Abstract

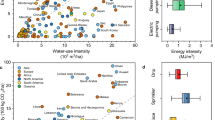

Global metal ore extraction tripled between 1970 and 2010 as metals are widely used in new infrastructure and advanced technology. Meanwhile, the energy and environmental costs of metal mining increase as lower ore grades are being exploited. The domestic use of metals has been found to reach a plateau when gross domestic product reaches US$15,000 per person. Here we present a quantification of the annual metal footprint (that is, the amount of metal ore extracted to satisfy the final demand of a country, including metals used abroad to produce goods that are then imported, and excluding metals used domestically to produce exports) for 43 large economies during 1995–2013. We use a panel analysis to assess short-term drivers of changes in metal footprint, and find that a 1% rise in gross domestic product raises the metal footprint by as much as 1.9% in the same year. Further, every percentage point increase in gross capital formation as a share of gross domestic product increased the metal footprint by 2% when controlling for gross domestic product. Other socioeconomic variables did not significantly influence the metal footprint. Finding ways to break the strong coupling of economic development and investment with metal ore extraction may be required to ensure resource access and a low-carbon future.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Graedel, T. E. & Cao, J. Metal spectra as indicators of development. Proc. Natl Acad. Sci. USA 107, 20905–20910 (2010).

Vidal, O., Goffé, B. & Arndt, N. Metals for a low-carbon society. Nat. Geosci. 6, 894–896 (2013).

Schandl, H. & West, J. Material flows and material productivity in China, Australia, and Japan. J. Ind. Ecol. 16, 352–364 (2012).

Schaffartzik, A., Mayer, A., Eisenmenger, N. & Krausmann, F. Global patterns of metal extractivism, 1950–2010: providing the bones for the industrial society’s skeleton. Ecol. Econ. 122, 101–110 (2016).

Bridge, G. Contested terrain: mining and the environment. Annu. Rev. Environ. Resour. 29, 205–259 (2004).

Özkaynak, B. et al. Mining Conflicts Around the World: Common Grounds from an Environmental Justice Perspective Report No. 7 (EJOLT, 2012).

van der Voet, E. et al. Environmental Risks and Challenges of Anthropogenic Metals Flows and Cycles, A Report of the Working Group on the Global Metal Flows to the International Resource Panel (United Nations Environment Programme, 2013).

Franks, D. M. et al. Conflict translates environmental and social risk into business costs. Proc. Natl Acad. Sci. USA 111, 7576–7581 (2014).

Graedel, T. E., Harper, E. M., Nassar, N. T., Nuss, P. & Reck, B. K. Criticality of metals and metalloids. Proc. Natl Acad. Sci. USA 112, 4257–4262 (2015).

Prior, T., Giurco, D., Mudd, G., Mason, L. & Behrisch, J. Resource depletion, peak minerals and the implications for sustainable resource management. Glob. Environ. Change 22, 577–587 (2012).

Northey, S., Mohr, S., Mudd, G., Weng, Z. & Giurco, D. Modelling future copper ore grade decline based on a detailed assessment of copper resources and mining. Resour. Conserv. Recycl. 83, 190–201 (2014).

Reck, B. K. & Graedel, T. E. Challenges in metal recycling. Science 337, 690–695 (2012).

The Department of Energy’s Critical Materials Strategy (US Department of Energy, 2017); https://www.energy.gov/epsa/initiatives/department-energy-s-critical-materials-strategy

Integrated Reform Plan for Promoting Ecological Progress (China’s State Council, 2015); http://www.gov.cn/guowuyuan/2015-09/21/content_2936327.htm

Policy and Strategy for Raw Materials (European Commission, 2017); https://ec.europa.eu/growth/sectors/raw-materials/policy-strategy_en

Promoting Resource Diplomacy Along with Foreign Direct Investment in Japan (Ministry of Foreign Affairs of Japan, 2017); http://www.mofa.go.jp/policy/other/bluebook/2017/html/chapter3/c030303.html

Henckens, M., Driessen, P., Ryngaert, C. & Worrell, E. The set-up of an international agreement on the conservation and sustainable use of geologically scarce mineral resources. Resour. Policy 49, 92–101 (2016).

Ali, S. H. et al. Mineral supply for sustainable development requires resource governance. Nature 543, 367–372 (2017).

Ekins, P. et al. Resource Efficiency: Potential and Economic Implications. A Report of the International Resource Panel (United Nations Environment Program, 2016).

Schandl, H. & West, J. Resource use and resource efficiency in the Asia–Pacific region. Glob. Environ. Change 20, 636–647 (2010).

Steinberger, J. K., Krausmann, F. & Eisenmenger, N. Global patterns of materials use: A socioeconomic and geophysical analysis. Ecol. Econ. 69, 1148–1158 (2010).

Binder, C. R., Graedel, T. E. & Reck, B. Explanatory variables for per capita stocks and flows of copper and zinc. J. Ind. Ecol. 10, 111–132 (2006).

Muller, D. B., Wang, T. & Duval, B. Patterns of iron use in societal evolution. Environ. Sci. Technol. 45, 182–188 (2011).

Tilton, J. E. in World Metal Demand: Trends and Prospects (ed. Tilton, J. E.) 35–76 (Resources for the Future, Washington, DC, 2015).

Jaunky, V. C. Is there a material Kuznets curve for aluminium? Evidence from rich countries. Resour. Policy 37, 296–307 (2012).

Crompton, P. Explaining variation in steel consumption in the OECD. Resour. Policy 45, 239–246 (2015).

Guzmán, J. I., Nishiyama, T. & Tilton, J. E. Trends in the intensity of copper use in Japan since 1960. Resour. Policy 30, 21–27 (2005).

Ghosh, S. Steel consumption and economic growth: Evidence from India. Resour. Policy 31, 7–11 (2006).

Rebiasz, B. Polish steel consumption, 1974–2008. Resour. Policy 49, 37–49 (2006).

Roberts, M. C. Metal use and the world economy. Resour. Policy 22, 183–196 (1996).

Wårell, L. & Olsson, A. Trends and developments in the intensity of steel use: an econometric analysis. In Securing the Future and 8th ICARD (Curran Associates, Inc., Skelleftea, 2009).

Canas, Â., Ferrão, P. & Conceição, P. A new environmental Kuznets c urve? Relationship between direct material input and income per capita: evidence from industrialised countries. Ecol. Econ. 46, 217–229 (2003).

Steinberger, J. K., Krausmann, F., Getzner, M., Schandl, H. & West, J. Development and dematerialization: an international study. PLoS ONE 8, e70385 (2013).

Radetzki, M. & Tilton, J. E. in World Metal Demand: Trends and Prospects (ed. Tilton, J. E.) 13–34 (Resources for the Future, Washington, DC, 1990).

Roberts, M. C. Predicting metal consumption: the case of US steel. Resour. Policy 16, 56–73 (1990).

Wiedmann, T. O., Schandl, H. & Moran, D. The footprint of using metals: new metrics of consumption and productivity. Environ. Econ. Policy Stud. 17, 369–388 (2015).

Wiedmann, T. O. et al. The material footprint of nations. Proc. Natl Acad. Sci. USA 112, 6271–6276 (2015).

Muñoz, P., Giljum, S. & Roca, J. The raw material equivalents of international trade empirical evidence for Latin America. J. Ind. Ecol. 13, 881–897 (2009).

Weinzettel, J. & Kovanda, J. Assessing socioeconomic metabolism through hybrid life cycle assessment. J. Ind. Ecol. 13, 607–621 (2009).

Schoer, K., Weinzettel, J., Kovanda, J., Giegrich, J. & Lauwigi, C. Raw material consumption of the European Union–concept, calculation method, and results. Environ. Sci. Technol. 46, 8903–8909 (2012).

Giljum, S., Bruckner, M. & Martinez, A. Material footprint assessment in a global input–output framework. J. Ind. Ecol. 19, 792–804 (2015).

Burke, P. J., Shahiduzzaman, M. & Stern, D. I. Carbon dioxide emissions in the short run: the rate and sources of economic growth matter. Glob. Environ. Change 33, 109–121 (2015).

Stadler, K. et al. EXIOBASE 3: developing a time series of detailed environmentally extended multi-regional input–output tables. J. Ind. Ecol. https://doi.org/10.1111/jiec.12715 (2018).

Pauliuk, S. & Müller, D. B. The role of in-use stocks in the social metabolism and in climate change mitigation. Glob. Environ. Change 24, 132–142 (2014).

Hertwich, E. G. et al. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl Acad. Sci. USA 112, 6277–6282 (2015).

Allwood, J. M., Gutowski, T. G., Serrenho, A. C., Ach, S. & Worrell, E. Industry 1.61803: the transition to an industry with reduced material demand fit for a low carbon future. Philos. Trans. Royal Soc. 375, 20160361 (2017).

World Mineral Statistics (British Geological Survey, 2014).

International Minerals Statistics and Information (US Geological Survey, Washington DC, 2014).

Reichl, C., Schatz, M. & Zsak, G. World Mining Data - Minerals Production (International Organizing Committee for the World Mining Congresses, Vienna, 2017).

Weisz, H. et al. Economy-Wide Material Flow Accounting. A Compilation Guide (Eurostat and the European Commission, 2007).

World Development Indicators (The World Bank, 2017); http://data.worldbank.org/data-catalog/world-development-indicators

Hertwich, E. G. & Peters, G. P. Carbon footprint of nations: A global, trade-linked analysis. Environ. Sci. Technol. 43, 6414–6420 (2009).

Acknowledgements

Funding for X.Z. and C.W. was provided by the National Natural Science Foundation of China (project no. 71525007). We thank M. Kotchen, F. Novajan and J. Reuning-Scherer for advice when developing the research.

Author information

Authors and Affiliations

Contributions

E.G.H. led and designed the research, X.Z. and R.Wang performed the research, R.Wood assembled EXIOBASE. All authors contributed to the interpretation of the results and provided substantial input to the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Data Tables, Figures and Discussion.

Rights and permissions

About this article

Cite this article

Zheng, X., Wang, R., Wood, R. et al. High sensitivity of metal footprint to national GDP in part explained by capital formation. Nature Geosci 11, 269–273 (2018). https://doi.org/10.1038/s41561-018-0091-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41561-018-0091-y

This article is cited by

-

Driving factors and key paths of metal consumption in China: Evidence from structural decomposition and structural path analysis

Environment, Development and Sustainability (2024)

-

Using Caenorhabditis elegans to assess the ecological health risks of heavy metals in soil and sediments around Dabaoshan Mine, China

Environmental Science and Pollution Research (2022)

-

Tourism adaptability amid the climate change and air pollution in BRICS: a method of moments quantile regression approach

Environmental Science and Pollution Research (2022)

-

Heading towards sustainable environment: exploring the dynamic linkage among selected macroeconomic variables and ecological footprint using a novel dynamic ARDL simulations approach

Environmental Science and Pollution Research (2022)

-

Implementing the material footprint to measure progress towards Sustainable Development Goals 8 and 12

Nature Sustainability (2021)