Abstract

Polyketides are an important class of bioactive small molecules valued not only for their diverse therapeutic applications, but also for their role in controlling interesting biological phenotypes in their producing organisms. While numerous polyketides are known to be derived from aerobic organisms, only a single family of polyketides has been identified from anaerobic organisms. Here we uncover a family of polyketides native to the anaerobic bacterium Clostridium acetobutylicum, an organism well-known for its historical use as an industrial producer of the organic solvents acetone, butanol, and ethanol. Through mutational analysis and chemical complementation assays, we demonstrate that these polyketides act as chemical triggers of sporulation and granulose accumulation in this strain. This study represents a significant addition to the body of work demonstrating the existence and importance of polyketides in anaerobes, and showcases a strategy of manipulating the secondary metabolism of an organism to improve traits relevant for industrial applications.

Similar content being viewed by others

Introduction

Polyketides are one of the most important classes of natural products given their wide range of applications in medicine and agriculture1,2. Encompassing several different chemical classes such as macrolides, polyenes, and aromatics, polyketides are employed for clinical use as antibiotics, anti-cancer agents, immunosuppressants, and even cholesterol-lowering drugs3. In addition to their role as therapeutic agents, many of these compounds are used by their producing organisms to access information about both the intracellular physiological status and extracellular environment, and control complex cellular processes such as morphological differentiation, virulence, stress response, and additional secondary metabolite production4. As virtually all known polyketides are derived from aerobic organisms (such as bacteria, fungi, and plants), there has been a long-standing assumption that anaerobic organisms are unable to produce these compounds5. However, recent genomic analysis has challenged this view by revealing that polyketide biosynthetic genes are widespread among anaerobic bacteria, and in particular, members from the genus Clostridium 6. This diverse genus, comprised of anaerobic endospore-forming Gram-positive firmicutes, includes several notorious human pathogens as well as non-pathogenic species useful for industrial biotechnology7. To date, only one family of polyketides, the clostrubins, has been identified from Clostridium, representing the only known polyketides from the anaerobic world8. Clostrubins are pentacyclic polyphenolic polyketides biosynthesized by type II polyketide synthases (PKSs) in Clostridium beijerinckii 8 and Clostridium puniceum 9, and display potent antibiotic activity against various pathogenic bacteria. Additionally, these aromatic polyketides have been shown to enable the plant pathogen C. puniceum to survive in an oxygen-rich environment. The discovery of clostrubins provided the first experimental evidence that anaerobes are capable of producing bioactive polyketides, and motivated further studies on anaerobes to reveal additional polyketide metabolites with novel structures and interesting biological functions.

Clostridium acetobutylicum is an organism historically used for industrial-scale production of the organic solvents acetone, n-butanol, and ethanol (ABE) through a process known as ABE fermentation10. Batch ABE fermentation by C. acetobutylicum ATCC 824 (the model ABE producer) is characterized by two distinctive phases, an acid production phase (acidogenesis) and a solvent production phase (solventogenesis)11. During exponential growth, short-chain fatty acids (acetate and butyrate) are produced and accumulate in the media, causing a drop in the culture pH. As the culture approaches stationary phase, the previously formed acids are re-assimilated, the culture pH rises, and solvent production is initiated. The metabolic switch from acidogenesis to solventogenesis coincides with the initiation of the complex development program of sporulation12. As part of these processes, a starch-like carbohydrate known as granulose is produced and accumulates in swollen, phase-bright clostridial forms, within which endospores develop13. Further morphological development yields free spores, heat- and chemical-resistant cell types that do not contribute to solvent production.

Although ABE fermentation of C. acetobutylicum has been extensively studied, chemical signals responsible for triggering solventogenesis and/or sporulation have not been elucidated, and no secondary metabolite that plays a role in regulating these processes has been reported from this organism. Motivated by a recent transcriptomic analysis of C. acetobutylicum 14, which showed that the expression of a type I modular PKS gene was significantly upregulated during early stationary phase (~40-fold higher transcription level compared to mid-exponential phase), we postulated that the corresponding polyketide product might regulate one or more of the key fermentation phenotypes associated with solventogenesis and sporulation. Here we report the discovery of a family of polyketide metabolites using comparative, untargeted metabolomics followed by large-scale compound purification and molecular structure elucidation. Using a reverse genetics approach and chemical complementation, we further show that deletion of the pks gene results in increased batch butanol production, and that the newly discovered polyketides are important in stimulating sporulation and granulose accumulation in C. acetobutylicum.

Results

Analysis and inactivation of pks locus in C. acetobutylicum

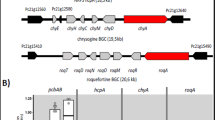

All sequenced C. acetobutylicum strains possess one pks gene (ca_c3355 in C. acetobutylicum ATCC 834) that encodes a type I single-module PKS with a predicted catalytic domain organization of ketosynthase, acyltransferase, dehydratase, ketoreductase, and acyl carrier protein (KS-AT-DH-KR-ACP) (Supplementary Fig. 1a). Homologous PKSs with the same domain structure could be identified, but the genes for these homologous PKSs are typically part of much larger biosynthetic gene clusters that encode additional PKSs and/or modification enzymes. ca_c3355 appears to be an orphan gene with no other biosynthetic enzyme encoded either upstream or downstream, although several transcriptional regulators and efflux pumps are encoded in the vicinity (Supplementary Fig. 1b). While we were able to predict that malonyl-CoA was the likely substrate recognized by the AT domain (Supplementary Fig. 1a), it was difficult to predict the identity of polyketides, which might be synthesized by this PKS, or if any chemical modifications of the nascent polyketide intermediate would be made by proteins encoded elsewhere on the genome. To determine the identity of any PKS-associated metabolites and probe the broader function of the pks locus, we performed a targeted in-frame deletion of the pks gene (ca_c3355) using an allelic exchange method developed for C. acetobutylicum 15. The resulting mutant (Δpks) was confirmed by PCR analysis (Supplementary Fig. 2).

Discovery of polyketides through comparative metabolomics

Quadruplicate batch fermentations with wild-type C. acetobutylicum and the mutant Δpks were performed and harvested at early stationary phase. Organic extracts from combined supernatants and cell pellets were obtained and analyzed via liquid chromatography-high-resolution mass spectroscopy (LC-HRMS). Following untargeted metabolomic comparisons of the two strains using XCMS16, three major species with molecular formulas C14H22O3 (1, calculated for C14H21O3 −: 237.1496; found: 237.1496), C20H32O7 (2, calculated for C20H31O7 −: 383.2075; found: 383.2080), and C26H42O12 (3, calculated for C26H41O12 −: 545.2604; found: 545.2600) were found to be present in wild-type culture extracts and completely absent in extracts of Δpks (Fig. 1a, b; Supplementary Figs. 3–5). A majority of 1–3 was found in the culture medium rather than cell pellets, suggesting that they were secreted into the culture medium upon production. 1–3 were UV active and featured identical UV absorption spectra (Supplementary Figs. 3–5), indicating that they share the same chromophore and likely the same biosynthetic origin. Furthermore, when the pks gene was introduced back into the Δpks mutant, the genetic complementation strain was found to have resumed the production of 1–3, demonstrating a direct relationship between the pks gene and the production of 1–3 (Fig. 1b).

Identification of polyketides from wild-type extracts. a Results of XCMS analysis of wild-type C. acetobutylicum and Δpks extracts taken from early stationary phase fermentation cultures (biological quadruplicates). Blue (upper) chromatograms depict MS traces of quadruplicate wild-type extracts, while orange/brown (lower) chromatograms depict MS traces of quadruplicate Δpks extracts. Green circles represent MS peaks unique to wild-type extracts, with corresponding m/z values indicated by the y-axis. No significant MS peaks were identified, which were unique to Δpks. The three peaks unique to wild type are identified as 1, 2, and 3. b UV–Vis traces (240 nm) of extracts from wild type, Δpks, and Δpks genetic complementation strain (Δpks (pCKO_pks)). c Elucidated structures of 1 and 3 based on NMR characterization

Isolation and structure elucidation of polyketides

To isolate compounds 1–3, we prepared 34 L of wild-type C. acetobutylicum culture broth. The culture was extracted with ethyl acetate and chromatographed on a silica gel column, followed by further purification via multiple rounds of HPLC using reverse-phase C18 columns (Supplementary Methods). These purification steps yielded pure compound 1 (1.1 mg) and 3 (0.9 mg). NMR spectra, including 1H, 13C, DQF-COSY, TOCSY, HSQC, and HMBC spectra, were obtained for compound 1 (Supplementary Table 1; Supplementary Fig. 6; Supplementary Methods). The proton signals at δ 5.43, 5.56, and 6.00 indicated a considerable overlap in the aliphatic double bond region, and their configuration (all E stereochemistry) was further resolved using the high-resolution HSQC spectrum without 13C decoupling. These assignments of geometric stereochemistry were also supported from 13C chemical shift values of allylic methylenes17. The carbon signals at δ 172.97 and 67.25, together with related HMBC and TOCSY correlations, indicated the presence of a carboxylic acid and a secondary alcohol. The absolute stereochemistry of 1 was determined to be in the R configuration by measuring the specific rotation of its fully reduced product, 3-hydroxytetradecanoic acid (3-HTA). In particular, 1 was reduced to 3-HTA through hydrogenation over a palladium catalyst, and the specific rotation of the product (\([{\mathrm{\alpha }}]_{\mathrm{D}}^{{\mathrm{20}}}\)−15.7° (c 1, CHCl3)) was consistent with the reported value of optically pure (R)-3-HTA (\([{\mathrm{\alpha }}]_{\mathrm{D}}^{{\mathrm{20}}}\)−16.2° (c 1, CHCl3))18 (Supplementary Methods). From these data, we elucidated the molecular structure of 1 to be a modified tetradecenoic acid, which we termed clostrienoic acid (Fig. 1c). The predicted molecular formulas, MS/MS analysis, and identical UV absorption spectra suggested that 2 and 3 were related to 1, likely containing additional monosaccharide and disaccharide moieties, respectively (Supplementary Figs. 3–5). Further 1D and 2D NMR spectroscopic analysis revealed that a disaccharide, α-d-galactofuranosyl(1−>2)-α-l-rhamnopyranoside, is connected to the backbone of clostrienoic acid through an ester linkage in 3, which we termed clostrienose (Fig. 1c; Supplementary Table 2; Supplementary Fig. 7; Supplementary Methods). It is notable that the same disaccharide sequence has been found in several polysaccharides produced by microorganisms, and the relative configuration of each monosaccharide substituent in 3 was further confirmed by comparison to previously published NMR spectra19,20,21,22. An ester linkage between a sugar moiety and acid is rare, and only a few naturally occurring glycosyl esters have been previously reported, such as the β-d-glycosyl ester of 5-isoprenylindole-3-carboxylate isolated from Streptomyces sp. RM-5-823, a microbial modification product of A58365A from Streptomyces chromofuscus NRRL 1509824, and a glycosyl ester of 3,4-seco-triterpene25. The minor compound 2 was indicated to contain one monosaccharide substituent (α-l-rhamnopyranoside) based on HRMS/MS analysis, but the titer was too low to be further confirmed by NMR spectroscopic analysis (Supplementary Fig. 4).

In vitro biochemical analysis of PKS

Based on the structures of 1 and 3, we hypothesized that the single-module PKS could use malonyl-CoA substrates and function iteratively to yield a heptaketide intermediate. Further modifications by putative auxiliary enzymes such as enoyl reductase, isomerase/desaturase, and thioesterase would then form the clostrienoic core (1). To confirm that ca_c3355 encodes a functional iterative type I PKS, the 203 kDa megasynthase was overexpressed and purified from Escherichia coli strain BAP126. After incubating the purified PKS with 14C-labeled malonyl-CoA (generated in situ from 2-14C-malonic acid and CoA by malonyl-CoA synthase [MatB]27), the 14C-labeled covalent acyl-S-thiolation intermediate was detected by SDS–PAGE autoradiography (Supplementary Fig. 8). Further in vitro reconstitution of the activity of PKS with malonyl-CoA showed a dominant product, the triketide lactone 4, which is a typical shunt product after spontaneous cyclic off-loading of the unreduced triketide. Addition of NADPH to this reaction enabled function of the KR domain (and the subsequent DH domain), leading to the production of the known shunt products tetraketide pyrone 5 and pentaketide pyrone 6 (Supplementary Figs. 8, 9). Similar derailment in the normal programmed steps to yield the same shunt products has been observed in other iterative type I PKSs such as LovB28 and ApdA29. These results demonstrated that ca_c3355 encodes a highly reducing type I PKS that functions iteratively to condense malonyl-CoA monomers. Furthermore, these results indicated that additional biosynthetic enzymes are needed for generating 1 and 3, and their encoding genes are located elsewhere on the genome of C. acetobutylicum.

Impact of pks gene on ABE fermentation

To determine whether polyketide production influenced ABE fermentation, we compared the batch fermentation performance of wild-type C. acetobutylicum and Δpks (Fig. 2a–c; Supplementary Fig. 10). While both strains displayed similar growth curves and the expected acidogenic and solventogenic phases, Δpks showed stronger butanol production with ~10% increases in both butanol titer and productivity relative to wild type (Fig. 2a, b). Perhaps related to the difference in butanol production, the butyrate concentration profiles also differed for Δpks and wild type; in the Δpks culture, butyrate was produced more rapidly and reached a higher concentration during acidogenesis (0–20 h), and was re-assimilated earlier during the transition to solventogenesis (20–23 h) (Fig. 2c). This was also reflected in the pH profiles of the two strains, with the fall and rise of the culture pH (corresponding to the changes in metabolism) occurring earlier for Δpks (Fig. 2a). Although less apparent, small increases in acetone and ethanol production were also observed for Δpks relative to wild type (Fig. 2b). These results established a clear link between the pks gene and ABE fermentation, with improvements in solvent production associated with deletion of the pks gene.

Time-course batch fermentation evaluation of wild-type C. acetobutylicum and Δpks. a Culture density (measured as optical density at 600 nm, OD600) (left axis) and pH (right axis) from batch fermentations of wild type and Δpks. b Production of acetone, butanol, and ethanol from batch fermentations of wild type and Δpks. c Production of acetate and butyrate from batch fermentations of wild type and Δpks. d Production of compounds 1–3 from batch fermentation of wild-type C. acetobutylicum ATCC 824. As indicated, the green region represents the acid production phase of the fermentation (acidogenesis), while the blue region represents the solvent production phase (solventogenesis). Error bars represent the standard deviation of values from duplicate fermentations. Experiments were repeated at least three times independently

To further probe the relationship between the production of the three polyketides and the ABE fermentation profile, we obtained production time-course profiles of 1–3 for wild-type C. acetobutylicum (Fig. 2d). Maximum levels of 1 (clostrienoic acid) and 2 were observed during the same period as maximum butyrate/acetate concentrations (20–23 h), while the production of 3 (clostrienose) and butanol/acetone initiated at approximately the same time (~16 h) and increased for the remainder of the fermentation. These results suggest a direct, although currently unclear, link between polyketide production and the ABE fermentation phases, with the production of 1 and 2 associating with acidogenesis, and the production of 3 associating with solventogenesis. We propose that 1 and 2 are biosynthetic intermediates of the end product 3, and feeding studies with 1 and 2 showed that these compounds were readily converted to 3 in cultures of C. acetobutylicum Δpks.

Polyketides affect sporulation and granulose accumulation

To better understand the broader biological impacts of polyketide production on C. acetobutylicum metabolism and physiology, we performed a transcriptome comparison of Δpks and wild-type strains using RNA-Seq. Analysis of samples taken at early stationary phase revealed a total of 392 genes that were differentially expressed (expression fold change > 2.0, p-value < 0.003) between Δpks and wild type, with 282 genes downregulated and 110 genes upregulated in Δpks. STRING network analysis30 showed that the expression of genes related to four major cellular processes was downregulated in Δpks, including sporulation (33 genes), carbohydrate transport (21 genes), carbohydrate metabolism (33 genes), and carbohydrate transfer (11 genes), and the expression of genes related to four other major cellular processes was upregulated in Δpks, including sulfur metabolism (12 genes), cofactor biosynthesis (6 genes), stress response (8 genes), and amino-acid transport (8 genes) (Fig. 3; Supplementary Data 1). It is notable that no significant difference in the expression of the key solventogenic genes (including the crucial sol operon31) was observed, suggesting that the difference in butanol production between Δpks and wild type was not due to the direct transcriptional regulation of solventogenic genes by the polyketides. Consistent with the higher solvent production observed for Δpks, the major pathways upregulated in Δpks (particularly class I, III, and IV heat shock response machinery) have previously been associated with improved solvent tolerance in C. acetobutylicum 14,32,33.

RNA-Seq comparison of wild-type C. acetobutylicum and Δpks. STRING network analysis of genes predicted to be transcriptionally downregulated (left) and upregulated (right) by RNA-Seq in Δpks fermentation culture relative to wild type. Nodes represent differentially expressed genes, and lines represent predicted connections between genes including shared functional pathways of encoded proteins, chromosomal proximity, co-occurrence of genes in other organisms, co-expression of genes, and protein homology. For clarity, only genes with at least one predicted connection are shown. Four major concentrations of connected nodes were observed for each group (indicated by a–h), signifying the cellular pathways most affected by deletion of the pks gene. Detailed results from the RNA-Seq analysis are presented in Supplementary Data 1

The sporulation genes downregulated in Δpks include those encoding late-stage sporulation proteins such as spore coat and germination proteins, and the sporulation-specific sigma factor K (σK), one of the core regulators of sporulation in C. acetobutylicum 34. Notably, transcription of the gene encoding the well-known master regulator of sporulation and solvent production, Spo0A35, was not significantly affected in Δpks. To determine whether reduced sporulation was an observable property of Δpks as suggested by the RNA-Seq analysis, sporulation assays in both liquid and solid media were performed for wild-type C. acetobutylicum and Δpks. Indeed, a significant decrease in sporulation was observed for Δpks, with spore formation decreasing by 3–4 orders of magnitude in liquid culture (Fig. 4a), and by ~2 orders of magnitude on solid media (Supplementary Fig. 11). Furthermore, the level of sporulation for Δpks was partially restored when Δpks culture broth was supplemented with clostrienose (3) (Fig. 4a). Since granulose biosynthesis and accumulation is related to the sporulation cycle, we then performed standard granulose accumulation assays using iodine staining. Colonies which have accumulated granulose are expected to stain dark brown/purple following exposure to iodine vapor, with darker staining indicating higher granulose production. Following the trend observed for sporulation, a significant decrease in granulose accumulation was observed for Δpks (little to no staining), and the addition of 3 to Δpks culture completely restored granulose accumulation (even appearing to exceed levels observed for wild type) (Fig. 4b). These assays revealed that the polyketides are important, although not essential, for triggering both sporulation and granulose accumulation in wild-type C. acetobutylicum.

Phenotype comparison of wild-type C. acetobutylicum and Δpks. a Sporulation assay results for liquid cultures of wild type, Δpks, and Δpks supplemented with clostrienose (3). Values represent the number of heat-resistant colony forming units per mL following incubation in liquid CBM-S medium for 5 days. Error bars represent the standard deviation of biological triplicate cultures. Experiments were repeated at least three times independently. b Granulose accumulation assay results for wild type, Δpks, and Δpks supplemented with clostrienose (3). Patches containing high levels of granulose are expected to stain dark brown/purple. c Dissecting microscope images of individual wild-type and Δpks colonies. Black scale bar shows 1 mm in length

Interestingly, pks inactivation also affected colony morphology of C. acetobutylicum. While wild-type colonies were relatively flat in elevation and featured a distinctive “spore center” in the middle of the colony, Δpks colonies were distinctively raised in elevation and featured a highly textured surface with no distinguishable spore center (Fig. 4c). This behavior suggested that one or more of the polyketides might act as surfactants to permit colony spreading over the agar surface, as self-produced surfactants are known to permit surface motility in some microbes36. To test this, we performed standard assays for surfactant activity (oil spreading and drop collapse assays) using pure clostrienose (3), given that this compound displays some structural similarities to known non-ionic surfactants such as n-dodecyl-β-d-maltosides37 and rhamnolipids38. As shown in Supplementary Tables 3 and 4, clostrienose displayed weak surfactant activity at relatively high concentrations (100 µM), but little to no surfactant activity near physiological concentrations (10 µM) according to the oil spreading assay. Surfactant activity was not observed using the drop collapse assay at either concentration of clostrienose (10 or 100 µM).

Discussion

Clostridium is one of the largest bacterial genera, ranking second in size only to Streptomyces 39. While members of Streptomyces are known to be prolific producers of secondary metabolites40, only a handful of secondary metabolites have been discovered from Clostridium. However, recent genomic analysis has indicated that secondary metabolite gene clusters can be found among diverse members of this genus, prompting efforts to identify and characterize these “cryptic” secondary metabolites6. In this study, we identified a suite of polyketides (clostrienoic acid and clostrienose) from C. acetobutylicum, a well-studied solvent-producing anaerobe with no previously associated natural products.

Clostrienoic acid and clostrienose are biosynthesized by a predicted type I single-module PKS. Through in vitro reconstitution of the activity of purified PKS, we demonstrated that this megasynthase functions as a highly reducing iterative type I PKS. We propose that the PKS functions iteratively to generate a heptaketide intermediate, which is then modified by tailoring enzymes encoded elsewhere on the genome to yield clostrienoic acid. Two subsequent glycosylation events are proposed to install first the rhamnopyranoside group, followed by the galactofuranoside group (generating clostrienose) (Supplementary Fig. 12). The proposed sequential biosynthesis of the three polyketides is consistent with the production timing of 1–3 observed in batch fermentation of C. acetobutylicum. Although galactofuranose has previously been detected in cultures of C. acetobutylicum 41 and the predicted biosynthetic genes for both sugar moieties are present on the C. acetobutylicum genome, the dedicated glycosyltransferases employed for the production of 3 are unclear. Due to the apparent non-clustered nature of genes encoding the enzymatic partners of PKS and the observation that hundreds of genes were upregulated along with ca_c3355 at early stationary phase in C. acetobutylicum, extensive future work is needed to identify additional biosynthetic genes and elucidate the complete biosynthetic pathway of 3.

Considering all of our results, comparison of wild-type C. acetobutylicum and Δpks along with chemical complementation of Δpks strongly suggest that the identified polyketide, clostrienose (3), serves as a signaling molecule that regulates granulose accumulation and sporulation in C. acetobutylicum. For clarity, we define “signaling molecule” here as a biologically derived secreted small molecule, which acts to directly or indirectly regulate gene expression (beyond that related to metabolizing or detoxifying the molecule)42,43. Although cellular communication by signaling small molecules has been reported in a variety of Gram-negative and Gram-positive bacteria, with well-known examples such as N-acyl-homoserine lactones44, 4-quinolones45, γ-butyrolactones46, and autoinducer (AI)-247, few signaling small molecules have been reported from Clostridium. In addition to clostrubin, which helps the pathogen C. puniceum access aerobic territory9, a putative AI-2-like system was reported to be involved in stimulating toxin production in C. perfringens 48. Furthermore, gene clusters with homology to the well-studied accessory gene regulator (agr) quorum sensing system have been shown to be important for cellular processes such as toxin production49,50,51,52, biofilm formation49, and sporulation52,53 in several Clostridium species, although none of these studies identified the molecular structure of the presumed bioactive small molecules. This work provides solid evidence that cellular differentiation can be regulated by secondary metabolites in Clostridium, and has revealed the molecular identity of the signal responsible for this behavior.

Although clostrienose displayed only weak surfactant activity near physiological concentrations observed under batch fermentation conditions (<6 µM), the possible role of clostrienose as both a biosurfactant as well as a signaling molecule draws interesting parallels to previously studied biosurfactants, which are known to act as signaling molecules to regulate gene expression. In the well-studied case of surfactin (widely classified as a quorum sensing signaling molecule54,55,56), this self-generated biosurfactant is known to regulate gene expression necessary for triggering extracellular matrix (ECM) production and efficient sporulation in Bacillus subtilis 54,57. Interestingly, surfactin is able to alter gene expression by forming membrane pores, which selectively leak potassium ions. The decrease in intracellular potassium is sensed by the membrane histidine kinase KinC, which then activates the regulatory circuit leading to ECM production54,55. In another case, N-acyl-homoserine lactones (AHLs, a well-known class of signaling molecules58,59) natively produced by the bacterium Rhizobium etli were shown to act as both biosurfactants and quorum sensing molecules to promote surface colonization60. These examples illustrate that self-produced biosurfactants are not restricted to their physiochemical role in decreasing surface tension, and can also serve to regulate gene expression by acting as signaling molecules for some microbes. For the case of C. acetobutylicum, it would be interesting to determine if clostrienose features a mode of action similar to that of surfactin.

Although extensive future work is needed to characterize the full regulatory network through which clostrienose controls cellular differentiation, results from our RNA-Seq analysis suggest that transcriptional regulation of the sporulation-specific sigma factor, σK, may play an important role in the mode of action. Based on our RNA-Seq results, we observed the downregulation of 33 genes related to sporulation, in particular, genes related to late endospore development (stages IV and V of the sporulation cycle12) and spore germination in Δpks relative to wild type (Supplementary Data 1). Of the well-characterized regulators of sporulation in C. acetobutylicum ATCC 824 (including Spo0A, σH, σE, σF, σG, and σK)12,61,62,63, only the gene encoding σK (sigK [ca_c1689]) was significantly downregulated in Δpks at the time of analysis (26 h post inoculation). A putative sigma factor encoded by ca_p0157 (believed to be involved in regulating very late-stage sporulation based on a prior study64) was also significantly downregulated in Δpks, suggesting that transcription of this regulator may be under the control of σK. It was reported recently that σK performs two developmentally separated roles in C. acetobutylicum ATCC 824, one in early sporulation and one in late sporulation34. In early sporulation, σK is important for upregulation of Spo0A, the master regulator of sporulation and solvent production. For this early role, sigK likely requires transcriptional activation by σE. Since Spo0A is important for initiating both solventogenesis and sporulation, sigK deletion results in low solvent, non-sporulating cultures. In late sporulation, σK is important for stage IV spore development, including assembly of the spore coat. For this late role, σK activation is σG dependent, likely through contributions of the σG dependent genes spoIVFB [ca_c1253] and spoIVB [ca_c2072], which are proposed to be required for post-translational processing of pro-σK to the mature σK form. Considering our results, we hypothesize that transcriptional downregulation of sigK in Δpks at this stage of the fermentation is relevant to the role of σK in late-stage spore development, as Δpks displayed severe reductions in observed sporulation rates, but ABE production was not decreased as would be expected for weakened early-stage σK activity. As we expect that some or all of sporulation genes downregulated in Δpks are members of the σK regulon, this suggests that clostrienose may have some role in stimulating late-stage σK activity, and thus, late-stage sporulation. Given what is known about the regulatory relationships between well-characterized sporulation sigma factors in C. acetobutylicum 12, we hypothesize that clostrienose may act to regulate late-stage σK activity through an unknown pathway between σG and σK, possibly involving contributions in post-translational regulation of σK from the σG-dependent enzymes SpoIVFB and SpoIVB (the encoding genes of which were also downregulated in Δpks) (Supplementary Data 1). While extensive follow up work is required to validate this hypothesis, this proposed mechanism could help to explain the means by which σG activates late σK activity in C. acetobutylicum, which is currently unknown12.

Solventogenic strains of Clostridium (such as C. acetobutylicum) were employed for industrial solvent production as early as 1916, and were eventually the source of 66% of US butanol production in 194510. Although industrial operations of this process largely ceased during the 1950s due to the growth of the petrochemical industry, ABE fermentation has recently gained renewed interest given the wide range of agricultural feedstocks, which can be converted to various commodity chemicals and potential biofuels using this process65. However, some drawbacks still exist that prevent the widespread use of ABE fermentation, such as low solvent titer/productivity due to solvent toxicity, and unfavorable cellular differentiation66. Rather than pursuing a traditional metabolic engineering strategy that focuses on the core metabolic pathway for solvent production, our work showcases an alternative approach by manipulating the secondary metabolism of the organism to improve traits significant for industrial ABE fermentation performance. In particular, given that both granulose biosynthesis and sporulation are undesirable traits for industrial fermentation (as granulose accumulation results in reduced solvent yields, and metabolically inactive spores do not contribute to solvent production)66, the reduced granulose accumulation and sporulation associated with Δpks represent improved industrial traits. Furthermore, although none of the solvent producing genes were upregulated in Δpks relative to wild type, both butanol titer and productivity were increased in Δpks. This may be explained by the decreased commitment of cells to sporulation in Δpks (yielding a higher proportion of cells capable of solvent production), as well as the upregulation of cellular machinery related to butanol stress and adaptation as indicated by transcriptomic analysis.

In summary, we have discovered a family of novel polyketides that are biosynthesized by a highly reducing iterative type I PKS in C. acetobutylicum ATCC 824. In addition to the type II PKS-derived clostrubin, our work provides the second example of polyketide metabolites from a strictly anaerobic bacterium, and encourages continued efforts in exploring the uncharted terrain of secondary metabolites in the anaerobic world. We have further shown that the newly identified polyketides are important for stimulating sporulation and granulose accumulation in C. acetobutylicum, adding to the extremely limited inventory of known signaling molecules used by Clostridium to control cellular physiology and metabolism. Furthermore, this work has yielded an engineered strain of C. acetobutylicum with improved traits for industrial ABE fermentation (reduced sporulation, reduced granulose accumulation, and increased butanol titer and productivity), demonstrating a novel strategy of manipulating secondary metabolism as a means of improving this important renewable bioprocess.

Methods

Bacterial strains and media

C. acetobutylicum ATCC 824 was cultured in an anaerobic chamber (Coy Laboratory Products) containing an atmosphere of 97% nitrogen and 3% hydrogen. 2xYTG medium67 contained 16 g/L tryptone, 10 g/L yeast extract, 5 g/L NaCl, and 10 g/L glucose (unless noted otherwise) with the pH adjusted to 5.2 for liquid media, and 5.8 for solid media (also containing 15 g/L agar). Clostridial growth medium (CGM)68 contained 30 g/L glucose (unless noted otherwise), 6.25 g/L yeast extract, 2.5 g/L ammonium sulfate, 1.25 g/L NaCl, 2.5 g/L asparagine, 0.95 g/L monobasic potassium phosphate, 0.95 g/L dibasic potassium phosphate, 0.5 g/L magnesium sulfate heptahydrate, 13 mg/L manganese sulfate heptahydrate, and 13 mg/L iron sulfate heptahydrate with the pH adjusted to 6.4. P2 medium69 contained 80 g/L glucose (unless noted otherwise), 1 g/L yeast extract, 2.2 g/L ammonium acetate, 0.5 g/L potassium phosphate monobasic, 0.5 g/L potassium sulfate dibasic, 0.2 g/L magnesium sulfate heptahydrate, 1 mg/L para-aminobenzoic acid, 1 mg/L thiamine hydrochloride, 10 µg/L biotin, 10 mg/L manganese sulfate heptahydrate, 10 mg/L ferrous sulfate heptahydrate, and 10 mg/L NaCl with the pH adjusted to 6.4. Clostridial basal medium (CBM)70 contained 10 g/L glucose, 0.5 g/L monobasic potassium phosphate, 0.5 g/L dibasic potassium phosphate, 4 g/L tryptone, 0.2 g/L magnesium sulfate heptahydrate, 10 mg/L manganese sulfate heptahydrate, 10 mg/L ferrous sulfate heptahydrate, 1 mg/L para-aminobenzoic acid, 1 mg/L thiamine hydrochloride, and 2 µg/L biotin with the pH adjusted to 6.9. For solid CGM plates, 15 g/L agar was added. CBM-S (used for liquid sporulation assays) was identical to CBM except 50 g/L glucose was used, and 5 g/L CaCO3 was added just prior to inoculation of cultures. E. coli TOP10 (Thermo Fischer Scientific) was grown in Luria-Bertani (LB) medium at 37 °C. For the appropriate Clostridium strains, culture media was supplemented with erythromycin (Ery; 40 µg/mL for solid media, 80 µg/mL for liquid media) and/or thiamphenicol (Th; 5 µg/mL for solid and liquid media). Kanamycin (Kan; 60 µg/mL) or chloramphenicol (Cm; 25 µg/mL) were added to E. coli culture media as indicated. Clostridium and E. coli strains were maintained as 20% v/v glycerol stocks stored at −80 °C.

Plasmid construction

Oligonucleotides were provided by Integrated DNA Technologies (Supplementary Table 5). Phusion polymerase (NEB) was used for all PCR reactions. For isolation of genomic DNA from C. acetobutylicum ATCC 824, an alkaline lysis method was used71. C. acetobutylicum was cultured overnight in 2xYTG medium to stationary phase (OD600 > 2.0), at which point 10 mL of culture was centrifuged at 3500×g for 15 min (room temperature). The supernatant was discarded and the cell pellet was resuspended in 5 mL SET buffer (75 mM NaCl, 25 mM EDTA pH 8.0, 20 mM Tris-HCl, pH 7.5). Lysozyme was added to a final concentration of 2 mg/mL, and the solution was gently mixed. The mixture was incubated at 37 °C for 60 min with gentle mixing performed every 15 min. Following the incubation period, 660 µL of lysis buffer (1 M NaOH, 10% w/v SDS) was added, and the solution was thoroughly mixed. Proteinase K was added to a final concentration of 0.5 mg/mL, and the solution was incubated at 55 °C for 1 h. Following this incubation period, an equal volume of phenol:chloroform (1:1) was added, and the solution was mixed by inversion for 5 min. The solution was then centrifuged at 3500×g for 15 min (room temperature), and the upper aqueous phase was discarded by pipetting. To the organic phase, 3 M sodium acetate was added (10% v/v in final solution). To precipitate genomic DNA, 2 volumes of ethanol were added and the solution was mixed. Precipitated genomic DNA was collected using a glass hook, and washed with 70% ethanol. The washed DNA was then dried over nitrogen gas for 15 min, resuspended in low TE buffer (10 mM Tris, 0.1 mM EDTA, pH 8.0), and dissolved by incubation at 50 °C.

For constructing plasmid pKO_mazF_mod (which would later serve as a template for pKO_pks), primers pKON_Fo and pKON_Ro were used to PCR amplify a 5.0 kb region from the pKO_mazF template15. This step was necessary to remove a 677 bp region from the pKO_mazF backbone, which we were unable to amplify via PCR. The 5.0 kb PCR product was gel purified, digested at the 5′ and 3′ ends using PshAI, ligated to form pKO_mazF_mod, and transformed into E. coli TOP10. Transformant clones were screened by purified plasmid test digestion, and Sanger sequencing was used to confirm the sequence of the final pKO_mazF_mod clone. For constructing plasmid pKO_pks (for deletion of the pks gene from C. acetobutylicum), a 3.8 kb region containing colE1, repL, bgaR, and mazF were PCR amplified from pKO_mazF_mod using primers pKO_F and pKO_R. Additionally, primers UHR_Fo and UHR_Ro, and DHR_Fo and DHR_Ro were used to PCR amplify 1 kb regions representing the upstream and downstream homologous regions (UHR and DHR) flanking the pks gene (CA_C3355) from a C. acetobutylicum ATCC 824 genomic DNA template. The chloramphenicol/thiamphenicol resistance gene and constitutive promoter (P ptb from C. acetobutylicum) were PCR amplified from pKO_mazF_mod using primers CMR_F and CMR_R (1.1 kb region). These four PCR products were ligated via Gibson assembly and transformed into E. coli TOP10. Transformant clones were screened by purified plasmid test digestion, and Sanger sequencing was used to confirm the sequence of the final pKO_pks clone. For constructing plasmid pAN315 (necessary for methylation of pKO_pks and pCKO_pks prior to transformation into C. acetobutylicum), a 6.4 kb region from plasmid pAN172 was amplified using primers pAN1_F and pAN1_R, and a 1.0 kb region containing the kanamycin resistance gene from vector pCOLA_Duet was amplified using primers KAN_Fo and KAN_Ro. The gel extracted PCR products were ligated via Gibson assembly and transformed in to E. coli TOP10. Transformant clones were screened by purified plasmid test digestion, and Sanger sequencing was used to confirm the sequence of the final pAN3 clone. For constructing plasmid pCKO_pks (for expression of the pks gene under the constitutive crotonase [crt] promoter from C. acetobutylicum), primers CPKS_Fo and CPKS_Ro were used to PCR amplify the 5.4 kb C. acetobutylicum ATCC 824 pks gene (CA_C3355) with appropriate overhangs for Gibson assembly. The pWIS_empty vector71 backbone (containing the constitutive crt promoter upstream of the multiple cloning site) was PCR amplified using primers pWIS_F and pWIS_R yielding a 5.0 kb product. The two gel purified PCR products were ligated via Gibson assembly and transformed into E. coli TOP10. Transformant clones were screened by purified plasmid test digestion, and Sanger sequencing was used to confirm the sequence of the final pCKO_pks clone.

For constructing plasmid pET24b_pks, the 5.4 kb C. acetobutylicum ATCC 824 pks gene (CA_C3355) was amplified from C. acetobutylicum genomic DNA using primers PKS_Fo and PKS_Ro. Doubly digested vector pET24b (EcoRI/XhoI digested) was ligated with doubly digested pks PCR product (EcoRI/XhoI digested), and the ligation product was transformed into E. coli TOP10. Transformant clones were screened by purified plasmid test digestion, and Sanger sequencing was used to confirm the sequence of the final pET24b_pks clone.

Electro-transformation of C. acetobutylicum

Prior to transformation into C. acetobutylicum, vector pKO_pks was co-transformed with pAN3 into E. coli TOP10 via electroporation. This procedure permitted methylation of pKO_pks necessary for overcoming the native restriction-modification system active in C. acetobutylicum 72. Plasmid purification of E. coli pKO_pks/pAN3 liquid culture was performed, and the resulting plasmid mixture was used for electroporations of C. acetobutylicum using the previously published method72 which we detail here. To prepare electrocompetent cells, a single colony of C. acetobutylicum from a 2xYTG plate (more than 1 week old) was heat shocked at 80 °C for 10 min, and used to inoculate 10 mL CGM. After incubating overnight at 37 °C and reaching mid-exponential phase (OD600 0.4–0.9), 6 mL culture was used to inoculate 54 mL fresh 2xYTG. This subculture was incubated at 37 °C until reaching OD600 1.2 (~5 h), at which point the subculture was centrifuged at 3500×g for 20 min (4 °C). Following removal of the supernatant, the cell pellet was resuspended in 20 mL ice-cold electroporation buffer (EPB; 270 mM sucrose, 5 mM NaH2PO4, pH 7.4). The resuspended cells were centrifuged at 3500×g for 10 min (4 °C), the supernatant was discarded, and the cell pellet was resuspended in 20 mL ice-cold EPB. After a final pelleting by centrifugation at 3500×g for 10 min (4 °C), the supernatant was discarded, and the pellet was resuspended in 2.3 mL ice-cold EPB. This final resuspension was used as the stock of electrocompetent cells. Electro-transformations were performed by first mixing (over ice) 500 µL competent cells and ~20 µL of plasmid DNA solution (1–5 µg total) to be transformed. The mixture was transferred to a 0.4 cm electroporation cuvette, and allowed to incubate on ice for 15 min. Electroporations were performed with the following parameters: voltage, 2000 V; capacitance, 25 µF; resistance, infinite Ω. Following electroporation, samples were resuspended in 1 mL 2xYTG and transferred to a tube containing 9 mL 2xYTG. After mixing by inversion, the cultures were allowed to recover at 37 °C for 4 h. The recovery cultures were centrifuged at 3500×g for 15 min (room temperature), and the supernatant was discarded. The cell pellet was resuspended in 500 µL 2xYTG, and 100 µL was plated onto solid 2xYTG plates supplemented with the appropriate antibiotic. The plate was incubated at 37 °C for 2–3 days, and transformant colonies were subjected to PCR-based verification.

Deletion of pks gene and genetic complementation

Targeted KO of the pks gene (ca_c3355) in C. acetobutylicum ATCC 824 was achieved using the previously published method15. In detail, 5 µg of methylated pKO_pks/pAN3 plasmid mixture was transformed into C. acetobutylicum using the method described above. Following recovery in liquid 2xYTG medium for 4 h, the cell pellets were collected by centrifugation (3500×g, 15 min, room temperature), resuspended in 0.5 mL of fresh liquid 2xYTG, and 100 µL of the resuspended cell culture was plated on solid 2xYTG + 5 µg/mL Th + 40 mM β-lactose plates. Under these plating conditions, only cells which have undergone the desired double crossover homologous recombination event are expected to survive. Counterselection of the vector backbone is provided by the lactose-inducible promoter (P bgaL ), which drives the toxin gene mazF on the pKO_pks vector backbone. Following this plating procedure, roughly 10 colonies were observed on the 2xYTG + 5 µg/mL Th + 40 mM β-lactose plates. Of these 10 colonies, four were twice restreaked and subjected to colony PCR verification. Four sets of primers were used as the basis of colony PCR verification, as detailed in Supplementary Fig. 2.

For generating the pks genetic complementation strain [∆pks (pCKO_pks)], electroporation of ∆pks C. acetobutylicum with a pCKO_pks/pAN3 plasmid mixture was performed as described above. Following electroporation and recovery, cultures were plated on solid 2xYTG + 5 µg/mL Th + 40 µg/mL Ery media. After twice restreaking on solid 2xYTG + 5 µg/mL Th + 40 µg/mL Ery media, potential colonies harboring pCKO_pks were screened via colony PCR using primers pCKO_F and pCKO_R.

LC-HRMS metabolomic analysis

For untargeted metabolomic comparisons of wild-type and ∆pks C. acetobutylicum, single colonies of each strain were heat shocked at 80 °C for 10 min and used to inoculate 10 mL of liquid CGM (30 g/L glucose). Following overnight incubation (stagnant) until reaching OD600 ~1.0, these cultures were used to inoculate 10 mL of liquid CGM (80 g/L glucose) with a 10% inoculum for subculturing. After ~5 h (OD600 ~1.0) of stagnant growth, the subcultures were used to inoculate quadruplicate flask fermentations (70 mL CGM, 80 g/L glucose + 5 µL Antifoam 204, 3% inoculum) agitated via magnetic stir bars. Calcium carbonate (6 g/L) was supplemented to the fermentation media for pH buffering. All culturing was performed at 37 °C. About 5 µg/mL Th was included in all cultures of ∆pks with the exception of the final fermentation culture, as certain antibiotics are known to perturb the ABE fermentation phases. Samples of fermentation broth (1 mL) from each replicate were taken during early stationary phase and extracted with 3 mL of 2:1 chloroform methanol. The mixtures were vortexed, separated via centrifugation (2700×g, 10 min), and the bottom chloroform-rich layer was transferred to a glass vial. These organic extracts were dried with nitrogen gas, resuspended in 100 µL methanol, and 10 µL was injected onto an Agilent Technologies 6520 Accurate-Mass QTOF LC-MS instrument fitted with an Agilent Eclipse Plus C18 column (4.6 × 100 mm). A linear gradient of 2–98% CH3CN (vol/vol) over 40 min in H2O with 0.1% formic acid (vol/vol) at a flow rate of 0.5 mL/min was used. The metabolomic analysis platform XCMS16 (The Scripps Research Institute) was used to compare the metabolomes of wild-type and ∆pks strains based on the quadruplicate LC-HRMS data. MS peaks unique to ∆pks (Fig. 1a) were identified using the following parameters: p-value < 0.01, fold change > 10.0, peak intensity > 5000.

Bioreactor fermentations

To compare ABE fermentation profiles of wild-type and ∆pks C. acetobutylicum, bioreactor fermentations were carried out in DASGIP Bioreactors (4 × GPI 100 Vessels, DASGIP Bioblock System) with 500 mL working volumes. Overnight cultures (10 mL CGM, 30 g/L glucose, stagnant, 34 °C) inoculated with heat shocked individual colonies of C. acetobutylicum were cultured until reaching OD600 ~1. A 10% inoculum was then used to start a subculture (30 mL P2 media, 80 g/L glucose, stagnant, 34 °C), and the subculture was incubated until reaching OD600 ~1. The 30 mL subcultures were then aseptically transferred into individual DASGIP Bioreactors pre-loaded with 500 mL P2 medium (80 g/L glucose, 100 µL Antifoam 204, 34 °C). The fermentations were allowed to proceed for 54 h with periodic sampling for optical density measurements, fermentation product analysis, and quantification of compounds 1, 2, and 3. The temperature was maintained at 34 °C throughout the fermentation, agitation was provided by stirring at 200 rpm, and the pH was maintained above 5.0 via automatic addition of 3 M NH4OH. To maintain anaerobic conditions, oxygen-free nitrogen gas was sparged at a rate of 2 sL/h for the duration of the fermentation. For quantification of compounds 1, 2, and 3, 1 mL of fermentation broth was mixed with 3 mL ethyl acetate, vortexed, separated via centrifugation (2700×g, 10 min, room temperature), and the upper organic layer isolated. The organic layer was dried by rotary evaporation, resuspended in 200 µL methanol, and 20 µL was injected onto an Agilent Technologies 6120 Quadrupole LC-MS (with DAD) instrument fitted with an Agilent Eclipse Plus C18 column (4.6 × 100 mm). A linear gradient of 2–98% CH3CN (vol/vol) over 40 min in H2O with 0.1% formic acid (vol/vol) at a flow rate of 0.5 mL/min was used. Compounds 1, 2, and 3 were identified by UV absorption (240 nm) as demonstrated in Fig. 1b, and were quantified by the integrated peak area (absorbance at 240 nm).

Fermentation analytical procedures

A spectrophotometer was used to determine cell densities by measuring the optical density at 600 nm (OD600). A Shimadzu Prominence UFLC system fitted with a Biorad Aminex HPX-87H column (300 mm × 7.8 mm) was used to analyze C. acetobutylicum fermentation broth for the concentration of glucose and fermentation products (acetate, butyrate, lactate, acetone, butanol, and ethanol). Samples of fermentation broth (1 mL) were first pelleted by centrifugation at 10,000×g for 3 min, followed by filtration of the supernatant using a 0.22 micron PVDF syringe filter. Samples of filtered supernatant (20 µL) were injected onto the UFLC system with 0.01 N sulfuric acid mobile phase flowing at 0.7 mL/min, column temperature of 35 °C, and were chromatographed for 35 min. Analytes were detected by use of a refractive index detector (used to quantify concentrations of glucose, acetate, lactate, butanol, and ethanol) and a diode array detector (used to quantify concentrations of butyrate (208 nm) and acetone (265 nm)).

RNA isolation and RNA-Seq analysis

Samples (10 mL) of fermentation broth were taken in biological triplicate from bioreactor fermentations of wild-type and ∆pks C. acetobutylicum 26 h post inoculation. The samples were centrifuged (4000×g, 10 min, 4 °C) and the pellets were resuspended and stored in RNAprotect Cell Reagent (Qiagen). Total RNA was extracted using an RNeasy Mini Kit (Qiagen) according the manufacturer’s instructions. An on-column DNase treatment was performed using DNase I (RNase-free) (NEB). RNA quality control, library construction, and library sequencing were performed by the University of California-Berkeley QB3 Functional Genomics Laboratory and Vincent J. Coates Genomic Sequencing Laboratory. RNA quality and concentration was assessed using a nanochip on an Agilent 2100 Bioanalyzer. Bacterial 16S and 23S rRNA was removed using a RiboZero Kit (Illumina). The resulting messenger RNA (mRNA) was converted to an RNA-Seq library using an mRNA-Seq library construction kit (Illumina). RNA library sequencing was performed on an Illumina HiSeq4000 with 50 bp single end reads. Sequencing reads (50 bp) were processed and mapped to the C. acetobutylicum ATCC 824 genome (NCBI accession NC_003030.1 [chromosome] and NC_001988.2 [megaplasmid]) using CLC Genomics Workbench 9.0 with default parameters. Reads that did not uniquely align to the genome were discarded. Differences in gene expression between wild-type and ∆pks C. acetobutylicum were calculated using the same software. Genes were considered differentially expressed with p-value < 0.003 (based on an unpaired t-test, n = 3) and |normalized fold change |> 2.0. False discovery rate corrections to p-values were calculated in CLC Genomics Workbench 9.0 using a published method73. Results of the RNA-Seq analysis are presented in Supplementary Data 1. STRING analysis30 was performed to determine putative protein–protein interactions between the differentially expressed genes revealed by RNA-Seq analysis.

Phenotype comparison assays

Liquid sporulation assays were performed with minor modifications74. Samples were taken from biological triplicate liquid cultures after 5 days of incubation (30 mL CBM-S, 37 °C). The 20 µL samples were heat shocked (80 °C, 10 min), dilutions (101–106) were spotted on 2xYTG plates, and colonies were enumerated after 30 h of incubation (37 °C) to calculate the number of heat-resistant colony forming units (cfu/mL). For chemical complementation of ∆pks in the liquid sporulation assay, purified clostrienose (final concentration 3.5 µM) was supplemented in CBM-S cultures of ∆pks C. acetobutylicum at the time of inoculation. Since compound 3 was added as a concentrated solution in methanol, the equivalent volume of methanol (60 µL) was added to all other liquid sporulation assay cultures (wild-type and non-complemented ∆pks) to control for this effect.

For solid sporulation assays, a previously described method75 was employed with some modifications. In detail, heat shocked (80 °C, 10 min) individual colonies were cultured in liquid media (10 mL CGM, 37 °C) for 24 h. Cultures were diluted by a factor of 106 and plated on solid CBM. Sampling was conducted 1, 2, 3, 4, and 6 days following initial plating. For sampling, three individual colonies were combined and thoroughly resuspended in 60 µL of liquid CGM. 20 µL of the resuspended colony mixture was then heat shocked (80 °C, 10 min), dilutions (101–106) were spotted on 2xYTG plates, and colonies were enumerated after 30 h of incubation (37 °C) to calculate the number of heat resistant colony forming units (cfu/colony). All samples were performed as biological triplicates.

Granulose accumulation assays were performed via iodine staining53. Mid-log phase (OD600 ~0.6) liquid cultures (P2, 37 °C) were plated on solid 2xYTG medium with elevated glucose levels (50 g/L) to enable granulose production. The plates were incubated at 30 °C for 4 days, at which point they were stained by exposure to a bed of iodine crystals for 10 min. The plates were then allowed to destain for 10 min prior to imaging. For chemical complementation of ∆pks in the granulose accumulation assay, purified clostrienose (final plate concentration 4.0 µM) was embedded in solid 2xYTG plates prior to plating of ∆pks culture. Since clostrienose was added to 2xYTG plates as a concentrated solution in methanol (mixed into the molten media prior to solidification), the equivalent volume of methanol (6 µL) was added to all other 2xYTG plates used in the granulose accumulation assays to control for this effect.

Individual colonies of C. acetobutylicum cultured on CBM plates for 48 h (37 °C) were viewed and imaged using a Leica MZ16 F dissecting microscope fitted with a Leica DFC300 FX camera.

Oil spreading assays were performed as previously described76,77,78. In detail, A 400 mL glass beaker (7.5 cm inner diameter) was filled with 300 mL water, and a 10 µL droplet of paraffin lamp oil was added and allowed to spread into a thin film on the water surface over a 5 min period (~25 mm in diameter). Solutions of surfactin, purified clostrienose, and a potassium phosphate buffer control were prepared at the indicated pH and concentration (prepared in 10 mM potassium phosphate buffer). About 10 µL of sample was carefully added to the center of the oil film, and the effect on the oil film was observed. Samples with surfactant activity are expected to form stable circular clearing zones in the oil film, with more potent surfactant activity corresponding to larger clearing zones (or complete dispersion of the oil film for very-high-surfactant activity). Drop collapse assays were performed77,79,80. Circular microwells (8 mm inner diameter) within the polystyrene lid of a 96-microwell plate (12.7 × 8.5 cm) were coated with a thin layer of paraffin lamp oil by adding 2.0 µL of paraffin lamp oil to each well, and allowing the droplet to spread evenly over the microwell over a 1 h period. Samples of surfactin, purified clostrienose, and potassium phosphate control were prepared as for the oil spreading assays. About 5 µL of sample was carefully added to the center of the microwell. After 5 min, the shape and degree of spreading of the droplet was observed. While buffer controls are expected to form stable beads on the microwell surface, samples containing surfactant are expected to collapse and spread over the microwell surface, with more potent surfactant activity corresponding to a higher degree of droplet spreading.

Purification and in vitro analysis of PKS protein

To purify the His6-tagged PKS protein for in vitro analysis, pET24b_pks was transformed into E. coli BAP1. A single colony was inoculated into 10 mL LB + 50 µg/mL kanamycin (Kan) for overnight growth at 37 °C. About 7 mL of overnight culture was used to inoculate 700 mL LB + 50 µg/mL Kan, and the culture was shaken at 240 rpm and 37 °C until reaching OD600 of 0.5. After icing the culture for 10 min, isopropyl thio-β-d-galactoside (IPTG) was added to a final concentration of 0.1 mM to induce protein expression, and the culture was incubated at 16 °C for 16 h. The cells were harvested by centrifugation (5500×g, 4 °C, 20 min), resuspended in 25 mL lysis buffer (25 mM HEPES, pH 8.0, 0.5 M NaCl, 5 mM imidazole), and lysed by homogenization over ice. Cell debris was removed by centrifugation (17,700×g, 4 °C, 60 min), and Ni-NTA agarose resin was added to the supernatant (2 mL/L culture). The mixture was nutated at 4 °C for 1 h, loaded onto a gravity flow column, and the PKS protein was eluted with increasing concentrations of imidazole in Buffer A (20 mM HEPES, pH 8.0, 1 mM DTT). Purified PKS protein was concentrated and buffer exchanged into Buffer A + 10% glycerol using a Vivaspin Centrifugal Concentrator. Aliquots of purified PKS protein were aliquoted and flash frozen in liquid nitrogen. The approximate protein yield was 5 mg/L (203 kDa).

A PKS loading assay with 14C-labeled substrate contained, in a total volume of 15 µL, 4 mM ATP, 2 mM MgCl2, 1 mM TCEP, 0.5 mM CoA, 2-14C-malonic acid (0.1 µCi), 10 µM MatB, 17 µM PKS, and 50 mM HEPES, pH 8.0. After 2 h of incubation at 25 °C, samples were quenched by adding an equal volume of 1× SDS sample buffer. Following SDS–PAGE analysis with a 4–15% TGX gel (Criterion), the gel was dried for 2 h at 50 °C and exposed on a storage phosphor screen (20 × 25 cm; Molecular Dynamics) for 5 days. Radiolabeled protein was imaged on a Typhoon 9400 phosphorimager (Storage Phosphor mode, 50 μm resolution; Amersham Biosciences).

For in vitro product assays (50 µL) of the PKS protein, 8 µM of PKS was incubated with malonyl-CoA (2 mM) in phosphate buffer (100 mM, pH 7.0) at room temperature for 2 h to generate compound 4, identified by comparison to a chemical standard. NADPH (2 mM) was added to the assay to generate compounds 5 and 6, both of which were identified by comparison to chemical standards. Following incubation, the assay mixtures were extracted twice with 100 µL of 99% ethyl acetate/1% acetic acid (v/v). The organic extracts were dried and resuspended in 100 µL of methanol, and 10 µL was injected onto an Agilent Technologies 6120 Quadrupole LC-MS (with DAD) instrument fitted with an Agilent Eclipse Plus C18 column (4.6 × 100 mm). A linear gradient of 2–98% CH3CN (vol/vol) over 40 min in H2O with 0.1% formic acid (vol/vol) at a flow rate of 0.5 mL/min was used. LC-HRMS analysis of the assay extracts was performed on an Agilent Technologies 6520 Accurate-Mass QTOF LC-MS instrument fitted with an Agilent Eclipse Plus C18 column (4.6 × 100 mm) using the same solvent gradient and flow rate described above.

Data availability

RNA-seq data generated in this study have been deposited in ArrayExpress (https://www.ebi.ac.uk/arrayexpress/) under accession number E-MTAB-6019. All other relevant data are available from the authors upon request.

References

Fischbach, M. A. & Walsh, C. T. Assembly-line enzymology for polyketide and nonribosomal peptide antibiotics:logic, machinery, and mechanisms. Chem. Rev. 106, 3468–3496 (2006).

Hertweck, C. The biosynthetic logic of polyketide diversity. Angew. Chem. Int. Ed. 48, 4688–4716 (2009). .

Newman, D. J. & Cragg, G. M. Natural products as sources of new drugs over the 30 years from 1981 to 2010. J. Nat. Prod. 75, 311–335 (2012).

Raaijmakers, J. M. & Mazzola, M. Diversity and natural functions of antibiotics produced by beneficial and plant pathogenic bacteria. Annu. Rev. Phytopathol. 50, 403–424 (2012).

Behnken, S. & Hertweck, C. Anaerobic bacteria as producers of antibiotics. Appl. Microbiol. Biotechnol. 96, 61–67 (2012).

Letzel, A.-C., Pidot, S. J. & Hertweck, C. A genomic approach to the cryptic secondary metabolome of the anaerobic world. Nat. Prod. Rep. 30, 392–428 (2013).

Paredes, C. J., Alsaker, K. V. & Papoutsakis, E. T. A comparative genomic view of clostridial sporulation and physiology. Nat. Rev. Microbiol. 3, 969–978 (2005).

Pidot, S., Ishida, K., Cyrulies, M. & Hertweck, C. Discovery of clostrubin, an exceptional polyphenolic polyketide antibiotic from a strictly anaerobic bacterium. Angew. Chem. Int. Ed. Engl. 126, 7990–7993 (2014).

Shabuer, G. et al. Plant pathogenic anaerobic bacteria use aromatic polyketides to access aerobic territory. Science 350, 670–674 (2015).

Jones, D. T. & Woods, D. R. Acetone-butanol fermentation revisited. Microbiol. Rev. 50, 484–524 (1986).

Lütke-Eversloh, T. & Bahl, H. Metabolic engineering of Clostridium acetobutylicum: recent advances to improve butanol production. Curr. Opin. Biotechnol. 22, 634–647 (2011).

Al-Hinai, M. A., Jones, S. W. & Papoutsakis, E. T. The clostridium sporulation programs: diversity and preservation of endospore differentiation. Microbiol. Mol. Biol. Rev. 79, 19–37 (2015).

Reysenbach, A. L., Ravenscroft, N., Long, S., Jones, D. T. & Woods, D. R. Characterization, biosynthesis, and regulation of granulose in Clostridium acetobutylicum. Appl. Environ. Microbiol. 52, 185–190 (1986).

Alsaker, K. V. & Papoutsakis, E. T. Transcriptional program of early sporulation and stationary-phase events in Clostridium acetobutylicum. J. Bacteriol. 187, 7103–7118 (2005).

Al-Hinai, M. A., Fast, A. G. & Papoutsakis, E. T. Novel system for efficient isolation of Clostridium double-crossover allelic exchange mutants enabling markerless chromosomal gene deletions and DNA integration. Appl. Environ. Microbiol. 78, 8112–8121 (2012).

Tautenhahn, R., Patti, G. J., Rinehart, D. & Siuzdak, G. XCMS online: a web-based platform to process untargeted metabolomic data. Anal. Chem. 84, 5035–5039 (2012).

Eya, B. K., Toshikazu, O., Isao, K. & Wood, D. L. Syntheses and NMR analyses of the eight geometric isomers of 3,6,8-dodecatrien-1-ol, subterranean termite trail pheromone. Tetrahedron 46, 2695–2706 (1990).

Nakahata, M., Imaida, M., Ozaki, H., Harada, T. & Tai, A. The preparation of optically pure 3-hydroxyalkanoic acid. The enantioface-differentiating hydrogenation of the C=O double bond with modified raney nickel. XXXVII. Bull. Chem. Soc. Jpn. 55, 2186–2189 (1982).

Petersson, C., Jachymek, W., Kenne, L., Niedziela, T. & Lugowski, C. Structural studies of the O-specific chain of Hafnia alvei strain PCM 1190 lipopolysaccharide. Carbohydr. Res. 298, 219–227 (1997).

Leivers, S. et al. Structure of the high molecular weight exopolysaccharide produced by Bifidobacterium animalis subsp. lactis IPLA-R1 and sequence analysis of its putative eps cluster. Carbohydr. Res. 346, 2710–2717 (2011).

Fedonenko, Y. P. et al. Structure of the O-polysaccharide of the lipopolysaccharide of Azospirillum irakense KBC1. Carbohydr. Res. 339, 1813–1816 (2004).

Perepelov, A. V., Guo, X., Filatov, A. V., Liu, B. & Knirel, Y. A. Structure and gene cluster of the O-antigen of Escherichia coli O43. Carbohydr. Res. 416, 32–36 (2015).

Wang, X. et al. Terfestatins B and C, new p-terphenyl glycosides produced by Streptomyces sp. RM-5–8. Org. Lett. 17, 2796–2799 (2015).

Mynderse, J. S., Fukuda, D. S. & Hunt, A. H. The microbial modification of A58365A, an angiotensin converting enzyme inhibitor. J. Antibiot. 48, 425–427 (1995).

Hahn, D., Kasai, R., Kim, J., Taniyasu, S. & Tanaka, O. A new glycosyl ester of a 3, 4-seco-triterpene from Korean medicinal plant, Acanthopanax Chiisanensis (araliaceae). Chem. Pharm. Bull. 32, 1244–1247 (1984).

Pfeifer, B. A., Admiraal, S. J., Gramajo, H., Cane, D. E. & Khosla, C. Biosynthesis of complex polyketides in a metabolically engineered strain of E. coli. Science 291, 1790–1792 (2001).

An, J. H. & Kim, Y. S. A gene cluster encoding malonyl-CoA decarboxylase (MatA), malonyl-CoA synthetase (MatB) and a putative dicarboxylate carrier protein (MatC) in Rhizobium trifolii. Eur. J. Biochem. 257, 395–402 (1998).

Ma, S. M. et al. Complete reconstitution of a highly reducing iterative polyketide synthase. Science 326, 589–592 (2009).

Xu, W., Cai, X., Jung, M. E. & Tang, Y. Analysis of intact and dissected fungal polyketide synthase-nonribosomal peptide synthetase in vitro and in Saccharomyces cerevisiae. J. Am. Chem. Soc. 132, 13604–13607 (2010).

Szklarczyk, D. et al. STRINGv10: protein-protein interaction networks, integrated over the tree of life. Nucleic Acids Res. 43, D447–D452 (2015).

Fischer, R. J., Helms, J. & Dürre, P. Cloning, sequencing, and molecular analysis of the sol operon of Clostridium acetobutylicum, a chromosomal locus involved in solventogenesis. J. Bacteriol. 175, 6959–6969 (1993).

Tomas, C. A., Beamish, J. & Papoutsakis, E. T. Transcriptional analysis of butanol stress and tolerance in Clostridium acetobutylicum. J. Bacteriol. 186, 2006–2018 (2004).

Tomas, C. A., Welker, N. E. & Papoutsakis, E. T. Overexpression of groESL in Clostridium acetobutylicum results in increased solvent production and tolerance, prolonged metabolism, and changes in the cell’s transcriptional program. Appl. Environ. Microbiol. 69, 4951–4965 (2003).

Al-Hinai, M. A., Jones, S. W. & Papoutsakis, E. T. σK of Clostridium acetobutylicum is the first known sporulation-specific sigma factor with two developmentally separated roles, one early and one late in sporulation. J. Bacteriol. 196, 287–299 (2014).

Steiner, E. et al. Multiple orphan histidine kinases interact directly with Spo0A to control the initiation of endospore formation in Clostridium acetobutylicum. Mol. Microbiol. 80, 641–654 (2011).

Kearns, D. B. A field guide to bacterial swarming motility. Nat. Rev. Microbiol. 8, 634–644 (2010).

Ali, M. S. & Al-Lohedan, H. A. Interaction of biocompatible sugar based surfactant n-dodecyl β-D-maltoside with lysozyme. J. Mol. Liq. 209, 662–668 (2015).

Abdel-Mawgoud, A. M., Lépine, F. & Déziel, E. Rhamnolipids: diversity of structures, microbial origins and roles. Appl. Microbiol. Biotechnol. 86, 1323–1336 (2010).

Duerre, P. Handbook on Clostridia (CRC Presss, Boca Raton, 2005).

Ikeda, H. Natural products discovery from micro-organisms in the post-genome era. Biosci. Biotechnol. Biochem. 81, 13–22 (2017).

Wang, Y.-F., Tian, J., Ji, Z.-H., Song, M.-Y. & Li, H. Intracellular metabolic changes of Clostridium acetobutylicum and promotion to butanol tolerance during biobutanol fermentation. Int. J. Biochem. Cell Biol. 78, 297–306 (2016).

Platt, T. G. & Fuqua, C. What’s in a name? The semantics of quorum sensing. Trends Microbiol. 18, 383–387 (2010).

Winzer, K., Hardie, K. R. & Williams, P. Bacterial cell-to-cell communication: sorry, can’t talk now—gone to lunch! Curr. Opin. Microbiol. 5, 216–222 (2002).

Schuster, M., Sexton, D. J., Diggle, S. P. & Greenberg, E. P. Acyl-homoserine lactone quorum sensing: from evolution to application. Annu. Rev. Microbiol. 67, 43–63 (2013).

Diggle, S. P., Cornelis, P., Williams, P. & Cámara, M. 4-Quinolone signaling in Pseudomonas aeruginosa: old molecules, new perspectives. Int. J. Med. Microbiol. 296, 83–91 (2006).

Takano, E. γ-Butyrolactones: Streptomyces signaling molecules regulating antibiotic production and differentiation. Curr. Opin. Microbiol. 9, 287–294 (2006).

Ren, D., Bedzyk, L. A., Ye, R. W., Thomas, S. M. & Wood, T. K. Differential gene expression shows natural brominated furanones interfere with the autoinducer-2 bacterial signaling system of Escherichia coli. Biotechnol. Bioeng. 88, 630–642 (2004).

Ohtani, K., Hayashi, H. & Shimizu, T. The luxS gene is involved in cell-cell signaling for toxin production in Clostridium perfringens. Mol. Microbiol. 44, 171–179 (2002).

Ohtani, K. et al. Virulence gene regulation by the agr system in Clostridium perfringens. J. Bacteriol. 191, 3919–3927 (2009).

Li, J., Chen, J., Vidal, J. E. & McClane, B. A. The agr-like quorum-sensing system regulates sporulation and production of enterotoxin and Beta2 toxin by Clostridium perfringens type a non-food-borne human gastrointestinal disease strain F5603. Infect. Immun. 79, 2451–2459 (2011).

Martin, M. J. et al. The agr locus regulates virulence and colonization genes in Clostridium difficile 027. J. Bacteriol. 195, 3672–3681 (2013).

Cooksley, C. M. et al. Regulation of neurotoxin production and sporulation by a putative agrBD signaling system in proteolytic Clostridium botulinum. Appl. Environ. Microbiol. 76, 4448–4460 (2010).

Steiner, E., Scott, J., Minton, N. P. & Winzer, K. An agr quorum sensing system that regulates granulose formation and sporulation in Clostridium acetobutylicum. Appl. Environ. Microbiol. 78, 1113–1122 (2012).

López, D. & Kolter, R. Extracellular signals that define distinct and coexisting cell fates in Bacillus subtilis. FEMS Microbiol. Rev. 34, 134–149 (2010).

López, D., Fischbach, M. A., Chu, F., Losick, R. & Kolter, R. Structurally diverse natural products that cause potassium leakage trigger multicellularity in Bacillus subtilis. Proc. Natl Acad. Sci. USA 106, 280–285 (2009).

Shank, E. A. & Kolter, R. Extracellular signaling and multicellularity in Bacillus subtilis. Curr. Opin. Microbiol. 14, 741–747 (2011).

Nakano, M. M. et al. srfA is an operon required for surfactin production, competence development, and efficient sporulation in Bacillus subtilis. J. Bacteriol. 173, 1770–1778 (1991).

Camilli, A. & Bassler, B. L. Bacterial small-molecule signaling pathways. Science 311, 1113–1116 (2006).

Williams, P., Winzer, K., Chan, W. C. & Cámara, M. Look who’s talking: communication and quorum sensing in the bacterial world. Philos. Trans. R. Soc. B Biol. Sci. 362, 1119–1134 (2007).

Daniels, R. et al. Quorum signal molecules as biosurfactants affecting swarming in Rhizobium etli. Proc. Natl Acad. Sci. USA 103, 14965–14970 (2006).

Jones, S. W., Tracy, B. P., Gaida, S. M. & Papoutsakis, E. T. Inactivation of σF in Clostridium acetobutylicum ATCC 824 blocks sporulation prior to asymmetric division and abolishes σE and σG protein expression but does not block solvent formation. J. Bacteriol. 193, 2429–2440 (2011).

Tracy, B. P., Jones, S. W. & Papoutsakis, E. T. Inactivation of σE and σG in Clostridium acetobutylicum Illuminates their roles in clostridial-cell-form biogenesis, granulose synthesis, solventogenesis, and spore morphogenesis. J. Bacteriol. 193, 1414–1426 (2011).

Bi, C., Jones, S. W., Hess, D. R., Tracy, B. P. & Papoutsakis, E. T. SpoIIE is necessary for asymmetric division, sporulation, and expression of σF, σE, and σG but does not control solvent production in Clostridium acetobutylicum ATCC 824. J. Bacteriol. 193, 5130–5137 (2011).

Jones, S. W. et al. The transcriptional program underlying the physiology of clostridial sporulation. Genome Biol. 9, R114 (2008).

Tracy, B. P., Jones, S. W., Fast, A. G., Indurthi, D. C. & Papoutsakis, E. T. Clostridia: the importance of their exceptional substrate and metabolite diversity for biofuel and biorefinery applications. Curr. Opin. Biotechnol. 23, 364–381 (2012).

Papoutsakis, E. T. Engineering solventogenic clostridia. Curr. Opin. Biotechnol. 19, 420–429 (2008).

J. D Oultram et al. Introduction of plasmids into whole cells of Clostridium acetobutylicum by electroporation. FEMS Microbiol. Lett. 56, 83–88 (1988).

Dusséaux, S., Croux, C., Soucaille, P. & Meynial-Salles, I. Metabolic engineering of Clostridium acetobutylicum ATCC 824 for the high-yield production of a biofuel composed of an isopropanol/butanol/ethanol mixture. Metab. Eng. 18, 1–8 (2013).

Baer, S. H., Blaschek, H. P. & Smith, T. L. Effect of butanol challenge and temperature on lipid composition and membrane fluidity of butanol-tolerant Clostridium acetobutylicum. Appl. Environ. Microbiol. 53, 2854–2861 (1987).

O’Brien, R. W. & Morris, J. G. Oxygen and the growth and metabolism of Clostridium acetobutylicum. Microbiology 68, 307–318 (1971).

Herman, N. A. et al. Development of a high-efficiency transformation method and implementation of rational metabolic engineering for the industrial butanol hyperproducer Clostridium saccharoperbutylacetonicum strain N1-4. Appl. Environ. Microbiol. 83, e02942–16 (2017).

Mermelstein, L. D. & Papoutsakis, E. T. In vivo methylation in Escherichia coli by the Bacillus subtilis phage phi 3T I methyltransferase to protect plasmids from restriction upon transformation of Clostridium acetobutylicum ATCC 824. Appl. Environ. Microbiol. 59, 1077–1081 (1993).

Benjamini, Y. & Hochberg, Y. Controlling the false discovery rate: a practical and powerful approach to multipletesting. J. R. Stat. Soc. Ser. B Methodol. 57, 289–300 (1995).

Ehsaan, M. et al. Mutant generation by allelic exchange and genome resequencing of the biobutanol organism Clostridium acetobutylicum ATCC 824. Biotechnol. Biofuels 9, 4 (2016).

Ren, C. et al. Pleiotropic functions of catabolite control protein CcpA in butanol-producing Clostridium acetobutylicum. BMC Genomics 13, 349 (2012).

Morikawa, M., Hirata, Y. & Imanaka, T. A study on the structure-function relationship of lipopeptide biosurfactants. Biochim. Biophys. Acta 1488, 211–218 (2000).

Płaza, G. A., Zjawiony, I. & Banat, I. M. Use of different methods for detection of thermophilic biosurfactant-producing bacteria from hydrocarbon-contaminated and bioremediated soils. J. Pet. Sci. Eng. 50, 71–77 (2006).

Youssef, N. H. et al. Comparison of methods to detect biosurfactant production by diverse microorganisms. J. Microbiol. Methods 56, 339–347 (2004).

Bodour, A. A. & Miller-Maier, R. M. Application of a modified drop-collapse technique for surfactant quantitation and screening of biosurfactant-producing microorganisms. J. Microbiol. Methods 32, 273–280 (1998).

Jain, D. K., Collins-Thompson, D. L., Lee, H. & Trevors, J. T. A drop-collapsing test for screening surfactant-producing microorganisms. J. Microbiol. Methods 13, 271–279 (1991).

Acknowledgements

We thank J. Liu (UC Berkeley) for performing the autoradiography labeling experiment, J. Pelton (UC Berkeley) for helping with NMR spectroscopic analysis, the University of California-Berkeley QB3 Functional Genomics Laboratory and Vincent J. Coates Genomic Sequencing Laboratory for performing the RNA-Seq library preparation and sequencing, the Papoutsakis Lab (University of Delaware) for providing plasmids pKO_mazF and pAN1, and the Tang Lab (UCLA) for providing chemical standards of compounds 4–6. This research was financially supported by the Energy Biosciences Institute, the Pew Scholars Program, the National Institutes of Health (DP2AT009148), and the Chan Zuckerberg Biohub Investigator Program.

Author information

Authors and Affiliations

Contributions

N.A.H. and W.Z. designed the experiments, analyzed the data, and wrote the manuscript. S.J.K. and W.C. performed purification and structure characterization of the polyketides. H.K. assisted with interpretation of NMR spectra of the polyketides. J.S.L. assisted with fermentation and phenotype characterization of C. acetobutylicum strains. N.A.H. performed all other experiments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article