Abstract

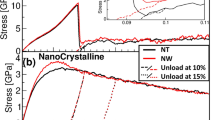

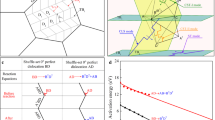

Nanotwinned metals are attractive in many applications because they simultaneously demonstrate high strength and high ductility, characteristics that are usually thought to be mutually exclusive. However, most nanotwinned metals are produced in polycrystalline forms and therefore contain randomly oriented twin and grain boundaries making it difficult to determine the origins of their useful mechanical properties. Here, we report the fabrication of arrays of vertically aligned copper nanopillars that contain a very high density of periodic twin boundaries and no grain boundaries or other microstructural features. We use tension experiments, transmission electron microscopy and atomistic simulations to investigate the influence of diameter, twin-boundary spacing and twin-boundary orientation on the mechanical responses of individual nanopillars. We observe a brittle-to-ductile transition in samples with orthogonally oriented twin boundaries as the twin-boundary spacing decreases below a critical value (∼3–4 nm for copper). We also find that nanopillars with slanted twin boundaries deform via shear offsets and significant detwinning. The ability to decouple nanotwins from other microstructural features should lead to an improved understanding of the mechanical properties of nanotwinned metals.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Callister, W. Materials Science and Engineering: An Introduction 4th edn (Wiley, 1997).

Hirth, J. P. & Lothe, J. Theory of Dislocations 2nd edn (Wiley, 1982).

Greer, J. R. & De Hosson, J. T. Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654–724 (2011).

Zhu, T. & Li, J. Ultra-strength materials. Prog. Mater. Sci. 55, 710–757 (2010).

Uchic, M. D., Shade, P. A. & Dimiduk, D. M. Plasticity of micrometer-scale single crystals in compression. Annu. Rev. Mater. Res. 39, 361–386 (2009).

Lu, L., Chen, X., Huang, X. & Lu, K. Revealing the maximum strength in nanotwinned copper. Science 323, 607–610 (2009).

Hodge, A., Wang, Y. M. & Barbee, T. Jr Mechanical deformation of high-purity sputter-deposited nano-twinned copper. Scripta Materialia 59, 163–166 (2008).

Dao, M., Lu, L., Shen, Y. & Suresh, S. Strength, strain-rate sensitivity and ductility of copper with nanoscale twins. Acta Materialia 54, 5421–5432 (2006).

Li, X., Wei, Y., Lu, L., Lu, K. & Gao, H. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 464, 877–880 (2010).

Wu, Z., Zhang, Y. & Srolovitz, D. J. Dislocation–twin interaction mechanisms for ultrahigh strength and ductility in nanotwinned metals. Acta Materialia 57, 4508–4518 (2009).

Deng, C. & Sansoz, F. Enabling ultrahigh plastic flow and work hardening in twinned gold nanowires. Nano Lett. 9, 1517–1522 (2009).

Wang, J. & Huang, H. Novel deformation mechanism of twinned nanowires. Appl. Phys. Lett. 88, 203112 (2006).

Zhu, T., Li, J., Samanta, A., Kim, H. G. & Suresh, S. Interfacial plasticity governs strain rate sensitivity and ductility in nanostructured metals. Proc. Natl Acad. Sci. USA 104, 3031–3036 (2007).

Asaro, R. J. & Kulkarni, Y. Are rate sensitivity and strength effected by cross-slip in nano-twinned fcc metals. Scripta Materialia 58, 389–392 (2008).

Ma, E. et al. Strain hardening and large tensile elongation in ultrahigh-strength nano-twinned copper. Appl. Phys. Lett. 85, 4932–4934 (2004).

Anderoglu, O. et al. Epitaxial nanotwinned Cu films with high strength and high conductivity. Appl. Phys. Lett. 93, 083108 (2008).

Bufford, D., Wang, H. & Zhang, X. High strength, epitaxial nanotwinned Ag films. Acta Materialia 59, 93–101 (2011).

Zhang, H., Schuster, B. E., Wei, Q. & Ramesh, K. The design of accurate micro-compression experiments. Scripta Materialia 54, 181–186 (2006).

Ogata, S., Li, J. & Yip, S. Ideal pure shear strength of aluminum and copper. Science 298, 807–811 (2002).

Jennings, A. T. & Greer, J. R. Tensile deformation of electroplated copper nanopillars. Phil. Mag. 91, 1108–1120 (2011).

Meyers, M. A. & Chawla, K. K. Mechanical Behavior of Materials 1st edn (Prentice-Hall, 1998).

Jennings, A. T., Li, J. & Greer, J. R. Emergence of strain-rate sensitivity in Cu nanopillars: transition from dislocation multiplication to dislocation nucleation. Acta Materialia 59, 5627–5637 (2011).

Wang, Y. & Sui, M. L. Atomic-scale in situ observation of lattice dislocations passing through twin boundaries. Appl. Phys. Lett. 94, 021909 (2009).

Chassagne, M., Legros, M. & Rodney, D. Atomic-scale simulation of screw dislocation/coherent twin boundary interaction in Al, Au, Cu and Ni. Acta Materialia 59, 1456–1463 (2011).

Zhang, Y. & Huang, H. Do twin boundaries always strengthen metal nanowires? Nanoscale Res. Lett. 4, 34–38 (2009).

Hong, C., Tao, N., Huang, X. & Lu, K. Nucleation and thickening of shear bands in nano-scale twin/matrix lamellae of a CuAl alloy processed by dynamic plastic deformation. Acta Materialia 58, 3103–3116 (2010).

Hodge, A., Furnish, T., Navid, A. & Barbee, T. Jr Shear band formation and ductility in nanotwinned Cu. Scripta Materialia 65, 1006–1009 (2011).

Qu, S., Zhou, H. & Huang, Z. Shear band initiation induced by slip-twin boundary interactions. Scripta Materialia 65, 715–718 (2011).

Wei, Y. Anisotropic size effect in strength in coherent nanowires with tilted twins. Phys. Rev. B 84, 014107 (2011).

Cao, A. J., Wei, Y. G. & Mao, S. X. Deformation mechanisms of face-centered-cubic metal nanowires with twin boundaries. Appl. Phys. Lett. 90, 151909 (2007).

Burek, M. J. & Greer, J. R. Fabrication and microstructure control of nanoscale mechanical testing specimens via electron beam lithography and electroplating. Nano Lett. 10, 69–76 (2010).

Nosé, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 81, 511–519 (1984).

Berendsen, H. J. C., Postma, J. P. M., Van Gunsteren, W. F., DiNola, A. & Haak, J. R. Molecular dynamics with coupling to an external bath. J. Chem. Phys. 81, 3684–4690 (1984).

Mishin, Y., Mehl, M., Papaconstantopoulos, D., Voter, A. & Kress, J. Structural stability and lattice defects in copper: ab initio, tight-binding, and embedded-atom calculations. Phys. Rev. B 63, 224106 (2001).

Tuckerman, M., Berne, B. J. & Martyna, G. J. Reversible multiple time scale molecular dynamics. J. Chem. Phys. 97, 1990–2001 (1992).

Van Swygenhoven, H., Farkas, D. & Caro, A. Grain-boundary structures in polycrystalline metals at the nanoscale. Phys. Rev. B 62, 831–838 (2000).

Acknowledgements

D.J. and J.R.G. acknowledge financial support from the NSF CAREER Grant (DMR-0748267) and the Office of Naval Research (N00014-09-1-0883). X.L. and H.G. also acknowledge financial support from the NSF-sponsored MRSEC Center at Brown University (DMR-0520651) and grant no. CMMI-0758535. The authors acknowledge critical support and infrastructure provided by the Kavli Nanoscience Institute at Caltech. The simulations were performed on the NICS Kraken Cray XT5 system (MS090046).

Author information

Authors and Affiliations

Contributions

D.J. conducted experiments, including synthesis and in situ testing of samples. X.L. performed atomistic simulations. J.R.G. and H.G. conceived the research and provided guidance. All authors analysed the data, discussed the results and wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary information (PDF 17768 kb)

Supplementary movie 1

Supplementary movie 1 (MOV 3228 kb)

Supplementary movie 2

Supplementary movie 2 (MOV 5578 kb)

Supplementary movie 3

Supplementary movie 3 (MOV 11536 kb)

Supplementary movie 4

Supplementary movie 4 (MOV 6956 kb)

Rights and permissions

About this article

Cite this article

Jang, D., Li, X., Gao, H. et al. Deformation mechanisms in nanotwinned metal nanopillars. Nature Nanotech 7, 594–601 (2012). https://doi.org/10.1038/nnano.2012.116

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2012.116

This article is cited by

-

Chemical inhomogeneity–induced profuse nanotwinning and phase transformation in AuCu nanowires

Nature Communications (2023)

-

Investigating size dependence in nanovoid-embedded high-entropy-alloy films under biaxial tension

Archive of Applied Mechanics (2023)

-

Microstructure and Mechanical Properties of a Ni-Based Superalloy Thin Film Investigated by Micropillar Compression

Metallurgical and Materials Transactions A (2023)

-

In situ atomistic mechanisms of detwinning in nanocrystalline AuAg alloy

Science China Materials (2022)

-

Phase-field approach to evolution and interaction of twins in single crystal magnesium

Computational Mechanics (2022)