Abstract

We introduce a novel surface wrinkling system based on the fabrication of a polyion complex (PIC) skin layer. PIC skin layers are fabricated on the surface of chitosan (CS) films via immersion in sodium alginate (AG) solutions. After removal of excess adsorbed AG, microscopic wrinkles appear upon drying. The wrinkle size can be controlled by the immersion temperature during the formation of the skin layer because of the differences in skin layer thicknesses. In addition, we demonstrate that there is only a two-fold difference in the elastic moduli between the PIC skin layer and the CS film. Furthermore, wrinkled films can be made water resistant by thermal crosslinking of the PIC skin layer. The thermally crosslinked wrinkled surfaces composed of covalently crosslinked CS and AG demonstrate the low cell adhesiveness that is required for implantable materials. Thus, this method that combines surface wrinkling induced by a PIC skin layer and subsequent thermal crosslinking can provide a variety of wrinkled biomaterials.

Similar content being viewed by others

Introduction

Surface wrinkling has attracted increased interest because it is generally easy to produce, requires low cost, and is environmentally benign, while the number of potential applications are large in fields such as optical [1] and electronic devices [2], surface-enhanced Raman spectroscopy substrates [3], promotion of tunable wettability [4] and adhesion [5], and the synthesis of cell culture scaffolds [6]. The wrinkles result from inhomogeneous changes that are induced by a skin layer that is a thin hard surface layer adhering to a substrate. In most wrinkling systems, the skin layers are fabricated on an elastic film by chemical vapor deposition [7], photocrosslinking [8], UV/O3 [9] or plasma [10] oxidation, or chemical reactions [11]. The characteristics of the skin layer strongly affect wrinkle morphology. In common wrinkles, the wavelength (λ) of the wrinkle is dependent on the skin thickness (d), and the mechanical properties of the film can be described by the following equation [12, 13]:

where Ē is the plane-strain modulus given by E/(1−ν2), the subscripts s and f refer to the skin layer and the foundation (substrate), respectively, E is the elastic modulus, and ν is the Poisson ratio. In addition, the amplitude (A) of the wrinkle is described by the following equation [12]:

where ε and εc are the applied and critical strain, respectively. εc is dependent on Ē as follows [12]:

Thus, the design of the skin layer, which includes material selection and control of the thickness and elastic modulus, is a key factor in the development of wrinkled surfaces with desirable morphologies.

A trigger is required to initiate the inhomogeneous changes that are necessary for the generation of wrinkles [14]. The application of external stress [9] or heat [7] are common approaches to induce/control surface wrinkling[13]. Alternatively, although surface wrinkling due to water evaporation is ubiquitous in nature [14,15,16], it has barely been considered during film consolidation to trigger surface wrinkling [17, 18]. We considered the possibility that this was because there is no common design concept for surface wrinkling upon drying, and recently reported an original approach to surface wrinkling using drying [19]. In this method, microscopic wrinkles were fabricated on a chitosan (CS) film by immersion in a phenolic acid solution, followed by a horseradish peroxidase-catalyzed surface reaction and drying [20]. We demonstrated that the crosslinking structure capable of skin-layer formation consisted of ionic bonds between the CS and oligomeric phenolic acid residues on the CS [21]. This evidence provided inspiration for further research. We hypothesized that a skin layer composed of ionic crosslinks would promote surface wrinkling upon drying; i.e., a polyion complex (PIC) skin layer prepared by simple immersion of a CS film into an anionic polymer solution would induce surface wrinkling. Establishing this simple concept based on the PIC skin layer would accelerate the development of wrinkled surfaces induced by drying. In addition, we expected that this method would be favorable for producing biopolymer-based wrinkled surfaces that were applicable for biomaterials, because with such an approach, it is not necessary to apply external stresses to induce surface wrinkling.

Alginate (AG) is an anionic polysaccharide that is extracted from brown algae [22]. AG salts dissolve in water to produce viscous liquids or hydrogels. AG is therefore widely used in a broad range of industries, as a rheological control agent in aqueous systems, and as a stabilizer for emulsions and suspensions [23]. Furthermore, AG has attracted much attention in the development of biomaterials by virtue of its biocompatibility and sustainability [24]. The carboxy groups on AG can interact electrostatically with the amino groups on CS to form gels, particles, and film materials for biomedical applications [24,25,26,27,28,29,30,31]. Thus, wrinkled surfaces prepared from AG and CS may provide unique biointerfaces with microscopic wrinkles.

Here, we introduce a new concept for developing surface wrinkling upon drying (Fig. 1). We fabricated a PIC skin layer on a CS film by immersion in an AG solution. After washing away excess adsorbed AG by soaking the film in water, the film with the PIC skin layer was dried. We then investigated the effect of the AG molecular weight, the AG concentration, and the immersion temperature in the skin layer formation process on the surface morphology. Our analysis revealed differences in the elastic moduli of the PIC skin layer and the CS substrate. Furthermore, we developed a methodology for preparing a water-resistant wrinkled surface via a thermal dehydration condensation reaction of the PIC skin layer. Finally, 3T3 cells were cultured on the thermally crosslinked wrinkled films.

Experimental procedures

Materials

CS was supplied by the Koyo Chemical Co., Ltd (Tottori, Japan). The Mn estimated by gel permeation chromatography analysis using Pullulan standards was 64.1 × 103 (MW/Mn = 2.03), and the degree of deacetylation estimated by elemental analysis was 76.5%. Sodium alginates (80–120, 300–400, and 500–600 cps, 10 g/L at 25 °C) and 0.25 w/v% Trypsin 1 mmol/L EDTA·4Na solution with phenol red were purchased from Wako Pure Chemical Industries (Osaka, Japan). Phosphate-buffered saline (PBS) (pH 7.4, 10×; GibcoTM), penicillin–streptomycin–neomycin (PSN) antibiotic mixture (GibcoTM), Dulbecco’s modified Eagle’s medium, high glucose (DMEM; GibcoTM), and Trypan blue (GibcoTM) were purchased from Thermo Fisher Scientific (Waltham, MA, USA). Other reagents were obtained as commercial grades and used without further purification.

Measurements

SEM images were obtained using a TM303Plus instrument (Hitachi High-Technologies Corporation, Japan) without coatings. The wrinkle amplitudes of the films were measured using a NanoCute-NanoNavi IIs system (Seiko Instruments, Japan). Optical microscopic images were obtained to evaluate the stability of the wrinkles in water and for cell culture experiments using BIX53 (Olympus, Japan) and CKX53 instruments (Olympus, Japan), respectively. Infrared (IR) spectra of the samples were obtained with a Spectrum 65 spectrometer (Perkin-Elmer Japan Co., Ltd, Japan) equipped with an ATR attachment. Film weights were obtained using an XS3DUV balance (METTLER TOLEDO, USA). Elastic moduli were measured with a universal testing instrument (AG-10KNX; Shimadzu, Japan).

Preparation of CS films

CS (2.0 g) was dissolved in 100 mL of an acidic aqueous solution containing 0.5 mL of acetic acid. Then, 10 mL of the CS solution was added to a Teflon Petri dish (φ = 50 mm) and degassed under reduced pressure. The CS solution was heated at 50 °C for 24 h to yield a CS film after evaporation. The film was then heated at 50 °C under reduced pressure for 12 h. The inhomogeneous edge of the film was cut with scissors, and the film was soaked in methanol for 2 days. It was then dried under reduced pressure; the weight and thickness of the CS film were ca. 0.15 g and ca. 110 µm, respectively. The air side of the CS film that formed during evaporation was used for this study.

Preparation of wrinkled films via soaking processes

In a typical experiment, a CS film was immersed in water for 5 min at room temperature. The swollen film was removed and soaked in 20 mL of an AG aqueous solution (1.0wt%, pH adjusted to 6.5 with 1.0 M HCl) at 30 °C for 24 h, after which the film was removed and gently washed with water. The film was soaked in 100 mL of water at 30 °C for 6 h, after which it was removed and dried at 40 °C for 12 h.

Preparation of PIC films

CS (2.0 g) was dissolved in 100 mL of an acidic aqueous solution containing 1.0 mL of acetic acid and, separately, AG (2.0 g) was dissolved in 100 mL of water. The AG solution was added dropwise to the CS solution, and the PIC solution was vigorously stirred for 2 h at room temperature. Then, 10 mL of the PIC solution was added to a Teflon Petri dish (φ = 50 mm) and degassed under reduced pressure. The PIC solution was heated at 50 °C for 24 h to yield a PIC film after evaporation.

Tensile tests of the PIC, CS, and AG films

The PIC, CS, and AG films were dried under reduced pressure at 25 °C. Stress–strain curves were obtained for rectangular samples (4.5 cm × 1.0 cm) at a crosshead speed of 1 mm/min and a gauge length of 2.5 cm. The elastic moduli (stress/strain) were calculated from the straight line portions of the stress–strain curves.

Dehydration condensation of PIC skin layer

The wrinkled film was placed in a vacuum oven (ca 10 Pa) that was gradually heated (10 °C/h) to 160 °C. The film was then cooled to room temperature under reduced pressure.

Film drying under stress

The CS film with a PIC skin layer that was prepared via immersion treatments with a 1.0wt% AG solution at 30 °C for 24 h was cut into a rectangle (4.5 cm × 3.0 cm). The film was clamped, a weight (50 g) was added to one end, and the film was set to hang for 12 h in air at 40 °C.

3T3 cell cultures on wrinkled films

The wrinkled CS films (diameter: 14 mm) were immersed in PBS (50 mL) containing a PSN antibiotic mixture (0.5 mL) for 1 h. These films were then placed in wells of 24-well culture plates (FALCON®, Corning, NY, USA). Each film was fixed with a silicon ring (outside diameter: 16 mm; inside diameter: 13 mm), and 0.5 mL of a 3T3 cell solution (3.4 × 104 cells/mL, 3T3 cells were diluted with DMEM) was seeded and cultured for 2 days (37 °C, 5% CO2). The cells were then washed twice with 0.5 mL of PBS and then peeled with trypsin. The peeled cells (10 μL) were mixed with trypan blue (10 μL), and the number of cells was calculated by a hemocytometer and an optical microscope.

Results and discussion

Preparation of wrinkled CS films

We investigated the effect of AG concentrations on wrinkle morphology using low-viscosity AG (80–120 cps) solutions. PIC skin layers were fabricated via an immersion treatment of CS in 0.25, 0.50, or 1.00wt% AG solutions at 30 °C for 24 h. Films were then washed by soaking in water at 30 °C for 6 h. The resulting films were dried at 40 °C. The duration for film washing was optimized (see Supplemental Material). Figure 2b–d shows SEM images of the films that were obtained. Microscopic wrinkles were observed for the 0.50 and 1.00wt% treatments, indicating that the PIC skin layer induced surface wrinkling as expected. In contrast, semispherical bumps were observed for the 0.25wt% treatment. Such surfaces are induced by a thin and/or softer skin layer [32, 33]. In this system, the depth that the AG permeated into a CS film corresponded to the thickness of the skin layer. This should be proportional to the amount of AG adsorbed. Therefore, we measured the amount of AG that was adsorbed from the weight differences of the films before and after treatments. The adsorbed amounts from the 0.25wt% treatment were 0.43 ± 0.10 mg/cm2, significantly lower than those obtained from 0.50 and 1.00wt% treatments (0.85 ± 0.14 and 0.93 ± 0.20 mg/cm2, respectively), suggesting that the semispherical bumps were induced by a thinner skin layer that was caused by the lower osmotic pressure of the 0.25wt% AG solution. These results indicate that the production of wrinkles and semispherical bumps could be controlled by the concentration of AG.

The effect of immersion temperature on wrinkle morphology was investigated with PIC skin layers that were prepared via immersion treatments with 1.0wt% AG solutions at 30, 40, 50, and 60 °C for 24 h. Figure 3a–e shows SEM images of the surfaces of the films that were obtained and their detailed characterization. Wrinkle size gradually increased with immersion temperature. Mean wrinkle wavelengths and amplitudes after treatment at 30, 40, 50, and 60 °C were 1.1 ± 0.2, 2.2 ± 0.6, 4.0 ± 0.8, and 5.1 ± 0.8 μm, respectively, and 0.3 ± 0.1, 0.5 ± 0.2, 0.9 ± 0.3, and 1.0 ± 0.3 μm, respectively. This result indicated that temperature was a suitable parameter for controlling the wrinkle size during skin layer formation. The amounts of AG adsorbed under treatment at 30, 40, 50, and 60 °C were 0.93 ± 0.20, 0.98 ± 0.16, 1.18 ± 0.13, and 1.22 ± 0.19 mg/cm2, respectively. Thus, the amounts gradually increased with immersion temperature. When the CS film was immersed in water at 30, 40, 50, or 60 °C, the CS weight gradually decreased with increases in immersion temperature (−0.32 ± 0.10, −0.63 ± 0.21, −0.08 ± 0.33, and −2.32 ± 0.19 mg/cm2, respectively), probably due to elution of soluble CS. Thus, the actual amounts of AG that were adsorbed were much higher than the amounts described above. The amounts of AG adsorbed and CS lost were 1.25, 1.61, 2.26, and 3.54 mg/cm2 in the case of 30, 40, 50, and 60 °C, respectively. These results suggest that the AG permeation depth increased with increasing immersion temperatures, and in turn formed a broader skin layer. The broader skin layers induced larger wrinkles as well as the relations shown in Eqs. (1) and (2).

We also evaluated the process using solutions with higher molecular weights of AG (300–400 and 500–600 cps). When the PIC skin layers were prepared via the immersion treatments with 1.0wt% AG solutions at 30 °C for 24 h, semispherical bumps were observed (Fig. 4). The amounts of AG that were adsorbed using 300–400 and 500–600 cps solutions were 0.43 ± 0.21 and 0.55 ± 0.18 mg/cm2, respectively. These values are comparable to those that were obtained using a 0.25wt% AG (80–120 cps) solution, where semispherical bumps formed as described above (Fig. 2). This result suggests that the production of thinner skin layers is due to the difficulty of high molecular weight AG permeating into the CS film. To confirm the production of thinner skin layers, we conducted an optical microscopic analysis of the cross-sections of the films with wrinkles and bumps (Fig. 5). The image shows the topmost layer, which is considered to be the skin layer, with an 80–120 cps solution of AG. This topmost layer was approximately 0.7-μm-thick. On the other hand, using the 300–400 cps solution of AG, the topmost layer could not be distinguished. These results indicate that semispherical bumps can be produced by using a higher molecular weight of AG because of the production of a much thinner skin layer.

When a higher molecular weight CS was used (Mn = 162.4 × 103 (MW/Mn = 1.98)), microstructured surfaces, including wrinkles and bumps, did not form. We suspect that AG could not permeate into films that were created by higher molecular weight CS because they absorb very little water, probably due to strong aggregation. Indeed, the lower molecular weight CS films swelled 2.6-fold in weight by immersion in water, whereas those films prepared with a higher molecular weight CS exhibited minimal swelling (1.3-fold in weight). Hence, CS films prepared using lower molecular weight CS, which have moderate water miscibility, are suitable for this system.

Elastic modulus of the PIC skin layer

Although the difference in the elastic moduli of the skin layer and substrate is important for wrinkle development, surface wrinkling upon drying has never been reported. The elastic moduli of the PIC skin layer can be estimated from the elastic moduli of the bulk PIC films. Thus, the elastic moduli of the PIC films composed of CS and AG were measured by tensile tests. In the PIC skin layer, it is unlikely that the amount of AG will exceed that of CS, because AG penetrates into the CS film. Accordingly, PIC films were prepared with 1/1, 1/2, and 1/3 AG/CS ratios by weights. Figure 6 shows the elastic moduli of the PIC, CS and AG films. The elastic modulus of the CS film was 1.19 ± 0.07 GPa. The elastic moduli of the PIC films prepared with 1/1, 1/2, and 1/3 AG/CS ratios were 2.43 ± 0.14, 2.53 ± 0.26, and 2.18 ± 0.24 GPa, respectively; these enhanced values were due to ionic crosslinking with AG. In the widely used surface wrinkling system based on fabrication of a skin layer on strained poly(dimethylsiloxane) (PDMS), the elastic moduli of the skin layers (~1 GPa) are ca. 1000-fold higher than that of PDMS (~1 MPa) [13, 34]. Surprisingly, in our system, the difference was only two-fold. This finding suggests that the surface wrinkling upon drying does not require a large difference in elastic moduli between the skin layer and the substrate.

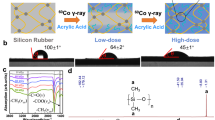

Preparation of wrinkled films with a thermally crosslinked PIC skin layer

Wrinkled films must be stable under aqueous conditions for use in biomedical applications. Therefore, we evaluated the stability of wrinkled films that were prepared via skin layer formation at 30 °C for 24 h with a 1.0wt% AG solution. Figure 7a, b shows the optical microscopic images of wrinkled films after soaking in water at 37 °C for 24 and 48 h, respectively. Although the wrinkles were relaxed by hydration of the skin layer, they remained after 24 h. However, after 48 h of hydration, the wrinkles completely disappeared. Therefore, we investigated dehydration condensation of the PIC skin layer by a thermal treatment under reduced pressure to stabilize the wrinkle morphology. The film that was obtained via a thermal treatment under ca. 10 Pa at 120 °C for 12 h was extremely brittle, probably due to hydrolysis that was promoted by adsorbed water molecules. Therefore, the wrinkled film was gradually heated from room temperature to 160 °C (10 °C/h) under ca. 10 Pa, so that adsorbed water molecules would be removed at lower temperatures. Figure 7e–d' shows the IR spectrum of the wrinkled films after thermal treatment. In the spectrum, the absorption peak attributed to the C = O (ester) stretching vibration is present at 1770 cm−1. Generally, primary amines have greater nucleophilicity than primary alcohols. Therefore, we suspect that both esters and amide bonds were actually present in the skin layer, even though the absorption peak attributed to the amide bond at approximately 1650 cm−1 was overlapped. Figure 7c, d shows optical microscopic images of the thermally crosslinked wrinkled film after soaking for 24 h and 1 week, respectively. Wrinkle morphologies were preserved after both soaking durations, with mean wrinkle wavelengths after 24 h and 1 week of 2.1 ± 0.5 and 3.0 ± 0.4 µm, respectively. This result indicates that the wrinkles induced by the PIC skin layers can be made water resistant by thermal crosslinking.

Rendering the wrinkled CS film with a PIC skin layer water resistant. Optical microscopic images of the wrinkled film after soaking in water for 24 h (a) and 48 h (b); of the thermally crosslinked wrinkled films after soaking for 24 h (c) and 1 week (d); and IR spectra of CS (a’), AG (b’), the wrinkled film (c’), and the thermally crosslinked wrinkled film (d’) (e)

3T3 cell cultures on wrinkled surfaces

The effect of wrinkled surfaces and thermally crosslinked PIC skin layers on cell culture warrants investigation, because we previously reported that microscopic wrinkled surfaces composed of CS and oligo(ferulic acid) showed good performance as a cell culture substrate [35]. To evaluate the effects of wrinkled surfaces, 3T3 cells were cultured on a surface obtained via the skin layer formation method at 30 °C for 24 h with a 1.0wt% AG solution, and its thermally crosslinked surface. The crosslinked anisotropic wrinkled surface (Figure S2) was also examined in order to evaluate the effect of wrinkle morphology. Figure 8a shows the number of 3T3 cells that were peeled from the substrates by trypsin treatment after 2 days of incubation. Cell numbers on the wrinkled and crosslinked wrinkled surfaces were 16.0 × 103 and 5.0 × 103 mL−1, respectively, which were lower than that obtained using polystyrene cell culture dishes.

In our previous report, the cell numbers obtained on surfaces with a similar wrinkle size were comparable to those using polystyrene. However, the number of cells on the crosslinked wrinkled surface was much lower than that obtained with a wrinkled surface. This indicated that wrinkled surfaces composed of crosslinked CS and AG were less effective for 3T3 cell adhesion compared to wrinkled surfaces composed of CS and oligo(ferulic acid). This was probably due to a decrease of positive charges caused by amide formation. Indeed, the adhesion of various cells on CS films was decreased by N-acetylation [36, 37]. Interestingly, on the crosslinked anisotropic wrinkled surface, the cell numbers were below 0.5 × 103 mL−1, suggesting that 3T3 cells adhered weakly to this surface. Indeed, as shown in Fig. 8b, no 3T3 cells were observed on the surface. (On the polystyrene plate, 3T3 cells were nearly confluent, as shown in Fig. 8c.) This finding demonstrates that thermally crosslinked wrinkled surfaces constitute a low cell-adhesion substrate. Moreover, cell adhesion was further weakened by wrinkle alignment. Wrinkled films that exhibit low cell adhesion and good biocompatibility may be suitable for use in an implantable device [38]. Clarification of the mechanisms involved in weakened cell adhesion is now in progress.

Conclusions

We investigated a novel surface wrinkling system based on the fabrication of a PIC skin layer. PIC skin layers were fabricated on the surface of CS films using a simple procedure that involved immersion in a sodium alginate (AG) solution and subsequent immersion in water to remove excess AG. Upon drying, microscopic wrinkles appeared. The wrinkle size could be controlled within a range of ca. 1–5 μm by the immersion temperature during skin layer formation because of the differences in the thicknesses of the skin layers. We also observed that the formation of thinner PIC skin layers using a low concentration AG solution or high molecular weight AG led to the formation of bumps. Furthermore, we demonstrated that there was only a two-fold difference in the elastic moduli between the PIC skin layer and the CS film. This result was very different from that obtained with a surface wrinkling system that was induced by mechanical stress. Thus, a design principle far from that generally used was necessary to develop a surface wrinkling system upon drying. Indeed, although the PIC between CS and AG is widely used, this wrinkling phenomenon has never been reported. This study is the first to demonstrate that the PIC skin layer is an effective tool for inducing surface wrinkling upon drying. This design concept could enable fabrication of various microscopic surfaces and simplification of surface wrinkling upon drying.

Moreover, we successfully rendered the wrinkled films water resistant by thermal crosslinking of the PIC skin layer. We then investigated the growth of 3T3 cells on the film. The thermally crosslinked wrinkled surfaces composed of covalently crosslinked CS and AG exhibited low cell adhesiveness, which is required for implantable materials. This method, involving surface wrinkling induced by a PIC skin layer and subsequent thermal crosslinking, will provide various wrinkled biomaterials that are applicable for wound healing [39], biological adhesives [40], and implantable drug delivery systems [41].

References

Ohzono T, Suzuki K, Yamaguchi T, Fukuda N. Tunable optical diffuser based on deformable wrinkles. Adv Opt Mater. 2013;1:374–80.

Lee SG, Kim H, Choi HH, Bong H, Park YD, Lee WH, et al. Evaporation-induced self-alignment and transfer of semiconductor nanowires by wrinkled elastomeric templates. Adv Mater. 2013;25:2162–6.

Stenberg H, Matikainen A, Daniel S, Nuutinen T, Stenberg P. Self-organized polymer wrinkles: a lithography-free pathway for surface-enhanced Raman scattering (SERS) substrates. Macromol Mater Eng. 2015;300:386–90.

Li YY, Dai SX, John J, Carter KR. Superhydrophobic surfaces from hierarchically structured wrinkled polymers. ACS Appl Mater Inter. 2013;5:11066–73.

Davis CS, Martina D, Creton C, Lindner A, Crosby AJ. Enhanced adhesion of elastic materials to small-scale wrinkles. Langmuir. 2012;28:14899–908.

Zhao ZQ, Gu JJ, Zhao YN, Guan Y, Zhu XX, Zhang YJ. Hydrogel thin film with swelling-induced wrinkling patterns for high-throughput generation of multicellular spheroids. Biomacromolecules. 2014;15:3306–12.

Bowden N, Brittain S, Evans AG, Hutchinson JW, Whitesides GM. Spontaneous formation of ordered structures in thin films of metals supported on an elastomeric polymer. Nature. 1998;393:146–9.

Gu JJ, Li XY, Ma HC, Guan Y, Zhang YJ. One-step synthesis of PHEMA hydrogel films capable of generating highly ordered wrinkling patterns. Polymer (Guildf). 2017;110:114–23.

Efimenko K, Rackaitis M, Manias E, Vaziri A, Mahadevan L, Genzer J. Nested self-similar wrinkling patterns in skins. Nat Mater. 2005;4:293–7.

Endo H, Mochizuki Y, Tamura M, Kawai T. Fabrication and functionalization of periodically aligned metallic nanocup arrays using colloidal lithography with a sinusoidally wrinkled substrate. Langmuir. 2013;29:15058–64.

Takeshima T, Liao W, Nagashima Y, Beppu K, Hara M, Nagano S, et al. Photoresponsive surface wrinkle morphologies in liquid crystalline polymer films. Macromolecules. 2015;48:6378–84.

Chung JY, Nolte AJ, Stafford CM. Surface wrinkling: a versatile platform for measuring thin-film properties. Adv Mater. 2011;23:349–68.

Genzer J, Groenewold J. Soft matter with hard skin: from skin wrinkles to templating and material characterization. Soft Matter. 2006;2:310–23.

Ionov L. Biomimetic 3D self-assembling biomicroconstructs by spontaneous deformation of thin polymer films. J Mater Chem. 2012;22:19366–75.

Evans AA, Cheung E, Nyberg KD, Rowat AC. Wrinkling of milk skin is mediated by evaporation. Soft Matter. 2017;13:1056–62.

Xiao H, Chen X. Modeling and simulation of curled dry leaves. Soft Matter. 2011;7:10794–802.

Huraux K, Narita T, Bresson B, Fretigny C, Lequeux F. Wrinkling of a nanometric glassy skin/crust induced by drying in poly(vinyl alcohol) gels. Soft Matter. 2012;8:8075–81.

Rizzieri R, Mahadevan L, Vaziri A, Donald A. Superficial wrinkles in stretched, drying gelatin films. Langmuir. 2006;22:3622–6.

Izawa H. Preparation of biobased wrinkled surfaces via lignification-mimetic reactions and drying: a new approach for developing surface wrinkling. Polym J. 2017;49:759–65.

Izawa H, Okuda N, Ifuku S, Morimoto M, Saimoto H, Rojas OJ. Bio-based wrinkled surfaces harnessed from biological design principles of wood and peroxidase activity. ChemSusChem. 2015;8:3892–6.

Izawa H, Dote Y, Okuda N, Sumita M, Ifuku S, Morimoto M, et al. Wood-mimetic skins prepared using horseradish peroxidase catalysis to induce surface wrinkling of chitosan film upon drying. Carbohydr Polym. 2017;173:519–25.

Pawar SN, Edgar KJ. Alginate derivatization: a review of chemistry, properties and applications. Biomaterials. 2012;33:3279–305.

Kurt ID, Størker TM, Gudmund, S, Olav S in Food polysaccharides and their applications 2nd edn (ed. Alistair MS, Glyn OP, Peter AW) Ch. 9, 289-334 (CRC press, London, UK, 2006).

Lee KY, Mooney DJ. Alginate: properties and biomedical applications. Prog Polym Sci. 2012;37:106–26.

Luo YC, Wang Q. Recent development of chitosan-based polyelectrolyte complexes with natural polysaccharides for drug delivery. Int J Biol Macromol. 2014;64:353–67.

Chen HN, Xing XD, Tan HP, Jia Y, Zhou TL, Chen Y, et al. Covalently antibacterial alginate-chitosan hydrogel dressing integrated gelatin microspheres containing tetracycline hydrochloride for wound healing. Mat Sci Eng C Mater. 2017;70:287–95.

Criado M, Criado M, Rebollar E, Nogales A, Ezquerra TA, Boulmedais F, et al. Quantitative nanomechanical properties of multilayer films made of polysaccharides through spray assisted layer-by-layer assembly. Biomacromolecules. 2017;18:169–77.

Fujie T, Matsutani N, Kinoshita M, Okamura Y, Saito A, Takeoka S. Adhesive, flexible, and robust polysaccharide nanosheets integrated for tissue-defect repair. Adv Funct Mater. 2009;19:2560–8.

Iijima K, Tsuji Y, Kuriki I, Kakimoto A, Nikaido Y, Ninomiya R, et al. Control of cell adhesion and proliferation utilizing polysaccharide composite film scaffolds. Colloid Surf B. 2017;160:228–37.

Zhang LL, Fang HW, Zhang KX, Yin JB. Homologous sodium alginate/chitosan-based scaffolds, but contrasting effect on stem cell shape and osteogenesis. ACS Appl Mater Interfaces. 2018;10:6930–41.

Iijima K, Ohyama S, Yuyama K, Shono A, Hashizume M. Selective fabrication of hollow and solid polysaccharide composite fibers using a microfluidic device by controlling polyion complex formation. Polym J. 2018;50:1187–98.

Breid D, Crosby AJ. Effect of stress state on wrinkle morphology. Soft Matter. 2011;7:4490–6.

Izawa H, Okuda N, Moriyama A, Miyazaki Y, Ifuku S, Morimoto M, et al. Biobased wrinkled surfaces induced by wood mimetic skins upon drying: effect of mechanical properties on wrinkle morphology. Langmuir. 2016;32:12799–804.

Befahy S, Lipnik P, Pardoen T, Nascimento C, Patris B, Bertrand P, et al. Thickness and elastic modulus of plasma treated PDMS silica-like surface layer. Langmuir. 2010;26:3372–5.

Izawa H, Okuda N, Yonemura T, Kuroda K, Ochi K, Ifuku S, et al. Application of bio-based wrinkled surfaces as cell culture scaffolds. Colloid Interface. 2018;2:15.

Chatelet C, Damour O, Domard A. Influence of the degree of acetylation on some biological properties of chitosan films. Biomaterials. 2001;22:261–8.

Freier T, Koh HS, Kazazian K, Shoichet MS. Controlling cell adhesion and degradation of chitosan films by N-acetylation. Biomaterials. 2005;26:5872–8.

Lee JH, Go AK, Oh SH, Lee KE, Yuk SH. Tissue anti-adhesion potential of ibuprofen-loaded PLLA-PEG diblock copolymer films. Biomaterials. 2005;26:671–8.

Izumi R, Komada S, Ochi K, Karasawa L, Osaki T, Murahata Y, et al. Favorable effects of superficially deacetylated chitin nanofibrils on the wound healing process. Carbohydr Polymer. 2015;123:461–7.

Azuma K, Nishihara M, Shimizu H, Itoh Y, Takashima O, Osaki T, et al. Biological adhesive based on carboxymethyl chitin derivatives and chitin nanofibers. Biomaterials. 2015;42:20–29.

Izawa H, Kawakami K, Sumita M, Tateyama Y, Hill JP, Ariga K. Beta-cyclodextrin-crosslinked alginate gel for patient-controlled drug delivery systems: regulation of host-guest interactions with mechanical stimuli. J Mater Chem B. 2013;1:2155–61.

Acknowledgements

This work was supported in part by JSPS KAKENHI Grant Number 16K05916.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Izawa, H., Miyazaki, Y., Yonemura, T. et al. Polysaccharide-based wrinkled surfaces induced by polyion complex skin layers upon drying. Polym J 51, 675–683 (2019). https://doi.org/10.1038/s41428-019-0174-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0174-7

This article is cited by

-

PJ ZEON Award for outstanding papers in Polymer Journal 2019

Polymer Journal (2020)