Abstract

This article focuses on the synthesis and thermal properties of poly(oligomethylene-cyclopentylene)s and poly(oligomethylene-cyclohexylene)s with regulated regio- and stereochemistry. Pd complexes with diimine ligands promote controlled isomerization polymerization of 4-alkylcyclopentenes to afford polymers with 1,3-trans-cyclopentylene groups and oligomethylene spacers alternating along the polymer chain. Pd complexes with a C2 symmetric structure enable isospecific polymerization of 4-alkylcyclopentenes, and the resultant isotactic polymers show liquid-crystalline properties. Cyclopolymerization of 1,6-heptadiene by bis(imino)pyridine Fe and Co catalysts produces poly(ethylene-1,2-cyclopentylene) with cis and trans-stereochemistry, respectively. Synthesis of poly(oligomethylene-1,4-cyclohexylene)s with trans or cis structure can be achieved by Pd-catalyzed isomerization polymerization of alkenylcyclohexanes or methylenecyclohexanes. The polymers with 1,4-trans-cyclohexylene show a high melting point that depends on the length of the oligomethylene spacer in the polymer. The thermal properties of the poly(oligomethylene-cyclopentylene)s and poly(oligomethylene-cyclohexylene)s are compared to those of previously reported polymers with different regio- or stereochemistry.

Similar content being viewed by others

Introduction

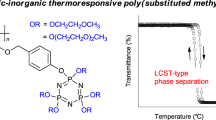

Hydrocarbon polymers with cycloalkane groups have recently attracted increased attention because they often exhibit high thermal stability and optical transparency [1]. The type of linkage and structure of the cycloalkylene groups affect the self-assembly of the polymer chains and the properties of the polymers. Thus, it is highly important to control the regio- and stereoselectivity of the cycloalkylene groups in the synthesis of the polymers. Figure 1 shows the previously reported polymerization for the synthesis of poly(oligomethylene-cyclopentylene)s and poly(oligomethylene-cyclohexylene)s [2,3,4]. Although there have been several examples of the syntheses of poly(oligomethylene-cyclopentylene)s with 1,2-cis, 1,2-trans, or 1,3-cis structure, selective synthesis of poly(oligomethylene-1,3-trans-cyclopentylene)s has not been reported to date. Examples of the synthesis of polymers bearing cyclohexylene groups with controlled regio- and stereochemistry have also been limited. It has been difficult to obtain the polymers with oligomethylene spacers that are longer than the trimethylene group.

Recently, we reported that late transition metal complexes are effective for cyclopolymerization of 1,6-dienes and isomerization polymerization of cycloolefins and alkenylcycloalkanes to afford poly(oligomethylene-cycloalkylene)s [5,6,7]. The present article focuses on the synthesis of polyolefins bearing cycloalkylene groups with regulated regio- and stereochemistry, reported by our group as well as others, and on the studies of the thermal properties of these polymers.

Poly(oligomethylene-cyclopentylene)s

Previously reported methods for the synthesis of poly(oligomethylene-cyclopentylene) include (1) cyclopolymerization of 1,5-hexadiene [8,9,10,11,12,13,14,15,16,17,18], (2) cyclocopolymerization of butadiene with ethylene [19], (3) alternating copolymerization of cyclopentene with ethylene [20, 21], and (4) ring-opening metathesis polymerization (ROMP) of norbornene or bicyclo[3.2.0]hept-6-ene followed by hydrogenation (Fig. 1) [22]. The polymer obtained by ROMP of norbornene has cis-fused 1,3-cyclopentylene groups. By contrast, cyclopolymerization of 1,5-hexadiene generally affords the polymer with both trans- and cis-fused 1,3-cyclopentylene groups, where the trans/cis ratio varies from 98/2 to 6/96 depending on the catalyst used. Polymers with 1,2-cyclopentylene groups can be obtained by copolymerization of cyclopentene with ethylene, cyclocopolymerization of butadiene with ethylene, and ROMP of bicyclo[3.2.0]hept-6-ene followed by hydrogenation. The 1,2-cyclopentylene groups of the butadiene/ethylene copolymer are predominantly controlled to be in the trans configuration. By contrast, the polymer obtained by ROMP of bicyclo[3.2.0]hept-6-ene and subsequent hydrogenation has cis-1,2-cyclopentylene groups only. Although 1st generation Grubbs catalyst affords an atactic polymer, the polymer obtained by the chiral Schrock catalyst shows isotactic stereoregularity. Alternating copolymerization of cyclopentene with ethylene also selectively affords a polymer containing cis-1,2-cyclopentylene groups only.

Recently, we found that diimine-Pd complexes in combination with Na[B{C6H3(CF3)2-3,5}4] (NaBARF) are effective for the isomerization polymerization of 4-alkylcyclopentenes (Fig. 2) [23]. The polymerization proceeds via face-selective coordination/addition of the Pd center to the C = C group of the monomer followed by the isomerization of the growing chain end via a chain-walking reaction of the Pd center to the terminal of the alkyl group. Selective insertion of the new monomer into the Pd-CH2R bond rather than into Pd-CHRR′ or Pd-CRR′R″ bonds leads to the formation of the polymer containing trans-1,3-cyclopentylene units and oligomethylene spacers alternating along the polymer chain. The polymer obtained by the Pd complex I with pseudo-C2v symmetric structure is atactic and is soluble in chloroform and tetrahydrofuran (THF). By contrast, the polymerization by the pseudo-C2 symmetric Pd complex (II) proceeded much faster than that by I and afforded the polymer with a highly trans-isotactic structure. The isotactic polymer is poorly soluble in common organic solvents at room temperature.

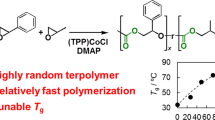

The use of diimine-Pd catalysts leads to the cyclopolymerization of 1,6-dienes with the substituents on the 4-position to afford the polymer with trans-1,2-cyclopentylene groups [24,25,26,27,28]. However, the cyclopolymerization of 1,6-heptadiene without substituents does not proceed by the Pd catalyst because the chain-walking of the Pd center on the 1,6-heptadiene will result in an inactive π-allyl Pd species. In contrast, bis(imino)pyridine Fe and Co complexes smoothly promote the cyclopolymerization of 1,6-heptadiene in the presence of modified methylaluminoxane (MMAO) to afford polymers with 1,2-cyclopentylene groups (Fig. 3) [29, 30]. Cyclization of the monomer occurs quantitatively during the polymerization, and the repeating units with six-membered rings are not included in the produced polymer. The cyclopentylene group of the polymer obtained by the Fe catalyst III is controlled in cis configuration predominantly (cis:trans = 95:5), and the microstructure of the polymer is mostly atactic. By contrast, the Co catalyst IV affords the polymer with trans-cyclopentylene group exclusively (trans > 99%). The microstructure of the polymer is moderately controlled, but its exact tacticity has not been determined.

Table 1 shows the summary of the phase-transition temperatures of the poly(oligomethylene-cyclopentylene)s with various regio- and stereochemistries. The polymers with 1,2-cis-cyclopentylene groups show high melting points (130 and 182 °C, respectively, for atactic and isotactic polymers (n = 2)) [22, 30]. The crystal structure of isotactic poly(ethylene-1,2-cis-cyclopentylene) has been reported [31, 32]. On the basis of X-ray diffraction, geometrical and conformational analyses of a single chain and packing energy calculations, it was revealed that the polymer chains are packed in an orthorhombic unit cell. A high degree of conformational disorder is present in the crystalline state due to the conformational freedom of the cyclopentylene groups. Poly(ethylene-1,2-trans-cyclopentylene) does not show a melting temperature in the range between –100 and 250 °C but shows a glass transition temperature at 3.2 °C [30]. Poly(trimethylene-1,2-trans-cyclopentylene) with isotactic structure shows glass transition and melting temperatures at 16.3 and 182.5 °C, respectively [19]. The crystal structure of the polymer with the 1,2-trans-cyclopentylene unit is unknown.

The polymers bearing the 1,3-cis-cyclopentylene groups also show high melting points of 171 and 134 °C, respectively, for the polymers with methylene and ethylene linkage between the cyclopentylene units [1, 33]. The atactic polymers with the 1,3-trans-cyclopentylene unit showed a phase transition due to the glass transition and/or melting in DSC measurements [33]. By contrast, two phase transitions were observed in the DSC measurements of the isotactic polymers [23]. Polymers with shorter oligomethylene spacers (n = 1 and 3) showed monotropic transitions, while those with longer oligomethylene spacers undergo enantiotropic transitions. Isotactic poly(oligomethylene-1,3-trans-cyclopentylene)s are liquid-crystalline in the range between these two phase-transition temperatures as observed by polarizing microscopy. The phase-transition temperature between the liquid-crystalline phase and the solid phase or isotropic phase can be varied by changing the length of the oligomethylene spacer of the polymer.

Thermal and crystal structure characterizations of poly(ethylene-1,2-cyclopentylene)s with trans- and cis-structures and with different tacticity have been reported [33, 34]. Regardless of the stereochemistry, the polymers adopt similar disordered crystalline structures, and the polymer chains were found to be packed in a hexagonal arrangement. The polymers with high cis structure show higher melting points, which is in line with the shorter distance between the polymer chains for the polymer with a higher cis content. The crystallinity of the polymer increases as the stereoregularity of the polymers becomes higher. It has been reported that low molecular weight polymers with 1,3-cyclopentylene groups with predominantly trans-stereochemistry, synthesized by the cyclopolymerization of 1,5-hexadiene by C2-symmetric zirconocene catalyst, are also liquid crystalline [35, 36]. As the polymer of 4-alkylcyclopentene with atactic structure is not liquid crystalline, the isotactic structure would be important for the ordered alignment of the polymer chain necessary for the liquid-crystalline properties. The polymer obtained by the cyclopolymerization of 1,5-hexadiene using a racemic C2-symmetric zirconocene catalyst shows Schlieren-like texture, indicating a nematic liquid crystal [35]. On the other hand, a fingerprint texture of the polymer produced by the optically active catalyst indicates a cholesteric liquid crystal [36]. The detailed phase structure of the isotactic poly(oligomethylene-cyclopentylene)s is currently not clear.

Poly(oligomethylene-cyclohexylene)s

Synthesis of poly(oligomethylene-1,3-cyclohexylene)s has been achieved by zirconocene-catalyzed cyclopolymerization of 1,6-heptadiene, where the trans/cis selectivity of the cyclohexylene group could not be controlled [9]. By contrast, some Hf and Zr catalysts enable cis-specific polymerization of the 1,6-heptadiene polymer (Fig. 1) [37,38,39]. Polyolefins with 1,2-cyclohexylene groups can also be synthesized by copolymerization of ethylene with cyclohexene by half-titanocene catalysts, where the incorporation of the cyclohexene unit reaches up to 16.2 mol% [40]. Cationic polymerization of β-pinene followed by hydrogenation affords the poly(isobutylene-1,4-cyclohexylene) [41]. ROMP of bicyclo[2.2.2]oct-2-ene [42] or bicyclo[4.2.0]octa-7-ene [43] produces the unsaturated hydrocarbon polymer bearing six-membered rings, but the subsequent hydrogenation has not been performed.

Attempted synthesis of polymer with the 1,2-cyclohexylene group by cyclopolymerization of 1,7-octadiene by the bis(imino)pyridine Co catalyst IV/MMAO results in no reaction. The reaction of 1,7-octadiene by the bis(imino)pyridine Fe catalyst III/MMAO produced oily product (up to 73% yield). Its 13C{1H} NMR spectrum shows the absence of vinyl carbon signals and the presence of many unassigned signals, including olefinic signals (δ 124–131). Thus, the structure of the product has not been confirmed, and its molecular weight is low. Synthesis of the polymer with the six-membered ring was also attempted by the isomerization polymerization of 3-methylcyclohexene by diimine-Pd catalysts. The reaction by using catalyst 2/NaBARF attained quantitative conversion of 3-methylcyclohexene. 13C{1H} NMR analysis of the product showed the signals due to olefinic carbons at δ 121, 126, and 131–133. The relative intensity of the olefin signals and those due to an aliphatic region indicate that the product is 7-8 mer.

In contrast to the above attempts, synthesis of poly(oligomethylene-trans-1,4-cyclohexylene)s can be achieved by the isomerization polymerization of alkenylcyclohexanes by diimine-Pd catalysts V/NaBARF (Fig. 4) [44]. The polymerization mechanism involves 2,1-insertion of the monomer to the cyclohexyl-Pd active end, chain-walking of the Pd center along the cyclohexane ring, and selective insertion of the new monomer when the Pd center is attached to the 4-position of the cyclohexyl group. Diimine-Pd catalysts are also effective for the isomerization polymerization of methylenecyclohexane to give poly(methylene-1,4-trans-cyclohexylene) [45]. Note that coordination polymerization of methylenecyclohexane has been difficult due to the bulky structure of the monomer. 4-Alkyl-1-methylenecyclohexanes undergo isomerization polymerization by the Pd catalyst to afford the polymers bearing the 1,4-cis-cyclohexylene group and oligomethylene spacer.

Table 2 summarizes the thermal properties of the poly(oligomethylene-cyclohexylene)s with various regio- and stereochemistries. It has been reported that DSC analysis of isotactic poly(1,3-cis-cyclohexylene-methylene) by a heat/cool/heat cycle at the rate of 10 °C/min showed Tg and Tm at 103.9 and 179.0 °C, respectively, in the first scan but only Tg in the second scan [37]. This result was ascribed to the slow crystallization kinetics of the polymer in an amorphous glassy state due to its high Tg value. Actually, DSC analysis at the rate of 1 °C/min showed Tg and Tm at 92.2 and 208.5 °C in the fourth scan [38]. Poly(oligomethylene-1,4-cyclohexylene)s (either trans or cis structure) with n < 3 did not show a transition or melting temperature in the 30–300 °C range. Poly(1,4-trans-cyclohexylene-oligomethylene)s with n ≥ 3 show high melting points ranging from 226 to 130 °C, depending on the length of the oligomethylene spacer in the repeating unit [44]. In particular, the melting point of poly(trimethylene-1,4-trans-cyclohexylene) (226 °C) is the highest among those of the previously reported poly(oligomethylene-cycloalkylene)s. By contrast, poly(tetramethylene-1,4-cis-cyclohexylene)s shows only a glass transition temperature at 162 °C [45]. These results may be due to the high crystallinity of the polymer with the 1,4-trans-cyclohexylene group compared to that with the 1,4-cis-cyclohexylene structure.

Summary

Fe- and Co-catalyzed cyclopolymerization of 1,6-heptadiene and Pd-catalyzed isomerization polymerization of 4-alkylcyclopentenes and alkenylcyclohexanes enable the synthesis of poly(oligomethylene-cycloalkylene)s with controlled regio- and stereochemistry. Some of the polymers are unprecedented, and the liquid-crystalline properties of the polymers with 1,3-trans-cyclopentylene group and the very high thermal stability of the polymers with the 1,4-trans-cyclopentylene group were revealed. Controlled synthesis of the polymers with 1,2- or 1,3-trans-cyclohexylene groups and the thermal properties of such polymers are still unknown. Further development of the synthetic method for poly(oligomethylene-cycloalkylene)s will enable a deeper understanding of the effect of cycloalkylene units on the self-assembly of the polymer chain and the thermal properties of the polymer.

References

Yamazaki M. Industrialization and application development of cyclo-olefin polymer. J Mol Catal A. 2004;213:81–87.

Dragutan V, Streck R. Advances in cycloolefin polymerization. In: Vasile C, editor. Handbook of polyolefins. 2nd ed. New York: Marcel Dekker; 2000. pp. 99–137.

Li X, Hou Z. Organometallic catalysts for copolymerization of cyclic olefins. Coord Chem Rev. 2008;252:1842–69.

Takeuchi D. Recent progress in olefin polymerization catalyzed by transition metal complexes: new catalysts and new reactions. Dalton Trans. 2010;39:311–28.

Takeuchi D. Novel controlled polymerization of cyclo-olefins, dienes, and trienes by utilizing reaction properties of late transition metals. Macromol Chem Phys. 2011;212:1545–51.

Takeuchi D. Stereo-controlled synthesis of polyolefins with cycloalkane groups by using transition metals. Polym J. 2012;44:919–28.

Takeuchi D, Osakada K. Controlled isomerization polymerization of olefins, cycloolefins, and dienes. Polym. 2016;82:392–405.

Resconi L, Waymouth RM. Diastereoselectivity in the homogeneous cyclopolymerization of 1,5-hexadiene. J Am Chem Soc. 1990;112:4953–4.

Coates GW, Waymouth RM. Chiral polymers via cyclopolymerization. J Mol Catal. 1992;76:189–94.

Coates GW, Waymouth RM. Enantioselective cyclopolymerization of 1,5-hexadiene catalyzed by chiral zirconocenes: a novel strategy for the synthesis of optically active polymers with chirality in the main chain. J Am Chem Soc. 1993;115:91–98.

Mitani M, Oouchi K, Hayakawa M, Yamada T, Mukaiyama T. Stereoselective cyclopolymerization of 1,5-hexadiene using novel bis(ferrocenyl)zirconocene catalyst. Chem Lett. 1995;24:905–6.

Sernetz FG, Mülhaupt R, Waymouth RM. Homo-, co-, and terpolymerization of 1,5-hexadiene using a methylalumoxane activated mono-cp-amido-complex. Polym Bull. 1997;38:141–8.

Jayaratne KC, Keaton RJ, Henningsen DA, Sita LR. Living Ziegler-Natta cyclopolymerization of nonconjugated dienes: new class of microphase-separated polyolefin block copolymers via a tandem polymerization/cyclopolymerization strategy. J Am Chem Soc. 2000;122:10490–1.

Kim I, Shin YS, Lee JK, Won M-S. Cyclopolymerization of 1,5-hexadiene catalyzed by various stereospecific metallocene compounds. J Polym Sci A. 2000;38:1520–7.

Napoli M, Costabile C, Pragliola S, Longo P. Closing cycles with C 2-symmetric Ziegler-Natta polymerization catalysts. Macromolecules. 2005;38:5493–7.

Yeori A, Goldberg I, Shuster M, Kol M. Diastereomerically-specific zirconium complexes of chiral salan ligands: isospecific polymerization of 1-hexene and 4-methyl-1-pentene and cyclopolymerization of 1,5-hexadiene. J Am Chem Soc. 2006;128:13062–3.

Yeori A, Goldberg I, Kol M. Cyclopolymerization of 1,5-hexadiene by enantiomerically-pure zirconium salan complexes. Polymer optical activity reveals α-olefin face preference. Macromolecules. 2007;40:8521–3.

Volkis V, Averbuj C, Eisen MS. Reactivity of group 4 benzamidinate complexes towards mono- and bis-substituted silanes and 1,5-hexadiene. J Organomet Chem. 2007;692:1940–50.

Choo TN, Waymouth RM. The dual-site alternating cyclocopolymerization of 1,3-butadiene with ethylene. J Am Chem Soc. 2003;125:8970–1.

Natta G, Dall’Asta G, Mazzanti G, Pasquon I, Valvassori A, Zambelli A. Crystalline alternating ethylene-cyclopentene copolymers and other ethylene-cycloolefin copolymers. Makromol Chem. 1962;54:95–101.

Lavoie AR, Ho MH, Waymouth RM. Alternating stereospecific copolymerization of cyclopentene and ethylene with constrained geometry catalysts. Chem Commun. 864–5 (2003).

Fujita M, Coates GW. Synthesis and characterization of alternating and multiblock copolymers from ethylene and cyclopentene. Macromolecules. 2002;35:9640–7.

Okada T, Takeuchi D, Shishido A, Ikeda T, Osakada K. Isomerization polymerization of 4-alkylcyclopentenes catalyzed by Pd complexes: hydrocarbon polymers with isotactic-type stereochemistry and liquid-crystalline properties. J Am Chem Soc. 2009;131:10852–3.

Park S, Takeuchi D, Osakada K. Pd complex-promoted cyclopolymerization of functionalized α,ω-dienes and copolymerization with ethylene to afford polymers with cyclic repeating units. J Am Chem Soc. 2006;128:3510–1.

Park S, Okada T, Takeuchi D, Osakada K. Cyclopolymerization and copolymerization of functionalized 1,6-heptadienes catalyzed by Pd complexes: mechanism and application to physical-gel formation. Chem Eur J. 2010;16:8662–78.

Okada T, Park S, Takeuchi D, Osakada K. Pd-catalyzed polymerization of dienes that involves chain-walking isomerization of the growing polymer end: synthesis of polymers composed of polymethylene and five-membered-ring units. Angew Chem Int Ed. 2007;46:6141–3.

Okada T, Takeuchi D, Osakada K. Cyclopolymerization of monoterminal 1,6-dienes catalyzed by Pd complexes. Macromolecules. 2010;43:7998–8006.

Motokuni K, Takeuchi D, Osakada K. Cyclopolymerization of 1,6-heptadienes and 1,6,11-dodecatrienes having acyclic substituents catalyzed by Pd-diimine complexes. Polym Bull. 2015;72:583–97.

Takeuchi D, Matsuura R, Park S, Osakada K. Cyclopolymerization of 1,6-heptadienes catalyzed by iron and cobalt complexes: synthesis of polymers with trans- or cis-fused 1,2-cyclopentanediyl groups depending on the catalyst. J Am Chem Soc. 2007;129:7002–3.

Takeuchi D, Matsuura R, Fukuda Y, Osakada K. Selective cyclopolymerization of α,ω-dienes and copolymerization with ethylene catalyzed by Fe and Co complexes. Dalton Trans. 2009;8955–62.

Auriemma F, De Rosa C, Esposito S, Coates GW, Fujita M. Alternating isotactic ethylene–cyclopentene copolyer: a crystalline engineering plastomer including high amounts of structural disorder. J Am Chem Soc. 2005;127:2850–1.

Auriemma F, De Rosa C, Esposito S, Coates GW, Fujita M. Crystal structure of alternating isotactic ethylene–cyclopentene copolymer. Macromolecules. 2005;38:7416–29.

de Ballesteros OR, Venditto V, Auriemma F, Guerra G, Resconi L, Waymouth R, Mogstad A-L. Thermal and structural characterization of poly(methylene-1,3-cyclopentane) samples of different microstructures. Macromolecules. 1995;28:2383–8.

de Ballesteros OR, Cavallo L, Auriemma F, Guerra G. Conformational analysis of poly(methylene-1,3-cyclopentane) and chain conformation in the crystalline phase. Macromolecules. 1995;28:7355–62.

Naga N, Yabe T, Sawaguchi A, Sone M, Noguchi K, Murase S. Liquid crystalline features in a polyolefin of poly(methylene-1,3-cyclopentane). Macromolecules. 2008;41:7448–52.

Naga N, Shimura H, Sone M. Liqiud crystalline features of optically active poly(methylene-1,3-cyclopentane). Macromolecules. 2009;42:7631–3.

Edson JB, Coates GW. Cyclopolymerization of nonconjugated dienes with a tridentate phenoxyamine hafnium complex supported by an sp3-C donor: isotactic enchainment and diastereoselective cis-ring closure. Macromol Rapid Commun. 2009;30:1900–6.

Crawford KE, Sita LR. Stereoengineering of poly(1,3-methylenecyclohexane) via two-state living coordination polymerization of 1,6-heptadiene. J Am Chem Soc. 2013;135:8778–81.

Crawford KE, Sita LR. De novo design of a new class of “hard–soft” amorphous, microphase-separated, polyolefin block copolymer thermoplastic elastomers. ACS Macro Lett. 2015;4:921–5.

Wang W, Fujiki M, Nomura K. Copolymerization of ethylene with cyclohexene (CHE) catalyzed by nonbridged half-titanocenes containing aryloxo ligand: notable effect of both cyclopentadienyl and anionic donor ligand for efficient CHE incorporation. J Am Chem Soc. 2005;127:4582–3.

Satoh K, Sugiyama H, Kamigaito M. Biomass-derived heat-resistant alicyclic hydrocarbon polymers: poly(terpenes) and their hydrogenated derivatives. Green Chem. 2006;8:878–82.

Hamilton JG, Ivin KJ, Rooney JJ. Ring-opening polymerisation of bicyclo[2.2.2]oct-2-ene. Br Polym J. 1985;17:41–42.

Thu CT, Bastelberger T, Höcker H. On the polymerization of bicyclo[4.2.0]octa-7-ene by a metathesis catalyst and by tungsten carbenes. Makromol Chem Rapid Commun. 1981;2:7–9.

Takeuchi D. Precise isomerization polymerization of alkenylcyclohexanes: stereoregular polymers containing six-membered rings along the polymer chain. J Am Chem Soc. 2011;133:11106–9.

Takeuchi D, Watanabe K, Sogo K, Osakada K. Polymerization of methylenecyclohexanes catalyzed by diimine-Pd complex. Polymers Having trans- or cis-1,4- and trans-1,3-cyclohexylene groups. Organometallics. 2015;34:3007–11.

Acknowledgements

DT is grateful to Professor Kohtaro Osakada of the Tokyo Institute of Technology for helpful suggestions and discussion.

Funding

This work was supported by JSPS KAKENHI Grant Numbers JP18750094 and JP2265012.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Takeuchi, D. Synthesis and thermal properties of poly(oligomethylene-cycloalkylene)s with regulated regio- and stereochemistry. Polym J 50, 573–578 (2018). https://doi.org/10.1038/s41428-018-0073-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0073-3

This article is cited by

-

Controllable Preparation of Branched Polyolefins with Various Microstructural Units via Chain-walking Ethylene and Pentene Polymerizations

Chinese Journal of Polymer Science (2023)

-

Synthesis of polycyclic polyolefins by a Pd-catalyzed isomerization polymerization of vinylcycloalkanes

Polymer Journal (2020)