Abstract

As a versatile intermediate, difluorocarbene is an electron-deficient transient species, meaning that its oxidation would be challenging. Herein we show that the oxidation of difluorocarbene could occur smoothly to generate carbonyl fluoride. The oxidation process is confirmed by successful trifluoromethoxylation, 18O-trifluoromethoxylation, the observation of AgOCF3 species, and DFT calculations.

Similar content being viewed by others

Introduction

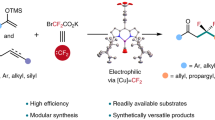

Due to the unique properties of fluorine element such as strong electronegativity and small atomic radius, the incorporation of fluorine atom(s) into organic molecules could usually lead to profound changes of the latter’s physical, chemical, and biological properties1. Therefore, significant efforts have been directed towards the development of efficient methods for introducing fluorine or fluorinated moieties into organic compounds2,3. Difluorocarbene (:CF2) has served as a versatile intermediate and the transformations of difluorocarbene has proved to be quite efficient for fluorine incorporation4,5. Typical difluorocarbene conversions, including insertions into X-H bonds (X=O, N, S, etc.)4,6,7, [2 + 1] cycloadditions with multi-bonds8,9, and coupling with other carbenes10,11,12, can conveniently construct various fluorinated functionalities, such as difluoromethyl, gem-difluorocyclopropyl and gem-difluoroalkenyl groups. However, these typical reactions are limited to the incorporation of a -CF2- moiety. We have previously found that difluorocarbene is so reactive that it can be readily trapped by a suitable sulfur13,14,15, selenium16, or nitrogen source17 to generate thiocarbonyl fluoride (CF2=S), selenocarbonyl fluoride (CF2=Se), and cyanide anion (CN−), respectively (Fig. 1a–c). On the basis of these findings, which offers more possibilities for difluorocarbene chemistry, it is reasonable to conceive that the oxidation of difluorocarbene with a suitable oxygen source may proceed to afford carbonyl fluoride (CF2=O) (Fig. 1d). Usually, oxidation reactions could proceed smoothly to oxidize electron-rich substrates, but not to electron-deficient substrates18,19. Since difluorocarbene is an electron-deficient transient intermediate20, its oxidation would be a challenging task. Furthermore, because CF2=O is a highly reactive gas and thus hard to detect, it cannot be determined simply by spectroscopic monitoring of the reaction whether the oxidation process occurs or not.

The transformations of difluorocarbene. a The transformation of difluorocarbene into thiocarbonyl fluoride. b The transformation of difluorocarbene into selenocarbonyl fluoride. c The transformation of difluorocarbene into cyanide anion. d The transformation of difluorocarbene into carbonyl fluoride.

Herein we describe the oxidation of difluorocarbene by using diphenyl sulfoxide (Ph2S=O) as the oxidant to provide carbonyl fluoride, a process which is confirmed by successful trifluoromethoxylation and 18O-trifluoromethoxylation reactions, the observation of AgOCF3 species, and DFT calculations. A late-stage trifluoromethoxylation for the synthesis of a Trioxsalen derivative is shown to further demonstrate the synthetic utility of this trifluoromethoxylation protocol.

Results

Optimization of the trifluoromethoxylation conditions

Ph3P+CF2CO2−, developed by us recently21, and AgF were used as a difluorocarbene reagent and the fluoride source, respectively, in our efforts to ascertain the oxidation process via the trifluoromethoxylation of benzyl bromide 1-1 (Table 1). AgF was used to convert CF2=O into AgOCF3, which may be experimentally observed22 to support the oxidation process. The oxidants were initially screened, but no desired trifluoromethoxylation product was detected in most cases (Table 1, entries 1–5). To our delight, the use of DMSO (dimethyl sulfoxide) as the oxidant afforded the expected product in 9% yield (Table 1, entry 6), suggesting that sulfoxides may be a suitable class of oxidants. We then examined other sulfoxides (Table 1, entries 7–8) and diphenyl sulfoxide was found to be a superior choice (Table 1, entry 8). Other fluoride sources, including inorganic (Table 1, entries 9–11) and organic (Table 1, entry 12, TBAF=tetra-n-butylammonium fluoride) fluoride salts, were examined, but they were all ineffective. This indicates that the Ag ion may play an important role in the reaction. A brief survey of reaction solvents (Table 1, entries 13–17) showed that THF (tetrahydrofuran) or DCM (dichloromethane) was the suitable solvent for this conversion (Table 1, entries 15 and 16). The use of 2,2′-bipyridine or a crown ether as a ligand (Table 1, entries 18 and 19) significantly increased the product yield. A 67% yield was obtained if both bipyridine and the crown ether were present (Table 1, entry 20). The concentration affected the reaction slightly, and the yield increased with increasing concentration (Table 1, entry 21 vs entry 20). At this concentration, the yield decreased if either the crown ether or 2,2′-bipyridine was not used (Table 1, entries 22−23).

Mechanistic investigations

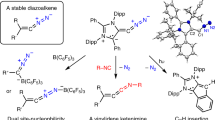

Further experimental evidence was collected to support the difluorocarbene oxidation process. The use of other difluorocarbene reagents such as FSO2CF2CO2TMS23 and TMSCF2Br8 could also give the desired trifluoromethoxylation product, albeit in a low yield, suggesting that difluorocarbene is a key intermediate (Fig. 2a). CF2=O could not be detected in the reaction mixtures, because it is a highly electrophilic species and would be rapidly attacked by AgF to provide AgOCF3. Even stirring the mixture of Ph3P+CF2CO2− and Ph2S=O alone could not lead to the observation of CF2=O, because CF2=O would easily react with the nucleophile, Ph3P generated from Ph3P+CF2CO2−9. Ph2S=O should be the oxygen source to oxidize difluorocarbene to generate CF2=O, since 18O-labeled diphenyl sulfoxide afforded the CF318O product (Fig. 2b), and diphenyl sulfoxide underwent deoxygenation to afford diphenyl sulfide (Ph2S) in a high yield based on Ph2S=O consumed (39% of Ph2S=O was recovered) (Fig. 2c) (Supplementary Methods). A stepwise reaction was performed to confirm the generation of the AgOCF3 complex (Fig. 2d). Without the presence of a substrate, heating a mixture of Ph3P+CF2CO2−/Ph2S=O/AgF with ligands at 60 °C for 0.5 h led to the formation of a number of unkonwn species, as detected by 19F NMR spectroscopy (Supplementary Fig. 2). Two broad signals, appearing at −21.66 and −21.94 ppm in the 19F NMR spectrum, respectively, may correspond to two different ligand-coordinated AgOCF3 complexes22. Subsequent addition of substrate 1–1 afforded the desired trifluoromethoxylation product, further supporting that AgOCF3 was generated from the Ph3P+CF2CO2−/Ph2S=O/AgF system (Fig. 2d). In addition to the trifluoromethoxylation product, a fluorination byproduct was observed (Fig. 2d). However, almost no fluorination byproduct was observed under the optimal conditions (Table 1, entry 21), which suggests that AgOCF3 was too reactive and decomposed easily.

Mechanistic investigation. a The use of other difluorocarbene reagents for trifluoromethoxylation. b The identification of the oxygen source by 18O-labeling. c The identification of the oxygen source by isolating Ph2S. d The confirmation of the AgOCF3 complex. aThe optimal conditions are shown as Table 1, entry 21: substrate 1 (0.2 mmol), Ph3P+CF2CO2− (2.5 equiv), Ph2S=O (2.5 equiv), AgF (2 equiv), 2,2′-bipyridine (1.5 equiv), and 2,3,11,12-dibenzo-18-crown-6 (0.5 equiv) in THF (1.5 mL) at 60 °C for 0.5 h; bYields were determined by 19F NMR spectroscopy. cThe 18O content was determined by EI-MS. dIsolated yield calculated based on substrate 1–1. eIsolated yield based on Ph2S=O consumed.

DFT calculations at the M062X//6–31 + + G(d,p)/LANL2DZ level provided insights into the mechanism of the oxidation of difluorocarbene and the subsequent trifluoromethoxylation. We have previously demonstrated that Ph3P+CF2CO2− is an efficient difluorocarbene precursor, and has proposed that difluorocarbene is generated via a decarboxylation process, i.e., Ph3P+CF2CO2− → Ph3P+CF2− → :CF214,15,24. Calculations revealed that the activation energy for this process is quite low (10.12 kcal mol−1) (Supplementary Fig. 3 and Supplementary Data 1), supporting the mechanistic proposal. As an electron-deficient species, difluorocarbene can be attacked by Ph2S=O to form an O–CF2 bond (Fig. 3, INT-1). The formation of this bond weakens the S–O bond in Ph2S=O, as shown by the increasing S–O bond length from TS-1 to INT-1. Back donation of the carbon lone pair strengthens the O–CF2 bond and further weakens the S–O bond (Fig. 3, TS-2). Complete cleavage of the S–O bond releases Ph2S and carbonyl fluoride (CF2=O), a process which is thermodynamically favored. CF2=O is electrophilic and is therefore trapped by AgF to generate AgOCF3, which can readily convert the substrates to the final products. The Ag ion can activate the substrates by precipitating the AgBr salt. Identification of transition state TS-2 enabled us to calculate the overall activation energy, i.e., 17.60 kcal mol−1; this value is low and in agreement with the rapid process.

The introduction of CF3O installation

The above results revealed that difluorocarbene could indeed be oxidized to give carbonyl fluoride. The oxidation of difluorocarbene and the subsequent trifluoromethoxylation provides an efficient protocol for CF3O incorporation. CF3O incorporation has received increasing attention because the CF3O group is a common structural motif in pharmaceuticals25,26, agrochemicals27,28, and functional materials29,30. A number of effective trifluoromethoxylation methods have been developed, including nucleophilic31,32,33,34,35,36,37, radical38,39,40, and transition-metal-promoted41,42,43,44 reactions. As the use of a CF3O-containing reagent is required, these approaches cannot be directly applied to 18O-labeling trifluoromethoxylation. Furthermore, the CF3O-containing reagents used are usually volatile, expensive, or difficult to prepare. In contrast, in the above protocol, CF3O moiety was formed from a reagent system consisting of Ph3P+CF2CO2−, which could be easily prepared and easy-to-handle, an oxygen source and fluoride anion. Apparently, this reaction provides a strategy for 18O-labeling trifluoromethoxylation, which may be achieved by replacing the oxygen source with 18O-source. 18O-trifluoromethoxylation may show great value as 18O-labeling has found widespread application in various research areas such as proteomics45,46,47 and synthetic chemistry48,49,50.

The substrate scope of trifluoromethoxylation

Since difluorocarbene could be oxidized and the subsequent trifluoromethoxylation proceeded smoothly (Table 1, entry 21), we then investigated the substrate scope of trifluoromethoxylation. Figure 4 shows that electron-deficient, -neutral, and -rich benzyl bromides were all converted to the desired products in moderate to good yields (5–1 ~ 5–17). Various functional groups were tolerated, e.g., halide, ketone, ester, alkene, cyano, nitro, ether, and various heterocycles. Heterocycles usually have interesting physicochemical properties, and therefore the easy access to CF3O-containing heterocycles could be useful in the life sciences (5–15 ~ 5–17). Transformation of secondary benzyl bromides gave moderate yields (5–18 ~ 5–22). The diphenyl substituted product (5–22) was unstable, and a heterolytic cleavage of the C–OCF3 bond readily occurred to form a diphenyl-stabilized methyl cation, hydrolysis of which led to an alcohol by product (Ph2CH-OH) in 35% isolated yield. In addition to benzyl bromides, allyl bromides were also converted under these conditions (5–23 ~ 5–28). The reactivity of alkyl bromide (5–29) was much lower than that of benzyl bromides. Alkyl iodides (5–30 ~ 5–33) underwent the desired reaction smoothly to give the expected products in moderate yields. A method for achieving direct access to a flavone derivative was developed (5–34) and a moderate yield was obtained for a large-scale reaction (5–4), demonstrating the synthetic utility of this trifluoromethoxylation protocol.

Difluorocarbene-oxidation-based trifluoromethoxylation. Isolated yields are shown. Reaction conditions: substrate 1 (0.8 mmol), Ph3P+CF2CO2− (2.5 equiv), Ph2S = O (2.5 equiv), AgF (2 equiv), 2,2′-bipyridine (1.5 equiv), and 2,3,11,12-dibenzo-18-crown-6 (0.5 equiv) in THF (6 mL) at 60 °C for 0.5 h. aThe yields in parentheses were determined by 19F NMR spectroscopy. b0.2 mmol of substrate was used. c8 mmol of substrate was used.

Trioxsalen, a furanocoumarin and a psoralen derivative obtained from plants, can be used for phototherapy treatment of vitiligo and hand eczema51. A convenient route to the CF3O-containing Trioxsalen derivative (8) was developed to further show the synthetic utility of this trifluoromethoxylation strategy. The trifluoromethoxylation of the precursor (7), prepared from the commercially available m-benzenediol by a reported procedure (Supplementary Fig. 1)52,53, occurred smoothly to give the Trioxsalen derivative in a moderate yield (Fig. 5).

18O-Trifluoromethoxylation

18O-Labeling trifluoromethoxylation is challenging, because all reported trifluoromethoxylation methods have to use a CF3O-containing reagent and the corresponding CF318O-reagents are difficult to prepare. Recently, Tang used an 18O-labeled reagent, ArSO2–18OCF3, to explore and elucidate the mechanism of the trifluoromethoxylation reaction; only a 33% 18O content was obtained in the desired product37. They proposed that the low 18O-content was because of the 16O-18O exchange in the SO2–18OCF3 moiety from the reagent. We employed 18O-labeled diphenyl sulfoxide (Ph2S=18O, 18O content: 89%) as the oxygen source in this difluorocarbene-oxidation-based trifluoromethoxylation reaction. Since the reagent, Ph2S=18O, did not contain any 16O atom, no 16O-18O exchange would occur and therefore the expected products were obtained with high 18O contents (Fig. 6).

Difluorocarbene-oxidation-based 18O-trifluoromethoxylation. Isolated yields. Reaction conditions: substrate 1 (0.2 mmol), Ph3P+CF2CO2− (2.5 equiv), Ph2S=18O (2.5 equiv), AgF (2 equiv), 2,2′-bipyridine (1.5 equiv), and 2,3,11,12-dibenzo-18-crown-6 (0.5 equiv) in THF (1.5 mL) at 60 °C for 0.5 h. The 18O contents were determined by EI-MS.

Discussion

In summary, we have shown that difluorocarbene could be oxidized to afford carbonyl fluoride. This process was confirmed by the successful trifluoromethoxylation, 18O-trifluoromethoxylation, the observation of AgOCF3 species, and DFT calculations. It is worth noting that the 18O-products were obtained with high 18O-contents. A CF3O-containing Trioxsalen derivative was synthesized by this trifluoromethoxylation protocol. The oxidation of difluorocarbene may provide more possibilities for difluorocarbene chemistry.

Methods

Typical procedure for trifluoromethoxylation

Into a 20 mL sealed tube were added benzyl bromide 1–1 (0.8 mmol, 197.7 mg, 1.0 equiv), Ph3P+CF2CO2− (2.0 mmol, 712.0 mg, 2.5 equiv), Ph2S=O (2.0 mmol, 404.6 mg, 2.5 equiv), AgF (1.6 mmol, 203.2 mg, 2.0 equiv), 2,2′-bipyridine (1.2 mmol, 187.4 mg, 1.5 equiv), 2,3,11,12-dibenzo-18-crown-6 (0.4 mmol, 144.2 mg, 0.5 equiv), and THF (6 mL) under a N2 atmosphere. The tube was sealed and the reaction mixture was stirred at 60 °C for 30 min. After the mixture was cooled to room temperature, the pure product was isolated by flash column chromatography.

Typical procedure for 18O-trifluoromethoxylation

Into a 10-mL sealed tube were added benzyl bromide 1–1 (0.2 mmol, 49.4 mg, 1.0 equiv.), Ph3P+CF2CO2− (0.5 mmol, 178.0 mg, 2.5 equiv), Ph2S=18O (0.5 mmol, 102.1 mg, 2.5 equiv), AgF (0.4 mmol, 51.0 mg, 2.0 equiv), 2,2′-bipyridine (0.3 mmol, 47.0 mg, 1.5 equiv), 2,3,11,12-dibenzo-18-crown-6 (0.1 mmol, 36.0 mg, 0.5 equiv), and THF (1.5 mL) under a N2 atmosphere. The tube was sealed and the reaction mixture was stirred at 60 oC for 30 min, and the mixture was cooled to room temperature. The pure product was isolated by flash column chromatography, and the 18O contents were determined by GC-MS (EI) spectroscopy.

For the preparation of starting materials and the characterization data of the products, see Supplementary Methods. For the NMR spectra of the compounds, see Supplementary Figs. 5–184. For EI spectra of the 18O-products, see Supplementary Figs. 185–214. For DFT calculations, see Supplementary Figs. 3 and 4 and Supplementary Data 1 and 2.

Data availability

The authors declare that the data supporting the findings of this study are available within the article and its Supplementary Information files or from the corresponding author on reasonable request.

References

Kirsch, P. Modern Fluoroorganic Chemistry: Synthesis, Reactivity, Applications 2nd edn (Wiley-VCH, Weinheim, Germany, 2013).

Alonso, C., Martinez de Marigorta, E., Rubiales, G. & Palacios, F. Carbon trifluoromethylation reactions of hydrocarbon derivatives and heteroarenes. Chem. Rev. 115, 1847–1935 (2015).

Tlili, A., Toulgoat, F. & Billard, T. Synthetic approaches to trifluoromethoxy-substituted compounds. Angew. Chem. Int. Ed. 55, 11726–11735 (2016).

Ni, C. & Hu, J. Recent advances in the synthetic application of difluorocarbene. Synthesis 46, 842–863 (2014).

Dilman, A. D. & Levin, V. V. Difluorocarbene as a building block for consecutive bond-forming reactions. Acc. Chem. Res. 51, 1272–1280 (2018).

Thomoson, C. S. & Dolbier, W. R. Use of fluoroform as a source of difluorocarbene in the synthesis of difluoromethoxy- and difluorothiomethoxyarenes. J. Org. Chem. 78, 8904–8908 (2013).

Xie, Q. et al. Efficient difluoromethylation of alcohols using TMSCF2 Br as a unique and practical difluorocarbene reagent under mild conditions. Angew. Chem. Int. Ed. 56, 3206–3210 (2017).

Li, L., Wang, F., Ni, C. & Hu, J. Synthesis of gem-difluorocyclopropa(e)nes and O-, S-, N-, and P-difluoromethylated compounds with TMSCF2Br. Angew. Chem. Int. Ed. 52, 12390–12394 (2013).

Deng, X.-Y., Lin, J.-H., Zheng, J. & Xiao, J.-C. Difluoromethylation and gem-difluorocyclopropenation with difluorocarbene generated by decarboxylation. Chem. Commun. 51, 8805–8808 (2015).

Hu, M., Ni, C., Li, L., Han, Y. & Hu, J. gem-difluoroolefination of diazo compounds with TMSCF3 or TMSCF2Br: transition-metal-free cross-coupling of two carbene precursors. J. Am. Chem. Soc. 137, 14496–14501 (2015).

Zheng, J. et al. Cross-coupling between difluorocarbene and carbene-derived intermediates generated from diazocompounds for the synthesis of gem-difluoroolefins. Org. Lett. 17, 6150–6153 (2015).

Zhang, Z. et al. Reaction of diazo compounds with difluorocarbene: an efficient approach towards 1,1-difluoroolefins. Angew. Chem. Int. Ed. 55, 273–277 (2016).

Zheng, J., Wang, L., Lin, J.-H., Xiao, J.-C. & Liang, S. H. Difluorocarbene-derived trifluoromethylthiolation and [18F]trifluoromethylthiolation of aliphatic electrophiles. Angew. Chem. Int. Ed. 54, 13236–13240 (2015).

Zheng, J. et al. An unconventional mechanistic insight into SCF3 formation from difluorocarbene: preparation of 18F-labeled alpha-SCF3 carbonyl compounds. Angew. Chem. Int. Ed. 56, 3196–3200 (2017).

Yu, J., Lin, J.-H. & Xiao, J.-C. Reaction of thiocarbonyl fluoride generated from difluorocarbene with amines. Angew. Chem. Int. Ed. 56, 16669–16673 (2017).

Chen, X.-L., Zhou, S.-H., Lin, J.-H., Deng, Q.-H. & Xiao, J.-C. Difluorocarbene-derived trifluoromethylselenolation of benzyl halides. Chem. Commun. 55, 1410–1413 (2019).

Zhang, M., Lin, J.-H. & Xiao, J.-C. Photocatalyzed cyanodifluoromethylation of alkenes. Angew. Chem. Int. Ed. 58, 6079–6083 (2019).

McGarrigle, E. M. & Gilheany, D. G. Chromium− and manganese−salen promoted epoxidation of alkenes. Chem. Rev. 105, 1563–1602 (2005).

Kolundzic, F., Noshi, M. N., Tjandra, M., Movassaghi, M. & Miller, S. J. Chemoselective and enantioselective oxidation of indoles employing aspartyl peptide catalysts. J. Am. Chem. Soc. 133, 9104–9111 (2011).

Uneyama K. Organofluorine Chemistry (Blackwell Publishing Ltd, 2006).

Zheng, J., Cai, J., Lin, J.-H., Guo, Y. & Xiao, J.-C. Synthesis and decarboxylative Wittig reaction of difluoromethylene phosphobetaine. Chem. Commun. 49, 7513–7515 (2013).

Chen, D., Lu, L. & Shen, Q. [Ag(bpy)(PPhtBu2)(OCF3)]: a stable nucleophilic reagent for chemoselective and stereospecific trifluoromethoxylation of secondary alkyl nosylates. Org. Chem. Front. 6, 1801–1806 (2019).

Tian, F. et al. A novel and highly efficient synthesis of gem-difluorocyclopropanes. Org. Lett. 2, 563–564 (2000).

Zheng, J., Lin, J.-H., Cai, J. & Xiao, J.-C. Conversion between difluorocarbene and difluoromethylene ylide. Chem. Eur. J. 19, 15261–15266 (2013).

Stover, C. K. et al. A small-molecule nitroimidazopyran drug candidate for the treatment of tuberculosis. Nature 405, 962–966 (2000).

Landelle, G., Panossian, A. & Leroux, F. Trifluoromethyl ethers and -thioethers as tools for medicinal chemistry and drug discovery. Curr. Top. Med. Chem. 14, 941–951 (2014).

Chen, Y., Zhang, A. F., Wang, W. X., Zhang, Y. & Gao, T. C. Baseline sensitivity and efficacy of thifluzamide in Rhizoctonia solani. Ann. Appl. Biol. 161, 247–254 (2012).

Amir, O. G. & Peveling, R. Effect of triflumuron on brood development and colony survival of free-flying honeybee, Apis mellifera L. J. Appl. Entomol. 128, 242–249 (2004).

Mamada, M. et al. A unique solution-processable n-type semiconductor material design for high-performance organic field-effect transistors. Chem. Mater. 27, 141–147 (2014).

Kirsch, P. & Bremer, M. Nematic liquid crystals for active matrix displays: molecular design and synthesis. Angew. Chem. Int. Ed. 39, 4217–4235 (2000).

Kolomeitsev, A. A., Vorobyev, M. & Gillandt, H. Versatile application of trifluoromethyl triflate. Tetrahedron Lett. 49, 449–454 (2008).

Marrec, O., Billard, T., Vors, J.-P., Pazenok, S. & Langlois, B. R. A deeper insight into direct trifluoromethoxylation with trifluoromethyl triflate. J. Fluor. Chem. 131, 200–207 (2010).

Marrec, O., Billard, T., Vors, J.-P., Pazenok, S. & Langlois, B. R. A new and direct trifluoromethoxylation of aliphatic substrates with 2,4-dinitro(trifluoromethoxy)benzene. Adv. Synth. Catal. 352, 2831–2837 (2010).

Hojczyk, K. N., Feng, P., Zhan, C. & Ngai, M.-Y. Trifluoromethoxylation of arenes: synthesis of ortho-trifluoromethoxylated aniline derivatives by OCF3 migration. Angew. Chem. Int. Ed. 53, 14559–14563 (2014).

Zhang, Q. W. & Hartwig, J. F. Synthesis of heteroaromatic trifluoromethyl ethers with trifluoromethyl triflate as the source of the trifluoromethoxy group. Chem. Commun. 54, 10124–10127 (2018).

Zhou, M., Ni, C., Zeng, Y. & Hu, J. Trifluoromethyl benzoate: a versatile trifluoromethoxylation reagent. J. Am. Chem. Soc. 140, 6801–6805 (2018).

Jiang, X., Deng, Z. & Tang, P. Direct dehydroxytrifluoromethoxylation of alcohols. Angew. Chem. Int. Ed. 57, 292–295 (2018).

Zheng, W., Morales-Rivera, C. A., Lee, J. W., Liu, P. & Ngai, M. Y. Catalytic C-H trifluoromethoxylation of arenes and heteroarenes. Angew. Chem. Int. Ed. 57, 9645–9649 (2018).

Zheng, W., Lee, J. W., Morales-Rivera, C. A., Liu, P. & Ngai, M.-Y. Redox-active reagents for photocatalytic generation of the OCF3 radical and (hetero)aryl C-H trifluoromethoxylation. Angew. Chem. Int. Ed. 57, 13795–13799 (2018).

Jelier, B. J. et al. Radical trifluoromethoxylation of arenes triggered by a visible-light-mediated N-O bond redox fragmentation. Angew. Chem. Int. Ed. 57, 13784–13789 (2018).

Huang, C., Liang, T., Harada, S., Lee, E. & Ritter, T. Silver-mediated trifluoromethoxylation of aryl stannanes and arylboronic acids. J. Am. Chem. Soc. 133, 13308–13310 (2011).

Chen, C., Chen, P. & Liu, G. Palladium-catalyzed intramolecular aminotrifluoromethoxylation of alkenes. J. Am. Chem. Soc. 137, 15648–15651 (2015).

Zha, G. F. et al. Silver-mediated direct trifluoromethoxylation of alpha-diazo esters via the (-)OCF3 anion. Chem. Commun. 52, 7458–7461 (2016).

Guo, S., Cong, F., Guo, R., Wang, L. & Tang, P. Asymmetric silver-catalysed intermolecular bromotrifluoromethoxylation of alkenes with a new trifluoromethoxylation reagent. Nat. Chem. 9, 546–551 (2017).

Reynolds, K. J., Yao, X. & Fenselau, C. Proteolytic 18O labeling for comparative proteomics: evaluation of endoprotease Glu-C as the catalytic agent. J. Proteome Res. 1, 27–33 (2002).

Miyagi, M. & Rao, K. C. S. Proteolytic 18O-labeling strategies for quantitative proteomics. Mass Spectrom. Rev. 26, 121–136 (2007).

Ye, X., Luke, B., Andresson, T. & Blonder, J. 18O stable isotope labeling in MS-based proteomics. Brief Funct. Genomic Protemic 8, 136–144 (2009).

Allen, A. D. et al. Ion pairs in the solvolysis of secondary systems. Salt effect, 18O-labeling, and polarimetric studies of 1-(4’-tolyl)-2,2,2-trifluoroethyl tosylate. J. Am. Chem. Soc. 117, 8974–8981 (1995).

Kudrik, E. V. & Sorokin, A. B. N-bridged diiron phthalocyanine catalyzes oxidation of benzene with H2O2 via benzene oxide with NIH shift evidenced by using 1,3,5-[D3]benzene as a probe. Chemistry 14, 7123–7126 (2008).

Sorokin, A. B., Kudrik, E. V. & Bouchu, D. Bio-inspired oxidation of methane in water catalyzed by N-bridged diiron phthalocyanine complex. Chem. Commun. 2562–2564 https://doi.org/10.1039/B804405H (2008).

Fischer, Alsins Treatment of psoriasis with trioxsalen baths and dysprosium lamps. Acta Derm. Venereol. 56, 383–390 (1976).

Qian, J. & Suo, J. KHSO4 catalysed pechmann condensation under solvent-free conditions. J. Chem. Res. 2005, 486–487 (2005).

Kaufman, K. D. et al. Reactions of furocoumarins. II. Synthetic aminomethyl psoralens via chloromethylation or benzylic bromination. J. Heterocycl. Chem. 19, 1051–1056 (1982).

Acknowledgements

We thank the National Natural Science Foundation (21421002, 21672242, 21971252), Key Research Program of Frontier Sciences (CAS) (QYZDJSSW-SLH049), the Fujian Institute of Innovation, Chinese Academy of Sciences (FJCXY18040102) for financial support. Computing resources were provided by the National Supercomputing Center of China in Shenzhen.

Author information

Authors and Affiliations

Contributions

J.Y. performed the experiments. D.Y. performed the DFT calculations. R.D. analyzed the data. J.-H.L. analyzed the data and wrote the manuscript. J.-C.X. designed the experiments and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks the anonymous reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yu, J., Lin, JH., Yu, D. et al. Oxidation of difluorocarbene and subsequent trifluoromethoxylation. Nat Commun 10, 5362 (2019). https://doi.org/10.1038/s41467-019-13359-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-019-13359-z

This article is cited by

-

Selective C-H trifluoromethoxylation of (hetero)arenes as limiting reagent

Nature Communications (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.