the decreases in average microband spacing with increasing local strain. The local strain has been estimated by the digital image correlation method.

Extended Data Fig. 4 Magnetic behaviour of the MCAs in a wide temperature range.

a, M(T) curves measured in the temperature range 10–1,000 K under a magnetic field of 40 kA m−1. b, M(H) loops of the MCAs measured at 800 K, confirming that the second phase in the S-MCA is ferromagnetic, with a Tc higher than 800 K. The measuring temperature of 800 K was selected on the basis of the M(T) results as marked by a black dashed line in a. c, M(H) loops of the individual cast fcc and L12 phases in the M-MCA measured at 300 K. d, Temperature dependence of the Ms of the investigated MCAs.

Extended Data Fig. 5 Atom probe characterization showing the tomography and composition of the L12 particles and fcc matrix in the MCAs.

a, APT datasets showing the reconstructed S-MCA and L-MCA containing L12 particles. b, Average chemical compositions of the fcc and L12 phases acquired from the APT subvolumes.

Extended Data Fig. 6 MOKE microscopy observation showing the pinning of the magnetic domain wall during the magnetization process in the M-MCA.

GBs and TBs act as the pinning sites for domain wall movement. The applied magnetic field is horizontal to the viewing plane. GB, grain boundary; TB, twin boundary.

Extended Data Fig. 7 Process for analysing the size distribution of the L12 particles by batch image-processing protocol.

First, an edge detection algorithm was applied to the raw images to isolate particles from the matrix. Second, a contour detection algorithm was used to search for closed contours. Third, the particle shape was approximately evaluated and converted into a square shape. Finally, the size distribution of closed contours (particles) was computed. The algorithm was constructed using a Python62. For each sample, the particle size distribution was derived from more than 20 ECC images of different sample regions.

Extended Data Fig. 9 Ashby map showing σUTS × TE as a function of saturation induction (Bs).

The investigated M-MCA is compared with a wide class of conventional SMMs, including Fe–Ni (refs. 24,25), Fe–Si (ref. 38), Fe–Co (refs. 39,40), Fe (ref. 41), amorphous alloys42,43,44,45 and other MCAs26,27,28,29,30,31,32,33,34,35,36,37. The Bs is calculated using the equation Bs = 4πMsρm/10,000, in which ρm = 8.6 g cm−3 is the mass density of the M-MCA.

Extended Data Fig. 10 Electrical resistivity of the Fe32Co28Ni28Ta5Al7 (at.%) MCAs.

The investigated MCAs are compared with a wide class of conventional SMMs, including pure iron, Fe–Ni (refs. 24,25) alloys, Fe–Si (ref. 38) alloys, Fe–Co (refs. 39,40) alloys and other established MCAs26,28,29,64,65,66. The inset shows the evolution of electrical resistivity with increasing annealing time of the current MCAs.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, L., Maccari, F., Souza Filho, I.R. et al. A mechanically strong and ductile soft magnet with extremely low coercivity. Nature 608, 310–316 (2022). https://doi.org/10.1038/s41586-022-04935-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-022-04935-3

This article is cited by

-

Elemental partitioning-mediated crystalline-to-amorphous phase transformation under quasi-static deformation

Nature Communications (2024)

-

Vortex-based soft magnetic composite with ultrastable permeability up to gigahertz frequencies

Nature Communications (2024)

-

An isotropic zero thermal expansion alloy with super-high toughness

Nature Communications (2024)

-

Correlation between microstructure, magnetic properties and mechanical behavior of the Permimphy alloy after high-pressure torsion

Journal of Materials Science (2024)

-

Superior zero thermal expansion dual-phase alloy via boron-migration mediated solid-state reaction

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.