Abstract

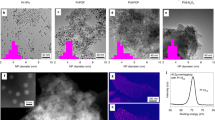

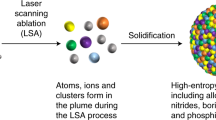

Metal nanoparticles with precisely controlled size and composition are highly attractive for heterogeneous catalysis. However, their poor thermal stability remains a major hurdle on the way towards application at realistic technical conditions. Recent progress in this area has focused on nanostructured oxides to stabilize embedded metal nanoparticles. Here, we report an alternative approach that relies on synthesizing bimetallic nanoparticles with precise compositional control to obtain improved high-temperature stability. We find that PtRh nanoparticles with sufficiently high Rh content survive extended calcination at temperatures up to ∼850 ∘C without significant sintering. For lower Rh content, sacrificial self-stabilization of individual nanoparticles through a distillation-like process is observed: the low-melting-point metal (Pt) bleeds out and the increasing concentration of the high-melting-point metal (Rh) leads to re-stabilization of the remaining nanoparticle. This principle of thermal self-stabilization should be broadly applicable to the development of multi-metallic nanomaterials for a broad range of high-temperature applications.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Van Hove, M. A. From surface science to nanotechnology. Catal. Today 113, 133–140 (2006).

Schlogl, R. & Abd Hamid, S. B. Nanocatalysis: Mature science revisited or something really new? Angew. Chem. Int. Ed. 43, 1628–1637 (2004).

Bell, A. T. The impact of nanoscience on heterogeneous catalysis. Science 299, 1688–1691 (2003).

Campbell, C. T., Parker, S. C. & Starr, D. E. The effect of size-dependent nanoparticle energetics on catalyst sintering. Science 298, 811–814 (2002).

Narayanan, R. & El-Sayed, M. A. Catalysis with transition metal nanoparticles in colloidal solution: Nanoparticle shape dependence and stability. J. Phys. Chem. B 109, 12663–12676 (2005).

Landman, U., Yoon, B., Zhang, C., Heiz, U. & Arenz, M. Factors in gold nanocatalysis: Oxidation of CO in the non-scalable size regime. Top. Catal. 44, 145–158 (2007).

Ahmadi, T. S., Wang, Z. L., Green, T. C., Henglein, A. & El-Sayed, M. A. Shape-controlled synthesis of colloidal platinum nanoparticles. Science 272, 1924–1925 (1996).

Rolison, D. R. Catalytic nanoarchitectures—the importance of nothing and the unimportance of periodicity. Science 299, 1698–1701 (2003).

Häkkinen, H., Abbet, S., Sanchez, A., Heiz, U. & Landman, U. Structural, electronic, and impurity-doping effects in nanoscale chemistry: Supported gold nanoclusters. Angew. Chem. Int. Ed. 42, 1297–1300 (2003).

Heiz, U. & Landman, U. Nanocatalysis. Nanocatalysis (Springer, p. preface V 2007).

Toshima, N. & Yonezawa, T. Bimetallic nanoparticles—novel materials for chemical and physical applications. New J. Chem. 22, 1179–1201 (1998).

Somorjai, G. A. & Borodko, Y. G. Research in nanosciences—Great opportunity for catalysis science. Catal. Lett. 76, 1–5 (2001).

Joo, S. H. et al. Thermally stable Pt/mesoporous silica core–shell nanocatalysts for high-temperature reactions. Nature Mater. 8, 126–131 (2009).

Ott, L. S. & Finke, R. G. Transition-metal nanocluster stabilization for catalysis: A critical review of ranking methods and putative stabilizers. Coord. Chem. Rev. 251, 1075–1100 (2007).

Narayanan, R. & El-Sayed, M. A. Effect of catalysis on the stability of metallic nanoparticles: Suzuki reaction catalyzed by PVP-palladium nanoparticles. J. Am. Chem. Soc. 125, 8340–8347 (2003).

Zarur, A. J. & Ying, J. Y. Reverse microemulsion synthesis of nanostructured complex oxides for catalytic combustion. Nature 403, 65–67 (2000).

Gandhi, H. S., Graham, G. W. & McCabe, R. W. Automotive exhaust catalysis. J. Catal. 216, 433–442 (2003).

Armor, J. N. The multiple roles for catalysis in the production of H2 . Appl. Catal. A 176, 159–176 (1999).

Ponec, V. & Bond, G. C. in Catalysis by Metals and Alloys (eds Delmon, B. & Yates, J. T.) (Elsevier Science, 1998).

Poltorak, O. M. & Boronin, V. S. Mitohedry—A new method of studying active centres in crystalline catalysts. Russ. J. Phys. Chem. 40, 1436–1445 (1966).

Kirchhoff, M., Specht, U. & Veser, G. Engineering high-temperature stable nanocomposite materials. Nanotechnology 16, S401–S408 (2005).

Bonnemann, H. et al. Nanoscale colloidal metals and alloys stabilized by solvents and surfactants—preparation and use as catalyst precursors. J. Org. Chem. 520, 143–162 (1996).

Ponec, V. Alloy catalysts: The concepts. Appl. Catal. A 222, 31–45 (2001).

Sanders, T., Papas, P. & Veser, G. Supported nanocomposite catalysts for high-temperature partial oxidation of methane. Chem. Eng. J. 142, 122–132 (2008).

Wang, Z. L., Petroski, J. M., Green, T. C. & El-Sayed, M. A. Shape transformation and surface melting of cubic and tetrahedral platinum nanocrystals. J. Phys. Chem. B 102, 6145–6151 (1998).

Palazov, A. et al. Adsorption and hydrogenation of ethylene, 1-hexene, and benzene and CO adsorption on Pt/Al2O3 and Pt–Sn/Al2O3 catalysts. J. Catal. 103, 249–260 (1987).

Collins, D. M. & Spicer, W. E. The adsorption of CO, O2, and H2 on Pt: I. Thermal desorption spectroscopy studies. Surf. Sci. 69, 85–113 (1977).

Baraldi, A. et al. CO adsorption and CO oxidation on Rh(100). Appl. Surf. Sci. 99, 1–8 (1996).

Ponec, V. & Bond, G. C. in Catalysis by Metals and Alloys (eds Delmon, B. & Yates, J. T.) (Elsevier Science, 1998).

Buffat, P. & Borel, J. P. Size effect on the melting temperature of gold particles. Phys. Rev. A 13, 2287–2298 (1976).

Schicks, J., Neumann, D., Specht, U. & Veser, G. Nanoengineered catalysts for high-temperature methane partial oxidation. Catal. Today 81, 287–296 (2003).

Gélin, P. & Primet, M. Complete oxidation of methane at low temperature over noble metal based catalysts: A review. Appl. Catal. B 39, 1–37 (2002).

Acknowledgements

This work was supported by the National Energy Technology Laboratory’s on-going research under the RDS contract DE-AC26-04NT41817, by the Department of Energy—Basic Energy Science through grant DE-FG02-05ER46233 and by the National Science Foundation through grant CTS-0553365. G.V. gratefully acknowledges a CNG faculty fellowship of the University of Pittsburgh’s Swanson School of Engineering. We thank Z. Liu for technical help with TEM characterizations and the Nanoscale Fabrication and Characterization Facility (NFCF) of the University of Pittsburgh for use of the electron microscopy facility.

Author information

Authors and Affiliations

Contributions

A.C. carried out all experimental work, including material synthesis, characterization and catalytic tests. G.V. designed and supervised the research programme. Both contributed to data analysis, discussion and writing of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 2449 kb)

Rights and permissions

About this article

Cite this article

Cao, A., Veser, G. Exceptional high-temperature stability through distillation-like self-stabilization in bimetallic nanoparticles. Nature Mater 9, 75–81 (2010). https://doi.org/10.1038/nmat2584

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat2584

This article is cited by

-

Magnetite immobilized metal nanoparticles in the treatment and removal of pollutants from wastewater: a review

Journal of Materials Science (2023)

-

Multidimensional thermally-induced transformation of nest-structured complex Au-Fe nanoalloys towards equilibrium

Nano Research (2022)

-

Thermal Stability of Ru–Re NPs in H2 and O2 Atmosphere and Their Activity in VOCs Oxidation: Effect of Ru Precursor

Catalysis Letters (2022)

-

Sinter-resistant and high-efficient Pt/CeO2/NiAl2O4/Al2O3@SiO2 model catalysts with “composite energy traps”

Science China Chemistry (2020)

-

Unravelling inherent electrocatalysis of mixed-conducting oxide activated by metal nanoparticle for fuel cell electrodes

Nature Nanotechnology (2019)