Abstract

Selective reduction of ketone/aldehydes to alcohols is of great importance in green chemistry and chemical engineering. Highly efficient catalysts are still demanded to work under mild conditions, especially at room temperature. Here we present a synergistic function of single-atom palladium (Pd1) and nanoparticles (PdNPs) on TiO2 for highly efficient ketone/aldehydes hydrogenation to alcohols at room temperature. Compared to simple but inferior Pd1/TiO2 and PdNPs/TiO2 catalysts, more than twice activity enhancement is achieved with the Pd1+NPs/TiO2 catalyst that integrates both Pd1 and Pd NPs on mesoporous TiO2 supports, obtained by a simple but large-scaled spray pyrolysis route. The synergistic function of Pd1 and PdNPs is assigned so that the partial Pd1 dispersion contributes enough sites for the activation of C=O group while PdNPs site boosts the dissociation of H2 molecules to H atoms. This work not only contributes a superior catalyst for ketone/aldehydes hydrogenation, but also deepens the knowledge on their hydrogenation mechanism and guides people to engineer the catalytic behaviors as needed.

Similar content being viewed by others

Introduction

Selective reduction of ketone/aldehydes to alcohols constitutes a great importance in green chemistry and chemical engineering1,2. The conventional noncatalytic method uses stoichiometric reducing agent (e.g., NaBH4) and derives a large amount of inorganic wastes. In this regard, the catalytic hydrogenation is more environmentally friendly and atomically economical because the reductant is abundant H2 and the ideal by-product is just renewable H2O3,4,5,6. As we known, the Pd/C and Raney Ni are the most used commercial catalysts for industry hydrogenation reactions. While, Raney Ni as well as other Pd-free catalysts are not often found in the hydrogenation of ketone/aldehydes because harsh conditions (high temperature and H2 pressure) are demanded to acquire high reaction kinetics7,8. Besides, the selectivity to alcohol presents low level under harsh hydrogenation conditions5,7,8. As for Pd/C catalysts, the active sites are Pd nanoparticles (NPs). Although they can be used under mild conditions, the catalytic efficiency are rather low due to the limited metal dispersion of Pd NPs9,10,11. Typically in the recent work of Zheng’ group, we can find that the commercial Pd/C still exhibit quite low reactivity in the case study of the hydrogenation of benzaldehyde11. Thus, it is still a challenging work to develop efficient catalysts for selective ketone/aldehydes hydrogenation under mild conditions, especially at room temperature.

In terms of ketone/aldehydes hydrogenation, both the activation of C=O group and dissociation of H2 are essential to the reaction kinetics12,13. Just as such, ketone/aldehydes hydrogenation greatly challenges both the conventional nanocatalysts and the recently focused single-atom catalysts. It is well known that the noble metal nanocatalysts (2–5 nm) such as Pd, Pt are active to ketone/aldehydes hydrogenation14,15, but they are suffered from not only the cost and Earth-scarcity but also low atomic efficiency. So, the reported noble metal nanocatalysts did not present satisfactory reactivity. To address the problems of noble metal nanocatalysts, in the recent years, great efforts have been focused on downsizing the supported nanocrystals to single-atom dispersed active sites for acquiring 100% atomic efficiency16,17, which has been greatly successful toward widely reactions such as CO oxidation18, water-gas shift reaction19,20, O2 electrocatalysis21, CO2 electroreduction22, etc. Unfortunately, it does not work for ketone/aldehydes hydrogenation because it damages the activity seriously. In the single-atom sites, the dissociation of H2 has to go heterolytic pathway, whose barrier is much higher than that in the nanosized metal surface with homolytic dissociation, especially the single-atom sites are strongly pre-covered by the substrate23,24. Thus, in the hydrogenation field, it can be understood that the single-atom noble metal catalysts are mostly presented in the selective semi-hydrogenation23,25,26,27, or show routine activity for aldehydes hydrogenation under mild conditions11. Therefore, it is emergency to design a single-atom based active sites that maintains high atomic efficiency but without sacrifice of the capacity for H2 dissociation toward ketone/aldehydes hydrogenation. Hydrogen spillover is a well-known phenomenon in catalysis28,29,30. The spillover H species are high-active to reduce Ti4+ for preparing black TiO231,32, W6+ for color switch for WO333,34, and so on. Similarly, they can migrate to the above-mentioned single-atom sites for hydrogenation to replace in-situ H2 dissociation.

Herein, we present mesoporous TiO2 supported Pd single-atoms/nanoparticles synergistic catalyst (Pd1+NPs/TiO2) based on hydrogen spillover phenomenon and realize a remarkable ketone/aldehydes hydrogenation activity at room temperature. As illustrated in Fig. 1, the Pd1+NPs/TiO2 catalyst integrates both Pd1 and PdNPs sites on mesoporous TiO2 supports, where the abundant Pd1 sites undertake the activation task of C=O group while PdNPs sites boost the dissociation of H2. The H atoms generated at PdNPs sites migrate to the C=O group bounded Pd1 sites to complete hydrogenation. Confirmed by the ketone/aldehydes hydrogenation at room temperature, the Pd1+NPs/TiO2 catalyst possesses more than twice reactivity of both simple Pd1/TiO2 and PdNPs/TiO2 catalysts, and exhibits 3.2 times activity of commercial Pd/C benchmark catalyst. Moreover, the Pd1+NPs/TiO2 synergistic catalyst is general to various ketone/aldehydes substrates with high activity and selectivity.

The Pd1+NPs/TiO2 integrates both single-atom Pd and PdNPs sites on TiO2 surface, in which the single-atom Pd sites undertake the activation task of C=O group while PdNPs sites boost the dissociation of H2. The H atoms migrate to the C=O group bounded single-atom Pd sites to complete hydrogenation. The kelly balls represent Ti atoms, the blue balls represent O atoms, the brown balls represent C atoms, the cyan balls represent the Pd atoms, and the gray balls represent the H atoms.

Results

Characterizations and catalytic activity of Pd1+NPs/TiO2

The Pd1+NPs/TiO2 synergistic catalyst was synthesized by a simple and large-scaled spray-assisted method with some modification35,36. The TiO2 support presents anatase phase and the morphology is mesoporous microsphere with sizes of 0.4–1.0 µm (Supplementary Fig. 1). Based on the N2 sorption isotherm (Supplementary Fig. 2a), the Pd1+NPs/TiO2 catalyst possesses a large surface of 212.8 m2 g−1 and pore volume of 0.36 cm3 g−1 (Supplementary Fig. 2b), which supplies enough surface for the location of Pd with a loading of 4.8 wt%. As shown in high-angle annular darkfield scanning transmission electron microscopy (HAADF-STEM) image (left-up in Fig. 2a, Supplementary Fig. 3a, b), clear Pd nanoparticles (brighter spots) disperse in the mesoporous TiO2 matrix. While, the energy dispersive X-ray spectroscopy (EDX)-mapping (Fig. 2a) of O (red), Ti (blue), and Pd (green) elements presents a uniform dispersion of Pd, suggesting there are atomically dispersed Pd sites. Demonstrated by the aberration-corrected HAADF-STEM (AC-HAADF-STEM) images (Fig. 2b, Supplementary Fig. 3c–e), clear single-atom Pd sites (Pd1, red circle highlighted) are co-loaded nearby the nanosized Pd nanoparticles (PdNPs, magenta square highlighted). In addition, a few Pd rafts (yellow circle) are found in the sample. Furthermore, the Fourier transform X-ray absorption fine structure spectra (FT-EXAFS, Fig. 2c and Supplementary Fig. 4) prove the coexistence of Pd-Pd and Pd-O coordination in Pd1+NPs/TiO2 sample (green line) with reference to Pd foil (black line) and bulk PdO sample (magenta line). Herein, the reference of metallic Pd foil is used to validate the Pd NPs in the sample. The Pd-Pd coordination is the nature of metallic Pd bulk or NPs. We observed an apparent Pd-Pd coordination in Pd1+NPs/TiO2 catalyst, indicating the existence of Pd NPs. Furthermore, the reference of PdO is used to confirm the contributor of Pd-O coordination. For single-atom Pd sites, only Pd-O coordination can be observed and the presence of Pd-O-Pd coordination is impossible. While, there would co-exist Pd-O and Pd-O-Pd coordination in PdO phase. In the EXAFS spectrum of Pd1+NPs/TiO2 catalyst, the Pd-O-Pd coordination disappears compared to PdO reference, suggesting the Pd-O coordination is originated from single-atom Pd sites. As shown in Supplementary Table 1 based on data fitting, the Pd-Pd coordination (2.79 Å) is assigned to the PdNP species, and Pd-O coordination (2.01 Å) is assigned to Pd-O-Ti species11,37, contributed by the Pd1 sites and interfacial Pd between TiO2 and Pd nanoparticles. Thus, the EXAFS study confirms the coexistence of PdNPs and Pd1 sites, which is well consistent with the result of AC-HAADF-STEM study. Above all, the characterizations well meet the model of Pd1+NPs/TiO2 synergistic catalyst shown in Fig. 1.

a, b HAADF-STEM-EDS mapping (a) and AC-HAADF-STEM image (b) of Pd1+NPs/TiO2. c R-spaced Pd K-edge FT-EXAFS spectra of Pd1+NPs/TiO2 (green line) referred to bulk Pd foil (black line) and PdO (magenta line). d 4-methylacetophene (MAP) conversion plots of Pd1+NPs/TiO2 (red circle), commercial Pd/C (black triangle), and TiO2 catalysts (blue square) under 1 atm. H2 pressure at 25 °C. e, f Time-dependent composition (MAP: black square; MPE (4-methylphenylethanol): red circle; MEB (4-methylethylbenzene): blue triangle) during MAP hydrogenation with Pd1+NPs/TiO2 (e) and Pd/C (f) under 0.3 MPa H2 at 40 °C.

The hydrogenation performance of the Pd1+NPs/TiO2 synergistic catalyst was checked by ketone/aldehydes hydrogenation. From a case study of 4-methylacetophenone (MAP) hydrogenation shown in Fig. 2d and Supplementary Table 2, the Pd1+NPs/TiO2 catalyst (red plots) exhibits a remarkable activity at 25 °C under 1 atm. H2 pressure. The substrate gets 100% converted within 1.0 h with a high alcohol selectivity of 99%. As a reference, the activity of pristine mesoporous TiO2 (Supplementary Fig. 5) is negligible (blue plots). To position the Pd1+NPs/TiO2 in terms of ketone/aldehydes hydrogenation performance, commercial Pd/C (5.2 wt%, black plots) benchmark catalyst (Supplementary Fig. 6) was studied. We can see that the reactivity of Pd1+NPs/TiO2 is 3.2 times better. The turnover frequency (TOF, based on the conversion at 15 min normalized by Pd dispersion)38 value reaches 4362 h−1, one order of magnitude higher than the reported results14,15,39,40. The 4-methylphenylethanol (MPE) and 4-methylethylbenzene (MEB) are the detected product from MAP hydrogenation. To show the superior selectivity of Pd1+NPs/TiO2, the MAP hydrogenation reactions were performed at 40 °C under 0.3 MPa H2. As for Pd1+NPs/TiO2 (Fig. 2e), the MAP conversion reaches 100% within 20 min and the alcohol (MPE) selectivity keeps a high level of 98%, which is much better than Pd/C benchmark (Fig. 2f) with 84% of MPE selectivity. The production of MEB mainly appears after complete formation of alcohol. While for Pd/C, the MEB formation appears synchronously with the production of alcohol. Therefore, the proposed Pd1+NPs/TiO2 synergistic catalyst achieves great success in active and selective hydrogenation of ketone/aldehydes to alcohol under mild conditions.

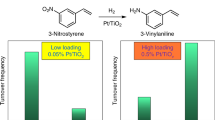

Confirming the synergistic function of Pt1 and PtNPs

To verify the role of the Pd1 and PdNPs in the hydrogenation behaviors, we designed additional two model catalysts: atomically Pd1/TiO2 (Fig. 3a) and nanosized PdNPs/TiO2 (Fig. 3b). With reference to Pd1+NPs/TiO2 (Fig. 3c), Pd1/TiO2 has no Pd nanoparticles and PdNPs/TiO2 has no single-atom Pd. The sample of Pd1/TiO2 (Supplementary Fig. 7) was prepared by same method to Pd1+NPs/TiO2 except lowing the Pd loading to 1.0 wt%. The PdNPs/TiO2 (Supplementary Fig. 8) was obtained by pre-reducing Pd(NO3)2 to Pd NPs with H2 before spray-pyrolysis. The Pd states were studied by the spectra of X-ray absorption near-edge structure (XANES, Fig. 3d). With references of Pd foil (black line) and bulk PdO (orange line), the intensity of while line indicates the Pd1/TiO2 is the most positive-charged, and subsequently Pd1+NPs/TiO2 (magenta line) and PdNPs/TiO2 (blue line), reflecting the relative content of metallic Pd and Pd-O-Ti species41. The EXAFS study (Supplementary Fig. 9) and fitting (Supplementary Fig. 10 and Supplementary Table 1) further clear the coordination of Pd. As shown in R-spaced FT-EXAFS spectra (Fig. 3e) with reference to Pd foil (black line) and bulk PdO (orange line), PdNPs/TiO2 (blue line) possesses much more metallic Pd-Pd coordination (2.83 Å) than that in Pd1+NPs/TiO2 (magenta line), agreeing with the full nanosized dispersion of Pd. The weak Pd-O coordination (2.00 Å) is contributed by the interfacial Pd-O-Ti. Moreover, the Pd in Pd1/TiO2 (green line) nearly presents total Pd-O coordination (2.01 Å) without neither Pd-Pd nor Pd-O-Pd coordination, confirming that Pd1+NPs/TiO2 indeed possesses atomic dispersion of Pd which is bonded to the surface oxygen of TiO2 support42,43.

a–c Illustration of Pd1/TiO2 (a), PdNPs/TiO2 (b), and Pd1+NPs/TiO2 (c) catalysts, where Pd single atom and Pd nanoparticle are represented by solid magenta circle and blue pentagon. d, e Pd foil (black line) and bulk PdO (orange line) referenced XANES (d) and R-spaced FT-EXAFS (e) spectra of Pd1/TiO2 (green line), PdNPs/TiO2 (blue line) and Pd1+NPs/TiO2 (magenta line). f MAP hydrogenation reaction plots of Pd1/TiO2 (green circle), PdNPs/TiO2 (blue square), and Pd1+NPs/TiO2 (magenta triangle) at 25 °C under 1 atm. H2.

The three model catalysts with Pd1 and PdNPs gradient serve as the platform to study the response of Pd1 and Pd-Pd sites to hydrogenation activities. To make the comparison meaningful, the ratio of Pd to the substrate (0.2 mol%) was controlled equally, and the reactions were performed under same conditions (25 °C, 1 atm. H2). Typically, 5 mg and 21 mg of Pd1+NPs/TiO2 and Pd1/TiO2 were used for one pot reaction with 1 mmol of MAP substrate, respectively. As shown in Fig. 3f, the absence of the Pd1 site of PdNPs/TiO2 (blue line) causes 67% drop of reactivity compared to Pd1+NPs/TiO2 (magenta line), revealing that atomically dispersed Pd1 site is crucial to get high performance of ketone/aldehydes hydrogenation. Furthermore, the Pd1/TiO2 (green line) with few Pd NPs presents 51% drop of reactivity, suggesting that Pd NPs is essential to ketone/aldehydes hydrogenation as well. By the way, the zero kinetics of Pd1/TiO2 is well consistent to the observation of Zheng’s group11. In addition, to exclude the Pd1 aggregation induced the low activity of Pd1/TiO2, the used Pd1/TiO2 catalysts were further studied by AC-HAADF-STEM images (Supplementary Fig. 11). Compared with fresh Pd1/TiO2 SAC sample (Supplementary Fig. 7), only a few Pd single-atoms aggregate to rafts or clusters (~1 nm) while no Pd nanoparticle appear in the used sample, indicating that the stability of Pd single atoms are acceptable to discuss their activity under our hydrogenation conditions. Therefore, the above results strongly and clearly point to a synergistic function of the Pd1 and PdNPs in Pd1+NPs/TiO2 catalysts toward ketone/aldehydes hydrogenation.

To further clear the role of Pd1 site and Pd NPs, their TOF values based on active Pd sites were evaluated. As shown in Supplementary Table 2, the dispersions of Pd1+NPs/TiO2 and PdNPs/TiO2 catalysts were measured as 17.7% and 6.2%, respectively. As for the Pd1/TiO2, we find the CO pulse chemisorption is inapplicable to determine the dispersion of Pd because the weak binding of CO on single-atom dispersed metal leads to large desorption of CO44,45. We estimated the Pd dispersion as 67% for 1% Pd1/TiO2 by leaching the surface Pd with a mixture of H2O2 and HCl solution, which is well consistent with the result in Pratsinis et al.’ work46. As summarized in Supplementary Table 2, the Pd1/TiO2 exhibited a lowest activity with TOF value of 645 h−1. Moreover, we found that the TOF value of PdNPs/TiO2 (4565 h−1) were highly close to that of Pd1+NPs/TiO2 (4361 h−1) catalyst, which means the high activity of ketone/aldehydes hydrogenation on Pd NPs. However, limited by the nature of low dispersion of NPs, PdNPs/TiO2 presents low-level reactivity. On the other side, although single-atom catalysts possess much higher metal efficiency, the reactivity of PdNPs/TiO2 also presents low-scale due to the low activity of Pd1 sites. The synergistic function of large numbered Pd1 sites and partial PdNPs additive brings a remarkable performance for ketone/aldehydes hydrogenation.

Understanding the synergistic function of Pt1 and PtNPs

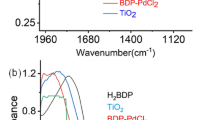

To understand the synergistic function of the Pd1 and PdNPs in Pd1+NPs/TiO2 catalysts, we studied the key steps of C=O adsorption and H2 dissociation by the density functional theory (DFT) calculation based on two models of Pd1/TiO2 (110) and metallic Pd (111) surfaces. According to the X-ray diffraction of Pd1+NPs/TiO2 catalysts (Supplementary Fig. 1c), the anatase TiO2 and face-centered cubic Pd was chosen to build the model for TiO2 (110) and Pd (111) surfaces, respectively. Herein, the van der Waals (vdW) interactions with Grimme method (B97-D) for DFT-D correction were considered for all the calculations47. To produce a more precise calculation than GGA, the GGA + U approach was performed to deal with all the TiO2-relative calculations, in which an intra-atomic electron–electron interaction was introduced as an on-site correction to describe systems with localized d and f states48. According to Li et al.’s work49, a U value of 7 eV for Ti atoms was considered. For C=O adsorption, two adsorption modes, η1 (O) (Fig. 4a) and η2 (C, O) (Fig. 4b) are possible14. The DFT results show η1 (O) mode is chosen on both Pd1/TiO2 (Fig. 4c) and Pd NPs (Fig. 4d). We can find the C=O adsorption energy (Ead) on Pd1/TiO2 (−0.92 eV) is much higher on metallic Pd surface (−0.34 eV), suggesting more efficiency of CO adsorption on Pd1 site. Besides, we studied the adsorption of MAP molecule on Pd1+NPs/TiO2 surface by ATR-FTIR (attenuated total internal reflectance Fourier transform infrared spectroscopy). As shown in Fig. 4e, with reference to pure MAP molecule (orange curve), the presence of the stretch and bend vibration of C=O group centered at 1679 and 1265 cm−1 indicates η1 (O) mode is preferentially formed because the C=O adsorption would be canceled if η2 (C, O) configuration presents50. In addition, a blue-shift of 3 cm−1 for C=O bend vibration reveals the strong adsorption, where a rigid structure of C=O-Pd causes enhanced energy for C=O bend vibration. For meaningful comparison, the C=O adsorption on Pd1/TiO2 (green curve), PdNPs/TiO2 (blue curve) and TiO2 (black curve) were also studied. The MAP adsorption on Pd1/TiO2 and PdNPs/TiO2 is similar to Pd1+NPs/TiO2, where we can also observe the C=O bend vibrational shift. However, the MAP adsorption TiO2 were too weak to be detected by our facility.

a, b Illustration of η1 (O) (a) and η2 (C, O) (b) configuration of C=O adsorption. c, d Models of C=O adsorbed on Pd1/TiO2 (110) (c) and Pd (111) (d) surface. e ATR-FTIR spectra of MAP substrate (orange line) and MAP adsorbed on TiO2 (black line), Pd1/TiO2 (green line), Pd1+NPs/TiO2 (magenta line), and PdNPs/TiO2 (blue line) catalysts. f–i Adsorption models of H2 molecule (f, h) and H atoms (g, i) on substrate covered Pd1/TiO2 (110) (f, g) and Pd (111) (h, i) surfaces. j Relative energy plots of H2 dissociation on Pd1/TiO2 (110) (magenta line) and Pd (111) (black line) surfaces. k Digital photographs of Pd1+NPs/TiO2 and Pd1/TiO2 powder before and after 5% H2/Ar flow for 2 min at room temperature.

The DFT study of the other essential step of H2 dissociation is shown in Fig. 4f–j. The H2 dissociation is an uphill process, and the activation energies (Ea) are calculated for the models of C=O group bonded Pd1/TiO2 (110) (Fig. 4f) and metallic Pd (111) (Fig. 4h) surface. It is interesting that H2 dissociation on Pd1/TiO2 goes heterolytic pathway (Fig. 4g) while it presents homolytic dissociation (Fig. 4i) on metallic Pd (111) surface. The heterolytic pathway on single-atom sites has been found by Zheng’s group11, but we further find that the barrier of H2 dissociation (Fig. 4j) gets much increased on Pd1/TiO2 (1.27 eV) compared to metallic Pd surface (0.78 eV). This suggests that H2 dissociation is difficult at Pd1 site and primarily goes on Pd NPs. Moreover, the difference of their interaction with H2 is visible. Figure 4k shows the digital photographs (k) of Pd1+NPs/TiO2 and Pd1/TiO2 powder before and after 5% H2/Ar flow for two minutes at room temperature. Vividly, the single-atom Pd is hardly to be reduced at room temperature, just because of the high dissociation barriers of H2 molecule to H atoms. While, the Pd1+NPs/TiO2 presents active interaction with H2 owning to the presence of Pd nanoparticles.

According to DFT results, H2 will dissociate preferentially on metallic Pd nanoparticles and ketone/aldehydes molecules can be adsorbed at Pd1 sites. In addition to the TOF values of Pd1/TiO2, PdNPs/TiO2, and Pd1+NPs/TiO2 catalysts, the H2 dissociation is more important than C=O group activation because the TOF values of PdNPs/TiO2 and Pd1+NPs/TiO2 are approximately equal although their C=O adsorption energies are quite different. To clear the synergy function of Pd1 atoms and NPs more clearly, we clarified it with a tandem working mechanism of Pd1 atoms and NPs. As shown in Fig. 1, the H2 molecules are dissociated into H atoms on Pd NPs with fast kinetics. The spillover of H atoms from Pd NPs migrates to the ketone/aldehydes-adsorbed Pd1 sites. The hydrogenation was finally completed at Pd1 sites. Herein, both Pd NPs and Pd1 atoms are key to high hydrogenation performance. In terms of the PdNPs/TiO2 with high activity, the nature of low dispersion caused a low hydrogenation exhibition. While, although atomically Pd1/TiO2 catalyst possessed the highest dispersion, the high H2 dissociate barrier induced low activity still made it present a low-level hydrogenation performance. The tandem working mechanism dissolved the disadvantages of both single-atom Pd1 site (low activity) and Pd NPs (low dispersion) synergistically. As observed above, the Pd1+NPs/TiO2 synergistic catalyst present more than twice reactivity of simple Pd1/TiO2 and PdNPs/TiO2 catalysts. According to Crook et al.’s work51,52 and the working mechanism of Pd1 atoms and NPs, the size of Pd NPs and ratio of Pd NPs/Pd1 sites would affect the hydrogenation performance of Pd1+NPs/TiO2 catalyst.

The universality and stability of Pd1+NPs/TiO2 catalysts

The high activity is also confirmed by the hydrogenation of other ketone/aldehydes (Table 1 and Supplementary Figs. 12–20). Acetophenone was observed to give the corresponding α-phenethyl alcohol in quantitative yield like MAP (Table 1, entries 1 and 2). The 3-methylacetophene was reduced to the corresponding alcohol in 99.7% yield (Table 1, entry 3). 1-phenyl-1-propanone could also be reduced to 1-phenyl-1-propanol in 99.5% yield (Table 1, entry 4). Benzaldehyde could also be reduced at mild condition with almost completer conversion (Table 1, entries 5 and 6), and even an unusual TOF value of 16,288 h−1 is acquired for benzaldehyde. Furfuryl alcohol is an important fine chemical, which is widely used in synthetic fibers, rubber and pesticides industries53. Using Pd1+NPs/TiO2 synergistic catalyst, furfural could be reduced into furfuryl alcohol in 98.2% conversion and more than 74% selectivity under 1 atm. H2 pressure at 25 °C (Table 1, entry 7). Cinnamyl alcohol was obtained in high conversion but moderate selectivity (Table 1, entry 8). The unique adsorption and activation mode of the catalyst for carbonyl and hydrogen, resulted in the universality of Pd1+NPs/TiO2 synergistic catalyst for ketone/aldehydes hydrogenation at room temperature and atmospheric pressure.

The stability of Pd1+NPs/TiO2 catalysts were evaluated by measuring the conversion at 0.5 h at each cycle of reusing. At each cycle, pure substrate was added into the reaction cell after completing the last reaction. As shown in Supplementary Fig. 21, the reactivity drops gradually with the increase of cycle. At fifth cycle, 45% of the reactivity was lost in comparison with the first cycle. However, we should caution that the reactivity of catalysts was also affected by the accumulated product induced chemical equilibrium because the product was also not separated out during the five cycles. To further evaluate the limit of Pd1+NPs/TiO2 catalysts, the substrate concentration was increased to 5 mmol without changing any other conditions, so the ratio of Pd to substrate was correspondingly decreased to 0.04 mol%. As shown in Supplementary Fig. 22, the reactivity of Pd1+NPs/TiO2 still kept high level although five times of substrate were added. The alcohol selectivity also reached more than 98%. However, resulted from the insufficient H2 diffusion in solvent, the TOF value (4084 h−1) presented slightly drop in comparison with that with 1 mmol substrate (4362 h−1). Above all, the Pd1+NPs/TiO2 catalyst exhibit acceptable stability to act as a reusable catalyst for ketone/aldehydes hydrogenation.

After the synergistic function of Pd1 sites and Pd NPs, we found that the TiO2 support played another key role in the ketone/aldehydes hydrogenation. As shown in Supplementary Fig. 23, the activity was negligible when Pd was supported on Al2O3, NiO, Fe2O3, Mn3O4, etc. Whatever the dispersion of Pd, it is an interesting result in comparison with anyone of Pd1/TiO2, PdNPs/TiO2, and Pd1+NPs/TiO2 catalysts. The systematically study on the fundamental knowledge of support-dependent activity would be presented in the future work.

In summary, this work proposes and confirms a highly efficient Pd1+NPs/TiO2 synergistic catalyst for selective ketone/aldehydes hydrogenation at room temperature and ambient H2 pressure. The high activity is contributed by the synergistic function of Pd1 and PdNPs on TiO2 that the abundant Pd1 sites undertake the activation task of C=O group while PdNPs sites boost the dissociation of H2. This work not only paves the way to green production of alcohols from selective ketone/aldehydes hydrogenation with Pd1+NPs/TiO2 catalyst, but also enlighten people in the fundamental knowledge of ketone/aldehydes hydrogenation on variously dispersed Pd/TiO2 catalysts.

Methods

Materials preparation

For Pd1+NPs/TiO2 catalyst, 1.0 mL concentrated hydrochloric acid (HCl, 35–37%), 0.5 g F127 (Sigma-Aldrich), 6.60 mL of Pd(NO3)2 (30 mM, Aladdin), and 1.36 g (4 mmol) tetrabutyl titanate (TBOT, Aladdin) are added into 34 mL deionized water in order. A mixture solution was obtained with ultrasonic assistance. The mixture was then sprayed into a tube furnace (600 °C). The powders were collected by a filter paper collector by a pump, and finally calcined at 400 °C for 2 h in air with heating rate of 2 °C/min. The final catalysts were obtained after washing the calcined powders with deionized water and absolute ethanol.

The preparation of Pd1/TiO2 catalyst is same to that of Pd1+NPs/TiO2 catalyst except the amount of Pd(NO3)2 (30 mM) is changed to 1.32 mL.

The preparation of PdNPs/TiO2 catalyst is same to that of Pd1+NPs/TiO2 with some modification. In detail, 1.0 mL hydrochloric acid (35–37%), 0.5 g F127, 6.60 mL of Pd(NO3)2 (30 mM), and 1.36 g TBOT are added into 34 mL deionized water in order. The Pd(NO3)2 in the mixture was pre-reduced to Pd nanoparticles by continuous flow of H2 (99.999%) for 5 min at room temperature. The follow processes are same to that of Pd1+NPs/TiO2.

The preparation of mesoporous TiO2 catalyst is the same as Pd1+NPs/TiO2 catalysts without addition of Pd(NO3)2 solution.

The final Pd loadings in the catalysts were determined by the inductively coupled plasma-atomic emission spectrometry (ICP-AES, Supplementary Fig. 24).

All the reagents were used as received without further purification. The resistivity of used water was more than 18.25 MΩ·cm.

Materials characterizations

All the catalysts were activated before characterizations and catalysis tests. The activation was performed at room temperature by 5% H2/Ar mixture for 3–5 min. During the activation, the color of the powder changes from light-yellow to dark-brown.

The materials are characterized with by SEM (Hitachi, S-4800, Japan) with 5 kV accelerate voltage and TEM (Technai G20 S-TWIN, FEI) with 200 kV accelerate voltage, high-angle annular darkfield scanning transmission electron microscopy (HAADF-STEM, JEOL2100), X-ray powder diffraction (XRD, D8, Brook) with Cu Kα radiation (λ = 0.15418 nm) operated at 40 kV and 40 mA, and HAADF-STEM EDS-mapping. The aberration-corrected high-angle annular darkfield scanning transmission electron microscopy (AC-HAADF–STEM) images were performed on JEM-ARM200F (JEOL) with accelerating voltage of 200 kV. The N2 sorption isotherms (77 K) with TriStar II 3020 V1.03 (Micromeritics, USA) was performed to analyze the Brunauer–Emmett–Teller (BET) specific surface area and Barrett–Joyner–Halenda (BJH) pore size distributions.

Pd dispersion measurement

The dispersion of Pd was determined by CO pulse chemisorption. Firstly, catalysts were pre-treated in He flow at 200 °C for 1 h. Subsequently, the catalysts were further reduced at 50 °C with 10% H2/Ar for 1 h. The cell was cleaned with He flow to remove H2/Ar. Finally, the CO pulse adsorption was performed at 50 °C and stopped the pulse until the no CO adsorption appeared on the samples. The accumulate CO adsorption was used for the calculation of dispersion. The Pd loading for calculating the dispersion was measured by ICP-AES with the samples prepared in the same batch to Pd dispersion measurement.

To estimate the Pd dispersion in 1% Pd/TiO2 by leaching the surface Pd, 16.5 mg of catalyst powder was dispersed into 5 mL of mixture solution containing 6% H2O2 and 7% HCl. The solution was treated at 60 °C for 2 h and constantly volumed to 100 mL. The solution was separated by a filter to remove the catalyst solid. The leached Pd was subsequently measured by ICP-AES. The Pd dispersion was defined as (leached Pd in solution)/(total Pd in catalyst).

The number of active sites were calculated based on the amount of Pd usage for one pot hydrogenation reaction (0.002 mmol) and Pd dispersion.

Catalytic hydrogenation tests

1 mmol substrate (AR, Aladdin) was dissolved in 5 mL ethanol (99.8%) in 25 mL glassy cell, and 5 mg 4.8 wt% Pd1+NPs/TiO2 was dispersed by ultrasonic assistance. The gas in the cell was replaced by high-purity H2 (99.999%) five times under a pressure of 0.3 MPa. For the hydrogenation reaction, an ambient H2 pressure is performed with a flow of about 10 mL/min controlled by a mass flowmeter (MFC). The reaction temperature was controlled by a cycling water. The magnetic stirring speed was 1000 rpm to reduce the diffusion effect. The conversion and selectivity were qualitatively determined by a gas chromatography (GC) equipped with a hydrogen flame ionization detector (FID). The well linear relationship between FID responded peak area and analyte concentration was shown in Supplementary Fig. 25.

The amount of metal Pd is kept the same to that in 5 mg of 4.8 wt% Pd1+NPs/TiO2 for the evaluation of other Pd-based catalysts. The ratio of Pd to substrate was controlled as 0.2 mol%.

The stability of Pd1+NPs/TiO2 catalysts were evaluated by measuring the conversion at 0.5 h for five cycles. At each cycle, 1 mmol of pure substrate was added into the reaction cell after completing the last reaction.

ATR-FTIR study

Typically, 0.1 g of catalyst powders were immersed in 10 mL of 0.2 mol/L 4-methylacetophenone (solvent: ethanol) for 12 h to acquire the adsorption equilibrium. The catalyst was separated by centrifugation, washed with absolute ethanol, and dried at 60 °C in vacuum box for 6 h. The powders were pressed to form a platelet. The attenuated total internal reflectance Fourier transform infrared spectroscopy (ATR-FTIR) were collected on a Thermo Scientific™ Nicolet iS5 FTIR Spectrometer with a resolution of 0.5 cm−1 at room temperature.

X-ray absorption spectra collection and data processing

The extended X-ray absorption fine structure (EXAFS) measurements at the Palladium K-edge were measured in transmission mode at the beamline BL14W1 station of SSFR (Shanghai Synchrotron Radiation Facility), P. R. China. All samples were pelletized as disks of 13 mm diameter with 1 mm thickness using graphite powder as a binder.

The acquired EXAFS data were processed according to the standard procedures using the ATHENA module implemented in the IFEFFIT software packages54. The EXAFS spectra were obtained by subtracting the post-edge background from the overall absorption and then normalizing with respect to the edge jump step. Subsequently, the χ(k) data were Fourier transformed to real (R) space using a hanning windows (dk = 1.0 Å−1) to separate the EXAFS contributions from different coordination shells. The quantitative information can be obtained by the least-squares curve fitting in the R space with a Fourier transform k space range of 2.4–13.2 Å−1, using the module ARTEMIS of programs of IFEFFIT. The backscattering amplitude F(k) and phase shift Φ(k) were calculated using FEFF8.0 code.

Method and model for DFT calculation

The first principles calculations in the framework of density functional theory, including structural, electronic performances, were carried out based on the Cambridge Sequential Total Energy Package known as CASTEP55. The exchange–correlation functional under the generalized gradient approximation (GGA)56 with norm-conserving pseudopotentials and Perdew–Burke–Ernzerhof (PBE) functional was adopted to describe the electron–electron interaction57. The van der Waals (vdW) interactions with Grimme method (B97-D) for DFT-D correction were considered for all the calculations47. To produce a more precise calculation than GGA, the GGA + U approach was performed to deal with all the TiO2-relative calculations, in which an intra-atomic electron–electron interaction was introduced as an on-site correction to describe systems with localized d and f states48. According to Li et al.’s work49, a U value of 7 eV for Ti atoms was considered. An energy cutoff of 750 eV was used and a k-point sampling set of 5 × 5 × 1 were tested to be converged. A force tolerance of 0.01 eV Å−1, energy tolerance of 5.0 × 10−7 eV per atom and maximum displacement of 5.0 × 10−4 Å were considered. The vacuum space along the z direction is set to be 15 Å, which is enough to avoid interaction between the two neighboring images. The bottom three atomic layers were fixed, and the top three atomic layers were relaxed. According to the XRD pattern (Supplementary Fig. 1c), anatase TiO2 crystal was chosen to cleave the stable TiO2(110) surface and face-centered cubic (FCC) Pd crystal was used to cleave Pd(111) surface. The model of (3 × 2) supercell slab (Ti36O72) including six atomic layers was adopted for anatase TiO2(110) surface. The termination of TiO2(110) surface contains the 4-fold coordinated Ti (Ti4c) and 2-fold coordinated O (O2c). The model of (4 × 4) supercell slab (Pd96) including six atomic layers was adopted for FCC Pd(110) surface. Then, the C8H8O and H2 had been absorbed on the surface of Pd(111) and Pd1/TiO2(110). Besides, the complete LST/QST search protocol and the SCF tolerance of 5.0 × 10−7 eV per atom are set for transition states.

Adsorption energy ΔE of A group on the surface of substrates was defined as

where *A and * denote the adsorption of A group on substrates and the bare substrates, EA denotes the energy of A group. The obtained adsorption energies were listed in Supplementary Table 3.

Data availability

The additional data are provided in the Supplementary Information. All the data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Meemken, F. & Baiker, A. Recent progress in heterogeneous asymmetric hydrogenation of C=O and C=C bonds on supported noble metal catalysts. Chem. Rev. 117, 11522–11569 (2017).

Shah, M. T. et al. Selective heterogeneous catalytic hydrogenation of ketone (C=O) to alcohol (OH) by magnetite nanoparticles following Langmuir–Hinshelwood kinetic approach. ACS Appl. Mater. Interfaces 7, 6480–6489 (2015).

Nakagawa, Y., Takada, K., Tamura, M. & Tomishige, K. Total hydrogenation of furfural and 5-hydroxymethylfurfural over supported Pd–Ir alloy catalyst. ACS Catal. 4, 2718–2726 (2014).

Ide, M. S., Hao, B., Neurock, M. & Davis, R. J. Mechanistic insights on the hydrogenation of α, β-unsaturated ketones and aldehydes to unsaturated alcohols over metal catalysts. ACS Catal. 2, 671–683 (2012).

Malyala, R. V. et al. Activity, selectivity and stability of Ni and bimetallic Ni-Pt supported on zeolite Y catalysts for hydrogenation of acetophenone and its substituted derivatives. Appl. Catal. A: Gen. 193, 71–86 (2000).

Bertero, N. M., Apesteguía, C. R. & Marchi, A. J. Catalytic and kinetic study of the liquid-phase hydrogenation of acetophenone over Cu/SiO2 catalyst. Appl. Catal. A: Gen. 349, 100–109 (2008).

Trasarti, A. F., Bertero, N. M., Apesteguía, C. R. & Marchi, A. J. Liquid-phase hydrogenation of acetophenone over silica-supported Ni, Co and Cu catalysts: Influence of metal and solvent. Appl. Catal. A: Gen. 475, 282–291 (2014).

Hočevar, B., Grilc, M., Huš, M. & Likozar, B. Mechanism, ab initio calculations and microkinetics of hydrogenation, hydrodeoxygenation, double bond migration and cis-trans isomerisation during hydrotreatment of C6 secondary alcohol species and ketones. Appl. Catal. B. Environ. 218, 147–162 (2017).

Sajiki, H., Hattori, K. & Hirota, K. Easy and partial hydrogenation of aromatic carbonyls to benzyl alcohols using Pd/C (en)-catalyst. J. Chem. Soc., Perkin Trans. 1, 4043–4044 (1998).

Hiyoshi, N., Sato, O., Yamaguchi, A. & Shirai, M. Acetophenone hydrogenation over a Pd catalyst in the presence of H2O and CO2. Chem. Commun. 47, 11546–11548 (2011).

Liu, P. X. et al. Photochemical route for synthesizing atomically dispersed palladium catalysts. Science 352, 797–800 (2016).

Vargas, A., Bürgi, T. & Baiker, A. Adsorption of activated ketones on platinum and their reactivity to hydrogenation: a DFT study. J. Catal. 222, 439–449 (2004).

King, A. E. et al. Understanding ketone hydrodeoxygenation for the production of fuels and feedstocks from biomass. ACS Catal. 5, 1223–1226 (2015).

Wang, Z. C. et al. Palladium-doped silica-alumina catalysts obtained from double-flame FSP for chemoselective hydrogenation of the model aromatic ketone acetophenone. J. Catal. 302, 10–19 (2013).

Chen, C.-S., Chen, H.-W. & Cheng, W.-H. Study of selective hydrogenation of acetophenone on Pt/SiO2. Appl. Catal. A Gen. 248, 117–128 (2003).

Yang, X. F. et al. Single-atom catalysts: a new frontier in heterogeneous catalysis. Acc. Chem. Res. 46, 1740–1748 (2013).

Liu, J. Y. Catalysis by supported single metal atoms. ACS Catal. 7, 34–59 (2017).

Qiao, B. T. et al. Single-atom catalysis of CO oxidation using Pt1/FeOx. Nat. Chem. 3, 634–641 (2011).

Yang, M. et al. Catalytically active Au-O(OH)x-species stabilized by alkali ions on zeolites and mesoporous oxides. Science 346, 1498–1501 (2014).

Zhai, Y. P. et al. Alkali-stabilized Pt-OHx species catalyze low-temperature water-gas shift reactions. Science 329, 1633–1636 (2010).

Zhao, Y. Y. et al. W. Stable iridium dinuclear heterogeneous catalysts supported on metal-oxide substrate for solar water oxidation. Proc. Natl Acad. Sci. USA 115, 2902–2907 (2018).

Zhao, C. M. et al. Ionic exchange of metal–organic frameworks to access single nickel sites for efficient electroreduction of CO2. J. Am. Chem. Soc. 139, 8078–8081 (2017).

Yan, H. et al. Understanding the underlying mechanism of improved selectivity in Pd1 single-atom catalyzed hydrogenation reaction. J. Catal. 366, 70–79 (2018).

Lucci, F. R. et al. Controlling hydrogen activation, spillover, and desorption with Pd-Au single-atom alloys. J. Phys. Chem. Lett. 7, 480–485 (2016).

Wang, A. Q., Li, J. & Zhang, T. Heterogeneous single-atom catalysis. Nat. Rev. Chem. 2, 65–81 (2018).

Wei, S. J. et al. Direct observation of noble metal nanoparticles transforming to thermally stable single atoms. Nat. Nanotechnol. 13, 856–861 (2018).

Feng, Q. C. et al. Isolated single-atom Pd sites in intermetallic nanostructures: high catalytic selectivity for semihydrogenation of alkynes. J. Am. Chem. Soc. 139, 7294–7301 (2017).

Prins, R. Hydrogen spillover. Facts and fiction. Chem. Rev. 112, 2714–2738 (2012).

Tierney, H. L., Baber, A. E., Kitchin, J. R. & Sykes, E. C. H. Hydrogen dissociation and spillover on individual isolated palladium atoms. Phys. Rev. Lett. 103, 246102 (2009).

Esposito, D. V., Levin, I., Moffat, T. P. & Talin, A. A. H2 evolution at Si-based metal-insulator-semiconductor photoelectrodes enhanced by inversion channel charge collection and H spillover. Nat. Mater. 12, 562–568 (2013).

Zhu, Y. M., Liu, D. S. & Meng, M. H2 spillover enhanced hydrogenation capability of TiO2 used for photocatalytic splitting of water: a traditional phenomenon for new applications. Chem. Commun. 50, 6049–6051 (2014).

Chen, X. B., Liu, L. & Huang, F. Q. Black titanium dioxide (TiO2) nanomaterials. Chem. Soc. Rev. 44, 1861–1885 (2015).

Dickens, P. G. & Hurditch, R. J. X-ray and neutron diffraction studies of a tetragonal hydrogen bronze HxWO3. Nature 215, 1266–1267 (1967).

Xi, Y. J., Zhang, Q. F. & Cheng, H. S. Mechanism of hydrogen spillover on WO3(001) and formation of HxWO3 (x = 0.125, 0.25, 0.375, and 0.5). J. Phys. Chem. C. 118, 494–501 (2014).

Li, R. G., Yang, Y. X., Sun, N. & Kuai, L. Mesoporous Cu-Ce-Ox solid solution from spray pyrolysis for superior low-temperature CO oxidation. Chem. Eur. J. 25, https://doi.org/10.1002/chem.201903680 (2019).

Kuai, L. et al. Atomically dispersed Pt/metal oxide mesoporous catalysts from synchronous pyrolysis–deposition route for water–gas shift reaction. Chem. Mater. 30, 5534–5538 (2018).

Zhang, X. Y. et al. C-C coupling on single-atom-based heterogeneous catalyst. J. Am. Chem. Soc. 140, 954–962 (2018).

Chen, Y. J. et al. Discovering partially charged single-atom Pt for enhanced anti-markovnikov alkene hydrosilylation. J. Am. Chem. Soc. 140, 7407–7410 (2018).

Zhang, X. B. Preparation of 1-phenylethanol by selective hydrogenation of acetophenone over alumina-supported Co catalysts. React. Kinet. Mech. Cat. 102, 417–424 (2011).

Yao, R. H., Li, J. R., Wu, P. & Li, X. H. The superior performance of a Pt catalyst supported on nanoporous SiC-C composites for liquid-phase selective hydrogenation of cinnamaldehyde. RSC Adv. 6, 81211–81218 (2016).

Wei, H. S. et al. FeOx-supported platinum single-atom and pseudo-single-atom catalysts for chemoselective hydrogenation of functionalized nitroarenes. Nat. Commun. 5, 5634 (2014).

Yan, H. et al. Single-atom Pd1/graphene catalyst achieved by atomic layer deposition: remarkable performance in selective hydrogenation of 1,3-butadiene. J. Am. Chem. Soc. 137, 10484–10487 (2015).

Wang, X. et al. Uncoordinated amine groups of metal-organic frameworks to anchor single Ru sites as chemoselective catalysts toward the hydrogenation of quinoline. J. Am. Chem. Soc. 139, 9419–9422 (2017).

Liu, J. L. et al. Tackling CO poisoning with single-atom alloy catalysts. J. Am. Chem. Soc. 138, 6396–6399 (2016).

DeRita, L. et al. Structural evolution of atomically dispersed Pt catalysts dictates reactivity. Nat. Mater. 18, 746–751 (2019).

Fujiwara, K. & Pratsinis, S. E. Single Pd atoms on TiO2 dominate photocatalytic NOx removal. Appl. Catal. B: Environ. 226, 127–134 (2018).

Grimme, S. Semiempirical GGA‐type density functional constructed with a long‐range dispersion correction. J. Comput. Chem. 27, 1787–1799 (2006).

Anisimov, V. I., Zaanen, J. & Andersen, O. K. Band theory and Mott insulators: Hubbard U instead of Stoner I. Phys. Rev. B: Condens. Matter Mater. Phys. 44, 943 (1991).

Li, C., Zhao, Y. F., Gong, Y. Y., Wang, T. & Sun, C. Q. Band gap engineering of early transition-metal-doped anatase TiO2: first principles calculations. Phys. Chem. Chem. Phys. 16, 21446–21451 (2014).

Chen, M. M., Maeda, N., Baiker, A. & Huang, J. Molecular insight into Pt-catalyzed chemoselective hydrogenation of an aromatic ketone by in situ modulation-excitation IR spectroscopy. ACS Catal. 2, 2007–2013 (2012).

Wilson, O. M., Knecht, M. R., Garcia-Martinez, J. C. & Crooks, R. M. Effect of Pd nanoparticle size on the catalytic hydrogenation of allyl alcohol. J. Am. Chem. Soc. 128, 4510–4511 (2006).

Jiang, F., Cai, J., Liu, B., Xu, Y. B. & Liu, X. H. Particle size effects in the selective hydrogenation of cinnamaldehyde over supported palladium catalysts. RSC Adv. 6, 75541–75551 (2016).

Khromova, S. A. et al. Furfural hydrogenation to furfuryl alcohol over bimetallic Ni-Cu sol-gel catalyst: a model reaction for conversion of oxygenates in pyrolysis liquids. Top. Catal. 59, 1413 (2016).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Rad. 12, 537–541 (2005).

Segall, M. D. et al. First-principles simulation: ideas, illustrations and the CASTEP code. J. Phys. Condens. Matter 14, 2717 (2002).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Hamann, D. R., Schlüter, M. & Chiang, C. Norm-conserving pseudopotentials. Phys. Rev. Lett. 43, 1494 (1979).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (21801003, 21871005, 21471006), the Research Start-up and Outstanding Youth Foundation of Anhui Polytechnic University (2016YQQ019, 2019JQ01), Natural Science Foundation of Anhui Province (1808085QB47), Natural Science Foundation of Anhui Provincial Education Department (KJ2017A111, KJ2017A112). The authors thank the National Synchrotron Radiation Laboratory (Shanghai, P. R. China). Authors thank Mr. Ming Zuo in University of Science and Technology of China (USTC) for the professional support of AC-HAADF-STEM observations and Hangzhou Precision New Materials and Technology Co., Ltd (Hangzhou, China) for the DFT study.

Author information

Authors and Affiliations

Contributions

B.G. and Y.L. conceived this work. L.K., Z.C., and S.L. collected the data. E.K., N.Y., Y.R., C.F., and X.L. analysis the data. L.K. and Z.C. wrote the paper, and all the authors contributed the paper revisions. L.K. and Z.C. contributed equally to this work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kuai, L., Chen, Z., Liu, S. et al. Titania supported synergistic palladium single atoms and nanoparticles for room temperature ketone and aldehydes hydrogenation. Nat Commun 11, 48 (2020). https://doi.org/10.1038/s41467-019-13941-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-019-13941-5

This article is cited by

-

Enhancing alkyne semi-hydrogenation through engineering metal-support interactions of Pd on oxides

Nano Research (2024)

-

Interfacial oxidized Pd species dominate catalytic hydrogenation of polar unsaturated bonds

Nano Research (2024)

-

Selective dissolution to synthesize densely populated Pt single atom catalyst

Nano Research (2023)

-

Revealing the surface atomic arrangement of noble metal alkane dehydrogenation catalysts by a stepwise reduction-oxidation approach

Nano Research (2023)

-

Determining the contribution of Mo single atoms components in MoO2 nanocatalyst in transfer hydrogenation

Nano Research (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.