Abstract

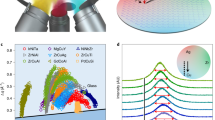

The identification of multicomponent alloys out of a vast compositional space is a daunting task, especially for bulk metallic glasses composed of three or more elements. Despite an increasing theoretical understanding of glass formation, bulk metallic glasses are predominantly developed through a sequential and time-consuming trial-and-error approach. Even for binary systems, accurate quantum mechanical approaches are still many orders of magnitude away from being able to simulate the relatively slow kinetics of glass formation. Here, we present a high-throughput strategy where ∼3,000 alloy compositions are fabricated simultaneously and characterized for thermoplastic formability through parallel blow forming. Using this approach, we identified the composition with the highest thermoplastic formability in the glass-forming system Mg–Cu–Y. The method provides a versatile toolbox for unveiling complex correlations of material properties and glass formation, and should facilitate a drastic increase in the discovery rate of metallic glasses.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Cui, J. et al. Combinatorial search of thermoelastic shape-memory alloys with extremely small hysteresis width. Nature Mater. 5, 286–290 (2006).

Johnson, W. L. Bulk glass-forming metallic alloys: science and technology. Mater. Res. Soc. Bull. 24, 42–56 (1999).

Wang, W. H. Roles of minor additions in formation and properties of bulk metallic glasses. Prog. Mater. Sci. 52, 540–596 (2007).

Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48, 279–306 (2000).

Sheng, H. W., Luo, W. K., Alamgir, F. M., Bai, J. M. & Ma, E. Atomic packing and short-to-medium-range order in metallic glasses. Nature 439, 419–425 (2006).

Inoue, A., Shen, B. L., Koshiba, H., Kato, H. & Yavari, A. R. Cobalt-based bulk glassy alloy with ultrahigh strength and soft magnetic properties. Nature Mater. 2, 661–663 (2003).

Pauly, S., Gorantla, S., Wang, G., Kuhn, U. & Eckert, J. Transformation-mediated ductility in CuZr-based bulk metallic glasses. Nature Mater. 9, 473–477 (2010).

Demetriou, M. D. et al. A damage-tolerant glass. Nature Mater. 10, 123–128 (2011).

Liu, Y. H. et al. Super plastic bulk metallic glasses at room temperature. Science 315, 1385–1388 (2007).

Kumar, G., Tang, H. X. & Schroers, J. Nanomoulding with amorphous metals. Nature 457, 868–872 (2009).

Klement, W., Willens, R. H. & Duwez, P. Non-crystalline structure in solidified gold–silicon alloys. Nature 187, 869–870 (1960).

Turnbull, D. Under what conditions can a glass be formed. Contemp. Phys. 10, 473–488 (1969).

Greer, A. L. Metallic glasses. Science 267, 1947–1953 (1995).

Wang, D., Tan, H. & Li, Y. Multiple maxima of GFA in three adjacent eutectics in Zr–Cu–Al alloy system—A metallographic way to pinpoint the best glass forming alloys. Acta Mater. 53, 2969–2979 (2005).

Miracle, D. B. A structural model for metallic glasses. Nature Mater. 3, 697–702 (2004).

Fujita, T. et al. Atomic-scale heterogeneity of a multicomponent bulk metallic glass with excellent glass forming ability. Phys. Rev. Lett. 103, 075502 (2009).

Egami, T. Universal criterion for metallic glass formation. Mater. Sci. Eng. A 226, 261–267 (1997).

Lu, Z. P. & Liu, C. T. Glass formation criterion for various glass-forming systems. Phys. Rev. Lett. 91, 115505 (2003).

Li, Y., Guo, Q., Kalb, J. A. & Thompson, C. V. Matching glass-forming ability with the density of the amorphous phase. Science 322, 1816–1819 (2008).

Park, E. S. & Kim, D. H. Correlation between volumetric change and glass-forming ability of metallic glass-forming alloys. Appl. Phys. Lett. 92, 091915 (2008).

Park, E. S., Kim, D. H. & Kim, W. T. Parameter for glass forming ability of ternary alloy systems. Appl. Phys. Lett. 86, 061907 (2005).

Bendert, J. C., Gangopadhyay, A. K., Mauro, N. A. & Kelton, K. F. Volume expansion measurements in metallic liquids and their relation to fragility and glass forming ability: an energy landscape interpretation. Phys. Rev. Lett. 109, 185901 (2012).

Ding, S. Y., Gregoire, J., Vlassak, J. J. & Schroers, J. Solidification of Au–Cu–Si alloys investigated by a combinatorial approach. J. Appl. Phys. 111, 114901 (2012).

Schroers, J. Processing of bulk metallic glass. Adv. Mater. 22, 1566–1597 (2010).

Busch, R. The thermophysical properties of bulk metallic glass-forming liquids. Jom-J. Min. Met. Mat. Soc. 52, 39–42 (2000).

Saotome, Y., Itoh, K., Zhang, T. & Inoue, A. Superplastic nanoforming of Pd-based amorphous alloy. Scr. Mater. 44, 1541–1545 (2001).

Schroers, J. On the formability of bulk metallic glass in its supercooled liquid state. Acta Mater. 56, 471–478 (2008).

Long, Z. L. et al. A new criterion for predicting the glass-forming ability of bulk metallic glasses. J. Alloy Compd. 475, 207–219 (2009).

Fan, G. J. & Fecht, H. J. A cluster model for the viscous flow of glass-forming liquids. J. Chem. Phys. 116, 5002–5006 (2002).

Nieh, T. G., Wadsworth, J., Liu, C. T., Ohkubo, T. & Hirotsu, Y. Plasticity and structural instability in a bulk metallic glass deformed in the supercooled liquid region. Acta Mater. 49, 2887–2896 (2001).

Waniuk, T. A., Schroers, J. & Johnson, W. L. Critical cooling rate and thermal stability of Zr–Ti–Cu–Ni–Be alloys. Appl. Phys. Lett. 78, 1213–1215 (2001).

Busch, R., Schroers, J. & Wang, W. H. Thermodynamics and kinetics of bulk metallic glass. Mater. Res. Soc. Bull. 32, 620–623 (2007).

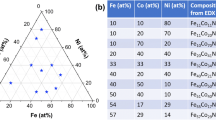

Ma, H., Zheng, Q., Xu, J., Li, Y. & Ma, E. Doubling the critical size for bulk metallic glass formation in the Mg–Cu–Y ternary system. J. Mater. Res. 20, 2252–2255 (2005).

Inoue, A., Kato, A., Zhang, T., Kim, S. G. & Masumoto, T. Mg–Cu–Y amorphous-alloys with high mechanical strengths produced by a metallic mold casting method. Mater. T. Jim. 32, 609–616 (1991).

Pitt, E. B., Kumar, G. & Schroers, J. Temperature dependence of the thermoplastic formability in bulk metallic glasses. J. Appl. Phys. 110, 043518 (2011).

Deng, Y. P. et al. A combinatorial thin film sputtering approach for synthesizing and characterizing ternary ZrCuAl metallic glasses. Intermetallics 15, 1208–1216 (2007).

Li, Y., Guo, Q., Kalb, J. A. & Thompson, C. V. Matching glass-forming ability with the density of the amorphous phase. Science 322, 1816–1819 (2008).

Guo, Q. et al. Density change upon crystallization of amorphous Zr–Cu–Al thin films. Acta Mater. 58, 3633–3641 (2010).

Bohmer, R., Ngai, K. L., Angell, C. A. & Plazek, D. J. Nonexponential relaxations in strong and fragile glass formers. J. Chem. Phys. 99, 4201–4209 (1993).

Sarac, B. et al. Three-dimensional shell fabrication using blow molding of bulk metallic glass. J. Microelectromech. Sys. 20, 28–36 (2011).

Busch, R., Liu, W. & Johnson, W. L. Thermodynamics and kinetics of the Mg65Cu25Y10 bulk metallic glass forming liquid. J. Appl. Phys. 83, 4134–4141 (1998).

Acknowledgements

The authors are grateful for support from NSF under Grant No. MRSEC DMR 1119826 (CRISP). The composition measurements were developed with support from the Department of Energy under Award Number DE-EE0005941. We also want to thank M. Power, M. Kanik and W. Chen for help with lithography.

Author information

Authors and Affiliations

Contributions

J.S. conceived and supervised the project. S.D., Y.Liu and Y.Li designed and conducted the experiments. Z.L. developed the model for viscosity calculation. S.S. fabricated the bulk samples and carried out thermoplastic formability test. F.J.W. carried out the structural characterization of the films. S.D., Y.Liu and J.S. analysed the data and wrote the paper. All authors discussed and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 746 kb)

Rights and permissions

About this article

Cite this article

Ding, S., Liu, Y., Li, Y. et al. Combinatorial development of bulk metallic glasses. Nature Mater 13, 494–500 (2014). https://doi.org/10.1038/nmat3939

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat3939

This article is cited by

-

A generative deep learning framework for inverse design of compositionally complex bulk metallic glasses

npj Computational Materials (2023)

-

Data-driven discovery of a universal indicator for metallic glass forming ability

Nature Materials (2022)

-

Compositional dependence of the fragility in metallic glass forming liquids

Nature Communications (2022)

-

Combinatorial measurement of critical cooling rates in aluminum-base metallic glass forming alloys

Scientific Reports (2021)

-

Metallic glass properties, processing method and development perspective: a review

The International Journal of Advanced Manufacturing Technology (2021)