Abstract

This protocol describes a procedure for the synthesis of 3,3′-bis(sulfonato)-4,4′-bis(chloroacetamido)azobenzene (BSBCA), a water-soluble, thiol-reactive, photo-switchable cross-linker. In addition, a protocol is outlined for installing the cross-linker in an intramolecular fashion onto proteins bearing two surface-exposed Cys residues. BSBCA is designed to be used as an in vitro activity switch that operates by exerting temporal and reversible photo-control over α-helix content within synthetic peptides and recombinant proteins. Synthesis of the cross-linker requires approximately 4.5 d, and cross-linking can be performed in 10–12 h.

Similar content being viewed by others

Introduction

The primary strategy for photo-regulation of biomolecular function using azobenzene is to change the host system by exploiting structural, electronic and volume changes that accompany a trans-to-cis azobenzene isomerization event. Examples of biomolecular systems into which azobenzene has been incorporated for photo-regulation are peptides1,2,3, enzymes4,5,6,7, oligonucleotides8,9 and ion channels10,11. Methods for incorporating azobenzene chromophores into biomolecules include solid-phase peptide or oligonucleotide synthesis7,12, nonsense suppression via azobenzene-charged suppressor tRNAs4, and both non-selective13 and targeted chemical modification of protein side chains14.

To be generally useful, azobenzene photo-switches intended to control protein activity should be incorporated under mild aqueous conditions and should target features that are common to all proteins. Ideally, one isomeric state of the chromophore locks the protein in an 'off' functional state, and in the other isomeric state the protein is in an 'on' state. The extent to which this is achieved depends critically on where the switch is placed and how well isomerization is coupled to protein conformational change. Incorrect placement can lead to inconsequential changes in conformation or to switches becoming locked in the cis or trans state15,16,17.

Chemical cross-linking is often employed as a way to introduce intramolecular bridges into peptides and proteins. Such bridges can be used to stabilize or alter protein structure, dynamics and function18,19. If the azobenzene chromophore is used as a component of these intramolecular bridges, photo-isomerization can be used to perturb the structure of the bridge reversibly, and thereby to alter key components of protein conformation. When properly targeted, these photo-switchable cross-linkers can be used to photo-control protein activity.

We have focused primarily on targeting the conformational control of helical structures using thiol-reactive, azobenzene-based photo-switchable cross-linkers3,16,20,21. As Cys residues can easily be introduced via site-directed mutagenesis, this azobenzene-based cross-linking strategy offers a fairly general way to photo-control protein α-helix content and thereby activity. We have reported on the design and synthesis of a number of different cross-linkers exhibiting a variety of properties3,21,22,23. Among the most generally useful of these is sodium 3,3′-bis(sulfonato)-4,4′-bis(chloroacetamido)azobenzene (BSBCA), a fully water-soluble, thiol-reactive cross-linker that can be isomerized from trans to cis by irradiation at 370 nm and can be relaxed thermally from cis to trans with a half-life of approximately 20 min at room temperature (20–24 °C).

Cross-linking reactions can be performed with BSBCA under mild conditions (room temperature, physiological pH and a completely aqueous environment). A variety of helical peptides and proteins bearing two Cys residues have been cross-linked, and their conformational and functional properties have been studied; these include the peptides JRK-7 and FK-11 and the proteins MyoD, engrailed and GCN427,29,30,31. Intermolecular cross-linking between proteins was not apparent in any of these cases and was likely suppressed by the fast intramolecular reaction between the chloroacetamide moiety of BSBCA and the second Cys residue. Photo-isomerization takes place rapidly, with high quantum yield, and occurs at wavelengths higher than 300 nm, so the light used to produce isomerization is not strongly absorbed by protein and nucleic acid present in biological targets7,24,25,26.

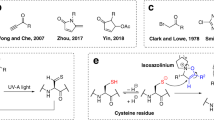

Here, we present our approach to the synthesis of BSBCA (Fig. 1) and a protocol for its use in protein cross-linking. Although the cross-linking reactions are robust and provide a route toward installing structural and activity switches into proteins and peptides in general, the following considerations will determine whether a particular protein or peptide is compatible with this cross-linking strategy. (i) Two Cys residues are required for cross-linking BSBCA. These Cys residues can be site-specifically mutated into the protein or peptide sequence, ideally within the helical region, to facilitate cross-linking. Pro and Gly, which often play particular conformational roles, and residues that are directly involved in protein activity (e.g., an enzyme active site residue or DNA-binding residue) should not be replaced. (ii) For proteins, the two Cys residues should be positioned so that they are exposed to the bulk solvent. (iii) To date, the effects of BSBCA on helical structures alone have been characterized. When Cys residues spaced i, i+4 or i, i+7 are cross-linked, trans-to-cis isomerization of the linker can promote helix formation, but when Cys residues spaced i, i+11 are cross-linked, trans-to-cis isomerization of the linker inhibits helix formation27. The extent of regulation of the helix structure depends on the energetics and dynamics of conformational changes in each particular case. This issue is discussed further in a recent review17. (iv) Although the cross-linking reaction can be limited to predetermined sites in the presence of a wide variety of side-chain functionalities, any native Cys residues that are surface-accessible should be mutated to Ser or Ala to ensure that cross-linking occurs in a chemoselective fashion. (v) Cys-containing peptides and proteins should be protected from oxidation to avoid disulfide bond formation, refolding or misfolding events and aggregation. For this reason, and to preserve the nucleophilicity of its cysteinyl thiols, the protein or peptide must be maintained in its reduced form at slightly basic pH (Fig. 2).

If each of these points is taken into consideration, cross-linking should proceed smoothly with the intended goal of chemoselectivity. Cross-linking can be monitored by BSI–MS (Fig. 3) and isomerization can be assessed using UV-visible spectroscopy (Fig. 4) and helix-coil switching can be assessed using CD spectroscopy (Fig. 5). Activity tests should be designed according to the protein or peptide under investigation.

A double-Cys-containing GCN4-bZIP protein (black lines). Predicted mass: (C291H505N99O84S4) 6,864; observed: 6,864 plus some 6,880 (methionine sulfoxide) species and 6,896 double methionine sulfoxide. After cross-linking with BSBCA (pink lines). Predicted mass: (C307H519N103O92S6) 7,317.5; observed: 7,317 plus 7,333 methionine sulfoxide species.

In this example, the Cys residues are spaced i, i+7 in a helical segment. Trans-to-cis isomerization of the azobenzene chromophore is evidenced by a loss in absorbance at 363 nm along with a concomitant slight increase in absorbance at 450 nm. Solution conditions: 10 mM phosphate buffer (pH 7.0), 50 mM NaCl at 10 ± 1 °C at a protein concentration of 2 μM (adapted with permission from ref. 29).

In this example, the Cys residues are spaced i, i+7 in a helical segment. Trans-to-cis isomerization increases helical content as judged by the stronger ellipticity at 222 nm. Solution conditions: 10 mM phosphate buffer pH 7.0, 50 mM NaCl at 10 ± 1 °C at a protein concentration of 20 μM (adapted with permission from ref. 29).

Materials

Reagents

-

2,5-Diaminobenzenesulfonic acid (Sigma-Aldrich, cat. no. 32776)

-

Glacial acetic acid (Sigma-Aldrich, cat. no. 537020)

Caution

Flammable and corrosive; handle only in a vented fumehood

-

Acetic anhydride (Sigma-Aldrich, cat. no. 242845)

Caution

Flammable, corrosive and toxic by inhalation; it also reacts violently with water and should be handled only in a vented fumehood

-

Sodium carbonate (Sigma-Aldrich, cat. no. 223530) (see REAGENT SETUP)

-

Sodium hypochlorite (Sigma-Aldrich, cat. no. 425044)

Caution

Corrosive acid; handle only in a vented fumehood

-

NaOH (Sigma-Aldrich, cat. no. 221465) (see REAGENT SETUP)

-

Chloroacetic acid (Sigma-Aldrich, cat. no. 402923)

Caution

Chloroacetic acid is highly toxic and corrosive; avoid inhalation and contact with skin; handle only in a vented fumehood

-

Chloroacetic anhydride (Sigma-Aldrich, cat. no. 215163)

Caution

Toxic and readily absorbed through the skin; handle only in a vented fumehood

-

Tris–HCl buffer (see REAGENT SETUP)

-

HCl

-

Tris-(2-carboxyethyl)phosphine hydrochloride (TCEP) (Sigma-Aldrich, cat. no. 93284)

-

Dichloromethane

Caution

Dichloromethane is a toxic carcinogen; handle only in a vented fumehood

-

Ethanol

Caution

Ethonol is highly flammable; handle only in a vented fumehood

-

Ice

-

Sodium phosphate buffer

Equipment

-

2 × 50-ml round-bottom flask

-

2 × 10-ml round-bottom flask

-

1 × 5-ml round-bottom flask

-

3 × white rubber septum (Sigma-Aldrich, cat. no. Z100749)

-

Magnetic heat plate with digital thermometer and probe (RET digi-visc, IKA Labortechnic)

-

Condenser and tubing for reflux

-

Heat bath oil

-

2 × large glass dewar dish

-

Plastic syringes (Henke Sass Wolf GmbH)

-

20-gauge 1.5-inch disposable syringe needles (Becton Dickinson)

-

P8, qualitative, coarse filter paper (Fisherbrand, cat. no. 09-795B)

-

Ceramic Hirsch funnel and vacuum tubing

-

Rotary evaporator (Buchi)

-

Vacuum pump

-

pH meter and probe (Radiometer, Copenhagen)

-

Balloon affixed to a 3-ml plastic syringe cut flush at 1-ml mark

-

Centrifugal filter tube (Amicon Ultra-15, Millipore)

-

Sorvall Legend T/RT, with Rectangular bucket 250 ml rotor

-

Nitrogen gas

-

70 W metal halide Tri-Lite lamp (World Precision Instruments)

-

370 ± 10 nm band-pass filter (Harvard Apparatus, Canada)

Reagent Setup

-

0.1 M sodium carbonate Dissolve 530 mg sodium carbonate in 50 ml H2O.

-

0.1 M sodium hydroxide Dissolve 200 mg sodium hydroxide in 50 ml H2O.

-

500 mM Tris–HCl buffer (pH 8.5) Dissolve 60.57 g Tris base in 900 ml H2O. Adjust the pH of this solution to 8.5 by adding approximately 14.8 ml 6 N HCl. Fill with dH2O up to 1 l.

Procedure

Synthesis of 2-acetylamino-5-aminobenzenesulfonic acid (1)

Timing 4 h 40 min

-

1

Weigh 6.47 g (34.4 mmol, 1.0 eq.) 2,5-diaminobenzenesulfonic acid into a 100-ml round-bottom flask containing a magnetic stir bar.

-

2

Add 50 ml glacial acetic acid to the reaction vessel and seal the flask with a white rubber septum.

-

3

Immerse the reaction flask in an oil bath (dewar dish) and heat to 94 °C while stirring the contents using a magnetic heat plate.

-

4

Dispense 4.0 ml acetic anhydride (42.4 mmol, 1.23 eq.) into the flask dropwise over 5 min using a 20-gauge 1.5-inch disposable needle and plastic syringe.

-

5

Stir this reaction mixture continuously for 2 h at 94 °C.

-

6

Remove the reaction flask from the hot oil bath and allow its contents to cool to room temperature (approximately 10 min).

-

7

Filter the mixture through P8, qualitative, coarse filter paper using a Hirsch funnel under aspirator vacuum.

-

8

Rinse the reaction flask (3 × 3 ml) with hot acetic anhydride and use this solution to wash the filtered precipitate.

-

9

Collect the 2-acetylamino-5-aminobenzenesulfonic acid precipitate from Step 7 into a clean round-bottom flask and dry using a vacuum pump (0.1–0.5 mm Hg).

Pause point

2-Acetylamino-5-aminobenzenesulfonic acid should be left under vacuum for a minimum of 2 h to remove residual acidic solvent; however, it can then be stored in a sealed glass vial and left refrigerated indefinitely. We have not observed significant decomposition of this sample even after 1 year in a refrigerator.

Synthesis of sodium 3,3′-bis(sulfonato)-4,4′-bis(acetamido)azobenzene (2)

Timing 3 d

-

10

Dissolve 2-acetylamino-5-aminobenzenesulfonic acid (1.725 g, 7.0 mmol) in H2O (18 ml) in a 50-ml round-bottom flask containing a magnetic stir bar.

-

11

Adjust the pH of the 2-acetylamino-5-aminobenzenesulfonic acid solution to 8.5 by adding 0.1 M sodium carbonate dropwise. The solution should change color from light pink to brown.

Critical Step

The pH must be adjusted to slightly basic to facilitate amine oxidation. If the pH is not properly adjusted, the yield will be significantly lowered.

-

12

Seal the reaction flask with a white rubber septum and immerse it in a −5 °C bath: ice/brine (saturated NaCl) solution contained in a glass dewar.

-

13

Dispense 19 ml sodium hypochlorite solution (neat, as supplied by vendor) into the reaction flask dropwise over 5 min using a 20-gauge 1.5-inch disposable needle and plastic syringe.

-

14

Continue stirring the reaction mixture for 2 h. It is necessary to add ice to the low-temperature bath to maintain the temperature at −5 °C.

-

15

Wrap the reaction flask in aluminum foil and incubate at 4 °C for 3 d.

Pause point

To maximize azobenzene yield, the 2-acetylamino-5-aminobenzenesulfonic acid reaction mixture can be stored in situ at 4 °C for up to 3 d.

Critical Step

Be sure to perform the oxidation in the dark and keep subsequent reaction mixtures and products away from direct exposure to light; exposure to light may lead to decomposition of the azobenzene chromophore, particularly at elevated temperatures or pHs.

-

16

Filter the mixture through P8, qualitative, coarse filter paper using a Hirsch funnel under aspirator vacuum.

-

17

Wash filtered material with hot ethanol to yield pure sodium 3,3′-bis(sulfonato)-4,4′-bis(acetamido)azobenzene.

Pause point

Pure sodium 3,3′-bis(sulfonato)-4,4′-bis(acetamido)azobenzene can be stored in a sealed glass vial and left refrigerated indefinitely. We have not observed significant decomposition of this sample even after 1 year in a refrigerator.

Synthesis of sodium 3,3′-bis(sulfonato)-4,4′-bis(amino)azobenzene (3)

Timing 15 h 30 min

-

18

Add sodium 3,3′-bis(sulfonato)-4,4′-bis(acetamido)azobenzene (82.3 mg, 0.18 mmol) and ddH2O (2.75 ml) to a 10-ml round-bottom flask containing a magnetic stir bar.

-

19

Add hydrochloric acid (ACS Reagent, 37%, 0.55 ml) to this reaction mixture, immerse the reaction flask in an oil bath (dewar dish) and reflux, while stirring at 110 °C for 2.5 h.

-

20

Cool the reaction mixture to room temperature and remove aqueous solvents using a rotary evaporator under aspirator vacuum.

-

21

Redissolve solid 3,3′-bis(sulfonato)-4,4′-bis(amino)azobenzene in H2O (8.0 ml) and adjust the pH of this solution to 8.5 by dropwise addition of 0.1 M NaOH.

-

22

Lyophilize the sodium 3,3′-bis(sulfonato)-4,4′-bis(amino)azobenzene solution in a 50-ml round-bottom flask and dry the solution overnight using a vacuum pump (0.1–0.5 mm Hg).

Pause point

Pure sodium 3,3′-bis(sulfonato)-4,4′-bis(amino)azobenzene can be stored in a sealed glass vial and left refrigerated indefinitely. We have not observed significant decomposition of this sample even after 1 year in a refrigerator.

Synthesis of BSBCA (4)

Timing 13 h

-

23

Add sodium 3,3′-bis(sulfonato)-4,4′-bis(amino)azobenzene (30 mg, 0.081 mmol), chloroacetic acid (191 mg, 2.03 mmol, 25 eq.) and chloroacetic anhydride (346 mg, 2.03 mmol, 25 eq.) to a 10-ml round-bottom flask containing a magnetic stir bar and seal the contents with a white rubber septum.

-

24

Immerse the reaction mixture in an oil bath, heat to 87 °C and stir continuously for 9 h. The melting points of chloroacetic acid and chloroacetic anhydride are 60–63 and 48–60 °C, respectively. Heating this reaction mixture will bring sodium 3,3′-bis(sulfonato)-4,4′-bis(amino)azobenzene into solution.

Pause point

Although the sodium 3,3′-bis(sulfonato)-4,4′-bis(amino)azobenzene mixture should be allowed to react for at least 9 h, we have found that it can be left stirring overnight (approximately 12–15 h) at 87 °C. In this case, neither the yield nor the purity of the final product is adversely affected.

-

25

Remove the reaction mixture carefully from the hot oil bath, allow it to cool to room temperature (approximately 15 min) and continue to cool the reaction mixture over ice for an additional 30 min to precipitate BSBCA.

-

26

The round-bottom flask will contain BSBCA as well as unreacted chloroacetic anhydride and chloroacetic acid. Wash these materials from the reaction vessel using excess dichloromethane (3–5 × 5 ml) and filter the mixture through P8, qualitative, coarse filter paper using a Hirsch funnel under aspirator vacuum.

-

27

Collect the filtered precipitate BSBCA in a clean 5-ml round-bottom flask and dry using a 0.1–0.5 mm Hg vacuum pump.

Pause point

Pure BSBCA should be left under vacuum for a minimum of 2 h to remove residual solvent; however, it can then be stored in a sealed glass vial and left refrigerated indefinitely. We have not observed significant decomposition of this sample even after 1 year in a refrigerator.

Protein cross-linking with BSBCA

Timing Approximately 12 h

-

28

Transfer 5 ml 100 μM double-Cys mutant protein (500 nmol) to a centrifugal filter tube (Millipore, Amicon Ultra-15) and centrifuge at 4,000 r.p.m. at 4 °C for 30 min until a final volume of 500 μl is reached. A Sorvall legend T/RT, with a 250-ml rectangular swinging bucket rotor, is suitable.

Critical Step

Centrifugal filter tubes offer a convenient means to concentrate and purify proteins and peptides. The protein solution should be pre-concentrated to improve rates of reaction in cross-linking with BSBCA.

-

29

Add 50 mM Tris–HCl buffer (pH 8.5) to the centrifugal filter tube up to 5 ml and repeat centrifugation (4,000 r.p.m., 4 °C, 30 min) at least three times to ensure buffer exchange.

Critical Step

The final protein concentration should be no less than 1 mM (centrifugation should proceed until 500 μl solution remains).

-

30

Fit a 5 ml-round-bottom flask containing a magnetic stir bar with a white rubber septum. Insert a nitrogen inlet and vent consisting of disposable syringe needles and blow nitrogen gas through the flask for 2 min to purge oxygen from the flask.

-

31

Attach an empty balloon to the end of a 3-ml plastic syringe that has been cut flush at the 1 ml mark (the balloon can be held in place with rubber bands). Fill the balloon with nitrogen gas and affix a 20-gauge 1.5-inch needle (Becton Dickinson) to the syringe. Insert this needle into the white rubber septum to maintain positive nitrogen pressure in the flask.

-

32

Using a disposable plastic syringe and needle, transfer the protein (500 μl) from the centrifugal filter tube to the round-bottom flask.

-

33

Using a disposable plastic syringe and needle, dispense 10 μl 500 mM TCEP into the reaction flask (final TCEP concentration is 10 mM) and stir at room temperature for 30 min.

Critical Step

Efficient protein cross-linking with BSBCA requires the reaction to be performed in the presence of a suitable reducing agent under nitrogen atmosphere. These measures help to prevent cysteinyl disulfide bond formation, an undesirable side reaction that inhibits protein cross-linking. TCEP, as a reducing agent, is found to be relatively unreactive toward the azobenzene moiety during protein cross-linking (D.C.B., Z.Z. and G.A.W., unpublished results) and should be used in preference to dithiothreitol, mercaptoethanol or any other sulfhydryl-based reducing agents. Commercially available TCEP is usually provided as a free acid and should be pre-buffered with 50 mM Tris–HCl to maintain the protein cross-linking reaction at pH 8.5. TCEP solutions (0.5 M; 71.65 mg TCEP in 0.5 ml 50 mM Tris–HCl) should be prepared fresh and maintained at 2–8 °C before use in cross-linking.

-

34

Add 3,3′-bis(sulfonato)-4,4′-bis(chloroacetamido)azobenzene (4) (1.3 mg, 2.55 μmol, 5.1 eq.) to the reaction mixture so that the final concentration is 5 mM. Immerse the reaction flask in an oil bath (dewar dish) and heat to 10 °C below the expected melting temperature of the protein so that it is maintained in a folded, functional state. Stir the reaction mixture continuously for 6 h.

-

35

Transfer the reaction mixture to a centrifugal filter tube and centrifuge at 4,000 r.p.m. at 4 °C for 30 min until a final volume of 500 μl is reached. Dilute the sample with 50 mM Tris–HCl buffer (pH 8.5) to 5 ml and repeat centrifugation at least three times to make sure that no free cross-linker remains (i.e., the filtrate has no color).

-

36

Check the completion of the reaction using UV spectroscopy by comparing A280 and A363. The cross-linker has molar extinction coefficients of 2,500 M−1 cm−1 at 280 nm and 24,000 M−1 cm−1 at 363 nm. The molar extinction coefficient at 280 nm of the un-cross-linked protein can be calculated using the Protein Parameter tool of the Expasy server (http://ca.expasy.org/tools/protparam.html)28. The calculated value should be added to the value for the cross-linker. If cross-linking is complete, the ratio of A280 to A363 should equal the ratio of extinction coefficients: (α280(protein) + α280(linker))/(α363(linker)).

-

37

Check the completion of the reaction and integrity of the protein using MALDI or electrospray mass spectrometry. The cross-linker adds 452.5 Da to the protein's mass.

Critical Step

Depending on the protein, up to three rounds of cross-linking may be required to acheive more than 98% cross-linking. In cases where additional rounds of cross-linking are necessary, Steps 28–36 should be repeated.

Preparation of cross-linked protein samples for UV-visible and CD spectroscopy

Timing Approximately 1–2 h

-

38

Dissolve samples for UV and CD analyses in 5–50 mM sodium phosphate buffer, pH 7.0, at a concentration from 1 to 50 μM depending on the cuvette to be used (typically 1 cm pathlength for UV and 0.1 cm pathlength for CD). Obtain spectra by following the manufacturer's instructions.

Critical Step

Irradiation of the sample to promote trans-to-cis photo-isomerization can be accomplished using a variety of light sources. For instance, a 70 W metal halide Tri-Lite lamp (World Precision Instruments) coupled to a 370 ± 10 nm band-pass filter (Harvard Apparatus, Canada) and placed in front of a cuvette containing cross-linker protein will produce a photo-stationary state with approximately 80 ± 10% cis isomer in 2–5 min at room temperature. Rapid cis-to-trans photo-isomerization can be accomplished using the same light source coupled to a 450 nm band-pass filter to produce 95% trans isomer within 1 min.

-

39

Measure the half-life for thermal relaxation back to the trans isomer by recording A363 over time.

Critical Step

It is important to ensure that the spectrometer measuring beam is sufficiently weak that it does not perturb the rate of relaxation. This can be tested by placing a neutral density filter (e.g., Thorlabs NE02B unmounted ∅1″ Absorptive ND Filter; optical density 0.2) in the path of the beam and testing for any effect on the measured decay rate.

Troubleshooting

Troubleshooting advice can be found in Table 1.

Timing

Steps 1–4: 15 min;

Step 5: 2 h;

Step 6: 10 min;

Steps 7–8: 15 min;

Step 9: 2–3 h;

Steps 10–12: 15 min;

Step 13: 5 min;

Step 14: 2 h;

Step 15: 3 d;

Steps 16–17: 15 min;

Step 18: 15 min;

Step 19: 2.5 h;

Steps 20–21: 30 min;

Step 22: 12 h;

Step 23: 15 min;

Step 24: 9 h;

Steps 25–26: 45 min;

Step 27: 2–3 h;

Steps 28–29: 2 h 15 min;

Steps 30–33: 45 min;

Step 34: 6 h;

Step 35: 2 h 15 min;

Steps 36–37: 30 min;

Steps 38–39: 1–2 h

Anticipated results

Analytical data

2-acetylamino-5-aminobenzenesulfonic acid (1)

Yield, 40%; purity by 1H NMR: greater than 97%; HRMS-EI (C8H10N2O4S) calculated (m/z) 230.0361, observed (m/z) 230.0365; 1H NMR (499.849 MHz, d6-DMSO) δ 2.078 (s, 3H, CH3), 7.30 (dd, J = 2.65 Hz; 8.75 Hz, 1H, Hb), 7.70 (d, J = 2.65 Hz; 1H, Ha), 8.39 (d, J = 8.72 Hz, 1H, Hc) 10.355 (s, 1H, NH) 13C NMR (125.698 MHz, d6-DMSO) δ 24.5 (CH3), 120.2 (CHc), 121.3 (CHa), 123.8 (CHb), 124.9 (CNH2), 134.4 (CSO3H), 135.6 (Cacetamido), 167.3 (C(O)).

Sodium 3,3′-bis(sulfonato)-4,4′-bis(acetamido)azobenzene (2)

Yield, 15%; purity by 1H NMR: greater than 97%; HRMS-ESI (C16H14N4O8S2) calculated (m/z) 455.0336, observed (m/z) 455.0318; 1H NMR (499.849 MHz, d6-DMSO) δ 2.208 (s, 3H, CH3), 7.794 (dd, J = 2.36 Hz; 8.74 Hz, 1H, Hb), 8.02 (d, J = 8.69 Hz; 1H, Hc), 8.179 (d, J = 2.34 Hz, 1H, Ha) 13C NMR (125.698 MHz, d6-DMSO) δ 23.7 (CH3), 121.9 (CHa), 124.2 (CHc), 125.9 (CHb), 133.82 (Cacetamido), 136.3 (CSO3H), 147.8 (Cazo), 172.4 (C(O)).

Sodium 3,3′-bis(sulfonato)-4,4′-bis(amino)azobenzene (3)

Yield, 96%; purity by 1H NMR: greater than 98%; HRMS-ESI (C12H10N4O6S2) calculated (m/z) 371.0125, observed (m/z) 371.0129; 1H NMR (499.849 MHz, d6-DMSO) δ 6.20 (s, 2H, NH2), 6.71 (d, J = 8.60 Hz, 1H, Hc), 7.53 (dd, J = 2.31 Hz; 8.65 Hz, 1H, Hb), 7.94 (d, J = 2.34 Hz, 1H, Ha) 13C NMR (125.698 MHz, d6-DMSO) δ 115.1 (CHc), 121.3 (CHa), 124.5 (CHb), 129.6 (CSO3−), 141.7 (CNH2), 147.0 (Cazo).

BSBCA (4)

Yield, 95%; purity by 1H NMR: greater than 97%; HRMS-ESI (C16H14Cl2N4O8S2) calculated (m/z) 522.9557, observed (m/z) 522.9560; 1H NMR (499.849 MHz, D2O) δ 4.42 (s, 2H, CH2), 7.98 (dd, J = 2.41 Hz; 8.86 Hz, 1H, Hb), 8.20 (d, J = 2.46 Hz, 1H, Ha), 8.53 (d, J = 8.82 Hz, 1H, Hc), 11.23 (s, 1H, NH) 13C NMR (125.698 MHz, d6- D2O) δ 42.9 (CH2), 119.0 (CHa), 119.9 (CHc), 125.7 (CHb), 135.8 (Cchloroacetamido), 136.5 (CSO3H), 146.8 (Cazo), 164.9 (C(O)).

Protein cross-linking

The cross-linking reaction should proceed with an anticipated yield of more than 65% based on more than 98% cross-linking efficiency and more than 93% retention per pass on the Amicon ultra-15 centrifugal filters under the conditions specified. The MALDI or ESI m/z of cross-linked protein, when compared with un-cross-linked protein, should yield a mass difference of approximately 452.5 Da. Figure 3 shows ESI mass spectra before and after reaction of a GCN4 protein with BSBCA.

UV-visible spectroscopy is typically employed to measure the degree of trans-to-cis isomerization in the cross-linked protein after irradiation (Fig. 4). For a BSBCA cross-linked protein in its thermally stable trans configuration, the UV-visible spectrum should show a strong maximum at 363 nm, which is typical for amide-substituted azobenzene π−π* transitions. Irradiation with light at a wavelength of 370 nm will lead to the loss of that absorption maximum along with a slight increase in absorbance at 450 nm, corresponding to the n−π* transition of cis-azobenzene. Thermal reversion from the cis-to-trans state typically proceeds over a range of half-lives (10–30 min at 25 °C) depending on the protein that has been cross-linked and the residue spacing spanning the cross-link.

CD spectroscopy can be used to gauge the degree of helix–coil transition brought about by irradiation (Fig. 5). For i−i+11 cross-linked α-helices, which are compatible with the thermally stable trans configuration of BSBCA, the CD spectrum should exhibit weaker molar ellipticity at 222 nm upon irradiation at 360 nm. This indicates that trans-to-cis photo-isomerization is coupled to helix unfolding within these proteins. In contrast, i−i+7 and i−i+4 cross-linked α-helices are compatible with the cis BSBCA configuration and should exhibit stronger molar ellipticity at 222 nm upon sample irradiation at 370 nm. Thus, an increase in helix content is coupled to trans-to-cis photo-isomerization within these proteins.

References

Renner, C. & Moroder, L. Azobenzene as a conformational switch on model peptides. Chembiochem 7, 868–878 (2006).

Ulysse, L., Cubillos, J. & Chmielewski, J. Photoregulation of cyclic peptide conformation. J. Am. Chem. Soc. 117, 8466–8467 (1995).

Kumita, J.R., Smart, O.S. & Woolley, G.A. Photo-control of helix content in a short peptide. Proc. Natl. Acad. Sci. USA 97, 3803–3808 (2000).

Bose, M., Groff, D., Xie, J.M., Brustad, E. & Schultz, P.G. The incorporation of a photoisomerizable amino acid into proteins in E.coli . J. Am. Chem. Soc. 128, 388–389 (2006).

Muranaka, N., Hohsaka, T. & Sisido, M. Photoswitching of peroxidase activity by position-specific incorporation of a photoisomerizable non-natural amino acid into horseradish peroxidase. FEBS Lett. 510, 10–12 (2002).

Nakayama, K., Endo, M. & Majima, T. A hydrophilic azobenzene-bearing amino acid for photochemical control of a restriction enzyme BamHI. Bioconjugate Chem. 16, 1360–1366 (2005).

James, D.A., Burns, D.C. & Woolley, G.A. Kinetic characterization of ribonuclease S mutants containing photoisomerizable phenylazophenylalanine residues. Protein Eng. 14, 983–991 (2001).

Tang, X.J. & Dmochowski, I.J. Controlling RNA digestion by RNase H with a light-activated DNA hairpin. Angew. Chem. Int. Ed. 45, 3523–3526 (2006).

Liu, Y. & Sen, D. Light-regulated catalysis by an RNA-cleaving deoxyribozyme. J. Mol. Biol. 341, 887–892 (2004).

Borisenko, V., Burns, D.C., Zhang, Z. & Woolley, G.A. Optical switching of ion-dipole interactions in a gramicidin channel analogue. J. Am. Chem. Soc. 122, 6364–6370 (2000).

Volgraf, M. et al. Allosteric control of an ionotropic glutamate receptor with an optical switch. Nat. Chem. Biol. 2, 47–52 (2006).

Asanuma, H., Ito, T. & Komiyama, M. Photo-responsive oligonucleotides carrying azobenzene in the side-chains. Tet. Lett. 39, 9015–9018 (1998).

Willner, I., Rubin, S. & Riklin, A. Photoregulation of papain activity through anchoring photochromic azo groups to the enzyme backbone. J. Am. Chem. Soc. 113, 3321–3325 (1990).

Muramatsu, S., Kinbara, K., Taguchi, H., Ishii, N. & Aida, T. Semibiological molecular machine with an implemented 'AND' logic gate for regulation of protein folding. J. Am. Chem. Soc. 128, 3764–3769 (2006).

Kumita, J.R., Flint, D.G., Smart, O.S. & Woolley, G.A. Photo-control of peptide helix content by an azobenzene cross-linker: steric interactions with underlying residues are not critical. Protein Eng. 15, 561–569 (2002).

Burns, D.C. et al. Origins of helix-coil switching in a light-sensitive peptide. Biochemistry 43, 15329–15338 (2004).

Woolley, G.A. Photo-controlling peptide α helices. Acc. Chem. Res. 38, 486–493 (2005).

Tyagi, R. & Gupta, M.N. Chemical modification and chemical cross-linking for protein/enzyme stabilization. Biochemistry (Mosc.) 63, 334–344 (1998).

Wong, S.S. & Wong, L.J.C. Chemical cross-linking and the stabilization of proteins and enzymes. Enzyme Microb. Technol. 14, 866–874 (1992).

Borisenko, V. & Woolley, G.A. Reversibility of conformational switching in light-sensitive peptides. J. Photochem. Photobiol. A-Chem. 173, 21–28 (2005).

Pozhidaeva, N., Cormier, M.E., Chaudhari, A. & Woolley, G.A. Reversible photocontrol of peptide helix content: adjusting thermal stability of the cis state. Bioconjugate Chem. 15, 1297–1303 (2004).

Chi, L., Sadovski, O. & Woolley, G.A. A blue-green absorbing cross-linker for rapid photoswitching of peptide helix content. Bioconjugate Chem. 17, 670–676 (2006).

Zhang, Z.H., Burns, D.C., Kumita, J.R., Smart, O.S. & Woolley, G.A. A water-soluble azobenzene cross-linker for photocontrol of peptide conformation. Bioconjugate Chem. 14, 824–829 (2003).

Rau, H. Azo Compounds. In Photochroism: Molecules and Systems, Revised Edition (eds. Dürr, H. & Bouas–Laurent, H.) 165–192 (Elsevier, Amsterdam, 2003).

Sporlein, S. et al. Ultrafast spectroscopy reveals subnanosecond peptide conformational dynamics and validates molecular dynamics simulation. Proc. Natl. Acad. Sci. USA 99, 7998–8002 (2002).

Bredenbeck, J., Helbing, J., Kumita, J.R., Woolley, G.A. & Hamm, P. α-Helix formation in a photoswitchable peptide tracked from picoseconds to microseconds by time-resolved IR spectroscopy. Proc. Natl. Acad. Sci. USA 102, 2379–2384 (2005).

Flint, D.G., Kumita, J.R., Smart, O.S. & Woolley, G.A. Using an azobenzene cross-linker to either increase or decrease peptide helix content upon trans-to-cis photoisomerization. Chem. Biol. 9, 391–397 (2002).

Gasteiger, E. et al. Protein Identification and Analysis Tools on the ExPASy Server. In The Proteomics Handbook (ed. Walker, J.M.) 571–607 (Humana Press, Hertfordshire, U.K.,2005).

Woolley, G.A. et al. Reversible photocontrol of DNA binding by a designed GCN4-bZIP protein. Biochemistry 45, 6075–6084 (2006).

Guerrero, L., Smart, O.S., Woolley, G.A. & Allemann, R.K. Photocontrol of DNA binding specificity of a miniature engrailed homeodomain. J. Am. Chem. Soc. 127, 15624–15629 (2005).

Guerrero, L. et al. Photochemical regulation of DNA-binding specificity of MyoD. Angew. Chem. Int. Ed. 44, 7778–7782 (2005).

Acknowledgements

This work was supported by the Natural Sciences and Engineering Research Council of Canada and the Canadian Institutes of Health Research Training Program on Protein Folding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Burns, D., Zhang, F. & Woolley, G. Synthesis of 3,3′-bis(sulfonato)-4,4′-bis(chloroacetamido)azobenzene and cysteine cross-linking for photo-control of protein conformation and activity. Nat Protoc 2, 251–258 (2007). https://doi.org/10.1038/nprot.2007.21

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2007.21

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.