Abstract

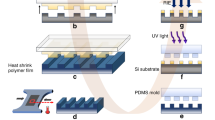

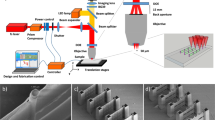

Periodic micro- and nanostructures (gratings) have many significant applications in electronic, optical, magnetic, chemical and biological devices and materials. Traditional methods for fabricating gratings by writing with electrons1, ions2 or a mechanical tip are limited to very small areas and suffer from extremely low throughput. Interference lithography can achieve relatively large fabrication areas, but has a low yield for small-period gratings3,4. Photolithography5, nanoimprint lithography6,7, soft lithography8,9 and lithographically induced self-construction10 all require a prefabricated mask, and although electrohydrodynamic instabilities11 can self-produce periodic dots without a mask, gratings remain challenging. Here, we report a new low-cost maskless method to self-generate nano- and microgratings from an initially featureless polymer thin film sandwiched between two relatively rigid flat plates. By simply prising apart the plates, the film fractures into two complementary sets of nonsymmetrical gratings, one on each plate, of the same period. The grating period is always four times the thickness of the glassy film, regardless of its molecular weight and chemical composition. Periods from 120 nm to 200 µm have been demonstrated across areas as large as two square centimetres.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Tennant, D. M. et al. Characterization of near-field holography grating masks for optoelectronics fabricated by electron-beam lithography. J. Vac. Sci. Technol. 10, 2530–2535 (1992).

Melngailis, J., Mondelli, A. A., Berry, I. L. & Mohondro, R. A review of ion projection lithography. J. Vac. Sci. Technol. 16, 927–957 (1998).

Yen, A., Anderson, E. H., Ghanbari, R. A., Schattenburg, M. L. & Smith, H. I. Achromatic holographic configuration for 100 nm-period lithography. Appl. Opt. 31, 4540–4545 (1992).

Solak, H. H. et al. Exposure of 38 nm period grating patterns with extreme ultraviolet interferometric lithography. Appl. Phys. Lett. 75, 2328–2330 (1999).

Hill, K. O., Malo, B., Bilodeau, F., Johnson, D. C. & Albert, J. Bragg gratings fabricated in monomode photosensitive optical fiber by UV exposure through a phase mask. Appl. Phys. Lett. 62, 1035–1037 (1993).

Chou, S. Y., Krauss, P. R. & Renstrom, P. J. Imprint lithography with 25-nanometer resolution. Science 272, 85–87 (1996).

Bailey, T. et al. Step and flash imprint lithography: Template surface treatment and defect analysis. J. Vac. Sci. Technol. 18, 3572–3577 (2000).

Kumar, A. & Whitesides, G. M. Features of gold having micrometer to centimeter dimensions can be formed through a combination of stamping with an elastomeric stamp and an alkanethiol ink followed by chemical etching. Appl. Phys. Lett. 63, 2002–2004 (1993).

Duffy, D. C., McDonald, J. C., Schueller, O. J. A. & Whitesides, G. M. Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal. Chem. 70, 4974–4984 (1998).

Chou, S. Y., Zhuang, L. & Guo, L. J. Lithographically induced self-construction of polymer microstructures for resistless patterning. Appl. Phys. Lett. 75, 1004–1006 (1999).

Chou, S. Y. & Zhuang, L. Lithographically induced self-assembly of periodic polymer micropillar arrays. J. Vac. Sci. Technol. 17, 3197–3202 (1999).

Deshpande, P. Nanolithography in thin polymer films using guided self-assembly. PhD Dissertation, Princeton University (2005).

Pease, L. F. III. Pattern formation in polymer via electrohydrodynamic instabilities and glassy fracture. PhD Dissertation, Princeton University (2005).

Bjerke, T., Li, Z. H. & Lambros, J. Role of plasticity in heat generation during high rate deformation and fracture of polycarbonate. Int. J. Plasticity 18, 549–567 (2002).

Benkoski, J. J., Fredrickson, G. H. & Kramer, E. J. Model for the fracture energy of glassy polymer–polymer interfaces. J. Polym. Sci. 40, 2377–2386 (2002).

Chai, H. A note on crack trajectory in an elastic strip bounded by rigid substrates. Int. J. Fracture 32, 211–213 (1987).

Cotterell, B. & Rice, J. B. Slightly curved or kinked cracks. Int. J. Fracture 16, 155–169 (1980).

Sumi, Y., Nemat-Nasser, S. & Keer, L. M. On crack path stability in a finite body. Eng. Fracture Mech. 22, 759–771 (1985).

Wang, J. S. & Suo, Z. Experimental determination of interfacial toughness curves using brazil-nut-sandwiches. Acta Metall. Mater. 38, 1279–1290 (1990).

Liu, J. et al. Fracture behavior of an epoxy/aluminum interface reinforced by sol–gel coatings. J. Adhesion Sci. Technol. 20, 277–305 (2006).

Freund, L. B. Dynamic Fracture Mechanics (Cambridge Univ. Press, Cambridge, 1998).

Acknowledgements

This work was supported by the Materials Research Science & Engineering Centers (MRSEC) (NSF-DMR-0213706), the Defence Advanced Research Projects Agency (DARPA), the Office of Naval Research (ONR) and the Department of Defense (NDSEG) through a fellowship to L.F.P. The authors thank Wen-di Li for preparation of certain graphs.

Author information

Authors and Affiliations

Contributions

P.D., L.F.P. and Y.W. performed the experiments. L.F.P., P.D., Y.W., W.B.R. and S.Y.C. designed and discussed the experiments, analysed the data and co-wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Pease, L., Deshpande, P., Wang, Y. et al. Self-formation of sub-60-nm half-pitch gratings with large areas through fracturing. Nature Nanotech 2, 545–548 (2007). https://doi.org/10.1038/nnano.2007.264

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2007.264

This article is cited by

-

Realization of wafer-scale nanogratings with sub-50 nm period through vacancy epitaxy

Nature Communications (2019)

-

Universality of periodicity as revealed from interlayer-mediated cracks

Scientific Reports (2017)

-

Quasi suppression of higher-order diffractions with inclined rectangular apertures gratings

Scientific Reports (2015)

-

Control and Manipulation of Nano Cracks Mimicking Optical Wave

Scientific Reports (2015)

-

Investigating the suitability of electrohydrodynamic lithography for the fabrication of cell substrates

Journal of Materials Science (2014)