Abstract

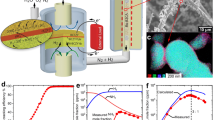

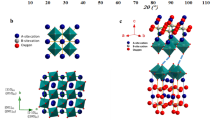

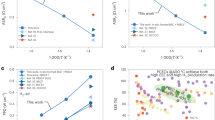

In spite of various advantages of protonic ceramic fuel cells over conventional fuel cells, distinct scepticism currently remains about their applicability because of lower-than-predicted performance and difficulty with scale-up. These challenges mainly stem from the refractory nature of proton-conducting ceramic electrolytes and the low chemical stability of these materials during the sintering process. Here, we present the fabrication of a physically thin, structurally dense and chemically homogeneous electrolyte, BaCe0.55Zr0.3Y0.15O3-δ (BCZY3), through a facile anode-assisted densification of the electrolyte on a structurally and compositionally uniform anode support, which resulted in breakthroughs in performance and scalability. A BCZY3-based protonic ceramic fuel cell with a size of 5 × 5 cm2 exhibits an area-specific ohmic resistance of 0.09 Ω cm2 and delivers a power as high as 20.8 W per single cell at 600 °C.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Steele, B. C. & Heinzel, A. Materials for fuel-cell technologies. Nature 414, 345–352 (2001).

Iwahara, H. Proton conducting ceramics and their applications. Solid State Ionics 86–88, 9–15 (1996).

Kreuer, K. D. Proton-conducting oxides. Annu. Rev. Mater. Res. 33, 333–359 (2003).

Medvedev, D. A., Lyagaeva, J. G., Gorbova, E. V., Demin, A. K. & Tsiakaras, P. Advanced materials for SOFC application: strategies for the development of highly conductive and stable solid oxide proton electrolytes. Prog. Mater. Sci. 75, 38–79 (2016).

Medvedev, D., Brouzgou, A., Demin, A., Tsiakaras, P. in Advances in Medium and High Temperature Solid Oxide Fuel Cell Technology (eds Boaro, M. & Aricò, A. S.) 77–118 (Springer, Berlin, 2016).

Duan, C. et al. Readily processed protonic ceramic fuel cells with high performance at low temperatures. Science 349, 1321–1326 (2015).

Contini, V. et al. Stationary and Emerging Market Fuel Cell System Cost Assessment DOE Hydrogen and Fuel Cells Program (Battelle Memorial Institute, 2017).

Dubois, A., Ricote, S. & Braun, R. J. Benchmarking the expected stack manufacturing cost of next generation, intermediate-temperature protonic ceramic fuel cells with solid oxide fuel cell technology. J. Power Sources 369, 65–77 (2017).

Coors, W. G. Protonic ceramic fuel cells for high-efficiency operation with methane. J. Power Sources 118, 150–156 (2003).

Kim, J. et al. Triple‐conducting layered perovskites as cathode materials for proton‐conducting solid oxide fuel cells. ChemSusChem 7, 2811–2815 (2014).

Ling, Y., Yu, J., Zhang, X., Zhao, L. & Liu, X. A cobalt-free Sm0.5Sr0.5Fe0.8Cu 0.2O3-δ–Ce0.8Sm0.2O2-δ composite cathode for proton-conducting solid oxide fuel cells. J. Power Sources 196, 2631–2634 (2011).

Bi, L., Fabbri, E., Sun, Z. & Traversa, E. A novel ionic diffusion strategy to fabricate high-performance anode-supported solid oxide fuel cells (SOFCs) with proton-conducting Y-doped BaZrO3 films. Energ. Env. Sci. 4, 409–412 (2011).

Guo, Y., Lin, Y., Ran, R. & Shao, Z. Zirconium doping effect on the performance of proton-conducting BaZryCe0.8−yY0.2O3-δ (0.0 ≤ y ≤ 0.8) for fuel cell applications. J. Power Sources 193, 400–407 (2009).

Nguyen, N. T. Q. & Yoon, H. H. Preparation and evaluation of BaZr0.1Ce0.7Y0.1Yb0.1O3-δ (BZCYYb) electrolyte and BZCYYb-based solid oxide fuel cells. J. Power Sources 231, 213–218 (2013).

Nien, S., Hsu, C., Chang, C. & Hwang, B. Preparation of BaZr0.1Ce0.7Y0.2O3-δ based solid oxide fuel cells with anode functional layers by tape casting. Fuel Cells 11, 178–183 (2011).

Shi, Z., Sun, W. & Liu, W. Synthesis and characterization of BaZr0.3Ce0.5Y0.2−xYbxO3-δ proton conductor for solid oxide fuel cells. J. Power Sources 245, 953–957 (2014).

Liu, M., Gao, J., Liu, X. & Meng, G. High performance of anode supported BaZr0.1Ce0.7Y0.2O3-δ (BZCY) electrolyte cell for IT-SOFC. Int. J. Hydrogen Energ. 36, 13741–13745 (2011).

Yang, L. et al. Enhanced sulfur and coking tolerance of a mixed ion conductor for SOFCs: BaZr0.1Ce0.7Y0.2–xYbxO3-δ. Science 326, 126–129 (2009).

Sun, W., Shi, Z., Liu, M., Bi, L. & Liu, W. An easily sintered, chemically stable, barium zirconate‐based proton conductor for high‐performance proton‐conducting solid oxide fuel cells. Adv. Funct. Mater. 24, 5695–5702 (2014).

Gorte, R. J. Cooling down ceramic fuel cells. Science 349, 6254 (2015).

Katahira, K., Kohchi, Y., Shimura, T. & Iwahara, H. Protonic conduction in Zr-substituted BaCeO3. Solid State Ionics 138, 91–98 (2000).

Guo, Y., Ran, R., Shao, Z. & Liu, S. Effect of Ba nonstoichiometry on the phase structure, sintering, electrical conductivity and phase stability of Ba1±xCe0.4Zr0.4Y0.2O3-δ (0 ≤ x ≤ 0.20) proton conductors. Int. J. Hydrogen Energ. 36, 8450–8460 (2011).

Wang, H., Peng, R. R., Wu, X. F., Hu, J. L. & Xia, C. R. Sintering behavior and conductivity study of yttrium-doped BaCeO3–BaZrO3 solid solutions using ZnO additives. J. Am. Ceram. Soc. 92, 2623–2629 (2009).

Han, D. et al. Origins of structural and electrochemical influence on Y-doped BaZrO3 heat-treated with NiO additive. J. Mater. Chem. A 2, 12552–12560 (2014).

German, R., Suri, P. & Park, S. Review: liquid phase sintering. J. Mater. Sci. 44, 1–39 (2009).

Guo, Y. M., Ran, R. & Shao, Z. P. A novel way to improve performance of proton-conducting solid-oxide fuel cells through enhanced chemical interaction of anode components. Int. J. Hydrogen Energ. 36, 1683–1691 (2011).

Yoo, Y. & Lim, N. Performance and stability of proton conducting solid oxide fuel cells based on yttrium-doped barium cerate–zirconate thin-film electrolyte. J. Power Sources 229, 48–57 (2013).

Ricote, S., Bonanos, N., Manerbino, A. & Coors, W. Conductivity study of dense BaCexZr(0.9−x)Y0.1O(3-δ) prepared by solid state reactive sintering at 1500 ℃. Int. J. Hydrogen Energ. 37, 7954–7961 (2012).

Liu, Y., Yang, L., Liu, M., Tang, Z. & Liu, M. Enhanced sinterability of BaZr0.1Ce0.7Y0.1Yb0.1O3-δ by addition of nickel oxide. J. Power Sources 196, 9980–9984 (2011).

Tong, J. H., Clark, D., Bernau, L., Sanders, M. & O’Hayre, R. Solid-state reactive sintering mechanism for large-grained yttrium-doped barium zirconate proton conducting ceramics. J. Mater. Chem. 20, 6333–6341 (2010).

Von Dollen, P. & Barnett, S. A study of screen printed yttria-stabilized zirconia layers for solid oxide fuel cells. J. Am. Ceram. Soc. 88, 3361–3368 (2005).

Reed, J. S. Principles of Ceramics Processing (Wiley-Interscience, Hoboken, 1995).

Shao, Z. & Haile, S. M. A high-performance cathode for the next generation of solid-oxide fuel cells. Nature 431, 170–173 (2004).

Grimaud, A. et al. Hydration properties and rate determining steps of the oxygen reduction reaction of perovskite-related oxides as H+-SOFC cathodes. J. Electrochem. Soc. 159, B683–B694 (2012).

Lin, Y. et al. Evaluation of Ba0.5Sr0.5Co0.8Fe0.2O3-δ as a potential cathode for an anode-supported proton-conducting solid-oxide fuel cell. J. Power Sources 180, 15–22 (2008).

Marrony, M. & Dailly, J. Advanced proton conducting ceramic cell as energy storage device. J. Electrochem. Soc. 164, F988–F994 (2017).

Hilpert, K., Das, D., Miller, M., Peck, D. H. & Weiβ, R. Chromium vapor species over solid oxide fuel cell interconnect materials and their potential for degradation processes. J. Electrochem. Soc. 143, 3642–3647 (1996).

Kim, Y., Chen, X., Jiang, S. P. & Bae, J. Effect of strontium content on chromium deposition and poisoning in Ba1–xSrxCo0.8Fe0.2O3-δ (0.3 ≤ x ≤ 0.7) cathodes of solid oxide fuel cells. J. Electrochem. Soc. 159, B185–B194 (2012).

Yan, A. et al. A temperature programmed desorption investigation on the interaction of Ba0.5Sr0.5Co0.8Fe0.2O3-δ perovskite oxides with CO2 in the absence and presence of H2O and O2. Appl. Catal. B 80, 24–31 (2008).

Acknowledgements

This work was supported by Technology Development Program to Solve Climate Changes through the National Research Foundation of Korea funded by the Ministry of Science, ICT & Future Planning (2017M1A2A2044982). H.A. thanks the Manpower Development Program for Energy supported by the Ministry of Knowledge and Economy.

Author information

Authors and Affiliations

Contributions

H.A. conceived the experiments and analyses. H.-W.L. developed the bilayer fabrication process. B.-K.K. provided suggestions for the cathode preparation. J.-W.S. and K.J.Y. analysed the electrochemical data. H.K. built the test stations. D.S., H.-I.J. and J.-H.L. supervised the research. H.A., H.-I.J. and J.-H.L. prepared and edited the manuscript with input from all the authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables 1–2, Supplementary Figures 1–19

Rights and permissions

About this article

Cite this article

An, H., Lee, HW., Kim, BK. et al. A 5 × 5 cm2 protonic ceramic fuel cell with a power density of 1.3 W cm–2 at 600 °C. Nat Energy 3, 870–875 (2018). https://doi.org/10.1038/s41560-018-0230-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-018-0230-0

This article is cited by

-

Comparison of Various Cathode Materials Fabricated by Pulsed Laser Deposition for Low-Temperature Ceramic Fuel Cells

International Journal of Precision Engineering and Manufacturing-Green Technology (2024)

-

Recent progress in oxygen electrodes for protonic ceramic electrochemical cells

Journal of the Korean Ceramic Society (2024)

-

The phase composition and electrochemical performance of CaZr1−xYbxO3−δ proton conductor

Ionics (2024)

-

Lowering the operating temperature of protonic ceramic electrochemical cells to <450 °C

Nature Energy (2023)

-

Functional layer engineering to improve performance of protonic ceramic fuel cells

Rare Metals (2023)