Abstract

Rechargeable zinc–manganese dioxide batteries that use mild aqueous electrolytes are attracting extensive attention due to high energy density and environmental friendliness. Unfortunately, manganese dioxide suffers from substantial phase changes (e.g., from initial α-, β-, or γ-phase to a layered structure and subsequent structural collapse) during cycling, leading to very poor stability at high charge/discharge depth. Herein, cyclability is improved by the design of a polyaniline-intercalated layered manganese dioxide, in which the polymer-strengthened layered structure and nanoscale size of manganese dioxide serves to eliminate phase changes and facilitate charge storage. Accordingly, an unprecedented stability of 200 cycles with at a high capacity of 280 mA h g−1 (i.e., 90% utilization of the theoretical capacity of manganese dioxide) is achieved, as well as a long-term stability of 5000 cycles at a utilization of 40%. The encouraging performance sheds light on the design of advanced cathodes for aqueous zinc-ion batteries.

Similar content being viewed by others

Introduction

In light of pressing concerns regarding environmental pollution and climatic deterioration associated with the combustion of fossil fuels, building a low-carbon society that is based on renewable energy sources has gained widespread attention. However, the utilization of renewable energy sources such as wind and solar requires a safe, green, economic, and efficient electrochemical energy conversion system that can accommodate/smoothen the intermittency of renewable power1,2,3,4. As a result, aqueous Li+ (or Na+) batteries are attracting extensive attention due to safety and environmentally friendliness that arise from the use of mild aqueous electrolytes containing Li+ (or Na+)5,6,7,8,9,10,11,12,13,14,15,16. Unfortunately, electrode materials for Li+ (or Na+) storage in aqueous electrolytes generally suffer from low capacity (<150 mA h g−1)5,6,7,8,9,10,11,12,13,14,15,16, which should be remedied with large-scale energy storage. In such situations, the electrode materials for Zn2+ storage in mild aqueous electrolytes have entered researchers’ spotlight. For example, copper hexacyanoferrate17,18, V2O53,19,20, and MnO221,22,23,24,25 have been recently reported for Zn2+ storage. Among these materials, MnO2 attracts much attention because of its high theoretical capacity (308 mA h g–1), low cost, and low toxicity23,24,25. As the most widespread primary battery, Zn–MnO2 alkaline battery has been commercialized for a very long time. However, the development of rechargeable Zn–MnO2 battery was dramatically hindered by the poor reversibility of MnO2 in alkaline electrolyte26,27.

Recently, the reversible Zn2+ and/or H+ insertion into a MnO2 host in a mild aqueous electrolyte was demonstrated21,22,23,24,25, triggering enthusiasm for the development of a rechargeable Zn–MnO2 battery using a mild aqueous electrolyte. Various manganese dioxide phases, including α-MnO222,23,28,29,30,31, β-MnO224, γ-MnO232, δ-MnO233, spinel-type MnO234, and other types35,36,37, have been reported as host materials for Zn2+/H+ insertion in a mild aqueous electrolyte. However, no matter what the original architecture is, the MnO2 hosts suffer serious structural transformation during cycling processes and transform into layered manganese oxide phases with interlaminar water molecules24,31,32 (Supplementary Fig. 1). The formation of the layered structure should be attributable to manganese dissolution and the insertion of hydrated Zn2+ (i.e., [Zn(H2O)6]2+) and H+ (i.e., H3O+) (see Supplementary Fig. 1 and Supplementary Note 1). With coordinated water molecules, the strong electrostatic repulsion between Zn2+ (or H+) and the host material can be diminished effectively19,31. That is to say, theoretically, that the layered structure with 1 × ∞ tunnels and extended interlayer spacing are advantageous for the storage of guest-hydrated cations. However, during the phase-change process (i.e., from α-, β-, γ-phase to layered structure with interlaminar water), large volumetric change leads to significant capacity fading24. In addition, with the insertion of a large amount of hydrated cations, the layered structure of manganese oxide will collapse during the charge/discharge process33,35, which aggravates capacity fading. As a result, when cycled with high charge/discharge depth, the MnO2 electrode generally exhibits very poor stability. Up to the present, the stable cycling of a MnO2 electrode with the utilization of >90% (~277 mA h g−1 = 308 mA h g−1 × 90%) has never been reported, to the best of our knowledge. Currently, the best reported cycle life of MnO2 in a mild aqueous electrolyte with high utilization of 84% (~260 mA h g−1) is 45 cycles, which was achieved by Liu’s group23. Very recently, Chen et al. demonstrated an improvement to 150 cycles with a lower utilization of 75% (~230 mA h g−1)24. Although there are some reports about high stability (more than 5000 cycles) of a MnO2 cathode in a mild aqueous electrolyte, excellent stability has been achieved with very low utilization of the theoretical capacity for MnO2 (<30%)23,25. Therefore, it is still a great challenge to efficiently utilize the high capacity of a MnO2 cathode in a mild aqueous electrolyte.

As mentioned above, the capacity fading of a MnO2 cathode arises from both the phase transformation and the instability of H2O-intercalated layered structure. Directly using the layered MnO2 as an electrode material, which can avoid phase transformations while intercalating a guest polymer into MnO2, to strengthen the extended layered structure is a promising solution. Here we prepare the polyaniline (PANI)-intercalated MnO2 nanolayers through an interface reaction. The nanoscale size of the layered MnO2 and the guest polymer in the interlayer efficiently facilitates the charge storage and strengthen the extended layered structure, and thus as-prepared PANI-intercalated MnO2 nanolayers exhibit high-rate capability and a long cycling life. Even with a high utilization of 90% (~280 mA h g−1), the PANI-intercalated MnO2 nanolayers still display a very stable cycling performance, which is superior to previous reports. Furthermore, a detailed investigation is performed to clarify the co-insertion mechanism of Zn2+ and H+.

Results

Structural characterization

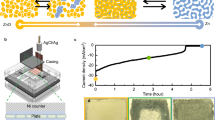

The PANI-intercalated MnO2 is prepared by a simple one-step inorganic/organic interface reaction (Fig. 1a), which was developed by our group38. At the interface of the organic phase (i.e., CCl4-containing aniline monomer) and the inorganic phase (i.e., KMnO4 aqueous solution), the chemical oxidation polymerization of aniline and the reduction of MnO42− occur simultaneously, facilitating the layer-by-layer assembly of the layered manganese dioxide and polyaniline (Fig. 1a). Furthermore, the diffusion of aniline from the organic phase to the inorganic phase and the production of PANI restrict the growth of MnO2 to two dimensions. Finally, the PANI-intercalated MnO2 nanolayers gather together to form a mesoporous structure. Figure 1b presents the scanning electron microscopy (SEM) image of the as-prepared sample, showing a grainy morphology that comprises aggregates of primary particles. Examination of transmission electron microscopy (TEM) data shown in Fig. 1c indicates that the PANI-intercalated MnO2 nanolayers composite exhibits a spongiform structure. The diffraction rings obtained from selected-area electron diffraction (SAED) analysis (inset of Fig. 1c) indicate polycrystalline character of the sample. The high-resolution transmission electron microscopy (HR-TEM) image (Fig. 1d) reveals that the PANI-intercalated MnO2 nanolayers possess a typical size around 10 nm and a distinct mesoporous structure, and the MnO2 nanolayers show an expanded interlayer space (~1.0 nm). The mesoporous structure is further supported by an obvious hysteresis loop in the nitrogen adsorption–desorption isotherms (Supplementary Fig. 2a), which indicate a large surface area of 277 m2 g−1 and a pore size that is mainly centered at 4 nm (Supplementary Fig. 2b). It should be noted that the layered structure of the MnO2 is not very apparent in Fig. 1d because of the shielding of PANI. In order to clarify this point, the PANI-intercalated MnO2 composite was heat treated at 400 °C in air for several minutes to obtain a clear view of the intercalated structure (Fig. 1e). After heat treatment to partially remove the shielding of PANI, the expanded interlayer space can be clearly detected in Fig. 1e. Certainly, the result of Fig. 1e also demonstrates that heat treatment at 400 °C did not destroy the expanded layer structure, indicating a good structure stability of the PANI-intercalated MnO2 nanolayers. The PANI in the composite was characterized with Fourier transform infrared (FT-IR) spectroscopy (Supplementary Fig. 3), and the weight percentage of PANI (5 wt%) was determined with thermogravimetric (TG) analysis (Supplementary Fig. 4). The broad peaks in the powder X-ray diffraction (XRD) pattern of the PANI-intercalated MnO2 nanolayers composite could be indexed to layered birnessite MnO2 (JCPDS 13–0105), as shown in Supplementary Fig. 5. X-ray photoelectron spectroscopy (XPS) (Supplementary Fig. 6) shows a spin-energy separation of 4.81 eV for the Mn 3 s doublet in the PANI-intercalated MnO2 nanolayers, indicating ~4.0 charge state of Mn in the composite39,40.

Preparation and characterization of the polyaniline-intercalated MnO2 nanolayers. a Schematic illustration of expanded intercalated structure of polyaniline (PANI)-intercalated MnO2 nanolayers. b Scanning electron microscopy image, c transmission electron microscopy (TEM) image (the inset shows the corresponding selected-area electron diffraction image), and d high-resolution (HR)-TEM image of the PANI-intercalated MnO2 nanolayers. The red dashed outlines are used to clarify the morphology profile and particle size of the MnO2 nanolayers. e HR-TEM image of the PANI-intercalated MnO2 nanolayers with heat treatment at 400 °C to remove the shield of PANI. Scale bars, b 1 μm; c 500 nm, and d, e 10 nm, respectively

Electrochemical characterization

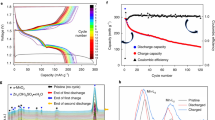

The electrochemical profile of the PANI-intercalated MnO2 nanolayers composite is characterized by the typical coin-type cell, which is composed of a PANI-intercalated MnO2 composite cathode, a Zn foil anode, and an aqueous electrolyte (2 M ZnSO4 + 0.1 M MnSO4) adsorbed with a glass fiber separator. According to Liu’s report23, the presence of 0.1 M MnSO4 could inhibit the dissolution of Mn2+ (from Mn3+ disproportionation) into the electrolyte. Furthermore, the presence of Mn2+ can improve the Zn-platting/stripping efficiency (Supplementary Fig. 7). Figure 2a shows the cyclic voltammetry (CV) data for the PANI-intercalated MnO2 nanolayers composite. There is an obvious cathodic peak around 1.23 V during the first cathodic sweep, while the corresponding anode peak appears around 1.56 V during the anodic sweep. In the following cycles, the strengths of the redox peaks mentioned above gradually decrease; meanwhile, one new pair of redox peaks emerge around 1.38 and 1.60 V. The two-step charge storage should be attributed to the different insertion mechanism of H+ and/or Zn2+ during the discharge process, which will be further clarified in the mechanism investigation. The galvanostatic charge/discharge profile of the PANI-intercalated MnO2 nanolayers composite is shown in Fig. 2b, where the applied current density and the achieved capacity are calculated by mass loading of PANI-intercalated MnO2 nanolayers composite in the cathode (i.e., 2 mg cm−2 with an electrode area of 1 cm−2). When tested at the low current of 50 mA g−1 (0.16 C), the cell exhibits initial discharge capacity of 260 mA h g−1, involving a slope discharge profile from 1.5 to 1.33 V (~50 mA h g−1 capacity) and a consequent discharge platform about 1.36 V (~210 mA h g−1 capacity). In the subsequent cycle, the discharge capacity is increased to 298 mA h g−1, which is close to the theoretical capacity of 308 mA h g−1 (based on single electron transfer between Mn4+ and Mn3+). Figure 2c presents the rate performance tested at different current densities, and corresponding cycle profile is given in Fig. 2d. As shown in Fig. 2c, d, the cell exhibits a reversible discharge capacity of 280 mA h g−1 at the current density of 200 mA g−1, which is very close to that achieved at the low current density of 50 mA g−1. Even at the high current density of 3000 mA g−1, the cell still can deliver a capacity of 110 mA h g−1, which is to the best of our knowledge among the best rate performances reported to date in this field23,24,25. It should be noted that the two discharge plateaus evolve to a single one at the high rate, which should be attributable to H+ insertion that dominates the discharge process at high rate. This phenomenon can be explained by the faster H+ insertion than Zn2+ insertion, which will be confirmed by the later electrochemical impedance measurements. Cycle stability of the PANI-intercalated MnO2 composite was evaluated at the current densities of 200 and 2000 mA g−1. From Fig. 2e, it can be seen that PANI-intercalated MnO2 nanolayers composite delivers 280 mA h g−1 capacity for 200 cycles with coulombic efficiency around 100%, in which an ultra-high utilization of more than 90% (based on theoretical capacity of 308 mA h g−1 of MnO2) is obtained. To the best of our knowledge, it is the highest utilization that can be stable for 200 cycles in an aqueous zinc-ion battery (see Supplementary Table 1 for detailed information). The charge/discharge curves at different cycles are shown in Supplementary Fig. 8 to clarify the potential evolution during the cycling test, where a slight potential evolution over 200 cycles can be detected. When tested at the high current density of 2000 mA g−1, the PANI-intercalated MnO2 nanolayers composite present a stable discharge capacity of around 125 mA h g−1 (up to 40% utilization) over 5000 cycles (Supplementary Fig. 9). The stable cycle life of 5000 cycles with the utilization of 40% is superior to previous reports (see Supplementary Table 2 for detailed information). The superior performance is largely attributable to the reinforcement of the layered structure with intercalated PANI, which avoids phase transformation and collapse of the layered structure during repeated insertion/extraction of hydrated cations. Simultaneously, the presence of Mn2+ in the electrolyte also alleviates the Mn2+ dissolution-induced capacity fading23,24.

Electrochemical performance of polyaniline-intercalated MnO2 nanolayers. a Cyclic voltammetry curves of the coin-type cell (Zn/polyaniline (PANI)-intercalated MnO2) using 2 M ZnSO4 + 0.1 M MnSO4 aqueous electrolyte at 0.1 mV s−1. b Typical galvanostatic charge/discharge curves at 50 mA g−1 between 1.0 and 1.8 V of the cell. c, d Rate performance and charge/discharge profiles of the cell tested with the charge/discharge current densities varying from 200 to 3000 mA g−1. e Cycling performance in terms of specific capacity (red) and the corresponding coulombic efficiency (blue) at a current density of 200 mA g−1

To further demonstrate the function of the PANI-reinforced layered structure, the cycling performance of the PANI-intercalated MnO2 nanolayers composite was also investigated using the ZnSO4 electrolyte without Mn2+ (Supplementary Fig. 10), and the corresponding result was compared with previous reports about MnO2 cycled in the electrolyte without Mn2+ (see Supplementary Table 3). On the other hand, it should be noted that the high cycle performance shown in Fig. 2e or Supplementary Fig. 9 is achieved by using excess Zn-anode (see Method section). The purpose is to exclude the effect of Zn-anode fading, which is similar with previous reports about MnO2 cathode22,23,24,25,26,27,28,29,30,31,32,33,34,35,36. SEM images of the cycled Zn electrode and PANI-intercalated MnO2 electrode are given in Supplementary Fig. 11 and Supplementary Fig. 12, respectively. In practical application, the issue of Zn-anode is another obstacle for Zn-ion batteries. The modification of an electrode developed by La Mantia et al41. and the electrolyte optimization reported by Chen’s group42 may be the potential solutions to improve the stability of Zn-anode.

Reaction mechanism

Until now, two reaction mechanisms for a manganese dioxide cathode, involving Zn2+ and H+ insertion/extraction, respectively, have been reported23,24,25,31. Due to various crystallographic polymorphs of manganese dioxide, the reaction mechanism during cycling in neutral aqueous electrolytes remains a topic of discussion. Here the insertion mechanism was investigated to better understand the electrochemical reaction during cycling. Ex situ XRD analysis of the PANI-intercalated MnO2 electrode in 2 M ZnSO4 + 0.1 M MnSO4 electrolyte was conducted during the charge/discharge cycle within the potential window of 1.0–1.8 V at a current density of 50 mA g−1 (Fig. 3a and Supplementary Fig. 13). During the first discharge platform (Region I, red color), only two sets of peaks (related to polytetrafluoroethylene (PTFE) binder at 18° and Ti current collector at 38.4° and 40.2°) could be clearly observed, and there is no obvious variation throughout Region I. However, from the beginning of the second discharge platform (Region II, blue color), some new peaks arise, including a very strong peak at 8.1° and obvious peaks at 16.2° and 24.4° 2θ. During the subsequence charge process, the strength of arisen peaks decreases gradually (Region III, cyan color), and finally recover to the original pattern (Region IV, pink color) which is as same as Region I, indicating a good reversibility of electrode reaction. In order to analyze the evolution more clearly, several selected XRD patterns from Fig. 3a were presented in Fig. 3b. The emerging peaks (including strong peaks at 8.1°, 16.2°, and 24.4° 2θ and other subtle peaks highlighted with inverted triangles) are indexed to (Zn(OH)2)3(ZnSO4)(H2O)5 (zinc hydroxide sulfate hydrate, JCPDS: 78–0246)23. The formation of zinc hydroxide sulfate is in consistence with Liu et al.’s report23. With the consumption of H+ in the electrolyte, the increasing amount of OH− leads to the formation of zinc hydroxide sulfate hydrate. SEM is further conducted to monitor the morphologic evolution of the PANI-intercalated MnO2 electrode (Fig. 3c–h). For Region I, there is no obvious change on the electrode surface, but in the Region II, increasingly large flakes emerge with discharging and gradually vanish during subsequent charging. The highly reversible morphologic transformation during the charge/discharge process is well consistent with the evolution observed in XRD patterns. Energy-dispersive spectroscopy (EDS) analysis shows that the flake-like product contains abundant Zn and S, but no evident Mn, which supports that the large flakes are zinc hydroxide sulfate hydrate (Supplementary Fig. 14), as indexed in the XRD patterns.

Structure evolution of polyaniline-intercalated MnO2 electrode during cycling. a Evolution of ex situ X-ray powder diffraction (XRD) patterns during the charge/discharge process (the vertical bars denoted with consecutive numbers indicate the locations where the XRD patterns were recorded). b Selected ex situ XRD patterns from a (corresponding to the XRD patterns denoted with 3, 10, 13, and 19 in a), which represent the typical XRD pattern in each corresponding charge/discharge region. c–h Scanning electron microscopy (SEM) images for morphologic evolution of electrode during cycling (the SEM images were taken at the locations indicated by vertical bars 3, 5, 10, 12, 16, and 20 in a, respectively). Scale bars, c–h 10 μm, respectively (the magnification is the same for images c–h)

As demonstrated by the above observation, the electrochemical reaction of the PANI-intercalated MnO2 nanolayers composite definitely involved H+ insertion, which supports the conclusion by Liu et al23. However, it does not preclude Zn2+ insertion during the discharge process. We presume that besides H+ insertion, Zn2+ insertion plays an important role in the discharge process because the two discharge platforms cannot be satisfactorily explained by only H+ insertion. Therefore, further investigation was performed to clarify this point. Figure 4a shows the discharge curves of the PANI-intercalated MnO2 nanolayers composite in different electrolytes (red curve: 2 M ZnSO4 + 0.1 M MnSO4, blue curve: 0.1 M MnSO4). As we know, PANI-intercalated MnO2 exhibits two discharge platforms in 2 M ZnSO4 + 0.1 M MnSO4 electrolyte (red curve). However, when Zn2+ was eliminated, a single-slope discharge profile was observed for the 0.1 M MnSO4 electrolyte (blue curve). From this result, we preliminarily conclude that the second discharge platform is related to Zn2+ insertion. Raman spectra (Fig. 4b) are used to further characterize Zn2+ insertion/extraction during charge/discharge states. A band of around 650 cm−1 can be observed throughout the whole charge/discharge process, which is attributed to the symmetric stretching vibration (Mn–O) of the MnO6 groups43,44. In addition, a pair of peaks between 300 and 400 cm−1 that are derived from Zn−O vibrations45,46 arise after discharge to 1 V and then vanish after consequent charging. This reversible Zn−O band demonstrates the insertion/extraction of Zn2+ in the PANI-intercalated MnO2 electrode. The conclusion is supported by the observation of Zn on the electrode surface with scanning electron microscopy–energy dispersive X-ray spectroscopy (SEM–EDX) analysis after discharge (Supplementary Fig. 15). Moreover, the kinetic behavior during the first and second discharge platform was investigated with electrochemical impedance spectroscopy (EIS, Supplementary Fig. 16), in which the calculated diffusion coefficient in the first discharge platform (5.84 × 10−12 cm2 s−1) is much higher than that in the second discharge platform (7.35 × 10−14 cm2 s−1), indicating different insertion ions during the two different discharge platforms.

Characterization of sequential insertion of H+ and Zn2+ during two discharge platforms. a The discharge profile of polyaniline (PANI)-intercalated MnO2 electrode at current density of 50 mA g−1 in different electrolytes (red curve: 2 M ZnSO4 + 0.1 M MnSO4, blue curve: 0.1 M MnSO4). b Raman spectra of PANI-intercalated MnO2 electrode after full discharge and full charge. c High-resolution transmission electron microscopy (HR-TEM) image of the testing electrode after the first discharge platform and the corresponding scanning transmission electron microscopy–energy dispersive spectroscopy (STEM–EDS) mappings for elements like Mn, Zn, and S. d HR-TEM image of the testing electrode after the second discharge platform and the corresponding STEM–EDS mappings for elements like Mn, Zn, and S. Red arrows indicate the PANI-intercalated MnO2 nanolayers and cyan arrows indicate the acetylene black in electrode. Scale bars, c, d 10 nm for TEM images and 100 nm for STEM–EDS mapping images

HR-TEM was further employed to gain insight into the structure evolution during the two-stage discharge process. As seen in Fig. 4c, after the first discharge platform, the layered structure with large lattice spacing (see red arrows) is maintained (the cyan arrow indicates the acetylene black in the electrode), and the corresponding scanning transmission electron microscopy–energy dispersive spectroscopy (STEM–EDS) mapping reveals abundant Mn, trace amounts of Zn, and negligible S in the discharge products, indicating H+ insertion in the initial discharge stage. The layered structure was also preserved well after the second discharge platform (Fig. 4d), but unlike the first discharge platform, zinc is abundant with homogeneous distribution in the PANI-intercalated MnO2 nanolayers according to STEM–EDS mapping, confirming Zn2+ insertion into the PANI-intercalated MnO2 nanolayers. Notably, the layered structure was preserved after the long cycle test (Supplementary Fig. 17), which strongly demonstrates the high stability of PANI-intercalated MnO2 nanolayers. On the contrary, other MnO2 crystallographic polymorphs suffer severe phase transformation, as reported by previous researchers24,31,32.

Based on the above analysis, we propose a co-insertion mechanism of H+ and Zn2+ in PANI-intercalated MnO2 nanolayers with a self-regulating function in the electrolyte (Fig. 5). In the first stage of discharge, H+ initially inserts into PANI-intercalated MnO2 nanolayers, leading to a gradual decrease of H+ concentration in the vicinity of the electrode. During the first discharge platform, the OH− concentration is not high enough to form zinc hydroxide sulfate. With sustained decrease of H+ concentration, the second discharge platform arises, which is caused by a Zn2+ insertion reaction; meanwhile, the amount of zinc hydroxide sulfate formed on the electrode surface increases. Along with the Zn2+ insertion, H+ insertion is ongoing in the second discharge platform, leading to the increased formation of flake-like zinc hydroxide sulfate. Note that this “self-regulation function” consumes superfluous OH−, which is beneficial for high cycle stability. On recharge, the released H+ can lead to the dissolution of the zinc hydroxide sulfate.

Diagram showing the sequential insertion of H+ and Zn2+. During the first discharge platform, H+ insertion into polyaniline (PANI)-intercalated MnO2 nanolayers dominates the electrode reaction, which gradually decreases H+ concentration around the electrode. With a sustained decrease of H+, Zn2+ insertion dominates the electrochemical reaction, raising the second discharge platform; meanwhile, the sustained decrease of H+ concentration leads to the formation of zinc hydroxide sulfate on the electrode surface

Discussion

In summary, PANI-intercalated MnO2 nanolayers were prepared and investigated as the cathode material for a rechargeable Zn–MnO2 battery using a mild aqueous electrolyte. With the typical nanosize, expanded interlayer space, uniform meso-structure and polymer-reinforced layered structure, the PANI-intercalated MnO2 nanolayers show a promising rate performance and an excellent cycling stability at high charge/discharge depth that is superior to previous reports. It is demonstrated that the PANI-reinforced layered structure combined with the nanoparticle-sized (~10 nm) MnO2 can efficiently eliminate the hydrated H+/Zn2+-insertion-induced phase transformation and the subsequent structure collapse, which is of vital significance to obtaining long cycle life along with high capacity utilization. Furthermore, the hydrated H+/Zn2+ co-insertion process in the layered MnO2 was investigated in detail, and a self-regulating mechanism of electrolyte-involved generation/dissolution of flake-like zinc hydroxide sulfate was clarified. These achievements cast light on the design of more advanced MnO2 cathode materials for rechargeable Zn–MnO2 batteries using mild aqueous electrolytes.

Methods

Material preparation

In a typical synthesis, aniline monomer (9 mL, Aldrich) was dissolved in CCl4 organic phase (450 mL, Aldrich) and potassium permanganate (0.45 g, Aldrich) was dissolved in distilled water (450 mL, pH 7). The solution was mixed to obtain an aqueous/organic stratification system with a clear interface. The reaction system was kept at 5 °C for 24 h. The chemical oxidation polymerization of aniline and reduction of potassium permanganate occurred simultaneously at the aqueous/organic interface, which is similar to our previous report38. By continuous diffusion of aniline from the organic phase to the aqueous phase, layer-by-layer self-assembly of layered manganese dioxide and polymer was established, and the final products were obtained after centrifugation and freeze drying.

Characterization

Powder XRD patterns were collected on a X-ray diffractometer (Bruker D8 Advance, Germany) with Cu Kα radiation (λ = 0.15406 nm). SEM images and EDX mapping were obtained on Field-emission JEOL JSM-6390 microscope. TEM and EDS mapping were performed on JEOL JEM-2010 microscope. XPS was tested on a Thermo Escalab 250 equipped with a hemispherical analyzer. Raman spectra were obtained on RENISHAW inVia Raman Microscope using 633 nm excitation. T.G. was measured by a STA209 PC (NETZSCH, Germany) analyzer with an O2 flow. Fourier transform infrared spectroscopy (FT-IR) spectrum was recorded with a NICOLET 6700 FT-IR Spectrometer using KBr pellets.

Electrochemical measurements

Electrochemical measurements were performed with CR2016 coin-type cells. The full cells were assembled using the PANI-intercalated MnO2 composite as the cathode, a zinc metal foil as the anode, a glass fiber as separator, and aqueous 2 M ZnSO4 with 0.1 M MnSO4 as electrolyte. The working electrode was fabricated by compressing a mixture of the active materials of PANI-intercalated MnO2 composite, the conductive material (acetylene black, AB), and the binder (polytetrafluoroethylene, PTFE) in a weight ratio of active materials/AB/PTFE = 80:10:10 onto a Ti grid at 20 MPa. The areal loading density of PANI-intercalated MnO2 is 2.0 mg cm–2, while the counter electrode (Zinc metal foil) is 20 mg cm–2 with the purpose of excluding the effect of Zn-anode fading. Galvanostatic charge/discharge performances were conducted on a battery test system (Neware BTS 4000). Cyclic voltammetry (0.1 mV s–1) and electrochemical impedance spectroscopy (an AC voltage of 5 mV amplitude) measurements were carried out using an AUTOLAB electrochemical work station (PGSTAT 302N). In order to avoid the conglutination between separator and electrode, the electrochemical tests for SEM, TEM, Raman, and XRD analysis were conducted with a simulated battery composed of a working electrode, counter electrode and electrolyte, but no separator.

Data availability

The authors declare that all the relevant data are available within the paper and its Supplementary Information file or from the corresponding author on reasonable request.

References

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Goodenough, J. B. Electrochemical energy storage in a sustainable modern society. Energ. Environ. Sci. 7, 14–18 (2014).

Kundu, D., Adams, B. D., Duffort, V., Vajargah, S. H. & Nazar, L. F. A high-capacity and long-life aqueous rechargeable zinc battery using a metal oxide intercalation cathode. Nat. Energy 1, 16119 (2016).

Chu, S. & Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 488, 294–303 (2012).

Suo, L. M. et al. “Water-in-salt” electrolyte enables high-voltage aqueous lithium-ion chemistries. Science 350, 938–943 (2015).

Luo, J. Y., Cui, W. J., He, P. & Xia, Y. Y. Raising the cycling stability of aqueous lithium-ion batteries by eliminating oxygen in the electrolyte. Nat. Chem. 2, 760–765 (2010).

Pasta, M., Wessells, C. D., Huggins, R. A. & Cui, Y. A high-rate and long cycle life aqueous electrolyte battery for grid-scale energy storage. Nat. Commun. 3, 1149 (2012).

Pasta, M. et al. Full open-framework batteries for stationary energy storage. Nat. Commun. 5, 3007 (2014).

Li, Q., Li, N., Liu, Y., Wang, Y. & Zhou, H. High-safety and low-cost photoassisted chargeable aqueous sodium-ion batteries with 90% input electric energy savings. Adv. Energy Mater. 6, 1600632 (2016).

Palomares, V. et al. Na-ion batteries, recent advances and present challenges to become low cost energy storage systems. Energ. Environ. Sci. 5, 5884 (2012).

Kim, H. et al. Aqueous rechargeable Li and Na ion batteries. Chem. Rev. 114, 11788–11827 (2014).

Wang, Y. et al. Ti-substituted tunnel-type Na0.44MnO2 oxide as a negative electrode for aqueous sodium-ion batteries. Nat. Commun. 6, 6401 (2015).

Liang, Y. L. et al. Universal quinone electrodes for long cycle life aqueous rechargeable batteries. Nat. Mater. 16, 841–848 (2017).

Li, Z., Young, D., Xiang, K., Carter, W. C. & Chiang, Y.-M. Towards high power high energy aqueous sodium-ion batteries: the NaTi2(PO4)3/Na0.44MnO2 system. Adv. Energy Mater. 3, 290–294 (2013).

Yan, J. et al. Rechargeable hybrid aqueous batteries. J. Power Sources 216, 222–226 (2012).

Yamada, Y. et al. Hydrate-melt electrolytes for high-energy-density aqueous batteries. Nat. Energy 1, 16129 (2016).

Trocoli, R. & La Mantia, F. An aqueous zinc-ion battery based on copper hexacyanoferrate. ChemSusChem 8, 481–485 (2015).

Canepa, P. et al. Odyssey of multivalent cathode materials: open questions and future challenges. Chem. Rev. 117, 4287–4341 (2017).

Yan, M. et al. Water-lubricated intercalation in V2O5∙nH2O for high-capacity and high-rate aqueous rechargeable zinc batteries. Adv. Mater. 30, 1703725 (2017).

He, P. et al. High-performance aqueous zinc-ion battery based on layered H2V3O8 nanowire cathode. Small 13, 1702551 (2017).

Xu, C., Du, H., Li, B., Kang, F. & Zeng, Y. Reversible insertion properties of zinc ion into manganese dioxide and its application for energy storage. Electrochem. Solid ST 12, A61 (2009).

Xu, C., Li, B., Du, H. & Kang, F. Energetic zinc ion chemistry: the rechargeable zinc ion battery. Angew. Chem. Int. Ed. 51, 933–935 (2012).

Pan, H. L. et al. Reversible aqueous zinc/manganese oxide energy storage from conversion reactions. Nat. Energy 1, 1639 (2016).

Zhang, N. et al. Rechargeable aqueous zinc-manganese dioxide batteries with high energy and power densities. Nat. Commun. 8, 405 (2017).

Sun, W. et al. Zn/MnO2 battery chemistry with H+ and Zn2+ coinsertion. J. Am. Chem. Soc. 139, 9775–9778 (2017).

Ingale, N. D., Gallaway, J. W., Nyce, M., Couzis, A. & Banerjee, S. Rechargeability and economic aspects of alkaline zinc–manganese dioxide cells for electrical storage and load leveling. J. Power Sources 276, 7–18 (2015).

McLarnon, F. R. & Cairns, E. J. The secondary alkaline zinc electrode. J. Electrochem. Soc. 138, 645–656 (1991).

Alfaruqi, M. H. et al. Enhanced reversible divalent zinc storage in a structurally stable α-MnO2 nanorod electrode. J. Power Sources 288, 320–327 (2015).

Alfaruqi, M. H. et al. A high surface area tunnel-type α-MnO2 nanorod cathode by a simple solvent-free synthesis for rechargeable aqueous zinc-ion batteries. Chem. Phys. Lett. 650, 64–68 (2016).

Lee, B. et al. Electrochemically-induced reversible transition from the tunneled to layered polymorphs of manganese dioxide. Sci. Rep. 4, 6066 (2014).

Lee, B. et al. Elucidating the intercalation mechanism of zinc ions into alpha-MnO2 for rechargeable zinc batteries. Chem. Commun. 51, 9265–9268 (2015).

Alfaruqi, M. H. et al. Electrochemically induced structural transformation in a γ-MnO2 cathode of a high capacity zinc-ion battery system. Chem. Mater. 27, 3609–3620 (2015).

Alfaruqi, M. H. et al. A layered δ-MnO2 nanoflake cathode with high zinc-storage capacities for eco-friendly battery applications. Electrochem. Commun. 60, 121–125 (2015).

Zhang, N. et al. Cation-deficient spinel ZnMn2O4 cathode in Zn(CF3SO3)2 electrolyte for rechargeable aqueous Zn-Ion battery. J. Am. Chem. Soc. 138, 12894–12901 (2016).

Wei, C., Xu, C., Li, B., Du, H. & Kang, F. Preparation and characterization of manganese dioxides with nano-sized tunnel structures for zinc ion storage. J. Phys. Chem. Solids 73, 1487–1491 (2012).

Lee, J., Ju, J. B., Cho, W. I., Cho, B. W. & Oh, S. H. Todorokite-type MnO2 as a zinc-ion intercalating material. Electrochim. Acta 112, 138–143 (2013).

Jiang, B. et al. Manganese sesquioxide as cathode material for multivalent zinc ion battery with high capacity and long cycle life. Electrochim. Acta 229, 422–428 (2017).

Wang, Y. G. et al. A polyaniline-intercalated layered manganese oxide nanocomposite prepared by an inorganic/organic interface reaction and its high electrochemical performance for Li storage. Adv. Mater. 20, 2166–2170 (2008).

Kalubarme, R. S., Jadhav, H. S. & Park, C. J. Electrochemical characteristics of two-dimensional nano-structured MnO2 for symmetric supercapacitor. Electrochim. Acta 87, 457–465 (2013).

Chigane, M. & Ishikawa, M. Manganese oxide thin film preparation by potentiostatic electrolyses and electrochromism. J. Electrochem. Soc. 147, 2246–2251 (2000).

González, M. A., Trócoli, R., Pavlovic, I., Barriga, C. & La Mantia, F. Layered double hydroxides as a suitable substrate to improve the efficiency of Zn anode in neutral pH Zn-ion batteries. Electrochem. Commun. 68, 1–4 (2016).

Sun, K. E. K. et al. Highly sustainable zinc anodes for a rechargeable hybrid aqueous battery. Chem. Eur. J. 24, 1667–1673 (2018).

Hsu, Y. K., Chen, Y. C., Lin, Y. G., Chen, L. C. & Chen, K. H. Reversible phase transformation of MnO2 nanosheets in an electrochemical capacitor investigated by in situ Raman spectroscopy. Chem. Commun. 47, 1252–1254 (2011).

Polverejan, M., Viliegas, J. C. & Suib, S. L. Higher valency ion substitution into the manganese oxide framework. J. Am. Chem. Soc. 126, 7774–7775 (2004).

Kim, Y. I., Page, K., Limarga, A. M., Clarke, D. R. & Seshadri, R. Evolution of local structures in polycrystalline Zn1–xMgxO (0≤x≤0.15) studied by Raman spectroscopy and synchrotron x-ray pair-distribution-function analysis. Phys. Rev. B 76, 115204 (2007).

Hadzic, B. et al. Raman study of surface optical phonons in hydrothermally obtained ZnO(Mn) nanoparticles. Opt. Mater. 58, 317–322 (2016).

Acknowledgements

The authors acknowledge funding support from the National Natural Science Foundation of China (21622303 and 21333002), National Key Research and Development Plan (2016YFB0901500 and 2016YFA0203302).

Author information

Authors and Affiliations

Contributions

Y.W. conceived this idea and designed the experiments. Y.W. and Y.X. directed the project. J.H., Y.W. and Z.W. performed the material process and characterization. J.H., M.H., X.D. and Y.L. carried out the electrochemical measurements and data analysis. J.H. and Y.W. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, J., Wang, Z., Hou, M. et al. Polyaniline-intercalated manganese dioxide nanolayers as a high-performance cathode material for an aqueous zinc-ion battery. Nat Commun 9, 2906 (2018). https://doi.org/10.1038/s41467-018-04949-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-018-04949-4

This article is cited by

-

Combined effect of endophytic Bacillus mycoides and rock phosphate on the amelioration of heavy metal stress in wheat plants

BMC Plant Biology (2024)

-

Proton-selective coating enables fast-kinetics high-mass-loading cathodes for sustainable zinc batteries

Nature Communications (2024)

-

Best practices for zinc metal batteries

Nature Sustainability (2024)

-

Advanced organic electrode materials for aqueous rechargeable batteries

Science China Chemistry (2024)

-

Research status and perspectives of MXene-based materials for aqueous zinc-ion batteries

Rare Metals (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.