Abstract

Developing a safe hydrogen carrier without the risks of high pressures and toxicities is an issue of significant urgency. In this study, we prepared a polymeric hydrogen carrier with high thermal stability by incorporating 2-propanol and acetone units into polymers. Poly(methyl vinyl ketone) with a high molecular weight (~105) was synthesized via bulk polymerization of methyl vinyl ketone and then dehydrogenated in one step to give poly(3-buten-2-ol) in high yield. Reversible hydrogen fixation and release by these polymers were achieved with full conversion under mild conditions (80–180 °C, ≦3 atm hydrogen pressure). A simple temperature-dependent hydrogenation/dehydrogenation cycle that operated at temperatures higher than the boiling points of 2-propanol and acetone in the presence of an iridium complex catalyst was established by virtue of having these groups as pendants of the vinyl chain, with a compact repeating unit to maximize the mass hydrogen storage density of 2.8 wt%.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Schlapbach L, Zuttel A. Hydrogen-storage materials for mobile applications. Nature. 2001;414:353–8. https://doi.org/10.1038/35104634.

Schlapbach L, Züttel A. Materials for sustainable energy. London: Nature Publishing Group; p. 265–70.

Staffell I, Scamman D, Velazquez Abad A, Balcombe P, Dodds PE, Ekins P, et al. The role of hydrogen and fuel cells in the global energy system. Energy Environ Sci. 2019;12:463–91. https://doi.org/10.1039/c8ee01157e.

Hirscher M, Autrey T, Orimo SI. Hydrogen energy. Chemphyschem. 2019;20:1157. https://doi.org/10.1002/cphc.201900429.

Bae D, Seger B, Vesborg PC, Hansen O, Chorkendorff I. Strategies for stable water splitting via protected photoelectrodes. Chem Soc Rev. 2017;46:1933–54. https://doi.org/10.1039/c6cs00918b.

Yao L, Rahmanudin A, Guijarro N, Sivula K. Organic semiconductor based devices for solar water splitting. Adv Energy Mater. 2018;8:1802585. https://doi.org/10.1002/aenm.201802585.

Ahn J, Shimizu R, Miyatake K. Sulfonated aromatic polymers containing hexafluoroisopropylidene groups: a simple but effective structure for fuel cell membranes. J Mater Chem A 2018;6:24625–32. https://doi.org/10.1039/c8ta09587f.

Miyake J, Miyatake K. Quaternized poly(arylene perfluoroalkylene)s (QPAFs) for alkaline fuel cells—a perspective. Sustain Energy Fuels. 2019;3:1916–28. https://doi.org/10.1039/c9se00106a.

Abe JO, Popoola API, Ajenifuja E, Popoola OM. Hydrogen energy, economy and storage: Review and recommendation. Int J Hydrog Energy. 2019;44:15072–86. https://doi.org/10.1016/j.ijhydene.2019.04.068.

Züttel A. Materials for hydrogen storage. Mater Today. 2003;6:24–33. https://doi.org/10.1016/s1369-7021(03)00922-2.

David E. An overview of advanced materials for hydrogen storage. J Mater Process Technol. 2005;162-163:169–77. https://doi.org/10.1016/j.jmatprotec.2005.02.027.

Sherif SA, Goswami DY, Stefanakos EL, Steinfeld A. Handbook of hydrogen energy. Florida: CRC Press; 2014.

Modisha PM, Ouma CNM, Garidzirai R, Wasserscheid P, Bessarabov D. The prospect of hydrogen storage using liquid organic hydrogen carriers. Energy Fuels. 2019;33:2778–96. https://doi.org/10.1021/acs.energyfuels.9b00296.

Shimbayashi T, Fujita K-i. Metal-catalyzed hydrogenation and dehydrogenation reactions for efficient hydrogen storage. Tetrahedron. 2020;76. https://doi.org/10.1016/j.tet.2020.130946.

Kawahara R, Fujita K, Yamaguchi R. Cooperative catalysis by iridium complexes with a bipyridonate ligand: versatile dehydrogenative oxidation of alcohols and reversible dehydrogenation-hydrogenation between 2-propanol and acetone. Angew Chem Int Ed Engl. 2012;51:12790–4. https://doi.org/10.1002/anie.201206987.

Kato R, Nishide H. Polymers for carrying and storing hydrogen. Polym J. 2017;50:77–82. https://doi.org/10.1038/pj.2017.70.

Yoshida M, Hirahata R, Inoue T, Shimbayashi T, Fujita K-i. Iridium-catalyzed transfer hydrogenation of ketones and aldehydes using glucose as a sustainable hydrogen donor. Catalysts. 2019;9. https://doi.org/10.3390/catal9060503.

Onoda M, Nagano Y, Fujita K-i. Iridium-catalyzed dehydrogenative lactonization of 1,4-butanediol and reversal hydrogenation: new hydrogen storage system using cheap organic resources. Int J Hydrog Energy. 2019;44:28514–20. https://doi.org/10.1016/j.ijhydene.2019.03.219.

Junge H, Beller M. Ruthenium-catalyzed generation of hydrogen from iso-propanol. Tetrahedron Lett. 2005;46:1031–4. https://doi.org/10.1016/j.tetlet.2004.11.159.

Junge H, Loges B, Beller M. Novel improved ruthenium catalysts for the generation of hydrogen from alcohols. Chem. Commun. 2007:522–4, https://doi.org/10.1039/B613785G.

Nielsen M, Kammer A, Cozzula D, Junge H, Gladiali S, Beller M. Efficient hydrogen production from alcohols under mild reaction conditions. Angew Chem Int Ed. 2011;50:9593–7. https://doi.org/10.1002/anie.201104722.

Kawahara R, Fujita K-i, Yamaguchi R. ChemInform abstract: cooperative catalysis by iridium complexes with a bipyridonate ligand: versatile dehydrogenative oxidation of alcohols and reversible dehydrogenation—hydrogenation between 2-propanol and acetone. ChemInform. 2013;44, https://doi.org/10.1002/chin.201317028.

Zhang L, Han Z, Zhao X, Wang Z, Ding K. Highly efficient ruthenium-catalyzed N-formylation of amines with H2 and CO2. Angew Chem Int Ed. 2015;54:6186–9. https://doi.org/10.1002/anie.201500939.

Zou Y-Q, von Wolff N, Anaby A, Xie Y, Milstein D. Ethylene glycol as an efficient and reversible liquid-organic hydrogen carrier. Nat Catal. 2019;2:415–22. https://doi.org/10.1038/s41929-019-0265-z.

Oka K, Kaiwa Y, Kataoka M, Fujita K-i, Oyaizu K. A polymer sheet-based hydrogen carrier. Eur J Org Chem. 2020;2020:5876–9. https://doi.org/10.1002/ejoc.202001004.

Kato R, Yoshimasa K, Egashira T, Oya T, Oyaizu K, Nishide H. A ketone/alcohol polymer for cycle of electrolytic hydrogen-fixing with water and releasing under mild conditions. Nat Commun. 2016;7:13032. https://doi.org/10.1038/ncomms13032.

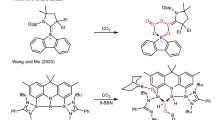

Kato R, Oka K, Yoshimasa K, Nakajima M, Nishide H, Oyaizu K. Reversible hydrogen releasing and fixing with poly(Vinylfluorenol) through a mild Ir-catalyzed dehydrogenation and electrochemical hydrogenation. macromol. Rapid Commun. 2019:e1900139, https://doi.org/10.1002/marc.201900139.

Miyake J, Ogawa Y, Tanaka T, Ahn J, Oka K, Oyaizu K, et al. Rechargeable proton exchange membrane fuel cell containing an intrinsic hydrogen storage polymer. Commun Chem. 2020;3:138. https://doi.org/10.1038/s42004-020-00384-z.

Oka K, Kaiwa Y, Furukawa S, Nishide H, Oyaizu K. Reversible hydrogen fixation and release under mild conditions by poly(vinylquinoxaline). ACS Appl Polym Mater. 2020;2:2756–60. https://doi.org/10.1021/acsapm.0c00338.

Oyaizu K, Nishide H. Radical polymers for organic electronic devices: a radical departure from conjugated polymers? Adv Mater. 2009;21:2339–44. https://doi.org/10.1002/adma.200803554.

Kaiwa Y, Oka K, Nishide H, Oyaizu K. Facile reversible hydrogenation of a poly(6-vinyl-2,3-dimethyl-1,2,3,4-tetrahydroquinoxaline) gel-like solid. Polym Adv Technol.;n/a, https://doi.org/10.1002/pat.5163.

Oka K, Strietzel C, Emanuelsson R, Nishide H, Oyaizu K, Stromme M, et al. Conducting redox polymer as a robust organic electrode-active material in acidic aqueous electrolyte towards polymer-air secondary batteries. ChemSusChem. 2020;13:2280–5. https://doi.org/10.1002/cssc.202000627.

Oka K, Löfgren R, Emanuelsson R, Nishide H, Oyaizu K, Strømme M, et al. Conducting redox polymer as organic anode material for polymer‐manganese secondary batteries. ChemElectroChem. 2020;7:3336–40. https://doi.org/10.1002/celc.202000711.

Oka K, Furukawa S, Murao S, Oka T, Nishide H, Oyaizu K. Poly(dihydroxybenzoquinone): its high-density and robust charge storage capability in rechargeable acidic polymer-air batteries. Chem Commun. 2020;56:4055–8. https://doi.org/10.1039/d0cc00660b.

Oka K, Kato R, Oyaizu K, Nishide H. Poly(vinyldibenzothiophenesulfone): its redox capability at very negative potential toward an all‐organic rechargeable device with high‐energy density. Adv Funct Mater. 2018;28:1805858. https://doi.org/10.1002/adfm.201805858.

Krumpfer JW, Giebel E, Frank E, Müller A, Ackermann L-M, Tironi CN, et al. Poly(methyl vinyl ketone) as a potential carbon fiber precursor. Chem Mater. 2016;29:780–8. https://doi.org/10.1021/acs.chemmater.6b04774.

Marvel CS, Levesque CL. The structure of vinyl polymers: the polymer from methyl vinyl ketone. J Am Chem Soc. 1938;60:280–4. https://doi.org/10.1021/ja01269a016.

Masuda T, Ibuki H. One-pot synthesis of optically active poly(3-buten-2-ol) from methyl vinyl ketone. Polym J. 1980;12:143–4. https://doi.org/10.1295/polymj.12.143.

Ware GW. Reviews of environmental contamination and toxicology: continuation of residue reviews. Ware GW, editor. New York: Springer; 1988. p. 133–41.

Japan TCSo. Handbook of chemistry: pure chemistry, 5th ed. Tokyo: Maruzen Publishing; 2004.

Monte MJS, Notario R, Calvinho MMG, Almeida ARRP, Amaral LMPF, LoboFerreira AIMC, et al. Experimental and computational study of the thermodynamic properties of 9-fluorenone and 9-fluorenol. J Chem Eng Data. 2012;57:2486–96. https://doi.org/10.1021/je300584m.

Acknowledgements

This work was partially supported by Grants-in-Aids for Scientific Research (17H03072, 18K19120, 18H03921, 18H05515, and 19J21527) and the Top Global University Project from MEXT, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Oka, K., Tobita, Y., Kataoka, M. et al. Synthesis of vinyl polymers substituted with 2-propanol and acetone and investigation of their reversible hydrogen storage capabilities. Polym J 53, 799–804 (2021). https://doi.org/10.1038/s41428-021-00475-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-021-00475-1

This article is cited by

-

Reversible and high-density energy storage with polymers populated with bistable redox sites

Polymer Journal (2023)