Abstract

The triboelectric nanogenerator (TENG) as a new power-generation technology was reported by Wang and co-workers in 2012. Because of its great potential for scavenging mechanical energy from living environment and sustainably driving portable devices, many researchers have developed various methods to improve output performances of TENG. In this paper, we review the progress in TENG made as flexible power sources by integrating flexible materials and stretching structures, especially for the applications of flexible electronics. For optimizing performances of TENG, the structural designs, material selections, and hybrid energy cells are presented. The reported TENG as flexible power sources has the potential applications in lighting up light emitting diodes (LEDs), powering sensors, and monitoring biomechanical motions.

Similar content being viewed by others

Introduction

With the growing requirement of electronics, it is of great importance to investigate clean and portable energy sources. Our surrounding environment has an abundance of energies including mechanical energy, wind power, solar energy, thermal energy, chemical energies etc,1,2,3,4 which can be collected and exploited. Researchers have developed various self-sufficient power sources by scavenging various forms of energy sources from the environment.5, 6 However, conventional technologies could not reach the requirement of high-efficient and sustainable capability. Therefore, it is necessary to develop new energy harvesters for solving the power source issues of future functional electronics. In 2012, Wang et al. fabricated a triboelectric nanogenerator (TENG), which can effectively convert various mechanical energies into electricity.7 For the TENG, there are many advantages, such as large output power, low cost, simple production, and high conversion efficiency. Wang and co-workers have developed various TENGs, which are mainly based on the coupling between triboelectric effect and electrostatic induction.8,9,10,11 Researchers have designed some outstanding TENGs, where the area power density can reach up to 500 W/m2 and a corresponding conversion total efficiency of about 85%.12, 13 With fast-growing demand for flexible electronics, such as wearable electronics, bendable displays, and electronic skin, flexible TENGs as power sources have been extensively studied. Suitable materials and optimized structures are two key elements, which can affect both the output performance and mechanical stability of the flexible TENGs. In the last 5 years, a significant amount of research work has been achieved to improve the performance and application of flexible TENGs.14,15,16

This review focuses on the progress of TENGs as flexible power sources for flexible electronics, which contain both scientific understanding and technology developments. First, we present a summary of the basic principle of TENGs, including fundamentals, structural designs, work mechanism, and output performance. Second, we present some methods to improve output performances of the TENGs. In this section, hybrid nanogenerators, which can simultaneously harvest multimode energies from the surrounding environment, will be emphatically explained. Third, we introduce some applications based on different kinds of flexible TENGs. Finally, some perspectives and challenges are discussed to open the way for future applications.

Flexible TENGs

Fundamentals

Triboelectrification is an effect that exists widely in human life. It is one of the fundamental principles of TENGs, which creates static polarized charges. TENGs always contain two different materials that are assembled face to face. When the two materials are in contact, opposite static charges appear on the surfaces due to contact electrification. In addition, the back side of the materials has an electrode. The charges can flow between two electrodes through an external circuit and a potential difference is created as the materials are separate. The transferred charges are defined as Q. The separation distance of the materials affects potential difference, which can be defined as V OC(x). Because of electrostatics, TENGs usually present capacitive behavior and the capacitance is defined as C . The V–Q–x relationship can be expressed as below17

Under short-circuit (SC) conditions, charges will transform between the two electrodes by to offset the potential difference. Eq. 2 can be utilized to express this condition.18

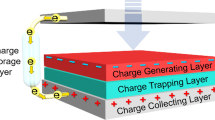

The vertical contact–separation mode was the first fundamental TENG working mode, which is based on periodic switching between the contact and separation conditions of the two triboelectric materials. In this mode, there are dielectric-to-dielectric and conductor-to-dielectric types for the different materials. Figure 1a illustrates a theoretical model for dielectric-to-dielectric contact-mode including two metal layers and dielectric plates.19 The dielectric plates are placed face to face, and thicknesses are d 1 and d 2. The relative dielectric constants of the plate are ε r1 and ε r2. The metal layers are fabricated on the back of the plates by a depositing process. With a mechanical force, the distance (x) between the two layers can be modified. When two dielectric materials contact each other, electrification led to opposite static charges appearing on the inner surface of two triboelectric layers. When the layers separate, potential difference emerges that will drive the electrons to flow under SC condition. And the induced charged density (\(\sigma '\)) can be expressed as18

a Theoretical model for dielectric-to-dielectric mode. Reproduced with permission.19 Copyright 2013 American Chemical Society. b Construction of the first flexible TENGE. Reproduced with permission.7 Copyright 2012 Elsevier. c Proposed mechanism of the TENG. Reproduced with permission.23 Copyright 2012 American Chemical Society

The fundamentals of conductor-to-dielectric model are similar to dielectric-to-dielectric contact model. The main difference is that one of the dielectric plates is replaced by a conductor layer. The conductor layer can be regarded as both the top triboelectric layer and the top electrode. As compared with the conductor-to-dielectric model, the efficiency of induced electron transfer in conductor-to-dielectric model is lower because of the electrostatic screening effect. However, the conductor-to-dielectric model is more practical because of the easier movements of triboelectric layer. For example, it has been utilized to scavenge energy from air flow,20 rotating tire,21 and rain drop.22 There are also other theoretical models such as metal-to-dielectric sliding-mode TENG, single electrode mode TENG, and sliding-mode freestanding TENG. In addition, these TENGs have been used to harvest energy from rotation motion, air flow, and a moving automobile.

Structural designs and working mechanism

In 2012, the first flexible triboelectric nanogenerator was invented to scavenge mechanical energy.7 Figure 1b is a typical structure of flexible TENG, which is based on the contact–separation mode. There are two different polymer sheets that were assembled as a sandwiched structure. The surface of the film has nanoscale roughness structure, which can produce friction. A thin Au film is deposited on the back of the polymer sheet. When the external force bends the polymer films, two films touched each other. Owing to nanoscale surface roughness, opposite charges emerge and distribute on the two surfaces of the films because of the contact electrification. Simultaneously, interface dipole layers are generated, which can give rise to inner potential layer between the two electrodes. And this device can work in a low strain (0.13%). If the capacitance and voltage of the flexible TENG are defined as C and V, the current of the system can be expressed.7

The working mechanism of the TENG is mainly based on contact charging and electrostatic induction, as shown in Fig. 1c.23 When an external force is applied on the TENG, the two triboelectric materials contact and the charge will transfer between the two materials. In this condition, one material surface that possesses a strong electron-attracting ability will produce negative charges. Positive charges will appear on another surface (Fig. 1cII). When the external force is released, an electric potential difference is established because of a separation of the two materials (Fig. 1cIII). The open-circuit voltage can be expressed as23

where σ is charge density, ε 0 is the vacuum permittivity, and d is the separation distance in an appointed condition. To balance the potential difference, the charges will flow from one side to another until the device is fully released, as illustrated in Fig. 1cV. Once the force is applied again, the potential difference will descend because of reduction of the interlayer distance. This process corresponds to an opposite current flow, as displayed in Fig. 1cVI. Thus, the TENG engenders an alternative current (AC) pulse output during a periodic switching, as presented in Fig. 1cIV. The advantage of this mode is the simple structure and high-power output, which can scavenge energy from mechanical vibration, breathing, and more. To transform various mechanical energies, researchers have developed varied structures of TENGs, such as arch-shaped, spring-supported, and cantilever-based.24,25,26

Output performances

The output performance of the TENG can be determined by measuring open-circuit voltage (V OC), SC current (I SC), and power density. A typical feature of the TENG is a high voltage and a low current, which can be explained both physically and mathematically. Figure 2a shows a schematic illustration of an implanted TENG (iTENG), which consists of a uniform polydimethylsiloxane (PDMS) film, an aluminum foil, a thin Kapton substrate, and a flexible polyethylene terephthalate (PET) spacer.27 The copper film was deposited on the paper by physical vapor deposition. Because of flexibility of the thin PDMS and Kapton layer, the TENG can transform slight vibration force to electrical energy. The V OC converts between 0 and 12 V owing to contact–separation mode, as illustrated in Fig. 2b. The I SC presents AC behavior with an average amplitude of 0.25 μA, as displayed in Fig. 2c. The power density is related to external loading resistances, as displayed in Fig. 2d. From 10 Ω to 1 MΩ, the output power density increases gradually and the maximal value is 8.44 mW/m2. Then, the output power density declines with the increasing resistance.

a Structure of iTENG. b Output voltage of the iTENG. c Output current. d Dependence of output power density on the loading resistances. Reproduced with permission.27 Copyright 2014 Wiley-VCH

As for different TENGs, it is difficult to evaluate output performance in a single standard owing to different materials and modes. Recently, Zi et al. established an evaluation model by finite element method and found that structure and material affect output performance of TENGs.28 This work not only provides an evaluation standard but also guides design of TENGs.

Enhancement of flexible TENGs

Material selection

To optimize performance of TENGs, various methods have been developed. Researchers found that the performance is related to the materials. The main reason is that different materials have different triboelectric charges. Because of the superposition principle of electric potential, the density of triboelectric charges could affect both the output voltage and current. Therefore, the chosen materials should produce triboelectric charges easily, where the triboelectric polarities of the two materials should be different. Many materials can be used in flexible TENGs, such as polyamide, polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), and silk.

Because that paper has low-cost, portable, and disposable properties, Fan et al. developed the paper-based flexible TENG.29 As illustrated in Fig. 3a, it includes a film of copper, a layer of paper, and a thin PTFE membrane. To improve bandwidth response, holes were fabricated on the paper substrate. For the circle shape, the maximum peak output of frequency–response emerges at about 320 Hz and other peaks appear at the frequencies around the integral multiples of about 80 Hz. The arrays of micro-holes on the thin membrane can induce the membrane to vibrate in a multimodal manner, resulting in a planar standing wave. Moreover, the standing wave gives rise to large deformations, which corresponds to the peaks in frequency. The PTFE film with nanostructure could increase the triboelectrification, which is related to the output performance. Figure 3b illustrates that the output current has little decline in the low-resistance region. When the resistor is larger than 800 KΩ, the voltage shows a reverse trend, which can be explained by the Ohmic loss. When the loading resistance is 800 KΩ, the power density reaches maximum value of about 121 mW/m2 under a sound pressure of 117 dBSPL (Fig. 3c). As a result, the paper-based flexible TENG can be utilized to scavenge acoustic energy from human talking.

a Structure of the paper-based TENG. b Dependence of voltage and current output for different loading resistances. c Relationship between output power and external loading resistance. Reproduced with permission.29 Copyright 2015 American Chemical Society. d Schematic of the fiber-based TENG. Output voltages of the PVDF nanogenerator as a function of strain rate with a maximum strain of about 0.05%. e Dependence of output current on the number of coils. f Dependence of output current on strains. Reproduced with permission.30 Copyright 2016 Wiley-VCH

Recently, He et al. reported a novel fiber-based flexible TENG.30 This device has a remarkable performance for sustaining high strains. The TENG has a fiber-like structure, which consists of silicon rubber, carbon nanotube, and copper, as sketched in Fig. 3d. The authors first selected silicone rubber as core fiber. Then, they adopted carbon nanotube and polymer matrix as a conductive layer. Finally, they used copper microwire as an electrode and convolved it onto the fiber. Owing to the material characteristics, including high flexibility, electrical conductivity, and mechanical stability, the TENG can be applied for power generation. Figure 3e illustrates the output performance of the fiber-based TENG, and it can be found that current is positively correlated with the number of coils. The stretch strain also affects the output current, as displayed in Fig. 3f. It is noticed that the bigger stretch strain produces higher current peaks as compared with those from smaller stretch strain. When the silicone fiber is stretched to 70% strain, the induced SC current attains 0.018 µA under a length of about 1 cm. The main reason is that the increase of stretch strain can increase circuit-transferred charges.

Structural optimization

For enhancing the output performance of the TENGs, various innovative structural designs have been reported. Zhu et al. developed a thin-film-based micrograting TENG (MG-TENG).12 This nanogenerator can effectively scavenge mechanical energy from sliding motions. The TENG has the grating structure, which can improve charge separation cycles. Figure 4a depicts a schematic illustration and a photograph of the MG-TENG. The device consists of metal strips and the PTFE thin film, which was modified by the PTFE nanoparticles. At a stable sliding velocity, the I SC and V OC are present in Fig. 4b, c, respectively. The I SC has an average amplitude of 2 mA and V OC switches between 0 and 500 V. The relationship between the optimum effective power and grating width is displayed in Fig. 4d. The effective output power attains a maximum value of 22.5 W at the grating width of 50 μm.

a Schematic diagram of the MG-TENG. b The output current at a sliding velocity of 2 ms−1. c The output voltage at a sliding velocity of 2 ms−1. d The relationship between output power and grating width. Reproduced with permission.12 Copyright 2014 Wiley-VCH. e Schematic illustrations of the paper-based TENG. f Photograph of the unit cell and multiple units. g Dependence of output current on the number of connection units. h The output current under different human motion conditions. Reproduced with permission.31 Copyright 2016 American Chemical Society

Furthermore, mutilayer structure has been widely utilized in the design of TENG owing to an enhanced output current and power density. Yang et al. reported a paper-based TENG, which was designed into slinky- and doodlebug-shaped structures.31 The TENG possesses multiple merits, such as flexibility, light weight, and recyclability, and can be utilized to harvest mechanical energy. It consists of a paper, PTFE thin film, and aluminum, as illustrated in Fig. 4e. Figure 4f presents a single unit cell and multiple units. The rectified I SC increases with the adding number of units, as displayed in Fig. 4g. It seems to be an approximately linear relationship between the output current and the number of connection units. The TENG can convert various mechanical motions to electric energy. Figure 4h presents that the rectified I SC from the stretching motions is higher than that from lifting and twisting motions. It can be explained that stretching motion generates bigger distance, which affects the device output performances. As for other structural optimizations, wavy layouts and filamentary serpentine layouts have been developed. Recently, Li et al. reported an innovative multilayer elastomeric TENG.32 They designed plane dielectric-conductive-dielectric parts and wavy conductive-dielectric-conductive parts, which could divide the whole large space into several layers of small space. Moreover, this method is beneficial for improving surface tribo-charge density, which can affect the output performances of TENG.

Hybridization based on TENG

As the surrounding environment possesses various kinds of energy sources such as light, mechanical motion, and thermal energy, a number of researchers have investigated hybrid energy cells based on TENGs. Hybrid energy cells can be created by integrating different energy harvesters, such as solar cells, electromagnetic generators, and electrochemical cells, in serial or parallel mode. Thus, hybrid devices could possess advantages of these individual energy harvesters and scavenge various energies.

Chen et al. developed a hybrid cell composed of fiber-based TENG and solar cells, as illustrated in Fig. 5a.33 The hybrid cell consists of photovoltaic textile, photo anode, polymer fiber, and PTFE. The Cu-coated polymer fiber not only can improve mechanical strength but can also serve as a counter electrode. To attain the requirement of the application, the triboelectric textile and photovoltaic textile could be combined by different modes, such as series, parallel, and regulated. The prepared hybrid textile can simultaneously harvest solar and mechanical energies. Figure 5b displays that output signals of hybrid devices work in separateness and in serial connection under different conditions. Under sunlight condition, the photovoltaic component could convert light to DC output signal. The output signals of current and voltage are 0.2 mA and 8 V, respectively. When a mechanical strain is applied to the device, the peak output voltage of the hybrid device can be enhanced to 80 V, and output current is enhanced to 0.25 mA. On the other hand, a range of loading resistances is optimized owing to the triboelectric textile. Figure 5c displays that the output power of the triboelectric textile reaches the maximum at 10 kΩ and the output power of the photovoltaic textile attains the maximum at a loading resistance of 10 MΩ. For the hybrid textile, the average output power is 0.5 mW under a wide range of loading resistances.

a Schematic diagram of the hybrid energy cell and three connection mode. b Output signal under different circumstances. c Dependence of the output power on hybrid cells and individual cell. Reproduced with permission.33 Copyright 2016 Nature Publishing Group. d Schematic diagram of the hybrid nanogenerator. e Dependence of the output power and voltage on the loading resistance. f Measured voltage of the capacitor with different generators. Reproduced with permission.34 Copyright 2014 American Chemical Society

Besides the hybridization of triboelectrification and photoelectric effect, a few researchers have developed other types of hybrid cells. For example, Yang et al. reported a hybrid cell by integrating TENG with electromagnetic induction generator.34 As displayed in Fig. 5d, the TENG cell is an arched structure with glass fibers (GFs), PDMS, fluorinated ethylene propylene (FEP), PET, silver nanowires (AgNws), Cu coil, and NdFeB magnet. The AgNWs were placed on one side of PDMS to improve the electroconductivity and flexibility of the GFs. Figure 5e presents the loading resistance dependence of both output power and current. The output current decreases with the increasing resistance from 1 Ω to 10 MΩ. The output power increases in low region of the resistance and reaches a maximum value of 0.34 mW at 20 KΩ. A major advantage of this hybrid cell is the outstanding charging performance. The charged time for the hybrid cell is 16 s, which are obviously smaller than the individual cells, as displayed in Fig. 5f.

Applications of TENGs as flexible power sources

Flexible power sources for lighting light emitting diodes (LEDs)

After the first TENG was invented, a large number of researchers have investigated the TENG’s practical applications. A typical application of the TENG is utilized to light up LEDs. Yang et al. fabricated a triboelectric generator (TEG) that can scavenges wind flow-induced mechanical energy.35 As illustrated in Fig. 6a, the TEG consists of two PTFE films, Al electrodes, Kapton films, and an acrylic tube. Under wind flow-driven vibration of a PTFE film, the PTFE film will periodically contact and separate with the Al electrodes, resulting in an alternating output signal. To increase the output current, the authors integrated more cells in parallel mode. And the total output current can be increased to about 150 μA by paralleling 10 cells. The integrated cells can simultaneously drive 10 LEDs for providing effective illumination in the dark environment, as presented in Fig. 6c.

a Schematic diagram of the TEG. b Output current for 10 paralleling cells. c Photographs of the LEDs were powered by 10 paralleling cells. Reproduced with permission.35 Copyright 2011 Wiley-VCH. d Schematic diagram of the self-powered triboelectric sensor. e Output voltage at a contact force. f A photograph showing that the TES can trigger a wireless alarm when a people steps on the top of the TES. g A photograph showing that the TES triggers the alarm when it was contacted by human hand. Reproduced with permission.36 Copyright 2014 American Chemical Society

Flexible power sources for powering wireless sensors

The past decades have an increasing interest in wireless sensors owing to the requirement of the internet of things. To drive the large number of sensors, researchers continuously seek new power sources. The TENG could be inherently flexible and can be used as a power source. In 2014, Zhu et al. developed a self-powered triboelectric sensor (TES) based on contact electrification mode.36 As displayed in Fig. 6d, a layer of FEP is on the top of the device, which can be used as an electrification layer and modified by aligned polymer nanowires. The nanowires can be utilized to improve the sensitivity for low-pressure detection. In the middle region, there is a three-layer structure, which contains a layer of PET and two transparent ITO layers. On the bottom, a nylon film is used to strengthen device mechanical characteristics. When a contact force of 20 mN was applied to the device, an equal output voltage of 35 V was measured, as illustrated in Fig. 6e. The authors also presented that the output voltage can increase with an increase in the forces due to the increased contact area between metal substance and the TES. For application, the TES can be utilized to start a siren alarm by integrating it with a signal-processing circuit. As displayed in Fig. 6f, the TES was placed between the carpet and ground. When a person walks across a top of the carpet, the TES will generate the output voltage because of the effective contact between it and the carpet. Then, the output voltage can drive the siren. The TES also can be installed on the door handle to detect contact between hand and handle, as displayed in Fig. 6g. Moreover, due to that the TES consists of flexible materials, it can be applied in a variety of circumstances.

Flexible power sources for biomechanical monitoring

The flexible TENG is a remarkable power source for powering flexible electronics because of its simple fabrication, light weight, and flexibility. In 2016, Yi et al. developed a shape-adaptive TENG (saTENG), which can be utilized as a self-powered biomechanical motion sensor.37 As exhibited in Fig. 7a, it includes a conductive liquid electrode and a rubber layer. To increase the triboelectric charge density, the nanorods were fabricated on the surface of the rubber by the etched process. A photograph of a typical unit is demonstrated in Fig. 7b. A copper wire is used to connect the conductive liquid. Many liquids can be invoked as the conductive liquid, such as water, liquid metal, and sodium chloride solution. This nanogenerator is based on single-electrode mode. And it will generate output signals when a nylon film touched the surface of rubber at a frequency of about 0.45 Hz, as displayed in Fig. 7c–e. The V OC switches between 0 and 67.71 V and I SC have a maximum amplitude of 0.8 mA. A transferred charge density is about 35.35 μC/m2. And this device can maintain its high performance after being stretched by 300%. For the application, the saTENG can scavenge various kinds of human motion energies. Figure 7d illustrates that the output voltage can directly light up 80 LEDs when a person keeps on tapping the device. In addition, the electricity from the device can be stored in capacitors when the device is connected to a capacitor and a bridge rectifier. The voltage increases under a tapping situation, while the voltage maintains a level once the tapping is interrupted, as illustrated in Fig. 7e.

a Schematic diagram of the saTENG. b A photograph of a typical unit. c–e Output signal of the saTENG when periodically touched. f A photograph showing that the saTENG lights LEDs when people tap the device. g Measured voltage of the capacitor under tapping and stop condition. Reproduced with permission.37 Copyright 2016 Nature Publishing Group

Prospects and challenges

As wearable electronics and other flexible sensors are widely used in daily life, self-powered systems are fundamental components. To realize this goal, various new energy-scavenging techniques have been exploited, such as solar cells, thermoelectric cells, and piezoelectric nanogenerators. As compared with these energy harvesters, the TENG as a new power-generating technology has many prominent advantages including high power density, high energy conversion efficiency, low cost, and easy fabrication. However, some potential issues still need to be solved. First, fundamental mechanism of contact electrification has not been clarified. Second, triboelectric materials are susceptible to mechanical wear. To realize large-scale applications, researchers need to fabricate new materials with stable and durable characteristics. Third, because of obvious effects of external environments on output performances of TENG, it is important to develop effective packing technology to protect these devices.

In recent years, many investigations have been focused on improving the output performances and demonstrating application examples of TENG. For the development of flexible TENGs, certain research aspects and works should be addressed.

-

(1)

Improving the performances of flexible TENG. A vast amount of advanced materials would be good choices, such as graphene,38, 39 carbon nanotube,40 and nano-Ag ink.41 It is found that nanoscale roughness on graphene can increase the surface charges, which can improve the output power of the TENG. Besides the materials, novel structural designs still need to be optimized to improve device durability and output stability, such as sponge structure, grating structure, and wavy structure.

-

(2)

Focusing the working mechanisms of TENG. Some fundamental mechanisms have been established, but no substantial conclusion has been proposed. It is important to understand the corresponding mechanisms for designing new high-performance TENGs.

-

(3)

Integration of TENG with other power generators to fabricate hybrid energy cells. The hybrid energy cells could enhance the output performances of the TENG and solve some key problems when facing different functional requirements in human life.

Summary

This paper systematically reviewed the recent development of flexible TENGs. From the first report of a flexible TENG in 2012, investigations in performance optimization have inspired extensive interest. By integrating the TENGs with other types of generators, the output performances of the TENGs have been dramatically improved, where the flexible TENGs can be utilized to directly power some personal electronics. With the continuous efforts by a large number of researchers around the world, we hope that the flexible TENGs could be extensively applied in our daily life, especially for waste biomechanical energy scavenging and self-powered sensor systems.

Data availability

The data that support the findings of this study are available from the corresponding author on request.

References

Lewis, N. S. Toward cost-effective solar energy use. Science 315, 798–801 (2007).

Himmel, M. E. et al. Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315, 804–807 (2007).

Wen, X., Yang, W., Jing, Q. & Wang, Z. L. Harvesting broadband kinetic impact energy from mechanical triggering/vibration and water waves. ACS Nano 8, 7405–7412 (2014).

Dagdeviren, C. et al. A. Recent progress in flexible and stretchable piezoelectric devices for mechanical energy harvesting, sensing and actuation. Extreme Mech. Lett. 9, 269–281 (2016).

Wang, Z. L. Self-powered nanosensors and nanosystems. Adv. Mater. 24, 280–285 (2012).

Dagdeviren, C., Li, Z. & Wang, Z. L. Energy harvesting from the animal/human body for self-powered electronics. Annu. Rev. Biomed. Eng. 19, 85–108 (2017).

Fan, F. R., Tian, Z. Q. & Wang, Z. L. Flexible triboelectric generator. Nano Energy 1, 328–334 (2012).

Wang, S. H., Wang, X., Wang, Z. L. & Yang, Y. Efficient scavenging of solar and wind energies in a smart city. ACS Nano 10, 5696–5700 (2016).

Yang, Y. et al. Human skin based triboelectric nanogenerators for harvesting biomechanical energy and as self-powered active tactile sensor system. ACS Nano 7, 9213–9222 (2013).

Zhao, K., Wang, Z. L. & Yang, Y. Self-powered wireless smart sensor node enabled by an ultrastable, highly efficient, and superhydrophobic-surface-based triboelectric nanogenerator. ACS Nano 10, 9044–9052 (2016).

Zhang, K. W., Wang, X., Yang, Y. & Wang, Z. L. Hybridized electromagnetic–triboelectric nanogenerator for scavenging biomechanical energy for sustainably powering wearable electronics. ACS Nano 9, 3521–3529 (2015).

Zhu, G. et al. A shape-adaptive thin-film-based approach for 50% high-efficiency energy generation through micro-grating sliding electrification. Adv. Mater. 26, 3788–3796 (2014).

Xie, Y. et al. Grating-structured freestanding triboelectric-layer nanogenerator for harvesting mechanical energy at 85% total conversion efficiency. Adv. Mater. 26, 6599–6607 (2014).

Bai, P. et al. Integrated multilayered triboelectric nanogenerator for harvesting biomechanical energy from human motions. ACS Nano 7, 3713–3719 (2013).

Zhong, J. et al. Fiber-based generator for wearable electronics and mobile medication. ACS Nano 8, 6273–6280 (2014).

Kim, S. et al. Transparent flexible graphene triboelectric nanogenerators. Adv. Mater. 26, 3918–3925 (2014).

Niu, S. et al. Theory of sliding-mode triboelectric nanogenerators. Adv. Mater. 25, 6184–6193 (2013).

Niu, S. et al. Theoretical investigation and structural optimization of single-electrode triboelectric nanogenerators. Adv. Funct. Mater. 24, 3332–3340 (2014).

Niu, S. et al. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 6, 3576–3583 (2013).

Yang, Y. et al. Triboelectric nanogenerator for harvesting wind energy and as self-powered wind vector sensor system. ACS Nano 7, 9461–9468 (2013).

Zhang, H. et al. Single-electrode-based rotating triboelectric nanogenerator for harvesting energy from tires. ACS Nano 8, 680–689 (2014).

Liang, Q. et al. Highly transparent triboelectric nanogenerator for harvesting water-related energy reinforced by antireflection coating. Sci. Rep 5, 9080–9087 (2015).

Zhu, G. et al. Triboelectric-generator-driven pulse electrodeposition for micropatterning. Nano. Lett. 12, 4960–4965 (2012).

Wang, S., Lin, L. & Wang, Z. L. Nanoscale triboelectric-effect-enabled energy conversion for sustainably powering portable electronics. Nano. Lett. 12, 6339–6346 (2012).

Wang, X., Wang, Z. L. & Yang, Y. Hybridized nanogenerator for simultaneously scavenging mechanical and thermal energies by electromagnetic-triboelectric-thermoelectric effects. Nano Energy 26, 164–171 (2016).

Wang, J. et al. A flexible fiber-based supercapacitor-triboelectric-nanogenerator power system for wearable electronics. Adv. Mater. 27, 4830–4836 (2015).

Zheng, Q. et al. In vivo powering of pacemaker by breathing-driven implanted triboelectric nanogenerator. Adv. Mater. 26, 5851–5856 (2014).

Zi, Y. et al. Standards and figure-of-merits for quantifying the performance of triboelectric nanogenerators. Nat. Commun. 6, 8376–8384 (2015).

Fan, X. et al. Ultrathin, rollable, paper-based triboelectric nanogenerator for acoustic energy harvesting and self-powered sound recording. ACS Nano 9, 4236–4243 (2015).

He, X. et al. A Highly stretchable fiber-based triboelectric nanogenerator for self-powered wearable electronics. Adv. Funct. Mater. 27, 1604378–1604386 (2017).

Yang, P. K. et al. Paper-based origami triboelectric nanogenerators and self-powered pressure sensors. ACS Nano 9, 901–907 (2015).

Li, S. et al. Sustainable energy source for wearable electronics based on multilayer elastomeric triboelectric nanogenerators. Adv. Energy Mater 7, 1520–1529 (2017).

Chen, J. et al. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nat. Energy 1, 16138–16146 (2016).

Zhang, K., Wang, Z. L. & Yang, Y. Conductive fabric-based stretchable hybridized nanogenerator for scavenging biomechanical energy. ACS Nano 10, 4728–4734 (2016).

Wang, S. et al. Flow-driven triboelectric generator for directly powering a wireless sensor node. Adv. Mater. 27, 240–248 (2014).

Zhu, G. et al. Self-powered, ultrasensitive, flexible tactile sensors based on contact electrification. Nano. Lett. 14, 3208–3213 (2014).

Fang, Y. et al. A highly shape-adaptive, stretchable design based on conductive liquid for energy harvesting and self-powered biomechanical monitoring. Sci. Adv 2, 1501624–1501635 (2016).

Kim, S. et al. Transparent flexible graphene triboelectric nanogenerators. Adv. Mater. 26, 3918–3925 (2014).

Chandrashekar, B. N. et al. Roll-to-roll green transfer of CVD graphene onto plastic for a transparent and flexible triboelectric nanogenerator. Adv. Mater. 27, 5210–5216 (2015).

Park, S. et al. Stretchable energy-harvesting tactile electronic skin capable of differentiating multiple mechanical stimuli modes. Adv. Mater. 26, 7324–7332 (2014).

Li, W., Sun, J. & Chen, M. Triboelectric nanogenerator using nano-Ag ink as electrode material. Nano Energy 3, 95–101 (2014).

Acknowledgements

This work was supported by the National Key R&D Program of China (Grant No. 2016YFA0202701), the National Natural Science Foundation of China (Grant No. 51472055, Grant No. 61404034), External Cooperation Program of BIC, Chinese Academy of Sciences (Grant No. 121411KYS820150028), the 2015 Annual Beijing Talents Fund (Grant No. 2015000021223ZK32), and the “thousands talents” program for the pioneer researcher and his innovation team, China.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, Y., Yang, Y. & Wang, Z.L. Triboelectric nanogenerators as flexible power sources. npj Flex Electron 1, 10 (2017). https://doi.org/10.1038/s41528-017-0007-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-017-0007-8

This article is cited by

-

Carbon fabric coated with nanostructured zinc oxide layers for use in triboelectric self-powered touch sensors

Journal of Materials Science: Materials in Electronics (2024)

-

Electrospun PVDF/aromatic HBP of 4th gen based flexible and self-powered TENG for wearable energy harvesting and health monitoring

Scientific Reports (2023)

-

Stretchable nanogenerators for scavenging mechanical energy

Nano Research (2023)

-

High-performance triboelectric nanogenerator using ZIF-67/PVDF hybrid film for energy harvesting

Journal of Materials Science: Materials in Electronics (2023)

-

Triboelectric nanogenerators: the beginning of blue dream

Frontiers of Chemical Science and Engineering (2023)