Abstract

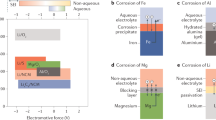

With the continuous upsurge in demand for energy storage, batteries are increasingly required to operate under extreme environmental conditions. Although they are at the technological forefront, Li-ion batteries have long been limited to room temperature, as internal phenomena during their operation cause thermal fluctuations. This has been the reason for many battery explosions in recent consumer products. While traditional efforts to address these issues focused on thermal management strategies, the performance and safety of Li-ion batteries at both low (<20 °C) and high (>60 °C) temperatures are inherently related to their respective components, such as electrode and electrolyte materials and the so-called solid-electrolyte interphases. This Review examines recent research that considers thermal tolerance of Li-ion batteries from a materials perspective, spanning a wide temperature spectrum (−60 °C to 150 °C). The structural stability of promising cathodes, issues with anode passivation, and the competency of various electrolyte, binder and current collectors are compared for their thermal workability. The possibilities offered by each of these cell components could extend the environmental frontiers of commercial Li-ion batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Tarascon, J. M. & Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001).

Forgez, C., Vinh Do, D., Friedrich, G., Morcrette, M. & Delacourt, C. Thermal modeling of a cylindrical LiFePO4/graphite lithium-ion battery. J. Power Sour. 195, 2961–2968 (2010).

Feng, X. et al. Thermal runaway features of large format prismatic lithium ion battery using extended volume accelerating rate calorimetry. J. Power Sour. 255, 294–301 (2014).

Williard, N., He, W., Hendricks, C. & Pecht, M. Lessons learned from the 787 Dreamliner issue on lithium-ion battery reliability. Energies 6, 4682–4695 (2013).

Linden, D. R. & Thomas B. Handbook of Batteries. 3rd edn (McGraw-Hill, 2002).

Mauger, A. & Julien, C. Surface modifications of electrode materials for lithium-ion batteries: status and trends. Ionics 20, 751–787 (2014).

Cho, Y., Eom, J. & Cho, J. High performance LiCoO2 cathode materials at 60 °C for lithium secondary batteries prepared by the facile nanoscale dry-coating method. J. Electrochem. Soc. 157, A617–A624 (2010).

Aurbach, D. et al. Review on electrode–electrolyte solution interactions, related to cathode materials for Li-ion batteries. J. Power Sour. 165, 491–499 (2007).

Kong, D. P., Ping, P., Wang, Q. S. & Sun, J. H. Study on high temperature stability of LiNi0.33Co0.33Mn0.33O2/Li4Ti5O12 cells from the safety perspective. J. Electrochem. Soc. 163, A1697–A1704 (2016).

Yan, C., Xu, Y., Xia, J., Gong, C. & Chen, K. Tris(trimethylsilyl) borate as an electrolyte additive for high-voltage lithium-ion batteries using LiNi1/3Mn1/3Co1/3O2 cathode. J. Energy Chem. 25, 659–666 (2016).

Ma, L., Nie, M., Xia, J. & Dahn, J. A systematic study on the reactivity of different grades of charged Li[NixMnyCoz]O2 with electrolyte at elevated temperatures using accelerating rate calorimetry. J. Power Sour. 327, 145–150 (2016).

Bloom, I. et al. Effect of cathode composition on capacity fade, impedance rise and power fade in high-power, lithium-ion cells. J. Power Sour. 124, 538–550 (2003).

Nitta, N., Wu, F., Lee, J. T. & Yushin, G. Li-ion battery materials: present and future. Mater. Today 18, 252–264 (2015).

Huang, Y. et al. Thermal stability and reactivity of cathode materials for Li-ion batteries. ACS Appl. Mater. Interfaces 8, 7013–7021 (2016). The authors investigate the thermal stability of several cathode materials in the delithated state showing that layered cathodes are the least stable and phosphates the most.

Zhao, H. et al. Enhanced elevated-temperature performance of LiAlxSi0.05Mg0.05Mn1.90–xO4 (0 ≤ x ≤ 0.08) cathode materials for high-performance lithium-ion batteries. Electrochimica Acta 199, 18–26 (2016).

Sun, Y. K. et al. Nanostructured high-energy cathode materials for advanced lithium batteries. Nat. Mater. 11, 942–947 (2012).

Rodrigues, M.-T. F. et al. Hexagonal boron nitride-based electrolyte composite for Li-ion battery operation from room temperature to 150 °C. Adv. Energy Mater. 6, 1600218 (2016). This work demonstrates that ionic liquids can allow Li-ion batteries to operate from room temperature to at least 150 °C, with relatively high coulombic efficiencies.

Hagh, N. M. & Amatucci, G. G. Effect of cation and anion doping on microstructure and electrochemical properties of the LiMn1.5Ni0.5O4−δ spinel. J. Power Sour. 256, 457–469 (2014).

Maccario, M., Croguennec, L., Le Cras, F. & Delmas, C. Electrochemical performances in temperature for a C-containing LiFePO4 composite synthesized at high temperature. J. Power Sour. 183, 411–417 (2008).

Muñoz-Rojas, D. et al. Development and implementation of a high temperature electrochemical cell for lithium batteries. Electrochem. Commun. 9, 708–712 (2007).

Chang, H.-H. et al. Effects of TiO2 coating on high-temperature cycle performance of LiFePO4-based lithium-ion batteries. J. Power Sour. 185, 466–472 (2008).

Gao, F. & Tang, Z. Kinetic behavior of LiFePO4/C cathode material for lithium-ion batteries. Electrochimica Acta 53, 5071–5075 (2008).

Zhang, S. S., Xu, K. & Jow, T. R. The low temperature performance of Li-ion batteries. J. Power Sour. 115, 137–140 (2003).

Fan, J. & Tan, S. Studies on charging lithium-ion cells at low temperatures. J. Electrochem. Soc. 153, A1081–A1092 (2006).

Kou, J. et al. Role of cobalt content in improving the low-temperature performance of layered lithium-rich cathode materials for lithium-ion batteries. ACS Appl. Mater. Interfaces 7, 17910–17918 (2015).

Li, G. et al. Effect of trace Al surface doping on the structure, surface chemistry and low temperature performance of LiNi0.5Co0.2Mn0.3O2 cathode. Electrochimica Acta 212, 399–407 (2016).

Rui, X. H., Jin, Y., Feng, X. Y., Zhang, L. C. & Chen, C. H. A comparative study on the low-temperature performance of LiFePO4/C and Li3V2(PO4)3/C cathodes for lithium-ion batteries. J. Power Sour. 196, 2109–2114 (2011). This work provides a detailed investigation on the origins of the enhanced performance of LVP at −20 °C, highlighting the benefit of a low activation energy for Li+ diffusion in the lattice to capacity retention.

Zhang, H., Xu, Y., Zhao, C., Yang, X. & Jiang, Q. Effects of carbon coating and metal ions doping on low temperature electrochemical properties of LiFePO4 cathode material. Electrochimica Acta 83, 341–347 (2012).

Waldmann, T., Wilka, M., Kasper, M., Fleischhammer, M. & Wohlfahrt-Mehrens, M. Temperature dependent ageing mechanisms in lithium-ion batteries — a post-mortem study. J. Power Sour. 262, 129–135 (2014).

Bodenes, L. et al. Lithium secondary batteries working at very high temperature: capacity fade and understanding of aging mechanisms. J. Power Sour. 236, 265–275 (2013).

Jalkanen, K. et al. Cycle aging of commercial NMC/graphite pouch cells at different temperatures. Appl. Energy 154, 160–172 (2015).

Shin, H., Park, J., Sastry, A. M. & Lu, W. Degradation of the solid electrolyte interphase induced by the deposition of manganese ions. J. Power Sour. 284, 416–427 (2015).

Zhang, S. S., Xu, K. & Jow, T. R. Electrochemical impedance study on the low temperature of Li-ion batteries. Electrochimica Acta 49, 1057–1061 (2004).

Zhang, S. S., Xu, K. & Jow, T. R. Low temperature performance of graphite electrode in Li-ion cells. Electrochimica Acta 48, 241–246 (2002).

Huang, C. K., Sakamoto, J. S., Wolfenstine, J. & Surampudi, S. The limits of low-temperature performance of Li-ion cells. J. Electrochem. Soc. 147, 2893–2896 (2000).

Zheng, H., Qu, Q., Zhang, L., Liu, G. & Battaglia, V. S. Hard carbon: a promising lithium-ion battery anode for high temperature applications with ionic electrolyte. Roy. Soc. Chem. Adv. 2, 4904–4912 (2012).

Gieu, J. B., Courrèges, C., El Ouatani, L., Tessier, C. & Martinez, H. Temperature effects on Li4Ti5O12 electrode/electrolyte interfaces at the first cycle: a X-ray photoelectron spectroscopy and scanning auger microscopy study. J. Power Sour. 318, 291–301 (2016).

Nordh, T., Younesi, R., Brandell, D. & Edström, K. Depth profiling the solid electrolyte interphase on lithium titanate (Li4Ti5O12) using synchrotron-based photoelectron spectroscopy. J. Power Sour. 294, 173–179 (2015).

He, Y. B. et al. Gassing in Li4Ti5O12-based batteries and its remedy. Sci. Rep. 2, 913 (2012).

Han, C. et al. Suppression of interfacial reactions between Li4Ti5O12 electrode and electrolyte solution via zinc oxide coating. Electrochimica Acta 157, 266–273 (2015).

Lu, Q. et al. A polyimide ion-conductive protection layer to suppress side reactions on Li4Ti5O12 electrodes at elevated temperature. Roy. Soc. Chem. Adv. 4, 10280 (2014).

Kalaga, K. et al. Quasi-solid electrolytes for high temperature lithium ion batteries. ACS Appl. Mater. Interfaces 7, 25777–25783 (2015).

Xu, K. & von Wald Cresce, A. Li+-solvation/desolvation dictates interphasial processes on graphitic anode in Li ion cells. J. Mater. Res. 27, 2327–2341 (2012).

Wang, Y. & Dahn, J. Phase changes in electrochemically lithiated silicon at elevated temperature. J. Electrochem. Soc. 153, A2314 (2006).

Fan, H. et al. Electrochemical properties and thermal stability of silicon monoxide anode for rechargeable lithium-ion batteries. Electrochemistry 84, 574–577 (2016).

Ababtain, K. et al. Ionic liquid-organic carbonate electrolyte blends to stabilize silicon electrodes for extending lithium ion battery operability to 100 °C. ACS Appl. Mater. Interfaces 8, 15242–15249 (2016).

Profatilova, I. A. et al. Thermally induced reactions between lithiated nano-silicon electrode and electrolyte for lithium-ion batteries. J. Electrochem. Soc. 159, A657–A663 (2012).

Lotfabad, E. M. et al. Si nanotubes ALD coated with TiO2, TiN or Al2O3 as high performance lithium ion battery anodes. J. Mater. Chem. A 2, 2504–2516 (2014).

Markevich, E., Salitra, G. & Aurbach, D. Low temperature performance of amorphous monolithic silicon anodes: comparative study of silicon and graphite electrodes. J. Electrochem. Soc. 163, A2407–A2412 (2016).

An, Y. et al. Mitigating mechanical failure of crystalline silicon electrodes for lithium batteries by morphological design. Phys. Chem. Chem. Phys. 17, 17718–17728 (2015).

Croce, F., Sacchetti, S. & Scrosati, B. Advanced, lithium batteries based on high-performance composite polymer electrolytes. J. Power Sour. 162, 685–689 (2006).

Akolkar, R. Modeling dendrite growth during lithium electrodeposition at sub-ambient temperature. J. Power Sour. 246, 84–89 (2014).

Winter, M. & Besenhard, J. O. Electrochemical lithiation of tin and tin-based intermetallics and composites. Electrochimica Acta 45, 31–50 (1999).

Jansen, A. N., Clevenger, J. A., Baebler, A. M. & Vaughey, J. T. Variable temperature performance of intermetallic lithium-ion battery anode materials. J. Alloys Compounds 509, 4457–4461 (2011).

Sen, U. K. & Mitra, S. High-rate and high-energy-density lithium-ion battery anode containing 2D MoS2 nanowall and cellulose binder. ACS Appl. Mater. Interfaces 5, 1240–1247 (2013).

Zhang, S. S., Xu, K. & Jow, T. R. A new approach toward improved low temperature performance of Li-ion battery. Electrochem. Commun. 4, 928–932 (2002).

Campion, C. L., Li, W. & Lucht, B. L. Thermal decomposition of LiPF6-based electrolytes for lithium-ion batteries. J. Electrochem. Soc. 152, A2327 (2005).

Wang, Y. et al. Accelerating rate calorimetry studies of the reactions between ionic liquids and charged lithium ion battery electrode materials. Electrochimica Acta 52, 6346–6352 (2007). This work disputes some claims of thermal stability of ionic liquids showing that some compositions undergo thermal runaway at lower temperatures than carbonate-based solvents.

Liao, L. et al. Fluoroethylene carbonate as electrolyte additive to improve low temperature performance of LiFePO4 electrode. Electrochimica Acta 87, 466–472 (2013).

Liao, L. et al. Enhancement of low-temperature performance of LiFePO4 electrode by butyl sultone as electrolyte additive. Solid State Ionics 254, 27–31 (2014).

Qin, Y., Chen, Z., Liu, J. & Amine, K. Lithium tetrafluoro oxalato phosphate as electrolyte additive for lithium-ion cells. Electrochem. Solid-State Lett. 13, A11 (2010).

Yamagiwa, K. et al. Improved high-temperature performance and surface chemistry of graphite/LiMn2O4 Li-ion cells by fluorosilane-based electrolyte additive. Electrochimica Acta 160, 347–356 (2015).

Chen, Z. et al. New class of nonaqueous electrolytes for long-life and safe lithium-ion batteries. Nat. Commun. 4, 1513 (2013). Proposes Li 2 B 12 F 9 H 3 as a new Li-salt exhibiting enhanced stability towards charged electrodes at elevated temperatures and overcharge protection.

Yaakov, D., Gofer, Y., Aurbach, D. & Halalay, I. C. On the study of electrolyte solutions for Li-ion batteries that can work over a wide temperature range. J. Electrochem. Soc. 157, A1383 (2010).

Xu, K. Tailoring electrolyte composition for LiBOB. J. Electrochem. Soc. 155, A733 (2008).

Smart, M. C., Ratnakumar, B. V. & Surampudi, S. Use of organic esters as cosolvents in electrolytes for lithium-ion batteries with improved low temperature performance. J. Electrochem. Soc. 149, A361 (2002). A comprehensive analysis of the implementation of acetates as co-solvents in electrolytes extending battery operability to −70 °C.

Smart, M. C., Ratnakumar, B. V., Chin, K. B. & Whitcanack, L. D. Lithium-ion electrolytes containing ester cosolvents for improved low temperature performance. J. Electrochem. Soc. 157, A1361 (2010).

Hu, L., Zhang, Z. & Amine, K. Fluorinated electrolytes for Li-ion battery: an FEC-based electrolyte for high voltage LiNi0.5Mn1.5O4/graphite couple. Electrochem. Commun. 35, 76–79 (2013).

Zhang, Z. et al. Fluorinated electrolytes for 5 V lithium-ion battery chemistry. Energy Environ. Sci. 6, 1806 (2013).

Kühnel, R.-S. & Balducci, A. Lithium ion transport and solvation in N-Butyl-N-methylpyrrolidinium Bis(trifluoromethanesulfonyl)imide–Propylene carbonate mixtures. J. Phys. Chem. C 118, 5742–5748 (2014).

Choi, B. K. & Kim, Y. W. Thermal history effects on the ionic conductivity of PEO-salt electrolytes. Mater. Sci. Eng. B 107, 244–250 (2004).

Li, Y.-H. et al. A novel polymer electrolyte with improved high-temperature-tolerance up to 170 °C for high-temperature lithium-ion batteries. J. Power Sour. 244, 234–239 (2013).

Wu, X.-L. et al. Enhanced working temperature of PEO-based polymer electrolyte via porous PTFE film as an efficient heat resister. Solid State Ionics 245–246, 1–7 (2013).

Bouchet, R. et al. Single-ion BAB triblock copolymers as highly efficient electrolytes for lithium-metal batteries. Nat. Mater. 12, 452–457 (2013).

Wang, Y. et al. Design principles for solid-state lithium superionic conductors. Nat. Mater. 14, 1026–1031 (2015).

Li, D., Ma, Z., Xu, J., Li, Y. & Xie, K. High temperature property of all-solid-state thin film lithium battery using LiPON electrolyte. Mater. Lett. 134, 237–239 (2014).

Mo, S. et al. High-temperature performance of all-solid-state battery assembled with 95(0.7Li2S-0.3P2S5)-5Li3PO4 glass electrolyte. Solid State Ionics 296, 37–41 (2016).

Kato, Y. et al. High-power all-solid-state batteries using sulfide superionic conductors. Nat. Energy 1, 16030 (2016).

Osada, I., de Vries, H., Scrosati, B. & Passerini, S. Ionic-liquid-based polymer electrolytes for battery applications. Angew. Chem. Int. Edn 55, 500–513 (2016).

Del Sesto, R. E. et al. Limited thermal stability of imidazolium and pyrrolidinium ionic liquids. Thermochimica Acta 491, 118–120 (2009).

Rodrigues, M.-T. F., Lin, X., Gullapalli, H., Grinstaff, M. W. & Ajayan, P. M. Rate limiting activity of charge transfer during lithiation from ionic liquids. J. Power Sour. 330, 84–91 (2016).

Yamagata, M. et al. High-performance graphite negative electrode in a bis(fluorosulfonyl)imide-based ionic liquid. J. Power Sour. 227, 60–64 (2013).

Zhou, Q. et al. Phase behavior of ionic liquid–LiX mixtures: pyrrolidinium cations and TFSI–anions — linking structure to transport properties. Chem. Mater. 23, 4331–4337 (2011).

Tsai, W.-Y. et al. Outstanding performance of activated graphene based supercapacitors in ionic liquid electrolyte from −50 to 80 °C. Nano Energy 2, 403–411 (2013).

Lee, J. H. et al. Hybrid ionogel electrolytes for high temperature lithium batteries. J. Mater. Chem. A 3, 2226–2233 (2015).

Jeong, H.-S., Hong, S. C. & Lee, S.-Y. Effect of microporous structure on thermal shrinkage and electrochemical performance of Al2O3/poly(vinylidene fluoride-hexafluoropropylene) composite separators for lithium-ion batteries. J. Membrane Sci. 364, 177–182 (2010).

Jiang, W. et al. A high temperature operating nanofibrous polyimide separator in Li-ion battery. Solid State Ionics 232, 44–48 (2013).

Lee, J., Lee, C.-L., Park, K. & Kim, I.-D. Synthesis of an Al2O3-coated polyimide nanofiber mat and its electrochemical characteristics as a separator for lithium ion batteries. J. Power Sour. 248, 1211–1217 (2014).

Yan, X. et al. Polyimide binder by combining with polyimide separator for enhancing the electrochemical performance of lithium ion batteries. Electrochimica Acta 216, 1–7 (2016).

Zhao, M. et al. Electrochemical stability of copper in lithium-ion battery electrolytes. J. Electrochem. Soc. 147, 2874 (2000).

Morita, M., Shibata, T., Yoshimoto, N. & Ishikawa, M. Anodic behavior of aluminum current collector in LiTFSI solutions with different solvent compositions. J. Power Sour. 119–121, 784–788 (2003).

Chen, X. et al. Mixed salts of LiTFSI and LiBOB for stable LiFePO4-based batteries at elevated temperatures. J. Mater. Chem. A 2, 2346 (2014).

Mun, J. et al. Linear-sweep thermammetry study on corrosion behavior of Al current collector in ionic liquid solvent. Electrochem. Solid-State Lett. 13, A109 (2010).

Li, J., Zhu, Y., Wang, L. & Cao, C. Lithium titanate epitaxial coating on spinel lithium manganese oxide surface for improving the performance of lithium storage capability. ACS Appl. Mater. Interfaces 6, 18742–18750 (2014).

Zhang, J. et al. Sustainable, heat-resistant and flame-retardant cellulose-based composite separator for high-performance lithium ion battery. Sci. Rep. 4, 3935 (2014).

Zheng, F. et al. Surfactants assisted synthesis and electrochemical properties of nano-LiFePO4/C cathode materials for low temperature applications. J. Power Sour. 288, 337–344 (2015).

Liao, L. et al. Effects of temperature on charge/discharge behaviors of LiFePO4 cathode for Li-ion batteries. Electrochimica Acta 60, 269–273 (2012).

Shui Zhang, S. An unique lithium salt for the improved electrolyte of Li-ion battery. Electrochem. Commun. 8, 1423–1428 (2006).

Zhou, Z.-B., Takeda, M., Fujii, T. & Ue, M. Li [C2F5BF3] as an electrolyte salt for 4 V class lithium-ion cells. J. Electrochem. Soc. 152, A351–A356 (2005).

Smart, M. C. et al. Improved performance of lithium-ion cells with the use of fluorinated carbonate-based electrolytes. J. Power Sour. 119–121, 359–367 (2003).

Zhu, G. et al. Materials insights into low-temperature performances of lithium-ion batteries. J. Power Sour. 300, 29–40 (2015).

Ryou, M.-H. et al. Effect of fluoroethylene carbonate on high temperature capacity retention of LiMn2O4/graphite Li-ion cells. Electrochimica Acta 55, 2073–2077 (2010).

Kang, K. S. et al. Effect of additives on electrochemical performance of lithium nickel cobalt manganese oxide at high temperature. J. Power Sour. 253, 48–54 (2014).

Liu, Y., Tan, L. & Li, L. Tris(trimethylsilyl) borate as an electrolyte additive to improve the cyclability of LiMn2O4 cathode for lithium-ion battery. J. Power Sour. 221, 90–96 (2013).

Rong, H. et al. A novel imidazole-based electrolyte additive for improved electrochemical performance at elevated temperature of high-voltage LiNi0.5Mn1.5O4 cathodes. J. Power Sour. 329, 586–593 (2016).

Pham, H. Q., Hwang, E.-H., Kwon, Y.-G. & Song, S.-W. Understanding the interfacial phenomena of a 4.7 V and 55 °C Li-ion battery with Li-rich layered oxide cathode and graphite anode and its correlation to high-energy cycling performance. J. Power Sour. 323, 220–230 (2016).

Aurbach, D. et al. On the use of vinylene carbonate (VC) as an additive to electrolyte solutions for Li-ion batteries. Electrochimica Acta 47, 1423–1439 (2002).

Han, H. et al. Lithium (fluorosulfonyl)(nonafluorobutanesulfonyl)imide (LiFNFSI) as conducting salt to improve the high-temperature resilience of lithium-ion cells. Electrochem. Commun. 13, 265–268 (2011).

Jin, Z. et al. A new class of phosphates as co-solvents for nonflammable lithium ion batteries blectrolytes. ECS Electrochem. Lett. 1, A55–A58 (2012).

MacNeil, D., Lu, Z., Chen, Z. & Dahn, J. R. A comparison of the electrode/electrolyte reaction at elevated temperatures for various Li-ion battery cathodes. J. Power Sour. 108, 8–14 (2002).

Plichta, E. J. & Behl, W. K. A low-temperature electrolyte for lithium and lithium-ion batteries. J. Power Sour. 88, 192–196 (2000).

Yabuuchi, N. & Ohzuku, T. Electrochemical behaviors of LiCo1/3Ni1/3Mn1/3O2 in lithium batteries at elevated temperatures. J. Power Sour. 146, 636–639 (2005).

Chen, K. et al. Evaluation of the low temperature performance of lithium manganese oxide/lithium titanate lithium-ion batteries for start/stop applications. J. Power Sour. 278, 411–419 (2015).

Luo, Y. et al. Hierarchical carbon decorated Li3V2(PO4)3 as a bicontinuous cathode with high-rate capability and broad temperature adaptability. Adv. Energy Mater. 4, 1400107 (2017).

Song, M.-S. et al. Is Li4Ti5O12 a solid-electrolyte-interphase-free electrode material in Li-ion batteries? Reactivity between the Li4Ti5O12 electrode and electrolyte. J. Mater. Chem. A 2, 631–636 (2014).

Cui, Y., Rohde, M., Mahmoud, M. M., Ziebert, C. & Seifert, H. J. Phosphate based ceramics as solid electrolyte for high temperature lithium ion batteries. ECS Meeting Abstracts 120, ma2016-01 (2016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Rodrigues, MT., Babu, G., Gullapalli, H. et al. A materials perspective on Li-ion batteries at extreme temperatures. Nat Energy 2, 17108 (2017). https://doi.org/10.1038/nenergy.2017.108

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/nenergy.2017.108

This article is cited by

-

Understanding the charge transfer effects of single atoms for boosting the performance of Na-S batteries

Nature Communications (2024)

-

Ligand-channel-enabled ultrafast Li-ion conduction

Nature (2024)

-

Microstructural, mechanical properties and electrical conductivity of Ag7(Si1-xGex)S5I-based ceramics

Ionics (2024)

-

Breaking solvation dominance of ethylene carbonate via molecular charge engineering enables lower temperature battery

Nature Communications (2023)

-

Electrolyte design for Li-ion batteries under extreme operating conditions

Nature (2023)