Abstract

We have studied the ring-opening metathesis polymerization of N-cyclohexyl-exo-norbornene-5,6-dicarboximide using the following 4 initiators: Grubbs 1, Grubbs 2, Hoveyda–Grubbs 1 (HG1) and Hoveyda–Grubbs 2 (HG2). Only the Grubbs 1 initiator was able to precisely control the polymer molecular weight. Polymerizations initiated by the HG1, Grubbs 2 and HG2 initiators could not be controlled well. Both the Grubbs 1 and HG1 yielded polymers with a high trans % (85–98%), whereas Grubbs 2 and HG2 yielded polymers with a lower trans % (50–52%). The level of molecular weight control for the four initiators decreased in the order Grubbs 1>HG1>HG2>Grubbs 2. We also demonstrated that, in the case of polymers produced using Grubbs 1, the refractive indices (RIs) of the polymers decreased in a linear and controllable fashion from 1.539 to 1.534 at 633 nm, as the molecular weight was increased from 6700 to 26 400. This change represented a decrease in the RI of 0.005.

Similar content being viewed by others

Introduction

The academic interest in poly(N-exo-norbornene-5,6-dicarboximide) (poly(NDI)) polymers has recently increased substantially, and its applications span physics,1 chemistry2 and biology.3 A small selection of these interesting applications include cell adhesion materials, membranes, insulating materials and various optics applications.4, 5, 6, 7, 8, 9 This breadth of applications can be attributed to the fact that, as a polymer class, poly(NDI)s have been demonstrated to exhibit favorable thermal and mechanical properties, which greatly extend their range of practical applications.10, 11, 12, 13, 14 Furthermore, ring-opening metathesis polymerization allows the preparation of well-defined random, block and alternating copolymers that extend the utility of poly(NDI)s as a system to prepare reactive and functional polymers.15, 16 Therefore, a systematic study of the influence of the Grubbs initiator on the precise controllability of the molecular weight and stereochemistry of a standard NDI monomer is of practical utility. Monomer preparation for poly(NDI)s is simple and easy.17 Tlenkopatchev and coworkers have studied poly(NDI)s in detail using the Grubbs 1 (G1) and Grubbs 2 (G2) initiators.13, 14, 18, 19 Such initiators are known to impart trans–cis conformations into the polymer backbone. In this study, we focused on the monomer N-cyclohexyl-exo-norbornene-5,6-dicarboximide (CyNDI (4)) (Scheme 1). This monomer and polymer are soluble in common organic solvents such as chloroform and tetrahydrofuran. Furthermore, the monomer CyNDI (4) is easy to prepare in large quantities. Currently, the four different initiators G1, G2, Hoveyda–Grubbs 1 (HG1) and Hoveyda–Grubbs 2 (HG2) are frequently used. In this investigation, our primary aim was to discover which of these four Grubbs initiators was best suited to control the polymer molecular weight, its polydispersity and, therefore, its refractive index (RI). A mismatch between the initiator reactivity and the monomer ring strain can lead to uncontrolled nonliving polymerizations that result in products with high molecular weights and polydispersities. We aimed to produce polymers of a target number-average molecular weight (Mn) between 2500 and 150 000. Species with molecular weights <10 000 are easily analyzed via matrix-assisted laser desorption ionization–time-of-flight mass spectrometry (MALDI–TOF MS) without inducing fragmentation of the polymer chain, whereas species with molecular weights >10 000 have the benefit of exhibiting the desirable physical characteristics of polymers with much greater Mn values, such as a high glass transition temperature (Tg) and a high thermal decomposition temperature (Td); they are also easily processed to form high-optical-quality films. We have demonstrated that the Mn of poly(CyNDI) can be precisely manipulated by altering the [monomer]/[initiator] ([M]/[I]) ratio using the G1 initiator (Scheme 1); this precise control was not possible with the G2, HG1 or HG2 initiator. Selected polymers were characterized using 1H and 13C nuclear magnetic resonance (NMR) spectroscopy, size-exclusion chromatography (SEC), differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), MALDI–TOF, elemental analysis (EA) and RI measurements.

Experimental Procedure

Materials

Dicyclopentadiene and cyclohexylamine were purchased from Tokyo Chemical Industry, Tokyo, Japan, and were used without prior purification. Maleic anhydride, methanol, anhydrous toluene, o-dichlorobenzene, ethyl vinyl ether, dimethylformamide, triethylamine, chlorobenzene and tetrahydrofuran were obtained from Kanto Chemical, Tokyo, Japan, and were also used without prior purification. Chloroform was also obtained from Kanto Chemical and was dried by distillation onto pre-dried molecular sieves. The four initiators G1, G2, HG1 and HG2 were purchased from Sigma-Aldrich, St Louis, MO, USA, and were used as received. The monomer CyNDI (4) was synthesized according to a modification of literature procedures.16

Techniques

1H- and 13C-NMR spectra were recorded on a JNM-LA400 spectrometer (Nihon Denshi JEOL, Tokyo, Japan) at 400 and 125 MHz, respectively, in deuterated chloroform (CDCl3) with tetramethylsilane as an internal standard. High-resolution mass spectrometry was performed using a JEOL MStation JMS 700 (Nihon Denshi JEOL). Thermogravimetric analysis and DSC were performed at a heating rate of 10 °C min−1 under a nitrogen atmosphere on a SII-TG/DTA 6200 (Seiko Instruments Inc, Tokyo, Japan) and a SII-DSC 6220 (Seiko Instruments Inc), respectively, with the samples being encapsulated in standard aluminum thermogravimetric analysis/DSC pans. To ensure a consistent DSC measurement, each sample was run twice, with the second measurement being quoted in this manuscript. SEC was employed to determine the molecular weights of the samples. Measurements were performed using a Shodex GPC K-804L (Showa Denko, Tokyo, Japan) column on a JASCO LC2000 liquid chromatography system (JASCO Corporation, Tokyo, Japan) with chloroform as the eluent. The system was calibrated against narrow polydispersity index (PDI) Shodex SM-105 polystyrene standards. Positive-ion MALDI–TOF measurements were performed on a Bruker Autoflex-III instrument (Bruker AXS k.k, Kanagawa, Japan) equipped with a smart-ion beam laser. Measurements were conducted in linear and reflector modes. The reflector mode usually gave the best spectra. Samples were prepared in tetrahydrofuran solution by mixing the matrix (20 mg ml−1), the polymer (20 mg ml−1) and the salt (20 mg ml−1) in a ratio of 100:10:1. The matrix employed was dithranol (1,8-dihydroxy-9(10H)-anthracenone), and sodium trifluoroacetate was used as the salt. The procedure used was as described in the literature.20 RIs were measured on a SPA-4000 instrument (Sairon Technology Inc, Tokyo, Japan) using the prism-coupled method at 633, 1310 and 1550 nm. EA was performed on a Yanako (New Science Inc, Kyoto, Japan) CHN corder MT-6.

Synthesis of exo-norbornene-5,6-dicarboxylic anhydride (2)

Endo/exo-norbornene-5,6-dicarboxylic anhydride (1) was synthesized according to a modification of the literature procedure.10 To a solution of maleic anhydride (188.2 g, 1.92 mol) in o-dichlorobenzene (200 ml) at 200 °C, dicyclopentadiene (128.6 g, 0.97 mol) was added dropwise. The solution was then heated at 250 °C for 1.5 h and subsequently allowed to cool to room temperature. After the reaction, the material crystallized out of the o-dichlorobenzene; the crystals were filtered off and the remaining o-dichlorobenzene was discarded. The exo isomer was obtained by multiple recrystallizations from mono-chlorobenzene in a yield of ∼50%. Endo-norbornene-5,6-dicarboxylic anhydride (1): 1H-NMR (400 MHz, CDCl3) δ: 1.44 (d, J=11 Hz, 2H), 1.67 (d, J=11 Hz, 2H), 3.46 (s, 2H), 3.51 (s, 2H), 6.34 (s, 2H) p.p.m.

Exo-norbornene-5,6-dicarboxylic anhydride (2): 1H-NMR (400 MHz, CDCl3) δ: 1.57 (d, J=11 Hz, 2H), 1.79 (d, J=11 Hz, 2H), 3.00 (s, 2H), 3.58 (s, 2H), 6.32 (s, 2H) p.p.m.

Synthesis of N-cyclohexyl-amic acid (3)

Exo-norbornene-5,6-dicarboxylic anhydride (2) (100 g, 0.61 mol) was dissolved in the minimum amount of anhydrous toluene (200 ml), and 60.85 g (0.61 mol) of cyclohexylamine was added dropwise to the stirred solution of exo-norbornene-5,6-dicarboxylic anhydride (2). The mixture was heated to 50 °C for 1 h. Precipitation occurred after 20 min. The precipitate was then filtered, washed with an excess of toluene and dried to give N-cyclohexyl-amic acid (3) in a yield of 72%. Because of its poor solubility, the white precipitate was carried forward to the next step without characterization.

Synthesis of CyNDI (4)

The monomer CyNDI (4) was prepared according to literature procedures.3, 16 N-Cyclohexyl-amic acid (3) (50 g, 189.87 mol) and triethylamine (28.78 g, 284.42 mmol) were dissolved in dry dimethylformamide (300 ml). The mixture was heated to 120 °C for 3 h. After the reaction, the crude CyNDI (4) was obtained by precipitation into water and then filtration in vacuo. The white solid was washed with an excess of deionized water and dried under vacuum at 60 °C for 5 h. This crude material was purified by multiple recrystallizations from boiling methanol in a yield of 54%. CyNDI (4): 1H-NMR (400 MHz, CDCl3) δ: 6.23 (2H, m), 5.89 (1H, m), 3.20 (2H, s), 2.56 (2H, s), 2.01–2.16 (2H, m), 1.70–1.82 (2H, m), 1.38–1.64 (4H), 1.33–1.10 (4H, m) p.p.m. 13C-NMR (125 MHz, CDCl3) δ: 178.55, 138.17, 51.81, 47.62, 45.61, 42.76, 28.95, 26.01, 25.24 p.p.m. High-resolution mass spectrometry (Electron Ionization, EI) calculated for C15H19NO2: m/z 245.1416; found: m/z 245.1416. EA: calculated C: 73.44%, H: 7.81%, N: 5.71%; found C: 73.37%, H: 7.82%, N: 5.67%.

Synthesis of poly(CyNDI)s (5a1-12, 5b1-6, 5c1-6 and 5d1-6)

This study involved the preparation of six polymers from each of the G2, HG1 and HG2 initiators (5b1-6, 5c1-6 and 5d1-6) with various [M]/[I] ratios that ranged from 10 to 60 and 12 polymers from the G1 initiator with various [M]/[I] ratios that ranged from 10 to 60 (5a1-6) and 100 to 600 (5a7-12). All polymers were prepared under identical reaction conditions to allow a direct comparison of the four initiators. A general procedure for the preparation of polymers 5a1, 5b1, 5c1 and 5d1 follows.

The monomer CyNDI (4) (0.50 g, 2.04 × 10−3 mol) was dissolved in nitrogen-degassed anhydrous chloroform (10 ml) and stirred at room temperature for 10 min. The initiator G1 (167.73 mg, 2.04 × 10−4 mol), G2 (173.19 mg, 2.04 × 10−4 mol), HG1 (122.52 mg, 2.04 × 10−4 mol) or HG2 (127.83 mg, 2.04 × 10−4 mol) was transferred to a separate flask under a nitrogen atmosphere and was also dissolved in nitrogen-degassed anhydrous chloroform (1.0 ml). After being thoroughly mixed using a vortex mixer, this solution was quickly transferred via syringe to the monomer solution. The mixture was stirred at room temperature for 1 h. The polymerization was quenched by the addition of an excess of ethyl vinyl ether (4 ml) and then allowed to stir at room temperature for an additional 30 min. The chloroform and ethyl vinyl ether were then evaporated; the polymers were subsequently dissolved in the minimum amount of chloroform and precipitated into stirred methanol. The crude polymers were isolated by filtration in vacuo with the residual ruthenium complex being removed by Soxhlet extraction in refluxing methanol for 2 h. The polymers were then dried under vacuum for 12 h at 60 °C. The obtained yields were almost quantitative, with material loss mainly occurring during the purification stages.

All polymers could be accurately assigned according to their expected structures by 1H-NMR.16, 21 Polymer 5a1: 1H-NMR (400 MHz, CDCl3) δ: 7.40–7.18 (end group—Ph), 6.61–6.47 (end group—vinyl), 6.34–6.23 (end group—vinyl), δ: 5.73 (1.54H, m) trans, 5.49 (0.25H, m) cis, 3.88 (1H, m), 2.90 (2H, m), 2.64 (2H, m), 2.10 (2H, m), 1.90–1.40 (6H, s), 1.24 (4H, s) p.p.m. Yield=84%. Polymer 5b1: 1H-NMR (400 MHz, CDCl3) δ: 5.74 (1.04H, m) trans, 5.49 (0.96H, m), 3.86 (1.00H, m), 3.46–2.54 (4H, m), 2.30–1.99 (2H, m), 1.89–1.45 (6H, m), 1.38–1.09 (4H, m) p.p.m. Yield=92%. EA: calculated C: 74.21%, H: 7.80%, N: 5.48%; found C: 72.58%, H: 7.67%, N: 5.61. Polymer 5c1: 1H-NMR (400 MHz, CDCl3) δ: 5.73 (1.37H, m) trans, 5.49 (0.23H, m) cis, 3.88 (0.80H, m), 3.69 (0.20H, m), 3.25 (0.20H), 2.91 (1.62H), 2.64 (1.31H, m), 2.09 (2.31H, m), 1.94–1.71 (1.99H), 1.69–1.45 (3.30H), 1.38–1.08 (2.84H) p.p.m. Yield=90%. Polymer 5d1: 1H-NMR (400 MHz, CDCl3) δ: 5.74 (1.04H, m) trans, 5.49 (0.96H, m), 3.86 (1.00H, m), 3.46–2.54 (3.85H, m), 2.30–1.99 (3.17H, m), 1.89–1.45 (7.52H, m), 1.38–1.09 (3.59H, m) p.p.m. Yield=90%.

Results and Discussion

Our aim in this investigation was to elucidate which of the four initiators enabled the most precise control of molecular weight under our standard reaction conditions and to clarify the effect of the initiator on the polymer microstructure. Consequently, the four initiators G1, G2, HG1 and HG2 were selected because of their differing ligands and reactivities.

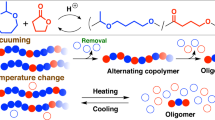

The monomer CyNDI (4) was prepared according to a modification of the literature procedures.3 The polymerization to yield poly(CyNDI)s 5a1-12, 5b1-6, 5c1-6 and 5d1-6 was initiated using G1, G2, HG1 or HG2 (Scheme 1). The Mn was controlled by a fine manipulation of the [M]/[I] ratio. The target-calculated Mn in each case was determined by multiplying the monomer molecular weight (245) by the desired [M]/[I] ratio.22, 23 Despite all polymerizations being conducted under exactly the same reaction conditions (monomer mass (500 mg), [M]/[I], concentration, temperature, reaction time (60 min) and solvent, accurate control of the Mn was only possible when G1 was used.

Well-controlled ring-opening metathesis polymerization has been established to proceed via a living chain growth mechanism.17 The mismatch in the reaction rates between the initiators G2, HG1 and HG2 and the CyNDI (4) monomer may have prevented effective control in these cases. The poly(CyNDI)s for analysis in this study are shown in the Scheme 1. All polymers were prepared by the addition of various concentrations of initiator solution to a fixed amount of monomer in solution. The general polymerization data as well as the Mn and trans % for the polymers are summarized in Table 1.

Because the monomer ring strain and the activity of all four initiators are high, we would expect such a result because of the nearly complete monomer consumption.4 The EA results confirm that the polymers were generally of very high purity, with little initiator residue and environmental impurities. The carbon % determined by EA was, on average, 72%, where ∼73% was expected from the calculation (see Supplementary Information). Figure 1 shows the 1H-NMR spectra for the four polymers 5a1, 5b1, 5c1 and 5d1.

These four 1H-NMR spectra were used to evaluate the trans–cis content of the polymers. On the basis of 1H-NMR integration, the polymerization by G1 (5a1-12) and HG1 (5c1-6) yielded trans-rich polymers (85–98% trans). High-Mn polymers 5a7-12 exhibited an elevated trans % compared with that of the low-Mn polymers (Table 1). The polymers 5b1-6 and 5d1-6 produced using initiators G2 and HG2 were expected to exhibit a much higher cis content than those produced using initiators G1 and HG1 because of the larger 1,3-bis(2,4,6-trimethylphenyl)imidazole-2-ylidene ligand (H2IMes) that the G2 and HG2 initiators incorporate.24 Consequently, the G2 and HG2 initiators yielded polymers with an ∼50–52% trans microstructure in the cases of polymers 5b1-6 and 5d1-6, respectively (Table 1). If the polymer Mn is low, signals due to the vinyl and phenyl end groups should be visible, although they are not visible in some cases because of a higher Mn. In this case, the ratio of end-group signals to polymer-main-chain signals is extremely small. In cases where the Mn is low but no end-group signals are observed in the 1H-NMR spectra, intramolecular backbiting may occur, resulting in a cyclic polymer with no end group. As evident from Figure 1a, the end groups are visible in this well-controlled case where G1 was used. In the cases represented in Figures 1b–d, end-group signals are not observed in the 1H-NMR spectra.

SEC was employed to determine the Mn. To elucidate the optimum reaction conditions for the polymerizations, kinetic studies using the four initiators were performed. Ideally, we sought to find a reaction time that allowed all of the polymers, irrespective of their molecular weight, to reach completion. A [M]/[I]=60 was used as the benchmark. An aliquot (2 ml) was collected from the reaction vessel at 12-min interval for 60 min. This aliquot was then quenched with ethyl vinyl ether (2 ml), dried and analyzed by SEC. Figure 2a shows the results of kinetic experiments for the polymerization of 500 mg of CyNDI (4) in chloroform (10 ml) at room temperature using the four initiators. When using G2, we observed that the polymer reached its maximum Mn in <12 min. The final Mn after 60 min (279 300) was much higher than that expected from calculation (14 719). In the case of HG1, the propagation rate was much slower than that in the case of G2, and the polymerization thus required almost 60 min to reach the maximum final Mn; however, as was the case for G2, this final Mn after 60 min (99 900) was much higher than that expected from calculation (14 719). The HG2 initiator provided better control than the G2 initiator, as indicated by the Mn in the case of the HG2 initiator being closer to the expected values; nonetheless, the achieved polymer Mn was much higher (135 700) than the calculated value (14 719) or even that of the polymers produced using G1 or HG1. Finally, the kinetic profile for the polymer produced using G1 was well controlled, with the maximum Mn being reached after 48 min. The initial Mn rapidly increased from 0 to 12 min, reaching 13 149 with a much slower increase afterward. The final Mn after 60 min (22 000) was similar to the target value of 14 719 and was much closer to the target value than that of any polymer produced using any other initiator. On the basis of these experiments, all of the polymerizations performed using the four initiators G1, G2, HG1 and HG2 were completed in approximately 1 h or less. Consequently, this reaction time was kept constant for all subsequent polymerizations.

(a) The kinetic data obtained using initiators G1 (dark blue), G2 (light blue), HG1 (purple) and HG2 (green) at a [monomer]/[initiator] ratio of 60. (b) The experimental Mn of polymers 5a1-12 (blue) produced from initiator G1 plotted against the values expected from calculations (red). (c) The experimental Mn of polymers 5b1-6 (green), 5c1-6 (purple) and 5d1-6 (black) produced from initiators G2, HG1 and HG2 plotted against the values expected from calculations. A full color version of this figure is available at Polymer Journal online.

Figure 2b shows the experimental and calculated Mn obtained for the well-controlled polymers 5a1-12, as analyzed by SEC. The G1 initiator yielded polymers (5a1-12) in a Mn range of 6700 to 181 500 (Table 1). All polymerizations (5a1-12) appeared to be well controlled, with Poisson-like curves at low and high Mn values (see Supplementary Information) and, consequently, very low PDIs (1.05–1.28). The PDIs for the higher-Mn polymers 5a7-12 exhibited the lowest values on average. When using G1, we observed that the experimentally measured Mn values were close to the expected values calculated by multiplying the monomer molecular weight and the [M]/[I] ratio. However, all of the values were slightly higher than expected, and this difference increased as the Mn increased, particularly for polymers 5a7-12. By contrast, the results in Figure 2c indicate that the polymers (5b1-6) were poorly controlled. All the experimentally measured Mn values (128 700–239 400) are much higher than the calculated values. However, an increase in the amount of initiator can lower the Mn, as was the case for G1, but in a much less controlled manner. When G2 was used, the PDIs became broader (1.06–1.39) (Table 1) in some cases, and the viscosity of the reaction mixture was noticeably higher, reflecting the higher-Mn materials produced. With respect to the polymerization of the high-strain monomer CyNDI (4), the use of G2 provided no advantage. In the cases of polymers (5c1-6) produced by HG1 (Figure 2c), all of the experimentally measured Mn values (55 900–111 800) were higher than the calculated values and were much higher even than those produced using G1 (Figure 2b). However, analysis of the PDIs (1.18–1.21) indicated that the polymerizations did not undergo intermolecular backbiting or other termination reactions. Interestingly, in the case of the HG2 initiator, all of the experimental Mn values (79 500–161 500) were higher than calculated but lower than those of the polymer produced using G2 (Figure 2c). In the case of the polymers produced using HG2, the PDIs were comparable to those of the polymers produced using G1 (1.09–1.10) (Table 1).

Our experimental results indicate that, to achieve well-controlled poly(CyNDI)s at room temperature, G1 is the initiator of choice; it is also the easiest to prepare chemically. A possible explanation for the optimum performance of G1 may be its reduced activity compared with those of the other three initiators.25 For a well-controlled polymerization, the activity of the initiator and the level of ring strain within the monomer must be well matched. The performance of the various ruthenium-benzylidene initiators has been fine-tuned by modifying or changing the phosphine ligands. This modification has both electronic as well as steric effects. In the case of G2 and HG2, the N-heterocyclic carbene ligand gives an enhanced activity over G1 and HG1, as well as greater stability to air, moisture and temperature. Hence, in many cases, they are too active for well-controlled living ring-opening metathesis polymerization.25 We observed no experimental advantages for using the HG1 and HG2 initiators in the polymerization of CyNDI (4). G2 was the worst-performing initiator. For a polymerization to be ‘living,’ chain-transfer and chain-termination steps must be absent. Such steps can lead to broadening of the molecular weight distribution.25 However, in most cases, the PDIs of the polymers produced using all four initiators were relatively narrow (<1.5). These narrow PDIs may be due to the short reaction time (60 min) of the experiments as well as the low temperature (25 °C) minimizing such occurrences. Because the ring strain of the monomer is high, we expect the initiation rate for all catalysts to be fairly rapid. Propagation rates should also be fairly rapid, provided the Mn and the solution viscosity are low.

For the applications of poly(NDI)s discussed in the introduction, a high Tg and Td are a practical requirement. Therefore, the Tg and Td values of the polymers were measured and evaluated. The G1 produced polymers (5a1-12) that were precisely controlled; therefore, as the Mn increased from 6700 to 181 500, the Tg also increased from 178 to 223 °C, as shown in Figure 3. The increase reached a plateau at 26 800, with the gradient being much steeper from 6700 to 9800. By contrast, because of the limited control and generally much higher Mn of all the polymers produced by the other three initiators, G2 (2b1-6), HG1 (2c1-6) and HG2 (2d1-6), the Tg values remained relatively constant at 209–211 °C for G2 and 206–215 °C for HG2 (Table 1). The Tg values were also nearly constant but always slightly higher in the case of HG1, at 214–224 °C (Figure 3). Our results indicate that Tg control is only possible through the use of the G1 initiator. In the case of polymers 5a1-12, as expected, the Td increased slightly as the Mn is increased (Table 1) from 407 to 427 °C. The Td values of the polymers produced by the G2, HG1 and HG2 initiators vary with the Mn of the polymers, 5b1-6 (400–427 °C), 5c1-6 (418–433 °C) and 5d1-6 (420–447 °C) (Table 1).

MALDI–TOF MS was used to determine the polymer end groups and to determine the degree of cyclization. If the polymers were to undergo cyclization, the position of the peaks in the MALDI–TOF would vary by 104 m/z, which is the mass of the combined vinyl and phenyl end groups. MALDI–TOF MS was also used to determine the absolute molecular weight of one sample polymer. Polymer 5a1, being of low Mn (6700) and narrow PDI (1.28), is an ideal candidate for MALDI–TOF MS analysis. The spectrum of polymer 5a1 was obtained according to the literature procedure.20 The resulting spectra and expansion can be observed in Figure 4. The complete spectrum in Figure 4a shows that the absolute polymer molecular weight is ∼3500 on the basis of the peak of the distribution. This molecular weight is very similar to the calculated value (2453) and is lower than that measured by SEC (6700). The expansion in Figure 4b reveals that only one set of peaks is present, thereby confirming the absence of cyclic polymers produced by the G1 initiator.

(a) The matrix-assisted laser desorption ionization–time-of-flight mass spectrometry spectrum obtained for polymer 5a1 using dithranol and sodium trifluoroacetate in tetrahydrofuran. (b) The expanded spectrum from 2000 to 3400 m/z. A full color version of this figure is available at Polymer Journal online.

As evident from the results in Table 2, the expansion of the MS was analyzed from n=8 to 13. A relatively close match was observed between the expected Mn values (including end groups and sodium ion) and those measured by the instrument. For example, in the case of entry with 10 repeat units, the calculation is as follows: monomer MW × repeat units+end groups+sodium ion (245.1416 × 10)+90.0470+14.0157+22.9898. Any difference between these two values is attributed to calibration of the instrument.

With a view toward their practical applications, the RIs of films of polymers 5a1-6, 5b1-6, 5c1-6 and 5d1-6 were measured. The polymers were dissolved in chloroform, spin coated onto a clean glass slide and dried before the measurements. The RIs were measured using the prism-coupled method at 633, 1310 and 1550 nm (see Supplementary Information for complete data). Figure 5 shows the RIs of the polymers 5a1-6, 5b1-6, 5c1-6 and 5d1-6 measured at 633 nm. As evident in the figure, the RIs could not be controlled for polymers produced using the G2 (5b1-6), HG1 (5c1-6) and HG2 (5d1-6) initiators because their Mn could not be controlled. However, for the well-controlled polymers 5a1-6 prepared using G1, the RIs decreased in a range of 1.539 to 1.534 at 633 nm as the polymer Mn increased from 6700 to 26 400. This change represents a decrease of 0.005.

The change in RI (dn/dc) as a function of polymer molecular weight is a key relationship for the determination of the Mn of polymers in dilute solutions. The molecular weight of a given polymer, as determined by light scattering, depends on the square of dn/dc; even a slight variation in dn/dc therefore results in a large error in the value of Mn.26 However, when the polymer is examined in solid-state-film form, the intermolecular interactions and packing efficiency become important. As the molecular weight of the polymers decreases, the intermolecular interactions and packing efficiency may lead to an increased packing density of the chains in a given area, as is described by the Lorenz–Lorentz relationship.27 Therefore, because only G1 allows precise control of the molecular weight, when the molecular weight is increased for this series, the RI decreases in a linear and well-controlled manner.

Conclusions

In this investigation, we evaluated the effects of four well-utilized Grubbs initiators with differing ligands on the stereochemistry and reaction rate of the ring-opening metathesis polymerization of CyNDI monomers. These initiators were the Grubbs 1, Grubbs 2, HG1 and HG2 initiators. We utilized the monomer CyNDI as a benchmark for this investigation. Of these four initiators, only Grubbs 1 was able to precisely control the polymer molecular weight. By contrast, polymerizations initiated by the HG1, Grubbs 2 and HG2 initiators could not be easily controlled and resulted in polymers with experimental molecular weights much higher than the calculated values. Both the Grubbs 1 and HG1 initiators yielded polymers with a trans % of 85–98%, whereas the Grubbs 2 and HG2 initiators gave polymers with a trans % of 50–52%. By manipulating the [M]/[I] ratio, we demonstrated that the order of molecular weight control for the four initiators was Grubbs 1>HG1>HG2>Grubbs 2. We also demonstrated that the RIs are not controllable for polymers produced using the Grubbs 2, HG1 and HG2 initiators because the Mn of the resulting polymers cannot be controlled. In the case of the Grubbs 1 initiator, the polymers exhibited a decrease in RI with increasing Mn.

Synthesis of poly(CyNDI)s (5a1-12, 5b1-6, 5c1-6 and 5d1-6) using the four characteristic initiators G1, G2, HG1 and HG2.

References

Santiago, A. A., Vargas, J., Cruz-Gomez, J., Tlenkopatchev, M. A., Gavino, R., Lopez-Gonzalez, M. & Riande, E. Synthesis and ionic transport of sulfonated ring-opened polynorbornene based copolymers. Polymer 52, 4208–4220 (2011).

Hilf, S. & Kilbinger, A. F. M. Thiol-functionalized ROMP polymers via Sacrificial Synthesis. Macromolecules 42, 4127–4133 (2009).

Lanier, M., Schade, D., Willems, E., Tsuda, M., Spiering, S., Kalisiak, J., Mercola, M. & Cashman, J. R. Wnt inhibition correlates with human embryonic stem cell cardiomyogenesis: a structure–activity relationship study based on inhibitors for the Wnt response. J. Med. Chem. 55, 697–708 (2011).

Patel, P. R., Kiser, R. C., Lu, Y. Y., Fong, E., Ho, W. C., Tirrell, D. A. & Grubbs, R. H. Synthesis and cell adhesive properties of linear and cyclic RGD functionalized polynorbornene thin films. Biomacromolecules 13, 2546–2553 (2012).

Choi, M. C., Hwang, J. C., Kim, C., Kim, Y. & Ha, C. S. Synthesis of poly(N-9-ethylcarbazole-exo-norbornene-5,6-dicarboximide) for hole-transporting layer in hybrid organic light-emitting devices. J. Polym. Sci. A Polym. Chem. 48, 5189–5197 (2010).

Yoon, K. H., Kim, K. O., Schaefer, M. & Yoon, D. Y. Synthesis and characterization of hydrogenated poly(norbornene endo-dicarboximide)s prepared by ring opening metathesis polymerization. Polymer 53, 2290–2297 (2012).

Yoon, K. H., Kim, K. O., Wang, C. Q., Park, I. & Yoon, D. Y. Synthesis and structure-property comparisons of hydrogenated poly(oxanorbornene-imide)s and poly(norbornene-imide)s prepared by ring-opening metathesis polymerization. J. Polym. Sci. A Polym. Chem. 50, 3914–3921 (2012).

Yu, F., Spring, A. M., Li, L., Qiu, F., Yamamoto, K., Maeda, D., Ozawa, M., Odoi, K. & Yokoyama, S. An enhanced host-guest electro-optical polymer system using poly(norbornene-dicarboximides) via ROMP. J. Polym. Sci. A Polym. Chem. 51, 1278–1284 (2013).

Jia, Y., Spring, A. M., Yu, F., Yamamoto, K., Aoki, I., Otomo, A. & Yokoyama, S. A norbornene polymer brush for electro-optic applications. Thin Solid Filmshttp://dxdoi.org/101016/jtsf201306071 (2013).

Castner, K. F. & Calderon, N. Ring-opening polymerization of cyclic olefins substituted with polar groups. 5-Norbornene-2,3-dicarboxy anhydride (CPD-MA). J. Mol. Catal. 15, 47–59 (1982).

Asrar, J. Metathesis polymerization of N-phenylnorbornenedicarboximide. Macromolecules 25, 5150–5156 (1992).

Asrar, J. High-temperature metathesis polymers: structure-property relationships. Macromolecules 27, 4036–4042 (1994).

Contreras, A. P. & Tlenkopatchev, M. A. Synthesis and gas transport properties of new high glass transition temperature ring-opened polynorbornenes. Macromolecules 35, 4677–4684 (2002).

Tlenkopatchev, M. A., Vargas, J., Lopez-Gonzalez, M. d. M. & Riande, E. Gas transport in polymers prepared via metathesis copolymerization of exo-N-phenyl-7-oxanorbornene-5,6-dicarboximide and norbornene. Macromolecules 36, 8483–8488 (2003).

Choi, M.-C., Hwang, J.-C., Kim, C., Kim, Y. & Ha, C.-S. Synthesis of poly(N-9-ethylcarbazole-exo-norbornene-5,6-dicarboximide) for hole-transporting layer in hybrid organic light-emitting devices. J. Polym. Sci. A Polym. Chem. 48, 5189–5197 (2010).

Contreras, A. P., Cerda, A. M. & Tlenkopatchev, M. A. Synthesis of high-Tg polymers by ring-opening metathesis polymerization of N-cycloalkylnorbornene dicarboximide. Macromol. Chem. Phys. 203, 1811–1818 (2002).

Leitgeb, A., Wappel, J. & Slugovc, C. The ROMP toolbox upgraded. Polymer 51, 2927–2946 (2010).

Tlenkopatchev, M., Vargas, J., Almaraz-Giron, M. A., Lopez-Gonzalez, M. & Riande, E. Gas sorption in new fluorine containing polynorbornenes with imide side chain groups. Macromolecules 38, 2696–2703 (2005).

Vargas, J., Santiago, A. A., Tlenkopatchev, M. A., Gavino, R., Laguna, M. F., Lopez-Gonzalez, M. & Riande, E. Gas transport and ionic transport in membranes based on polynorbornenes with functionalized imide side groups. Macromolecules 40, 563–570 (2007).

Binder, W. H., Pulamagatta, B., Kir, O., Kurzhals, S., Barqawi, H. & Tanner, S. Monitoring block-copolymer crossover-chemistry in ROMP: catalyst evaluation via mass-spectrometry (MALDI). Macromolecules 42, 9457–9466 (2009).

Vargas, J., Colin, E. S. & Tlenkopatchev, M. A. Ring-opening metathesis polymerization (ROMP) of N-cycloalkyl-7-oxanorbornene dicarboximides by well-defined ruthenium initiators. Eur. Polym. J. 40, 1325–1335 (2004).

Spring, A. M., Yu, C.-Y., Horie, M. & Turner, M. L. MEH-PPV by microwave assisted ring-opening metathesis polymerisation. Chem. Commun. 19, 2676–2678 (2009).

Yu, C.-Y., Horie, M., Spring, A. M., Tremel, K. & Turner, M. L. Homopolymers and block copolymers of p-phenylenevinylene-2,5-diethylhexyloxy-p-phenylenevinylene and m-phenylenevinylene-2,5-diethylhexyloxy-p-phenylenevinylene by ring-opening metathesis polymerization. Macromolecules 43, 222–232 (2009).

Buchmeiser, M. R. Homogeneous metathesis polymerization by well-defined group VI and group VIII transition-metal alkylidenes:fundamentals and applications in the preparation of advanced materials. Chem. Rev. 100, 1565–1604 (2000).

Grubbs, R. H. Handbook of Metathesis, (Wiley-VCH, 2003).

Itakura, M., Sato, K., Lusenkova, M. A., Matsuyama, S., Shimada, K., Saito, T. & Kinugasa, S. Molecular weight dependency of refractive index increment of polystyrene determined by uniform oligomers. J. Appl. Polym. Sci. 94, 1101–1106 (2004).

Askadskii, A. A. Influence of chemical structure on the properties of polymers. Pure Appl. Chem. 46 19–27 (1976).

Acknowledgements

We acknowledge financial support from the following funding sources and collaborators: Nissan Chemical Industries and Kyushu University, the Global Centers of Excellence Program, Nano-Macro Materials, the Devices and Systems Research Alliance, the Cooperative Research Program of ‘Network Joint Research Center for Materials and Devices’ of the Ministry of Education, Culture, Sports, Science and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Spring, A., Yu, F., Qiu, F. et al. The preparation of well-controlled poly(N-cyclohexyl-exo-norbornene-5,6-dicarboximide) polymers. Polym J 46, 576–583 (2014). https://doi.org/10.1038/pj.2014.26

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.26

Keywords

This article is cited by

-

Glass transition temperature control by poly(norbornene-dicarboximide) copolymers

Polymer Bulletin (2015)