Abstract

We designed dielectric gels, a new type of polymer-based dielectric material. By using solvents with high dielectric constants, the gels achieve a unique combination of ultra-high dielectric constant, low elastic modulus, and excellent transparency, which are extremely challenging or impossible to realize with traditional polymer dielectrics. The gels exhibit high stretchability (stretch of approximately 10) and low mechanical hysteresis. We demonstrated the use of the dielectric gels by fabricating a bioinspired tunable lens, the focal length of which can be adjusted by varying the applied voltage. We believe that the dielectric gels, as a new type of polymer dielectric, offer new opportunities for soft robotics, sensors, electronics, optics, and biomimetics.

Similar content being viewed by others

Introduction

As soft and flexible electrical insulators, polymer dielectrics have enabled diverse modern technologies, including electric power systems1, flexible electronics2, non-volatile memory devices3, electrocaloric cooling4, and soft robotics5,6,7, benefiting from their diverse functionality. Deformable polymer dielectrics can express mechanical motions in response to electrical stimulation: when a dielectric membrane is subjected to a voltage across its thickness, the membrane suffers an electrostatic force, the so-called Maxwell stress, and thus squeezes in the thickness direction and expands in the area direction. Such dielectrics behave as actuators, as demonstrated by ferroelectric polymers8, liquid crystal elastomers9, electrostrictive polymers10, and dielectric elastomers5. However, the high voltage needed for actuation and the poor mechanical reliability hinder developments in practical applications. Improving the dielectric constant and lowering the elastic modulus of the polymer dielectrics are efficient ways of lowering the actuating voltage11,12. Conductive particles or high-k ceramics have been filled into elastomers to increase their dielectric constants, but these rigid fillers have also dramatically increased the elastic modulus and reduced the extensibility13,14,15,16. Another approach is to use fluids as fillers; liquid–metal microdroplets have been integrated into elastomer substrates, which increased the dielectric constant by over 400% and avoided the internal compliance mismatch of rigid fillers17.

However, polymer dielectrics with optical transmittance functionality are emerging materials with practical significance in next-generation flexible displays and flexible touchscreen panels. By fabricating graphene interlayers to form polymer/graphene/polymer structures, Kim et al. prepared flexible and transparent dielectric films with a high dielectric constant (ε) of 51 and a transmittance of ~90%18. Park et al. used ultralong metal nanofibers as fillers to increase ε and obtained flexible and transparent dielectric cellulose nanofiber films (ε above 9.2 with a high transmittance of 90%)19.

Herein, we introduce a new type of polymer dielectric, dielectric gels. The new materials achieve a unique combination of ultra-high ε (30–50), low elastic modulus (from 20 to 60 KPa), and excellent transparency (~99%). A gel is a polymer composite with a three-dimensional polymer network that contains a large amount of solvent20,21. Gels are present as solid-state soft materials. We designed dielectric gels by using solvents with ultra-high ε and a polymer network that matched well with the solvents. Dielectric gels offer new opportunities for soft robotics, sensors, electronics, optics, and biomimetics.

Materials and methods

Synthesis of the dielectric gels

We mixed appropriate amounts of 4-acryloylmorpholine (ACMO, monomer), N,N′-methylenebis(acrylamide) (MBA, cross-linker), and 1-hydroxycyclohexyl phenyl ketone (photoinitiator 184) with solvents to form gelation precursor solutions. Unless otherwise stated, the solvent content was fixed at 50 wt%. The precursor solution was poured into a transparent glass mold with a silicone spacer and release films. After irradiation with ultraviolet light (365 nm, 400 W power) for 5 min, the dielectric gel was formed. We controlled the thickness of the dielectric gel by adjusting the thickness of the silicone spacer. Dielectric gels for electroactive actuation and tunable lens experiments were synthesized by a similar photocuring process. The solvent (PC:EC = 1:4) content was fixed at 20 wt%, the volume ratio of 4-acryloylmorpholine (ACMO) and 2-ethylhexyl acrylate (2-EHA) monomers was fixed at 1:1, and the molar ratios of the photoinitiator and monomer and the cross-linker and monomer were fixed at 1% and 0.1%, respectively.

Mechanical tests

Mechanical tests were performed on an electronic tensile machine (CMT6503, MTS) with a 500 N load cell. The gels were cut into dumbbell shapes (testing dimensions of 12.0 × 2.0 × 2.0 mm3) for the tests.

Dielectric tests

Dielectric tests were performed on a broadband dielectric/impedance spectrometer (Novocontrol GmbH). The gels were 1-mm thick, the testing cupper electrodes were 30 mm in diameter, and the testing Vrms (Volt root mean square) was set at 1 V. The gel samples were treated without metal sputtering on their surfaces.

Transparency tests

The transparency tests were performed on a ultraviolet–visible spectrophotometer (UV–vis) spectrophotometer (PE Lambda950, Instrument Analysis Center of Xi’an Jiaotong University). The gels for the tests were 1-mm thick.

Lens fabrication

The lenses were fabricated from two gel membranes with silicone oil sealed between them. The membranes were equally biaxially pre-stretched by λ = 2.5 with an original thickness h = 1 mm.

Results

We chose propylene carbonate (PC) and ethylene carbonate (EC) as solvents for the dielectric gels (Fig. 1a) because they possess ultra-high ε (65 for PC and 90 for EC)22, good chemical stability, low vapor pressure, and low toxicity23. They are widely used as electrolyte solvents in lithium-ion batteries. The melting points of PC and EC are −48.8 °C and 36.4 °C, respectively24. Although EC is icy at room temperature, it can be mixed with PC to form a homogeneous solution. The mixed solution is liquid at room temperature and has a higher ε than PC. We mixed appropriate amounts of 4-acryloylmorpholine (ACMO, monomer), N,N′-methylenebis (acrylamide) (MBA, cross-linker), and 1-hydroxycyclohexyl phenyl ketone (photoinitiator 184) with the solvents to form gelation precursor solutions (Fig. 1b). Unless otherwise stated, the solvent content was fixed at 50 wt%. The precursor solution was poured into a transparent glass mold with a silicone spacer and release films. After irradiation with ultraviolet light (365 nm, 400 W power) for 5 min, the dielectric gel was formed (Fig. 1c, d).

a Schematic of a dielectric gel. Both the polymer chain and the solvents in the gel system are dielectric materials. b Ingredients: monomer, 4-acryloylmorpholine (ACMO); cross-linker N,N′-methylenebis (acrylamide) (MBA); photoinitiator, 1-hydroxycyclohexyl phenyl ketone; and solvents, propylene carbonate (PC) and ethylene carbonate (EC). c Fabrication process of a dielectric gel. The gel was synthesized in minutes by photoinitiated polymerization. d Photographs of the dielectric gels demonstrating good stretchability and high transparency. The upper photograph is the gel without stretching and the lower photograph is the stretched gel

The gels were then cut into dumbbell shapes with dimensions 12.0 × 2.0 × 2.0 mm3. Mechanical tests were performed on an electronic tensile machine with a 500 N load cell. The stretching rate was set at 100 mm min−1 during both loading and unloading. The gels possess a low elastic modulus (tens of KPa) and good stretchability (with elongation at break ranging from ~200 to ~1100%), as shown in Fig. 2a, b. The cross-linker content of a gel greatly affects its mechanical properties: as the cross-linker content increases, the elastic modulus of a gel increases and the elongation at break decreases. A poly(4-acryloylmorpholine) gel with a cross-linker content of 0.15% was chosen for the cyclic loading–unloading tests (Fig. 2c). The initial loading cycle was set with a strain of 100%. After the loading–unloading cycle, the sample was immediately reloaded to 300% strain and then to 500% strain. The gel showed negligible mechanical hysteresis at each strain cycle, and it fully recovered its original length after unloading. A long-term cyclic loading–unloading test was also performed, in which the strain was set to 400%; the 100th cycle curve almost coincided with that of the initial cycle, and the elastic modulus remained unchanged (Figure S1).

The polymer and solvent contents of the testing gels are fixed at 50 wt% each. a Stress–strain curves of dielectric gels with different cross-linker contents (molar ratios to monomer, as labeled). Each gel was stretched until rupture. b Elastic modulus (calculated from the stress–strain curves at a strain of 10%) and strain at break, plotted against the cross-linker content. c Cyclic loading of a dielectric gel (cross-linker content of 0.15%). The initial loading cycle was set to 100% strain. After the loading–unloading cycle, the sample was immediately reloaded to 300% strain for the second cycle and then 500% strain for the third cycle. d Plot of the dielectric constants versus testing frequency for the dielectric gels with PC and EC/PC solvents; the ratio represents the volume ratio. e Plot of the dielectric dissipation factor versus testing frequency for the dielectric gels with PC and EC/PC solvents. f Transmittance test of a 1-mm-thick dielectric gel in the visible range

Dielectric properties were tested on a broadband dielectric/impedance spectrometer. The testing samples were 1-mm thick, and the testing copper electrodes were 30 mm in diameter. The gel samples were soft enough to be in good contact with the electrodes. The testing Vrms was set at 1 V. Figure 2d, e shows the dielectric properties of gels with solvents of different EC/PC volumetric ratios. The gels exhibit a high ε (30~50) over a broad frequency range (1 K–10 MHz). The solvent composition greatly affects the ε of the gels. A higher EC content results in a higher ε. As the frequency increases, the ε decreases slightly, as shown in Fig. 2d. This may be because the switching of the small-molecule dipoles is unable to match the switching of the electric field at high frequencies. The dielectric loss (loss tangent) of the gels was maintained at <0.1 over a frequency range of 20 K–10 MHz. At low frequencies (10–20 KHz), as the frequency decreases, the dielectric loss increases sharply (Figure S2), while the ε does not change much (Figure S3). We used pure PC as the solvent and studied the dielectric properties of gels with varying polymer contents of 50, 55, 60, and 65%. As the polymer content increases, ε decreases, and the dielectric loss at low frequency decreases substantially (Figures S4, S5).

The transmittance was measured on an UV–vis spectrophotometer. The gels are highly transparent in the visible range, as shown in Fig. 2f. A sample with a thickness of 1 mm showed a transmittance of 92.3% at 550 nm, corresponding to a transmittance of 99.2% for a 100-μm-thick gel. The transparency was calculated from the Lambert–Beer equation log(T) = KI, where T is the transparency, I is the thickness of the sample, and K is a constant.

Figure 3a plots the elastic modulus versus ε for various dielectric elastomers. Our dielectric gels possess a very low elastic modulus and ultra-high ε. The diagram of transmittance versus ε for different transparent materials is shown in Fig. 3b. We labeled the thickness of the materials for comparison in Fig. 3b and show the original transparency of the 1-mm-thick dielectric gel. We also show the transparency of our 0.1-mm-thick dielectric gel calculated according to the Lambert–Beer law. The dielectric gels showed very high transparency and high ε.

a Dielectric constant (testing frequency, 1 KHz) plotted against elastic modulus for dielectric gels, elastomers11, lead magnesium niobate-lead titanate (PMN-PT)-embedded silicones13, poly(3-hexylthiophene) (P3HT)-embedded silicones14, multiwalled carbon nanotube (MWCNT)-embedded poly(styrene-b-(ethylene-co-butylene)-b-styrene) (SEBS)15, silver nanoparticle (AgNP)-embedded silicones16, liquid-metal-embedded elastomers17, barium titanate (BT) nanoparticle- and dibutyl phthalate (DBP)-embedded polyurethane29, P(VDF-TrFE) electrostrictor10, CuPc-embedded P(VDF-TrFE)7, and PANI-embedded P(VDF-TrFE-CTFE)30. b Dielectric constant (testing frequency, 100 KHz) plotted against transparency for dielectric gels (100-μm thick, this work), glass, transparent plastics, metal-embedded cellulose films31, graphene-interlayered films28, and BT-embedded poly(vinyldene fluoride) (PVDF) films30

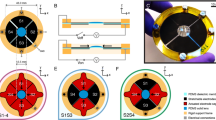

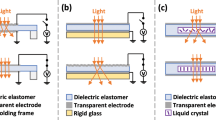

We demonstrated the use of the dielectric gel as an electroactive actuator. Figure 4a shows the voltage-induced deformation of the dielectric gel and VHB 4905 (3 M Company), the most frequently used material worldwide with a relative ε of ~4 and a shear modulus of a few tens of KPa. A voltage-induced 2200% areal actuation strain has been achieved, and many functional devices have been demonstrated using VHB25,26,27. The dielectric gel and VHB material originally had diameter D = 40 mm and thickness h = 0.5 mm, and both were equally biaxially pre-stretched 1.5 times by 18 clamps. Subsequently, a circular area at the center of the membrane was coated with carbon grease on both sides to act as electrodes. The effective actuation area was actuated from 25 to 28 mm with a linear strain of 12% (Supplementary Movie 1). The voltage needed for the dielectric gel is 2000 V, which is much lower than that for VHB (4200 V). Figure 4b, c shows the relationship between the electric field and the areal actuation strain. The gels for the electroactuation tests were both equally biaxially pre-stretched 1.5 times by 18 clamps. Subsequently, a circular area at the center of the membrane was coated with carbon grease on both sides to act as electrodes. We used a camera to catch the effective actuation area as the applied voltage increased until breakdown. The ordinate values were the linear strain. In Fig. 4b, we fixed the polymer content of the gels at 80%, and as the cross-linker content increased, the maximum actuation strain increased. At a fixed actuation strain, the needed voltage increases, which may be due to the higher elastic modulus of the gels at higher cross-linker content. Figure 4c shows the electroactuation properties of gels with different polymer contents. At higher polymer content, the maximum actuation strain was higher, and high voltages were difficult to sustain for gels with high liquid content (low polymer content). Figure 4d shows a demonstration of a voltage-driven tunable lens made of dielectric gels, referring to a similar configuration28. Transparent liquid was sandwiched between two membranes composed of the dielectric gels. The physical properties, including the mechanical and dielectric properties, of the dielectric gels used for electroactive actuation tests are shown in Figures S6, S7. When a voltage is applied, the two membranes tend to close and squeeze the liquid in the center, resulting in a change in the focal length of the biomimic lens. One can clearly resolve an object near the lens or an object far away from the lens by varying the applied voltage (Fig. 4d, Supplementary Movie 2). The design of the lens is inspired by human eyes. For human eyes, the ciliaris contracts to change the focal length of the eye. In our design, the dielectric gel acts as the muscle. When the dielectric gel is subjected to a voltage, it contracts to change the focal length of the lens.

a The voltage-induced deformation of the dielectric gel (left) and VHB 4905 (right). The initial diameter and thickness are the same. b Strain amplitude as a function of the applied voltage measured at room temperature for dielectric gels with 80% polymer content. c Strain amplitude as a function of the applied voltage measured at room temperature for dielectric gels with different polymer contents. d Demonstration of a bioinspired tunable lens made of dielectric gel. The focal length of the lens can be adjusted by varying the applied voltage

Discussion

In conclusion, by using high ε solvents, i.e., PC and EC/PC mixtures, we designed and fabricated a series of high-performance dielectric gels that simultaneously displayed ultra-high ε (30–50), low elastic modulus (from 20 to 60 KPa), and excellent transparency. The dielectric gels showed high stretchability (stretch of ~10) and low mechanical hysteresis. We demonstrated that the voltage needed for the same actuation strain is reduced by a half using our dielectric gels, which are electroactive materials, compared with the most commonly used dielectric elastomer VHB. We demonstrated the use of the dielectric gel by fabricating a bioinspired tunable lens, the focal length of which can be adjusted by varying the applied voltage. As a new type of polymer dielectric, we believe that these dielectric gels offer new opportunities for soft robotics, sensors, electronics, optics, and biomimetics.

References

Chu, B. et al. A dielectric polymer with high electric energy density and fast discharge speed. Science 313, 334–336 (2006).

Mannsfeld, S. C. B. et al. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 9, 859–864 (2010).

Naber, R. C. G. et al. High-performance solution-processed polymer ferroelectric field-effect transistors. Nat. Mater. 4, 243–248 (2005).

Ma, R. J. et al. Highly efficient electrocaloric cooling with electrostatic actuation. Science 357, 1130–1134 (2017).

Pelrine, R., Kornbluh, R., Pei, Q. B. & Joseph, J. High-speed electrically actuated elastomers with strain greater than 100%. Science 287, 836–839 (2000).

Carpi, F., Bauer, S. & De Rossi, D. Stretching dielectric elastomer performance. Science 330, 1759–1761 (2010).

Zhang, Q. M. et al. An all-organic composite actuator material with a high dielectric constant. Nature 419, 284–287 (2002).

Gao, Q. & Scheinbeim, J. I. Dipolar intermolecular interactions, structural development, and electromechanical properties in ferroelectric polymer blends of nylon-11 and poly(vinylidene fluoride). Macromolecules 33, 7564–7572 (2000).

Lehmann, W. et al. Giant lateral electrostriction in ferroelectric liquid-crystalline elastomers. Nature 410, 447–450 (2001).

Zhang, Q. M., Bharti, V. & Zhao, X. Giant electrostriction and relaxor ferroelectric behavior in electron-irradiated poly(vinylidene fluoride-trifluoroethylene) copolymer. Science 280, 2101–2104 (1998).

Brochu, P. & Pei, Q. Advances in dielectric elastomers for actuators and artificial muscles. Macromol. Rapid Commun. 31, 10–36 (2010).

Madsen, F. B., Daugaard, A. E., Hvilsted, S. & Skov, A. L. The current state of silicone-based dielectric elastomer transducers. Macromol. Rapid Commun. 37, 378–413 (2016).

Gallone, G., Carpi, F., De Rossi, D., Levita, G. & Marchetti, A. Dielectric constant enhancement in a silicone elastomer filled with lead magnesium niobate-lead titanate. Mater. Sci. Eng. C Biomim. Supramol. Syst. 27, 110–116 (2007).

Carpi, F., Gallone, G., Galantini, F. & De Rossi, D. Silicone-poly(hexylthiophene) blends as elastomers with enhanced electromechanical transduction properties. Adv. Funct. Mater. 18, 235–241 (2008).

Yadav, S. K., Mahapatra, S. S., Cho, J. W. & Lee, J. Y. Functionalization of multiwalled carbon nanotubes with poly(styrene-b-(ethylene-co-butylene)-b-styrene) by click coupling. J. Phys. Chem. C 114, 11395–11400 (2010).

Quinsaat, J. E. Q. et al. Highly stretchable dielectric elastomer composites containing high volume fractions of silver nanoparticles. J. Mater. Chem. A 3, 14675–14685 (2015).

Bartlett, M. D. et al. Stretchable, high-k dielectric elastomers through liquid-metal inclusions. Adv. Mater. 28, 3726–3731 (2016).

Kim, J.-Y. et al. Flexible and transparent dielectric film with a high dielectric constant using chemical vapor deposition-grown graphene interlayer. ACS Nano 8, 269–274 (2014).

Ji, S. et al. High dielectric performances of flexible and transparent cellulose hybrid films controlled by multidimensional metal nanostructures. Adv. Mater. https://doi.org/10.1002/adma.201700538 (2017).

Kamata, H., Akagi, Y., Kayasuga-Kariya, Y., Chung, U. & Sakai, T. “Nonswellable” hydrogel without mechanical hysteresis. Science 343, 873–875 (2014).

Sun, J.-Y. et al. Highly stretchable and tough hydrogels. Nature 489, 133–136 (2012).

Payne, R. & Theodorou, I. E. Dielectric properties and relaxation in ethylene carbonate and propylene carbonate. J. Phys. Chem. 76, 2892–2900 (1972).

Schaffner, B., Schaffner, F., Verevkin, S. P. & Borner, A. Organic carbonates as solvents in synthesis and catalysis. Chem. Rev. 110, 4554–4581 (2010).

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4417 (2004).

An, L., Wang, F. F., Cheng, S. B., Lu, T. Q. & Wang, T. J. Experimental investigation of the electromechanical phase transition in a dielectric elastomer tube. Smart Mater. Struct. 24, https://doi.org/10.1088/0964-1726/24/3/035006 (2015).

Anderson, I. A., Gisby, T. A., McKay, T. G., O’Brien, B. M. & Calius, E. P. Multi-functional dielectric elastomer artificial muscles for soft and smart machines. J. Appl. Phys. 112, https://doi.org/10.1063/1.4740023 (2012).

Lu, T. Q., Shi, Z. B., Shi, Q. & Wang, T. J. Bioinspired bicipital muscle with fiber-constrained dielectric elastomer actuator. Extreme Mech. Lett. 6, 75–81 (2016).

Carpi, F., Frediani, G., Turco, S. & De Rossi, D. Bioinspired tunable lens with muscle-like electroactive elastomers. Adv. Funct. Mater. 21, 4152–4158 (2011).

Yin, G. et al. Dielectric elastomer generator with improved energy density and conversion efficiency based on polyurethane composites. ACS Appl. Mater. Interfaces 9, 5237–5243 (2017).

Huang, C., Zhang, Q. M. & Su, J. High-dielectric-constant all-polymer percolative composites. Appl. Phys. Lett. 82, 3502–3504 (2003).

Kamezawa, N., Nagao, D., Ishii, H. & Konno, M. Transparent, highly dielectric poly(vinylidene fluoride) nanocomposite film homogeneously incorporating BaTiO3 nanoparticles with fluoroalkylsilane surface modifier. Eur. Polym. J. 66, 528–532 (2015).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Nos. 51773165, 11772249), the Fundamental Research Funds for the Central Universities (xjj2015119), and the Science Technology Innovation Commission of Shenzhen Municipality (JCYJ 20170817171930009). We thank Mr. Junjie Zhang, Ms. Axin Lu (Instrument Analysis Center of Xi’an Jiaotong University), and Ms. Jingjing Liu for their valuable assistance during testing.

Author information

Authors and Affiliations

Contributions

L.S., R.Y., S.L., T.L., and S.D. designed the study and interpreted the results. L.S. developed the protocol for fabrication of the gels and prepared the initial samples. R.Y. designed and performed the electroactive actuation tests and tunable lens tests. T.W. and W.W. contributed to the discussion of the results. L.S., T.L., and S.D. wrote the manuscript. All authors commented on the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shi, L., Yang, R., Lu, S. et al. Dielectric gels with ultra-high dielectric constant, low elastic modulus, and excellent transparency. NPG Asia Mater 10, 821–826 (2018). https://doi.org/10.1038/s41427-018-0077-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41427-018-0077-7

This article is cited by

-

Tough and stretchable ionogels by in situ phase separation

Nature Materials (2022)

-

Deep eutectic solvent inclusions for high-k composite dielectric elastomers

Frontiers of Chemical Science and Engineering (2022)

-

Effect of carbon nanotubes on the interface evolution and dielectric properties of polylactic acid/ethylene–vinyl acetate copolymer nanocomposites

Advanced Composites and Hybrid Materials (2022)

-

Soft, tough, and fast polyacrylate dielectric elastomer for non-magnetic motor

Nature Communications (2021)

-

Electroactive dielectric polymer gels as new-generation soft actuators: a review

Journal of Materials Science (2021)