Abstract

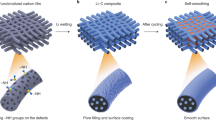

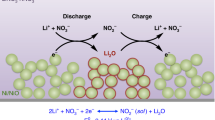

Loss of lithium in the initial cycles appreciably reduces the energy density of lithium-ion batteries. Anode prelithiation is a common approach to address the problem, although it faces the issues of high chemical reactivity and instability in ambient and battery processing conditions. Here we report a facile cathode prelithiation method that offers high prelithiation efficacy and good compatibility with existing lithium-ion battery technologies. We fabricate cathode additives consisting of nanoscale mixtures of transition metals and lithium oxide that are obtained by conversion reactions of metal oxide and lithium. These nanocomposites afford a high theoretical prelithiation capacity (typically up to 800 mAh g−1, 2,700 mAh cm−3) during charging. We demonstrate that in a full-cell configuration, the LiFePO4 electrode with a 4.8% Co/Li2O additive shows 11% higher overall capacity than that of the pristine LiFePO4 electrode. The use of the cathode additives provides an effective route to compensate the large initial lithium loss of high-capacity anode materials and improves the electrochemical performance of existing lithium-ion batteries.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Tarascon, J.-M. & Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001).

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J.-M. Li-O2 and Li-S batteries with high energy storage. Nature Mater. 11, 19–29 (2012).

Whittingham, M. S. Lithium batteries and cathode materials. Chem. Rev. 104, 4271–4301 (2004).

Goodenough, J. B. & Park, K.-S. The Li-ion rechargeable battery: A perspective. J. Am. Chem. Soc. 135, 1167–1176 (2013).

Armand, M. & Tarascon, J.-M. Building better batteries. Nature 451, 652–657 (2008).

Verma, P., Maire, P. & Novák, P. A review of the features and analyses of the solid electrolyte interphase in Li-ion batteries. Electrochim. Acta 55, 6332–6341 (2010).

Zaghib, K., Nadeau, G. & Kinoshita, K. Effect of graphite particle size on irreversible capacity loss. J. Electrochem. Soc. 147, 2110–2115 (2000).

Aurbach, D. et al. The study of electrolyte solutions based on ethylene and diethyl carbonates for rechargeable Li batteries: II. Graphite electrodes. J. Electrochem. Soc. 142, 2882–2890 (1995).

Arakawa, M. & Yamaki, J.-I. The cathodic decomposition of propylene carbonate in lithium batteries. J. Electroanal. Chem. Interfacial Electrochem. 219, 273–280 (1987).

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4417 (2004).

Matsumura, Y., Wang, S. & Mondori, J. Mechanism leading to irreversible capacity loss in Li ion rechargeable batteries. J. Electrochem. Soc. 142, 2914–2918 (1995).

Wang, D. Y., Sinha, N. N., Petibon, R., Burns, J. C. & Dahn, J. R. A systematic study of well-known electrolyte additives in LiCoO2/graphite pouch cells. J. Power Sources 251, 311–318 (2014).

Hassoun, J., Lee, K.-S., Sun, Y.-K. & Scrosati, B. An advanced lithium ion battery based on high performance electrode materials. J. Am. Chem. Soc. 133, 3139–3143 (2011).

Liu, N., Hu, L. B., McDowell, M. T., Jackson, A. & Cui, Y. Prelithiated silicon nanowires as an anode for lithium ion batteries. ACS Nano 5, 6487–6493 (2011).

Jarvis, C. R., Lain, M. J., Yakovleva, M. V. & Gao, Y. A prelithiated carbon anode for lithium-ion battery applications. J. Power Sources 162, 800–802 (2006).

Wang, Z. H. et al. Application of stabilized lithium metal powder (SLMP®) in graphite anode—A high efficient prelithiation method for lithium-ion batteries. J. Power Sources 260, 57–61 (2014).

Zhao, J. et al. Dry-air-stable lithium silicide–lithium oxide core–shell nanoparticles as high-capacity prelithiation reagents. Nature Commun. 5, 5088 (2014).

Shanmukaraj, D. et al. Sacrificial salts: Compensating the initial charge irreversibility in lithium batteries. Electrochem. Commun. 12, 1344–1347 (2010).

Singh, G. et al. An approach to overcome first cycle irreversible capacity in P2-Na2∕3[Fe1∕2Mn1∕2]O2 . Electrochem. Commun. 37, 61–63 (2013).

Kim, M. G. & Cho, J. Air stable Al2O3-coated Li2NiO2 cathode additive as a surplus current consumer in a Li-ion cell. J. Mater. Chem. 18, 5880–5887 (2008).

Noh, M. & Cho, J. Role of Li6CoO4 cathode additive in Li-ion cells containing low coulombic efficiency anode material. J. Electrochem. Soc. 159, A1329–A1334 (2012).

Poizot, P., Laruelle, S., Grugeon, S., Dupont, L. & Tarascon, J. M. Nano-sized transition-metal oxides as negative-electrode materials for lithium-ion batteries. Nature 407, 496–499 (2000).

Taberna, P. L., Mitra, S., Poizot, P., Simon, P. & Tarascon, J. M. High rate capabilities Fe3O4-based Cu nano-architectured electrodes for lithium-ion battery applications. Nature Mater. 5, 567–573 (2006).

Cabana, J., Monconduit, L., Larcher, D. & Palacín, M. R. Beyond intercalation-based Li-ion batteries: The state of the art and challenges of electrode materials reacting through conversion reactions. Adv. Mater. 22, E170–E192 (2010).

Reddy, M. V., Subba Rao, G. V. & Chowdari, B. V. R. Metal oxides and oxysalts as anode materials for Li ion batteries. Chem. Rev. 113, 5364–5457 (2013).

Lou, X. W., Deng, D., Lee, J. Y., Feng, J. & Archer, L. A. Self-supported formation of needlelike Co3O4 nanotubes and their application as lithium-ion battery electrodes. Adv. Mater. 20, 258–262 (2008).

Wang, H. L. et al. Mn3O4-graphene hybrid as a high-capacity anode material for lithium ion batteries. J. Am. Chem. Soc. 132, 13978–13980 (2010).

Li, H., Balaya, P. & Maier, J. Li-storage via heterogeneous reaction in selected binary metal fluorides and oxides. J. Electrochem. Soc. 151, A1878–A1885 (2004).

Sun, J. P. et al. Overpotential and electrochemical impedance analysis on Cr2O3 thin film and powder electrode in rechargeable lithium batteries. Solid State Ion. 179, 2390–2395 (2008).

Wu, Z. Z. et al. Prelithiation activates Li(Ni0.5Mn0.3Co0.2)O2 for high capacity and excellent cycling stability. Nano Lett. 15, 5590–5596 (2015).

Li, H., Richter, G. & Maier, J. Reversible formation and decomposition of LiF clusters using transition metal fluorides as precursors and their application in rechargeable Li batteries. Adv. Mater. 15, 736–739 (2003).

Hu, Y.-S. et al. Electrochemical lithiation synthesis of nanoporous materials with superior catalytic and capacitive activity. Nature Mater. 5, 713–717 (2006).

Huang, J. Y. et al. In situ observation of the electrochemical lithiation of a single SnO2 nanowire electrode. Science 330, 1515–1520 (2010).

McDowell, M. T. et al. In situ TEM of two-phase lithiation of amorphous silicon nanospheres. Nano Lett. 13, 758–764 (2013).

Zheng, G. Y., Yang, Y., Cha, J. J., Hong, S. S. & Cui, Y. Hollow carbon nanofiber-encapsulated sulfur cathodes for high specific capacity rechargeable lithium batteries. Nano Lett. 11, 4462–4467 (2011).

Acknowledgements

Y.C. acknowledges the support from the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies of the US Department of Energy under the Battery Materials Research (BMR) Program. S. Lee and G. Zheng are acknowledged for discussions and help.

Author information

Authors and Affiliations

Contributions

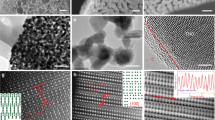

Y.S. and Y.C. conceived and designed the experiments. Y.S. performed materials fabrication, characterization and electrochemical measurements. H.-W.L. conducted in situ TEM and HR-TEM characterization. Y.S. and Y.C. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Table 1, Supplementary Figures 1–18 and Supplementary References. (PDF 1454 kb)

Supplementary Video 1

The in situ TEM results show that the N-Co/N-Li2O particles continuously shrink upon the delithiation process and less than 1/2 of the initial volume of a particle aggregate is retained after the delithiation. (MP4 12780 kb)

Rights and permissions

About this article

Cite this article

Sun, Y., Lee, HW., Seh, Z. et al. High-capacity battery cathode prelithiation to offset initial lithium loss. Nat Energy 1, 15008 (2016). https://doi.org/10.1038/nenergy.2015.8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/nenergy.2015.8

This article is cited by

-

Extra lithium gives a boost

Nature Energy (2023)

-

Roll-to-roll prelithiation of lithium-ion battery anodes by transfer printing

Nature Energy (2023)

-

One-step hydrothermal synthesis of VO2(B) as cathode materials for high-capacity and high-rate Li-ion batteries

Journal of Solid State Electrochemistry (2023)

-

Mo2C catalyzed low-voltage prelithiation using nano-Li2C2O4 for high-energy lithium-ion batteries

Science China Materials (2023)

-

Li2S as a cathode additive to compensate for the irreversible capacity loss of lithium iron phosphate batteries

Ionics (2022)