Abstract

Antisite defects are a type of point defect ubiquitously present in intercalation compounds for energy storage applications. While they are often considered a deleterious feature, here we elucidate a mechanism of antisite defects enhancing lithium intercalation kinetics in LiFePO4 by accelerating the FePO4 → LiFePO4 phase transformation. Although FeLi antisites block Li movement along the [010] migration channels in LiFePO4, phase-field modeling reveals that their ability to enhance Li diffusion in other directions significantly increases the active surface area for Li intercalation in the surface-reaction-limited kinetic regime, which results in order-of-magnitude improvement in the phase transformation rate compared to defect-free particles. Antisite defects also promote a more uniform reaction flux on (010) surface and prevent the formation of current hotspots under galvanostatic (dis)charging conditions. We analyze the scaling relation between the phase boundary speed, Li diffusivity and particle dimensions and derive the criteria for the co-optimization of defect content and particle geometry. A surprising prediction is that (100)-oriented LiFePO4 plates could potentially deliver better performance than (010)-oriented plates when the Li intercalation process is surface-reaction-limited. Our work suggests tailoring antisite defects as a general strategy to improve the rate performance of phase-changing battery compounds with strong diffusion anisotropy.

Similar content being viewed by others

Introduction

Point, line and/or planar defects are ubiquitously present in all materials and frequently have beneficial effects on material properties. The intentional introduction and control of defects plays a key role in the development of advanced materials with better performance and new functionality. Well-known examples include doping semiconductors to modify the band structure and using phase or grain boundaries to strengthen alloys. Like other materials, battery intercalation compounds contain various types of defects. “Defect engineering” is a promising strategy for this class of materials, which nonetheless has not yet been widely explored. In particular, recent studies find that antisite defects, which are common in battery compounds, can promote Li transport and enhance rate performance by opening up alternative diffusion channels with lowered migration energies in numerous lithium-ion battery electrode materials. Such phenomena have been reported in Li1.211Mo0.467Cr0.3O2,1 Li2(Mn,Fe)P2O7,2 α-LiMn1−xFexPO4 (ref. 3) and Li4Ti5O12,4 etc. In refs. 5,6, antisite defects are also reported to improve the stability and cyclability of cubic LixTi2O4, where the random mixing of Li and Ti on octahedral sites in the cubic phase electrochemically induced from amorphous TiO2 enables reversible capacity that cannot be achieved otherwise. These examples demonstrate that the rational tailoring of antisite defects provides a potentially general approach to improving battery electrode properties.

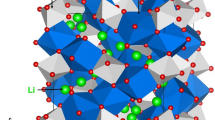

Here we present a computational study that reveals a new mechanism of antisite defects enhancing the rate capability of intercalation compounds by accelerating surface-reaction-limited (SRL) phase transformation during battery charge/discharge. Antisite defects are generated when the sites of intercalating ions are occupied by other cations that are usually less mobile. A prominent effect of antisite defects in battery electrodes is to block the existing paths of intercalating ions and generate new migration pathways at the same time. For intercalation compounds with strong anisotropic transport properties, which are common among battery materials, such effect usually leads to the reduction in the diffusion anisotropy of intercalating ions. For example, lithium iron phosphate olivine (LiFePO4) is theoretically predicted to have predominantly one-dimensional (1D) Li diffusion in the [010] direction.7 However, experiments show that practically synthesized LiFePO4 with just a few percent of Li–Fe antisite defects (Li/Fe) instead exhibit two-dimensional (2D) Li diffusivity.8,9 This discrepancy is explained by first-principles calculation10 that finds Li/Fe to impede Li movement along [010] migration channels but facilitate Li hopping between the channels via vacancies on Fe sites created by antisite defects. Similar observations of antisite defects reducing ion diffusion anisotropy are also reported for Li2MP2O7 (ref. 2), Li4Ti5O12 (ref. 4), Na2+δFe2−δ/2 (SO4)311 and LiMnBO3.12

In this work, we show that antisite defects in LiFePO4 lead to an unexpected increase in the SRL phase transition rate. This is achieved by an increase in the surface reaction area for Li intercalation due to defect-enhanced Li diffusion along [100] even though antisites impede Li movement in the fast [010] diffusion direction. Analysis of the interplay between surface reaction and Li diffusion reveals that the inclusion of antisite defects in LiFePO4 qualitatively changes the particle size dependence of phase transformation rate in the SRL regime. As a result, the rate performance of defect-containing LiFePO4 is less sensitive to particle dimensions, which facilitates the use of larger particles to improve the packing density and reduce side reaction of the electrodes. Under galvanostatic conditions, the presence of antisites also reduces the risk of electrode damage from current hotspots by distributing the reaction flux more uniformly on particle surface. Due to the kinetic competition between surface reaction and bulk diffusion, an optimal defect concentration is predicted to exist for a given particle geometry to maximize the Li (de)intercalation rate. Criteria for the co-design of defect content and particle morphology are proposed. Counterintuitively, we find that (100)-oriented LiFePO4 platelike particles may exhibit even better rate performance than (010)-oriented plate particles in the SRL kinetic regime at relatively low defect levels, whereas the latter is commonly viewed as the most desirable LiFePO4 particle morphology. While we demonstrate the possibility of using antisite defects to accelerate phase transitions in LiFePO4, it may have general applicability to other phase-changing battery materials that exhibit ion diffusion anisotropy.

Results

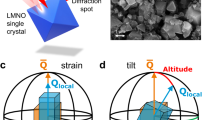

Electrochemically driven first-order phase transformations in battery electrode materials upon ion (de)intercalation are subject to the kinetic control of various rate-limiting steps. We previously show9 that the competition between Li diffusion and surface reaction can give rise to three distinct phase transformation modes in LiFePO4, i.e. bulk-diffusion-limited (BDL), SRL and an intermediate hybrid mode, in which phase boundary migration is BDL or SRL in different directions. As illustrated in Fig. 1, these transformation modes are associated with different phase growth morphologies and rates. They are not unique to LiFePO4 and can operate in other intercalation compounds. Phase transformation becomes SRL when Li insertion/extraction at the electrode particle surface is much more sluggish than its diffusion inside the particles. This could occur at small particle sizes, low applied over/under-potentials and/or low exchange current density for charge transfer, etc.9 In a pioneering study, Singh, Ceder and Bazant (SCB) investigated the SRL phase transformation kinetics using a depth-averaged model of LiFePO4.13 They show that a salient feature of the SRL mode is that phase boundary travels at a constant velocity perpendicular to the main Li intercalation direction (Fig. 1), which is in sharp contrast to the behavior of the BDL mode. Although the SCB theory assumes 1D Li transport in LiFePO4 in accordance with the DFT prediction,7 the characteristics of the SRL mode are independent of Li diffusion anisotropy and also apply to cases with higher dimensional Li diffusivity in the presence of antisite defects.9

Antisite defects accelerate SRL phase transformation

We study the SRL phase transformation process in defect-containing LiFePO4 particles using the mesoscale phase-field simulation method,14,15,16 which has been applied to the modeling of LiFePO4.17,18,19,20,21 An unexpected phenomenon that antisite defects can increase the phase boundary migration speed is observed from the simulations, in which the influence antisite defects exert on the discharge process is captured by their effect on the anisotropic Li diffusivity in LiFePO4. In ref. 10, Malik et al. evaluate from first-principles calculation the activation barrier required for Li+ to cross over to a neighbor channel through an antisite in LiFePO4. The calculated Li migration barrier is employed to determine the defect concentration dependence of Li diffusivity along [010], [100] and [001] axes, D[010], D[100] and D[001], at 440 K. While D[010] at the room temperature (300 K) is also reported at several defect levels in ref. 10, the values of D[100] and D[001] at 300 K are not provided in that work. As they are required for our simulations, we calculated all the three diffusion coefficients at 300 K as a function of antisite concentration following the approach of Malik et al.10 (see Methods). As shown in Supplementary Fig. 1 in the Supplementary Information (SI), D[100] exhibits an approximately inverse relationship with D[010] at 300 K. Both of them approach 10−12–10−11 cm2 s−1 at high defect concentrations, consistent with our previous observation of 2D room-temperature Li diffusivity D[010] ≈ D[100]/[001] ≈ 10−11 cm2 s−1 in defect-containing LiFePO4 microparticles.9 The calculated Li diffusivity values at 300 K are used in the phase-field simulations presented below.

Figure 2 compares the discharge simulations for two LiFePO4 particles with different antisite contents at a constant underpotential Δϕ = 35 mV, which is below the underpotential required to form a metastable solid solution in LiFePO4. The particles are given (010)-oriented platelike shape in simulations to facilitate fast Li diffusion along the [010] direction and ensure that the phase transition is in the SRL regime. Such particle morphology is commonly obtained in hydrothermal synthesis.22,23 In the simulations, Li is inserted into the particle from (010) surface only, and zero-flux boundary condition is applied to (100) surfaces. The “defect-lean” particle contains 0.5% antisites and has a large D[010] = 1.3 × 10−10 cm2 s−1 but a much smaller D[100] = 3.9 × 10−14 cm2 s−1. The “defect-rich” particle contains 25% antisites and has a much reduced Li diffusion anisotropy with D[010] = 5.4 × 10−12 cm2 s−1 and D[100] = 2.6 × 10−12 cm2 s−1. Because phase boundaries are observed to be parallel to the [001] axis in platelike particles,18,22,24,25 simulations were reduced to two dimensions to improve computation efficiency. Coherency stress that arises from the lattice mismatch between LiFePO4 (LFP) and FePO4 (FP) phases plays a critical role in inducing the metastable solid solution behavior at high (dis)charge rates.18,26 However, it is found that the omission of coherency stress does not cause any significant change on the phase transformation kinetics in the SRL regime (see Supplementary Fig. 2), and stress is thus not considered in simulations to simplify the theoretical analysis described later. As shown in Fig. 2, the FP → LFP phase transition in both particles is in the SRL mode, with the phase boundary traveling along [100] at a constant speed. However, the phase boundary velocity in the defect-rich particle is six times higher than in the defect-lean particle, even though the Li diffusivity in the main intercalation direction [010] is two decades larger in the latter. We also performed similar simulation for SRL phase transformation at T = 440 K using the defect-concentration-dependent Li diffusivity values at this temperature reported in ref. 10. Supplementary Fig. 3 shows a similar increase of the phase boundary speed by one order of magnitude in LiFePO4 containing 10% defects at 440 K. This finding is surprising as SRL phase transformation is expected to be kinetically limited by surface reaction and insensitive to Li diffusion kinetics.

a Snapshots at time = 2000, 4000, 6000 and 8000 s. The dashed black boxes indicate the regions showing bulk diffusion flux distributions in Fig. 3b. b Phase boundary location along [100] vs time.

A revealing clue to this counter-intuitive result can be found in Fig. 3a, which shows the distribution of Li intercalation flux js on (010) surface in both particles. Li insertion in the defect-lean particle only takes place near the phase boundary and js decays rapidly away from the boundary center. The narrow surface reaction region moves together with the phase boundary, resulting in the sequential filling of [010] Li channels along the [100] direction during discharge. Such behavior is analogous to the prediction of SCB theory and the “domino-cascade” model proposed by Delmas et al.27 In contrast, the entire (010) surface actively intercalates Li in the defect-rich particle. While its peak value is the same as that in the defect-lean particle, js decreases more slowly away from the phase boundary. As such, more Li ions are inserted into the defect-rich particle per unit time, which explains its higher phase transformation rate. Figure 3b shows that the wider surface reaction region on the defect-rich particle is a direct result of the enhanced [100] diffusivity enabled by defects. It can be seen that the Li diffusion flux in the defect-lean particle is confined near phase boundary. However, significant Li diffusion flux along [100] exists within the entire defect-rich particle, which transports Li atoms inserted at surface locations distant from the phase boundary to the boundary to participate in phase transformation. This results in a larger surface reaction area. Therefore, a key insight we obtained is that an increased Li diffusivity along the phase boundary migration direction ([100] here) benefits the SRL phase transformation kinetics in LiFePO4 by expanding the surface reaction region. This differs from the effect of faster Li diffusion on improving phase transformation kinetics in the BDL regime, in which a higher diffusivity enhances phase boundary velocity in the same direction. It represents a new mechanism of accelerating phase transitions through the interplay between Li diffusion and surface reaction, which has not been explored so far.

a Li intercalation flux js on (010) particle surface when phase boundary is at the particle center. b Li bulk diffusion flux distribution inside a region within 50 nm from the phase boundary. Arrow length is proportional to the magnitude of flux. To make the flux distribution in the defect-lean particle more visible, its scaling factor is set five times larger than in defect-rich particle.

To further shed light on the effect of Li diffusion on SRL kinetics, especially the quantitative dependence of phase boundary velocity on [100] and [010] Li diffusivity, a series of particle discharge simulations under constant Δϕ = 35 mV were carried out. Instead of obeying the relation given by Supplementary Fig. 1, the values of D[010] and D[100] are independently varied in simulations in order to study their respective effects on the phase transition kinetics. The [010] thickness of the particle is L[010] = 50 nm, and its [100] dimension L[100] is assumed to be much larger than the surface reaction region so that the phase boundary velocity VPB is independent of L[100]. As shown in Fig. 4, varying D[010] from 10−9 to 10−12 cm2 s−1 at a given D[100] has little effect on the calculated phase boundary velocity VPB and the surface reaction zone width W, which is defined as the width of the region where js is larger than 35% of its peak value. This confirms that phase transition is indeed in the SRL mode and hence insensitive to D[010]. We note that D[010] in defect-containing LiFePO4 is predicted to increase beyond the bulk diffusivity value at very small [010] particle thickness when antisites can no longer block the 1D migration channels.10 The results above suggest that this particle size dependence of D[010] does not have a large impact on the predicted acceleration of phase transition by antisites in the SRL regime. On the other hand, increasing D[100] from 10−14 to 10−11 cm2 s−1 while keeping D[010] constant causes both W and VPB to increase by more than 20 times.

Depth-averaged model

We found that the 2D simulation results can be well approximated by a 1D depth-averaged model similar to the SCB theory, which is derived by assuming that Li concentration c is uniform along [010] and a function of [100]-coordinate x only. With the simplification, the governing equation of the phase-field model becomes

where the surface reaction flux js on one (010) facet is given by the Butler-Volmer equation (Methods). Equation 1 has the form of a reaction-diffusion equation. It reduces to the SCB model when the diffusion term disappears from Eq. 1 at D[100] = 0. Phase boundary velocity VPB and surface reaction zone width W predicted by this model are shown as solid lines in Fig. 4. The excellent agreement with the full simulations allows one to use the depth-averaged model to efficiently analyze the SRL kinetics in the presence of [100] Li diffusion.

Scaling relation

The simulation results in Fig. 4 show that both VPB and W hold the same parabolic relation with D[100], i.e. \(V_{{\mathrm{PB}}} \propto D_{[100]}^{1/2}\) and \(W \propto D_{[100]}^{1/2}\), when D[100] > ~ 10−14 cm2 s−1. Furthermore, VPB is proportional to W over the entire range of D[100]. When D[100] → 0, W approaches the intrinsic diffuse interface width in the phase-field model, and VPB reaches the prediction of the SCB model. It shows that a defect-free LFP particle has a very low SRL phase boundary velocity (<10−3 nm s−1) because of a very narrow surface reaction zone (~2 nm). As a result, good rate performance can only be achieved when the FP → LFP first-order phase transition is bypassed. However, when an adequate amount of antisite defects are present in the particle, the surface reaction area can increase by orders of magnitude and results in a similar increase in the phase boundary velocity to enable much better rate capability in the absence of metastable solid solution.

A more transparent understanding of the scaling relation can be obtained from an approximate analytical solution to the depth-averaged model, which is based on the sharp-interface assumption (see derivation in Methods). The solution gives the following expressions of surface reaction zone width W and phase boundary velocity VPB:

where the expressions of λ1 and λ2, which are functions of Δϕ, are given in Methods, and i0 is the exchange current density. As shown in Fig. 4, Eqs. 2 and 3 show excellent agreement with the numerical solution when W is significantly larger than the diffuse-interface width of the phase boundary. In addition to explaining the parabolic dependence of W and VPB on D[100], Eq. 3 shows that VPB varies with i0 and [010] particle thickness L[010] as i01/2 and \(L_{[010]}^{ - 1/2}\), respectively. Notably, these relations qualitatively differ from defect-free LFP particles with 1D Li diffusivity, in which VPB has a stronger dependence on i0 and L[010], i.e. \(V_{{\mathrm{PB}}} \propto i_0^{}\) and \(V_{{\mathrm{PB}}} \propto L_{[010]}^{ - 1}\), according to the SCB theory. Such difference in the scaling behavior lies in that upon decreasing i0 or increasing L[010], the surface reaction area W increases in defect-containing particles (Eq. 2), which contributes to a less pronounced reduction of VPB.

Particle size dependence of phase transformation time

The phase boundary speed predicted by Eq. 3 applies to the situation where the [100] particle size is larger than the surface reaction zone width W. When L[100] < W, the entire (010) particle surface is active for Li intercalation during discharge. An interesting prediction thus arises: VPB should increase approximately linearly with L[100] in the SRL regime, i.e. the longer the travel distance of the phase boundary, the faster it moves. Accordingly, the particle transformation time, given by tf ≈ L[100]/VPB, should be insensitive to L[100]. This prediction is confirmed by calculations shown in Fig. 5, which plots the average VPB and tf as a function of L[100] for Li intercalation into a defect-rich (25% antisites) particle at Δϕ = 35 mV. It can be seen that VPB is proportional to L[100] and tf increases very slowly with L[100] up to ~1 μm, which makes tf only dependent on [010] particle size as \(t_{\mathrm{f}} \propto \sqrt {L_{[010]}}\). In contrast, tf is proportional to L[100]L[010] in defect-free particles. Along with Eq. 3, this comparison shows that the inclusion of antisite defects results in qualitatively different particle size dependence of the SRL phase transition kinetics. The weaker dependence of tf on both L[100] and L[010] in defect-containing particles implies another benefit of antisite defects, i.e. they enable the rate performance of LiFePO4 to degrade less severely with particle dimensions. This facilitates the use of larger particles in applications, which can improve the packing density and reduce side reactions between particles and electrolyte in electrodes.

Galvanostatic cycling behavior

Besides constant underpotential condition, we also studied the difference between defect-rich and defect-lean particles under galvanostatic discharge or constant current conditions. Figure 6a compares the distributions of Li intercalation flux js on the (010) surface of particles with different defect contents when galvanostatically discharged to 50% state of charge at 0.005 C (nC = fully discharged in 1/n hours). While the total amount of Li intercalated into the particles per unit time is the same, the peak value of js decreases sharply with D[100] because faster [100] diffusion causes the reaction flux to be more evenly distributed on (010) surface. A 123-fold reduction in the peak flux occurs when D[100] increases from 0 cm2 s−1 (0% antisites) to 2.6 × 10−12 cm2 s−1 (25% antisites). Meanwhile, increasing D[100] also significantly decreases the underpotential required from 30 mV to 0.3 mV as shown in Fig. 6b. Therefore, antisite defects are beneficial under galvanostatic cycling conditions by reducing polarization and mitigating degradation caused by current hotspots and electrochemical shock.28,29,30

Optimization of defect concentration and particle morphology

After demonstrating the benefits of antisite defects on phase transformation kinetics in the SRL regime, we ask the question whether there exists an optimal defect concentration and how it depends on the LiFePO4 particle geometry. We still consider the platelike particle morphology here for its practical relevance. The SRL transformation rate is maximized when the entire plate surface is active for Li intercalation during (dis)charge, which requires L[100] < W. Using Eq. 2, this leads a criterion on [100] Li diffusivity

On the other hand, Li bulk diffusion along the [010] plate thickness direction should be sufficiently facile so that it does not limit the transformation kinetics. This condition can be described by the inequality \(L_{[010]}^2/D_{[010]} < W/V_{{\mathrm{PB}}}\), where \(L_{[010]}^2/D_{[010]}\) is the characteristic Li diffusion time along the [010] axis and W/VPB is the time a [010] channel stays active for Li intercalation. Applying Eqs. 2 and 3, we derive a criterion on [010] Li diffusivity

Equations 4 and 5 provide the guidance on tuning the defect concentration for given particle sizes, or conversely, the particle geometry for a given defect content.

Because increasing antisite defect concentration has opposite effects on D[100] and D[010], Eqs. 4 and 5 may not always be satisfied simultaneously and an optimal defect level may exist. We numerically examine the defect concentration dependence of SRL transformation rate in 2D phase-field simulations, in which a (010)-oriented LiFePO4 particle of L[100] × L[010] = 400 nm × 50 nm is discharged at Δϕ = 35 mV. Figure 7 shows that the lithium intercalation time keeps decreasing with antisite concentration up to 25%, which implies an optimal defect level at higher defect levels that nonetheless may be practically unfeasible to realize. However, we find that comparable performance may be attained at much lower defect concentrations by changing the particle shape from (010)-oriented to (100)-oriented plates. For such particle morphology, the main reaction surface is the (100) facet, which is observed to be active for Li intercalation in defect-containing LFP particles in recent in situ TXM experiments.9,31 Because SRL phase boundary movement is parallel to the [010] fast Li diffusion direction in (100)-oriented plates, the phase boundary velocity could be significantly improved over (010)-oriented plates at the same defect concentration. This is confirmed by simulations shown in Fig. 7. For a (100)-oriented particle with L[100] × L[010] = 50 nm × 400 nm, the minimum intercalation time is reached at 5% defect concentration. We note that this result is obtained assuming that the exchange current density i0 for Li intercalation is the same for (100) and (010) surfaces, which is taken to be 0.01 A m−2 based on estimate from ref. 32 While direct measurement of i0 on the (100) facet is not available in literature, experimental observations of Li intercalation on non-(010) surfaces in LiFePO49,31 implies that it is comparable to that of (010) surface. For example, the hybrid-mode phase boundary migration speed on (100)/(001) surfaces in a LiFePO4 microrod sample is fitted with i0 = 0.1 A m−2 in ref. 9. Therefore, without introducing excessive amount of defects, (100)-oriented plates could potentially provide better performance in the SRL regime than (010)-oriented plates, which are usually assumed to be the desired particle shape for fast (dis)charging. Interestingly, a recent study indeed finds (100)-oriented LFP nanoplates to exhibit excellent rate capability33 even better than (010)-oriented nanoparticles,34 which may be related to the defect-based mechanism discussed here.

As a commercial cathode material for Li-ion batteries, LiFePO4 is known for its exceptional rate capability. Recent experiments26,35,36 and modeling studies18,37,38 establish the formation of metastable solid solution in LiFePO4 during fast (dis)charge, and it is widely believed that bypassing the sluggish first-order phase transition is responsible for considerably accelerating the Li intercalation kinetics. Here we demonstrate a different, defect-based acceleration mechanism without the suppression of the FP → LFP phase transformation. Compared to the former, such mechanism could be effective at low overpotentials where the metastable solid solution does not form. This could be attractive for battery operation where the magnitude of applied overpotential is limited. For example, the development of thick-electrode battery cells has gained significant interest recently as a way to improve energy density.39,40,41 However, thick electrodes are often plagued by severe reaction non-uniformity as a wide range of overpotentials typically exists across the electrodes due to electrolyte polarization.41 The inability of LFP particles to form solid solution in the low overpotential region is likely to exacerbate the nonuniform reaction and cause capacity underutilization. Using defect-containing LFP particles in thick electrodes could alleviate this issue. The enhancing effect of defects on SRL phase transformation rate also offers a promising way to improve the performance of electrode materials that do not exhibit metastable solid solution behavior and/or have very sluggish surface reaction kinetics.

In a recent work,42 Li et al. reveal that fast Li surface diffusion on LiFePO4 surface facilitated by adsorbed fluids promotes Li redistribution within the (010) plane inside the particles and significantly enhances the intra-particle phase separation kinetics. There, Li surface diffusion plays a similar role of antisite defects in increasing the effective Li diffusivity along non-[010] directions. A reaction-diffusion equation similar to Eq. 1 is employed in ref. 42 to analyze the stability of LixFePO4 solid solution in the presence of Li surface diffusion. Although Li et al. focuses on the effect of fast surface diffusion on phase separation kinetics, it is also expected to increase the surface reaction area and accelerate SRL phase transformation in the two-phase coexistence regime, where phase separation is fully developed. This phenomenon can be analyzed within the same theoretical framework of this work by considering the contribution of surface diffusion to D[100] in Eq. 1. Li diffusivity on (010) LiFePO4 surface in contact with electrolyte is conservatively estimated to be ~10−12 cm2 s−1, which leads to an effective in-plane diffusivity of ~ 10−14 cm2 s−1 in 150nm-thick, (010)-oriented LiFePO4 plates.42 Compared to D[100] ≈ 10−12 cm2 s−1 in defect-rich particles, this represents a relatively small contribution to [100] Li transport although its importance will certainly increase with decreasing particle size, which warrants further study. Conversely, like Li surface diffusion antisite defects can also promote phase separation at high underpotentials where a metastable solid solution can form (Δϕ > 45 mV in our model). In a phase-field modeling study,43 Dargaville and Farrell show that increasing [100] Li diffusivity induces phase separation in LiFePO4 under high discharge currents, which otherwise favor the solid-solution intercalation behavior. Antisite defects may have a beneficial effect on SRL intercalation kinetics even in this regime. For instance, Supplementary Fig. 4a compares the lithiation rate of defect-rich (25% antisites) vs defect-lean (0.5% antisites) particles under Δϕ = 50 mV. It shows that the former is fully lithiated at ~8000 s, when the latter only reaches ~60% lithiation. The reason for such difference lies in that defect-enhanced [100] Li diffusion causes phase separation to initiate in LixFePO4 metastable solid solution at an earlier time of ~5700 s (see Supplementary Fig. 4b), after which the Li chemical potential at the particle surface is reduced to the LFP/FP two-phase equilibrium level. As shown in Supplementary Fig. 4b, this in turn increases the surface reaction overpotential in the Butler–Volmer kinetics to generate a larger Li intercalation flux. A detailed analysis of the interplay between antisites, phase separation and Li intercalation kinetics will be presented elsewhere.

Finally, we discuss potential experimental strategy to examine the predicted beneficial effects of antisite defects in LiFePO4. We suggest that our predictions could be tested experimentally by annealing hydrothermally synthesized LiFePO4 platelike particles at different temperatures to vary the defect level. In general, increasing the annealing temperature reduces the amount of defects in electrode materials.2,44,45,46 For instance, this approach has been demonstrated by Chen and Graetz,44 who report that the FeLi antisite concentration in LiFePO4 prepared by a hydrothermal method decreases from 8 to 0% when the post-synthesis annealing temperature is increased from 440 °C to 500 °C. In ref. 2, Kim et al. synthesized Li2MnP2O7 with ~0%, 20% and 30% Li/Mn antisites by calcinating samples at 700 °C, 650 °C and 600 °C, respectively, which are tested to confirm the effect of antisite defects on promoting Li diffusion in this material.

Discussion

In summary, we reveal that the inclusion of antisite defects in LiFePO4 particles could result in orders-of-magnitude improvement in SRL phase transformation kinetics by increasing the active surface area for Li intercalation. Such phenomenon originates from the experimentally confirmed effect of antisite defects on reducing the Li diffusion anisotropy and is expected to be applicable to other phase-changing intercalation compounds with anisostropic ion transport properties. We numerically and analytically study the interplay between Li diffusion and surface reaction in the SRL regime. The results show that antisite defects qualitatively change the scaling dependence of the phase transformation rate on Li diffusivity, exchange current density and particle size. Upon potentiostatic discharge, the Li intercalation rate deteriorates more slowly with increasing particle dimensions in defect-rich particles, which facilitates the use of larger electrode particles without severely compromising rate performance. Antisites also induce a more uniform distribution of the reaction flux on particle surface under galvanostatic discharge conditions, which reduces the risk of electrode degradation due to electrochemical shock. We show that the optimal defect concentration that maximizes Li intercalation rate is dependent on particle geometry, and (100)-oriented platelike LiFePO4 potentially offers better rate performance than (010)-oriented plates during SRL (dis)charge process. Our work highlights the promise and opportunities of improving battery electrode compounds through intentional defect manipulation guided by a mechanistic understanding.

Methods

Antisite concentration dependence of Li diffusivity

We follow the approach described in ref. 10 to determine the Li diffusivity as a function of antisite concentration in LiFePO4 based on Li migration barriers calculated from the DFT calculations.7,10 In short, a 1D random walk model is set up to simulate the hopping of a Li ion between two FeLi antisites within a [010] channel, which are separated by a distance d that depends on the antisite concentration p as d = (1 + p−1)lb/2 where lb is the lattice constant of LFP along [010]. The Li ion makes fast random jumps within the channel with an activation barrier of 270 meV taken from ref. 7 Whenever Li hops to a site next to an FeLi, it may cross over to the nearest migration channel to circumvent the obstruction of the antisite with an activation energy of 491 meV as calculated by Malik et al. 10 The frequencies of the two types of jumps are given by Γ = v exp(−Ea/kT), where ν = 1012 s−1 is the attempted frequency and Ea is the activation energy. With Γ as input, 500 kinetic Monte Carlo simulations are run to estimate the average time < t > it takes for the Li ion to escape the channel blocked by the two antisites. The Li diffusivity is calculated as D = L2/(2 < t > ), in which L = d/2 for D[010], la/2 for D[100] and lc/2 for D[001] (la / lc – [100] / [001] lattice constants of LFP). We verified our calculation by reproducing the Li diffusivity values at 440 K and D[010] at 300 K reported in ref. 10 and then used the method to determine D[100], D[010] and D[001] at different defect concentrations at 300 K, which is shown in Supplementary Fig. 1.

Phase-field model

We use a previously reported phase-field model9,25 to simulate phase transformation in LiFePO4 upon Li intercalation, which is briefly described here. The site occupancy fraction of Li in LicFePO4, c(r), serves as the field variable to distinguish between LFP (c = 1) and FP (c = 0) phases in the model. Li diffusion and the LFP ↔ FP phase transformation are described by the Cahn–Hilliard equation for c(r)47,48

where the Li chemical potential μLi is given by

In Eqs. 6 and 7, D is the diffusion coefficient tensor, Vm = 43.8 cm3 mol−1 is the molar volume of LiFePO4.49 R is the gas constant and \(\mu _{{\mathrm{Li}}}^{{\mathrm{eq}}}\) is the equilibrium Li chemical potential at LFP/FP two-phase coexistence. A regular solution model is used to describe the homogeneous chemical free energy density fchem of LicFePO4 with Ω = 12 kJ mol−1.25 The gradient coefficient κ is given a value of 1.68 × 10−12 J cm−1, which produces a phase boundary energy of 0.072 J m−2 that averages the (100), (010) and (001) interface energies obtained from first-principles calculations.50

As the boundary condition, the Li intercalation flux at particle surface is described by the Butler–Volmer equation:

where \(\eta = \mu _{{\mathrm{Li}}}^{{\mathrm{el}}} - \mu _{{\mathrm{Li}}}\) is the surface reaction overpotential with \(\mu _{{\mathrm{Li}}}^{{\mathrm{el}}}\) and \(\mu _{{\mathrm{Li}}}^{}\) being Li chemical potentials in the surrounding electrolyte and at particle surface, respectively. The underpotential Δϕ is related to \(\mu _{{\mathrm{Li}}}^{{\mathrm{el}}}\) as \(\Delta \phi = F(\mu _{{\mathrm{Li}}}^{{\mathrm{el}}} - \mu _{{\mathrm{Li}}}^{{\mathrm{eq}}})/V_{\mathrm{m}}\). We set i0 = 0.01 A m−2 (ref. 32) and α = 0.5 in Eq. 8. Supplementary Table 1 in SI summarizes the parameters used in the model and the sources of their values.

1D depth-averaged model

The model is derived in a similar way as in ref. 13 Integrating Eq. 6 along the [010] axis, one has

where \(\bar c\left( {x,t} \right) = \mathop {\int }\nolimits_0^{L_{[010]}} c(x,y,t)dy/L_{[010]}\) is the average Li concentration in the [010] direction. With the assumption of facile Li transport along [010] so that c(r) is uniform along [010], i.e. \(c(x,y,t) = \bar c(x,t)\), Eq. 7 becomes

Accordingly, the 2D Cahn–Hilliard equation (Eq. 6) is reduced to the depth-averaged equation (Eq. 1), in which the overbar on c is dropped.

Analytical solution to the depth-averaged model

An analytical expression of the traveling wave solution to the depth-averaged model can be derived with a few approximations. Applying the ansatz \(c(x,t) = c(x - V_{{\mathrm{PB}}}t)\) to Eq. 1, one obtains

The term on the left-hand side can be omitted from Eq. 11 when phase boundary migration is not very fast. In the sharp interface limit, the gradient term \(\kappa d^2c/dx^2\) is removed from \(\mu _{{\mathrm{Li}}}\) in Eq. 10. This approximation is valid when the surface reaction zone width is much larger than the intrinsic thickness of the diffuse phase boundary. Equation 1 is thus simplified to

Letting x = 0 be the phase boundary location, Eq. 12 is completed by the following boundary conditions

where \(c_{{\mathrm{LFP}}}^{{\mathrm{eq}}}\) and \(c_{{\mathrm{FP}}}^{{\mathrm{eq}}}\) are LFP and FP compositions at two-phase equilibrium, and \(c_{{\mathrm{LFP}}}(\Delta \phi )\) and \(c_{{\mathrm{FP}}}(\Delta \phi )\) are the metastable LFP and FP compositions at underpotential \(\Delta \phi\), respectively. By solving Eq. 12 through integration and applying Eq. 13, we obtain an implicit form of the traveling wave solution in the LFP (x < 0) and FP (x > 0) domains:

Function I is defined as \(I(c_1,c_2) \equiv {\int\nolimits_{c_1}^{c_2}} \hat j_s(c^\prime ,\Delta \phi )dc^\prime\) and \(\hat j_{\mathrm{s}} = j_{\mathrm{s}}/(i_0/F)\) is the dimensionless reaction flux. Inverting Eq. 14, the solution is explicitly expressed as

Supplementary Fig. 5 shows that the Li concentration profile predicted by Eq. 15 agrees very well the numerical solution.

As mentioned above, the surface reaction zone is defined as the region in which \(\hat j_{\mathrm{s}}(c) > \alpha \hat j_{\mathrm{s}}^{{\mathrm{max}}}\), where \(\hat j_{\mathrm{s}}^{\max } = \hat j_{\mathrm{s}}(c(x = 0))\) is the peak reaction flux and α is given a somewhat arbitrary value of 0.35. Using Eq. 15, the surface reaction zone width W is given by

Calculating the phase boundary velocity VPB from mass conservation, i.e.

\(V_{{\mathrm{PB}}} = 2{\int \nolimits_{ - \infty }^{ + \infty }} j_{\mathrm{s}}(c(x))dx/(\Delta cL_{[010]})\), where \(\Delta c = c_{{\mathrm{LFP}}}(\Delta \phi ) - c_{{\mathrm{FP}}}(\Delta \phi )\), one obtains

Figure 4 shows that W and VPB predicted by Eqs. 16 and 17 have very good agreement with the numerical solutions except at very small D[100], where W is comparable to the diffuse phase boundary width and the sharp-interface assumption is not valid.

Data availability

The data that support the findings of this study are available from the corresponding author upon request.

References

Lee, J. et al. Unlocking the potential of cation-disordered oxides for rechargeable lithium batteries. Science 343, 519 (2014).

Kim, J., Lee, B., Kim, H., Kim, H. & Kang, K. Redesign of Li2MP2O7 (M = Fe or Mn) by tuning the Li diffusion in rechargeable battery electrodes. Chem. Mater. 28, 6894 (2016).

Hu, J. et al. Tuning Li-ion diffusion in α-LiMn1-xFexPO4 nanocrystals by antisite defects and embedded β-phase for advanced Li-ion batteries. Nano Lett. 17, 4934 (2017).

Heenen, H. H., Scheurer, C. & Reuter, K. Implications of occupational disorder on ion mobility in Li4Ti5O12 battery materials. Nano Lett. 17, 3884 (2017).

Xiong, H. et al. Self-improving anode for lithium-ion batteries based on amorphous to cubic phase transition in TiO2 nanotubes. J. Phys. Chem. C. 116, 3181 (2012).

Xiong, H. et al. Compositional tuning of structural stability of lithiated cubic titania via a vacancy-filling mechanism under high pressure. Phys. Rev. Lett. 110, 078304 (2013).

Morgan, D., Van der Ven, A. & Ceder, G. Li conductivity in LixMPO4 (M = Mn, Fe, Co, Ni) olivine materials. Electrochem. Solid-State Lett. 7, A30 (2004).

Amin, R., Maier, J., Balaya, P., Chen, D. P. & Lin, C. T. Ionic and electronic transport in single crystalline LiFePO4 grown by optical floating zone technique. Solid State Ion. 179, 1683 (2008).

Hong, L. et al. 2D Li diffusion behavior and probable hybrid phase transformation kinetics in olivine lithium iron phosphate. Nat. Commun. 8, 1194 (2017).

Malik, R., Burch, D., Bazant, M. & Ceder, G. Particle size dependence of the ionic diffusivity. Nano Lett. 10, 4123 (2010).

Wong, L. L., Chen, H. M. & Adams, S. Sodium-ion diffusion mechanisms in the low cost high voltage cathode material Na2+δFe2-δ/2(SO4)3. Phys. Chem. Chem. Phys. 17, 9186 (2015).

Kim, J. C., Seo, D. H., Chen, H. L. & Ceder, G. The effect of antisite disorder and particle size on Li intercalation kinetics in monoclinic LiMnBO3. Adv. Energy Mater. 5, 1401916 (2015).

Singh, G. K., Ceder, G. & Bazant, M. Z. Intercalation dynamics in rechargeable battery materials: general theory and phase-transformation waves in LiFePO4. Electrochim. Acta 53, 7599 (2008).

Chen, L.-Q. Phase-field models for microstructure evolution. Annu. Rev. Mater. Res. 32, 113 (2002).

Boettinger, W. J., Warren, J. A., Beckermann, C. & Karma, A. Phase-field simulation of solidification. Annu. Rev. Mater. Res. 32, 163 (2002).

Moelans, N., Blanpain, B. & Wollants, P. An introduction to phase-field modeling of microstructure evolution. Calphad 32, 268–294 (2008).

Tang, M. et al. Model for the particle size, overpotential, and strain dependence of phase transition pathways in storage electrodes: application to nanoscale olivines. Chem. Mater. 21, 1557 (2009).

Cogswell, D. A. & Bazant, M. Z. Coherency strain and the kinetics of phase separation in LiFePO4 nanoparticles. ACS Nano 6, 2215 (2012).

Heo, T. W., Chen, L. Q. & Wood, B. C. Phase-field modeling of diffusional phase behaviors of solid surfaces: a case study of phase-separating LiXFePO4 electrode particles. Comput. Mater. Sci. 108, 323 (2015).

Zhang, W. et al. Localized concentration reversal of lithium during intercalation into nanoparticles. Sci. Adv. 4, eaao2608 (2018).

Heo, T. W., Tang, M., Chen, L. Q. & Wood, B. C. Defects, entropy, and the stabilization of alternative phase boundary orientations in battery electrode particles. Adv. Energy Mater. 6, 1501759 (2016).

Chen, G., Song, X. & Richardson, T. J. Electron microscopy study of the LiFePO4 to FePO4 phase transition. Electrochem. Solid-State Lett. 9, A295 (2006).

Li, Y. et al. Current-induced transition from particle-by-particle to concurrent intercalation in phase-separating battery electrodes. Nat. Mater. 13, 1149 (2014).

Laffont, L. et al. Study of the LiFePO4/FePO4 two-phase system by high-resolution electron energy loss spectroscopy. Chem. Mater. 18, 5520 (2006).

Tang, M., Belak, J. F. & Dorr, M. R. Anisotropic phase boundary morphology in nanoscale olivine electrode particles. J. Phys. Chem. C. 115, 4922 (2011).

Liu, H. et al. Capturing metastable structures during high-rate cycling of LiFePO4 nanoparticle electrodes. Science 344, 1252817 (2014).

Delmas, C., Maccario, M., Croguennec, L., Le Cras, F. & Weill, F. Lithium deintercalation in LiFePO4 nanoparticles via a domino-cascade model. Nat. Mater. 7, 665 (2008).

Christensen, J. & Newman, J. Stress generation and fracture in lithium insertion materials. J. Solid State Electrochem. 10, 293 (2006).

Woodford, W. H., Chiang, Y.-M. & Carter, W. C. “Electrochemical shock” of intercalation electrodes: a fracture mechanics analysis. J. Electrochem. Soc. 157, A1052 (2010).

Woodford, W. H., Carter, W. C. & Chiang, Y.-M. Design criteria for electrochemical shock resistant battery electrodes. Energy Environ. Sci. 5, 8014 (2012).

Wang, J., Karen Chen-Wiegart, Y. C., Eng, C., Shen, Q. & Wang, J. Visualization of anisotropic-isotropic phase transformation dynamics in battery electrode particles. Nat. Commun. 7, 12372 (2016).

Lim, J. et al. Origin and hysteresis of lithium compositional spatiodynamics within battery primary particles. Science 353, 566 (2016).

Li, Z. et al. [100]-Oriented LiFePO4 nanoflakes toward high rate li-ion battery cathode. Nano Lett. 16, 795 (2016).

Li, Z. et al. Orientation-dependent lithium miscibility gap in LiFePO4. Chem. Mater. 30, 874 (2018).

Zhang, X. et al. Rate-induced solubility and suppression of the first-order phase transition in olivine LiFePO4. Nano Lett. 14, 2279 (2014).

Hess, M., Sasaki, T., Villevieille, C. & Novak, P. Combined operando X-ray diffraction-electrochemical impedance spectroscopy detecting solid solution reactions of LiFePO4 in batteries. Nat. Commun. 6, 8169 (2015).

Malik, R., Zhou, F. & Ceder, G. Kinetics of non-equilibrium lithium incorporation in LiFePO4. Nat. Mater. 10, 587 (2011).

Bai, P., Cogswell, D. A. & Bazant, M. Z. Suppression of phase separation in LiFePO4 nanoparticles during battery discharge. Nano Lett. 11, 4890 (2011).

Bae, C. J., Erdonmez, C. K., Halloran, J. W. & Chiang, Y. M. Design of battery electrodes with dual-scale porosity to minimize tortuosity and maximize performance. Adv. Mater. 25, 1254 (2013).

Sander, J. S., Erb, R. M., Li, L., Gurijala, A. & Chiang, Y. M. High-performance battery electrodes via magnetic templating. Nat. Energy 1, 16099 (2016).

Gallagher, K. G. et al. Optimizing areal capacities through understanding the limitations of lithium-ion electrodes. J. Electrochem. Soc. 163, A138 (2016).

Li, Y. Y. et al. Fluid-enhanced surface diffusion controls intraparticle phase transformations. Nat. Mater. 17, 915 (2018).

Dargaville, S. & Farrell, T. W. The persistence of phase-separation in LiFePO4 with two-dimensional Li+ transport: the Cahn-Hilliard-reaction equation and the role of defects. Electrochim. Acta 108, 876 (2013).

Chen, J. J. & Graetz, J. Study of antisite defects in hydrothermally prepared LiFePO4 by in situ X-ray diffraction. ACS Appl. Mater. Inter. 3, 1380 (2011).

Zou, Y. H. et al. Suppressing Fe-Li Antisite defects in LiFePO4/carbon hybrid microtube to enhance the lithium ion storage. Adv. Energy Mater. 6, 1601549 (2016).

Chung, S.-Y., Choi, S.-Y., Yamamoto, T. & Ikuhara, Y. Atomic-scale visualization of antisite defects in LiFePO4. Phys. Rev. Lett. 100, 125502 (2008).

Cahn, J. W. & Hilliard, J. E. Free energy of a nonuniform system .1 Interfacial free energy. J. Chem. Phys. 28, 258 (1958).

Cahn, J. W. On spinodal decomposition. Acta Metall. 9, 795 (1961).

Meethong, N., Huang, H. Y. S., Speakman, S. A., Carter, W. C. & Chiang, Y. M. Strain accommodation during phase transformations in olivine-based cathodes as a materials selection criterion for high-power rechargeable batteries. Adv. Funct. Mater. 17, 1115 (2007).

Abdellahi, A., Akyildiz, O., Malik, R., Thornton, K. & Ceder, G. Particle-size and morphology dependence of the preferred interface orientation in LiFePO4 nano-particles. J. Mater. Chem. A. 2, 15437 (2014).

Acknowledgements

K.Y. and M.T. are supported by DOE under project number DE-SC0019111. L.H. was supported by DOE under project number DE-SC0014435. We acknowledge supercomputing allocations provided by the Texas Advanced Computing Center (TACC) at The University of Texas, and the National Energy Research Scientific Computing Center, a DOE Office of Science User Facility supported by the Office of Science of the U.S. Department of Energy under Contract No. DE-AC02-05CH11231.

Author information

Authors and Affiliations

Contributions

M.T. conceived the project. K.Y. and L.H. performed the phase-field simulations. K.Y. and M.T. carried out the theoretical analysis and the kinetic Monte Carlo simulations. M.T., L.H. and K.Y. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hong, L., Yang, K. & Tang, M. A mechanism of defect-enhanced phase transformation kinetics in lithium iron phosphate olivine. npj Comput Mater 5, 118 (2019). https://doi.org/10.1038/s41524-019-0255-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41524-019-0255-3