Abstract

Two-dimensional materials have been an ideal material platform for constructing flexible ultrathin-film supercapacitors, offering great advantages of flexibility, ultra-thinness and even transparency. Exploring new two-dimensional pseudocapacitive materials with high electrochemical activity is needed to achieve flexible ultrathin-film supercapacitors with higher energy densities. Here we report an inorganic graphene analogue, α1-vanadyl phosphate ultrathin nanosheets with less than six atomic layers, as a promising material to construct a flexible ultrathin-film pseudocapacitor in all-solid-state. The material exhibits a high potential plateau of ~ 1.0 V in aqueous solutions, approaching the electrochemical potential window of water (1.23 V). The as-established flexible supercapacitor achieves a high redox potential (1.0 V) and a high areal capacitance of 8,360.5 μF cm−2, leading to a high energy density of 1.7 mWh cm−2 and a power density of 5.2 mW cm−2.

Similar content being viewed by others

Introduction

A rapidly growing demand for portable consumer electronics, such as flexible displays, mobile phones and notebook computers, has greatly promoted the development of flexible energy devices in all-solid-state1,2,3,4,5,6,7. As the future-generation energy storage device, the flexible thin-film supercapacitor in all-solid-state offers the synergic benefits of flexibility, thinness and transparency2,8,9,10,11,12. Among the different types of supercapacitors, pseudocapacitors have the advantage of a highly electroactive surface of the electrode materials owing to fast redox reaction, and exhibit much higher energy density compared with electrical double-layer capacitors as well as higher power density compared with lithium-ion batteries13,14, holding great promise for realizing high-performance flexible ultrathin-film supercapacitor in all-solid-state (FUSA) with pseudocapacitive behaviour15,16,17. Pursuing two-dimensional (2D) graphene-like materials with pseudocapacitive characteristics represents a promising direction to accomplish the flexible ultrathin-film pseudocapacitor in all-solid-state (FUPA) with higher energy density, and potentially excellent mechanical flexibility18,19,20. Moreover, obtaining the graphene-like pseudocapacitive materials not only requires the intrinsic layered structures that can be exfoliated into 2D ultrathin nanosheets, but also needs to possess a high electrochemical activity and high redox potential that can lead to higher energy density (E~ V2). However, the development of graphene-like pseudocapacitive materials is still at its early stage, especially for the FUPAs with high power and energy densities. For example, the reversible redox Faradaic reactions occurred on the surface of layered Ni(OH)2 and Co3O4 exhibit the potential windows of only about 0.5 and 0.4 V, respectively13,20, both of which are still much lower than the limited electrochemical window of the aqueous solution (1.23 V)21. Therefore, the discovery of new graphene-like pseudocapacitive materials with enhanced electrochemical performance is much needed for constructing FUSA with higher power and energy densities, vital for satisfying the practical applications.

Vanadyl phosphate (VOPO4) has seen tremendous advances for layered materials with higher electrochemical performance22,23,24. Due to the enhanced inionicity of (V–O) bonds when (PO4)3− anion is introduced, V4+/V5+ redox couple of VOPO4 possesses the higher potential than that for simple vanadium oxide25. Layered VOPO4 has a high redox potential of 1.0 V versus normal hydrogen electrode (NHE), and thus it is promising to establish the pseudocapacitors with improved energy density (Supplementary Fig. S1)26,27. Furthermore, dehydrated vanadyl phosphate (VOPO4 2H2O) has the characteristic layered structure, in which the sheets of VOPO4 form from vertex-sharing VO6 octahedra linking to phosphate PO4 tetrahedra. Between each VOPO4 layer, one water molecule coordinates with a vanadium atom through an oxygen atom and the other links adjacent layers together through weak hydrogen bonds (Supplementary Fig. S2)28. The presence of weak hydrogen bonds in VOPO4·2H2O provides the feasible clue to the exfoliation of layered VOPO4·2H2O into VOPO4 ultrathin nanosheets while maintaining the integrity of the in-plane structure. With the synergic advantages of high redox potential and the layered structure, the exfoliated VOPO4 ultrathin nanosheets could be a promising new 2D graphene-like material with greatly enhanced electrochemical properties. Although VOPO4 shows great potential for applications in flexible supercapacitors, its graphene-like material has long been unexplored in the past years, let alone the realization of the corresponding energy storage devices.

Here we report a simple 2-propanol-assisted ultrasonication method to effectively exfoliate bulk VOPO4·2H2O into VOPO4 ultrathin nanosheets, with a thickness of less than six atomic layers, as a new graphene-like material. To fully explore the electrochemical performance of VOPO4, a VOPO4/graphene hybrid film was layer-by-layer assembled to achieve both high planar conductivity and superior electrochemical performance. The FUPA based on the VOPO4/graphene hybrid thin film demonstrated a high output voltage, a large specific capacitance and a high energy density, opening up opportunities for exploring new quasi-2D materials for flexible energy device with higher energy density.

Results

VOPO4 ultrathin nanosheet

The VOPO4 ultrathin nanosheets were achieved by exfoliation of bulk VOPO4·2H2O through a simple ultrasonication method in 2-propanol with a short reaction time of 15 min. For bulk VOPO4·2H2O, VOPO4 layers are linked together by hydrogen bonds from the interaction between H2O molecular and VOPO4 layers. As one kind of weak intermolecular force, hydrogen bond is very sensitive to the applied external force29. For example, the applied strong ultrasonication provides the powerful force to trigger the breaking of hydrogen bonds. In our case, the exfoliation process from bulk VOPO4 2H2O to VOPO4 graphene-like material was conducted in 2-propanol solution, in that 2-propanol as a secondary alcohol is more suitable than primary alcohols as the dispersant due to the lower reactivity of hydroxyl group with the VOPO4 layer matrix (Supplementary Fig. S3). The interaction force of hydrogen bonds between 2-propanol and H2O further promoted the H2O molecules extracted from the interlayer space of bulk VOPO4·2H2O. (Fig. 1a). The obtained VOPO4 ultrathin nanosheets were homogeneously dispersed in solution with high stability for over several months.

(a) Schematic illustration for 2-propanol-assisted exfoliation process from bulk VOPO4·2H2O to graphene-like VOPO4 nanosheets. During the process of ultrasonication in 2-propanol solution, the VOPO4 layers were swelled and interlayered H2O molecules effused, resulting in the VOPO4 ultrathin nanosheets. (b,c) XRD and Raman spectra of samples for the elongated ultrasonication time of 0, 5, 10 and 15 min, respectively. The insets in c are the symmetric bending (left) and stretching (right) modes of O–P–O, respectively.

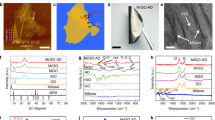

The structural transformation process during the exfoliation could be revealed by the characterizations of X-ray powder diffraction (XRD) patterns and Raman spectra, which performed on the transferrable VOPO4 thin films. The XRD characterization of vacuum-filtration assembled films of samples at different sonication time is shown in Fig. 1b. The XRD pattern at the initial sonication process can be readily indexed into the tetragonal VOPO4·2H2O with the standard JCPDS card No.84-0111 (VOPO4·2H2O, space group P4/nmm, a=6.202 Å, b=6.202 Å, c=7.410 Å). As the strong ultrasonication proceeds, the (001) peak became relatively stronger compared with other XRD peaks, revealing that the applied sonication waves triggered the structural arrangements and enhanced the c axis orientation for the formation process of high-quality 2D nanosheets. Furthermore, the (001) peak of VOPO4·2H2O gradually shifted from lower 2θ (11.74°) to a higher one (13.5°) during the sonication process, indicating the decrease of the interlayer spacing distance from VOPO4·2H2O to the final VOPO4 ultrathin nanosheets as a result of the escape of molecular H2O from VOPO4 interlayers.

In addition, Raman spectra shown in Fig. 1c further verified structural evolutions during the exfoliation process. The bands at 937 cm−1 were assigned to the symmetric O–P–O stretching modes30,31. With the elongated exfoliation time, the red shift of Raman peaks of O–P–O stretching mode was more noticeable. Obviously, there was a strong microstructural correlation between symmetry of O–P–O stretching modes with the hydrogen bonding among the interlayered H2O molecular. With the breaking of hydrogen bonds from the oxygen atoms of the P–O bond in VOPO4, the mitigation of the steric hindrance would facilitate the occurrence of the O–P–O stretching modes with lower energy. However, the peaks related to the symmetric bending vibrations of O–P–O, V–O and V=O stretching mode demonstrated little shift with no obvious peak position evolution (Supplementary Fig. S4). The Raman results confirmed that the exfoliated VOPO4 nanosheets maintained the integrity of the in-plane VOPO4 structure without obvious structural deformations.

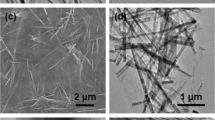

To unravel the microscopic outlook and structural crystallinity of exfoliated 2D VOPO4 nanosheets, microstructural characterizations were performed. Scanning electron microscopy (SEM) images of the precursor VOPO4·2H2O and graphene-like VOPO4 nanosheets were taken and compared as shown in Fig. 2 and Supplementary Fig. S5. The bulk VOPO4·2H2O exhibited the typical layered structure, of which the layers were tightly stacked. In contrast, SEM image of the exfoliated products after 15 min ultransonication (Fig. 2b) shows the morphology of ultrathin nanosheets with a typical size ranging from 400 nm to several micrometres. Transmission electron microscopy (TEM) image of the exfoliated VOPO4 nanosheet in Fig. 2c reveals a free-standing, sheet-like morphology with a lateral size of ~ 1 μm, and the nearly transparent feature implies the ultrathin thickness of exfoliated nanosheets. Atomic force microscopy image in Fig. 2d was taken to further evaluate the thickness of the VOPO4 nanosheet. The measured height was ~ 4.07 nm, denoting that the nanosheet was comprised of 5–6 single layers, given that the c parameter of the VOPO4·2H2O is 7.410 Å. The corresponding HR-TEM image and fast Fourier transform pattern are shown in Fig. 2e, demonstrating that the exfoliated sheets were single crystalline with [001] preferential orientation. The interplanar distance of 0.31 nm fits well with the plane distance of d200 and d202, respectively. The orientation angle values 90° of these two planes of (200) and (020) in HR-TEM image and fast Fourier transform pattern was consistent with those calculated from tetragonal crystallographic parameters of VOPO4·2H2O. These characterization results showed that VOPO4·2H2O was successfully exfoliated into ultrathin VOPO4 nanosheets that exhibited good crystallinity and high c axis orientation, providing strong basis for further assembly of VOPO4 nanosheets into large-area practical energy storage devices.

(a) Field emission scanning electron microscopy image of bulk VOPO4·2H2O precursors, where the stacked layers can be clearly seen. Scale bar, 200 nm. (b) The SEM image of exfoliated VOPO4 ultrathin nanosheets with warped edges exhibiting the ultrathin features. Scale bar, 200 nm. (c) TEM image of a typical ultrathin nanosheet. Scale bar, 500 nm. (d) Atomic force microscopy image of a typical nanosheet with a thickness of 4.07 nm, corresponding to less than six atomic layers. Scale bar, 100 nm. (e) High-resolution TEM (HR-TEM) image of a typical nanosheets showing the lattice fringes of (200) and (020) planes, and the inset is the corresponding fast Fourier transform patterns of the same area in the HR-TEM image. Scale bar, 2 nm.

2D hybrid thin film

The bulk VOPO4 is well known as a high-performance electrochemical material with a high redox voltage under aqueous solution of 1.0 V versus NHE, approaching the electrochemical window of water (1.23 V)21, which entails the great fascination for the construction of high-efficiency energy storage devices. (Supplementary Fig. S1) In our work, VOPO4 ultrathin nanosheets with <6 atomic layers, as a new inorganic graphene-like material, provide an ideal 2D material platform to investigate their electrochemical behaviour, and to give the feasibility to construct the FUPA. Because of the poor conductivity of VOPO4 nanosheet, a layer-by-layer strategy was adopted to assemble a VOPO4/graphene hybrid film, and the hybrid thin film exhibits advantageous features of being uniform, compact and nearly transparent (Fig. 3a). The hybrid film could be readily transferred and free-standing due to its high-quality film structure. Fig. 3b is the cross-section SEM image of the hybrid film, showing the compact layer-by-layer structure with the thickness of ~ 90 nm thick. The inset in Fig. 3c is the SEM image of the smooth hybrid film, where the graphene was underneath VOPO4 layers as illustrated by the white arrows. The combined analyses of the TEM and XRD results further reveal that the as-formed VOPO4/graphene hybrid film was the stacking of serial layers of chemically integrated VOPO4 nanosheets on graphene sheets exhibiting the highly c axis crystalline orientation, in which the VOPO4 nanosheets integrated on the graphene sheet as the building units and they assembled in stacks to form the final VOPO4/graphene hybrid films (Supplementary Figs S6 and S7). To better understand the layer-by-layer assembly of VOPO4 nanosheets with graphene, Fig. 3c shows the Raman spectra of VOPO4 film, graphene film and VOPO4/graphene hybrid film, respectively. The brown line is the Raman spectrum of graphene, which possesses two pronounced peaks at 1,580 cm−1 (G) and 2,700 cm−1 (2D) of graphene. The stronger intensity of G peak shows that the synthesized graphene is of good quality and high crystallinity and the weaker D peak at ~ 1,347 cm−1 corresponds to the lower disordering32,33,34. The red line represents the Raman spectrum of VOPO4 nanosheets film with characteristic peaks of VOPO4 at ~ 866 cm−1 and 1,019 cm−1 corresponding to the symmetric stretching vibration ν1(PO4) and V=O stretching mode. The Raman spectrum of VOPO4/graphene hybrid film (blue line) in Fig. 3c had the characteristic peaks of both VOPO4 nanosheets and graphene with homogeneous distribution. The VOPO4/graphene hybrid films were of high-quality with uniform, compact, free-standing and high transparency features.

(a) Demonstration of VOPO4/graphene hybrid thin film on the surface of PET substrate, exhibiting transparent feature. (b) The cross-section SEM image of the hybrid thin film with the thickness of ~ 90 nm. The surface of the hybrid film, of which the graphene lies under the VOPO4 layers as indicated by the white arrows, is shown in the inset. Scale bar, 500 nm; Inset scale bar, 100 nm. (c) The Raman spectra of graphene film (brown line), VOPO4 film (red line) and VOPO4/graphene hybrid film (blue line), respectively. (d) The temperature dependence of planar resistivity of the VOPO4/graphene hybrid film and pure VOPO4 nanosheet thin film, where the incorporation of graphene greatly enhanced the electrical conductivity in the VOPO4/graphene hybrid film.

In addition, hybrid VOPO4/graphene films exhibited greatly enhanced electrical properties. The hybrid film can be transferred onto various target substrates (Supplementary Fig. S8) for electrical measurements. Temperature dependence of planar electrical resistivity of the VOPO4/graphene hybrid film was carried out as shown in Fig. 3d. As can be seen, the hybrid film possessed good conductivity in a wide temperature range from 150 to 300 K with slight resistivity change from 1.9 × 10−1 Ω cm (150 K) to 1.6 × 10−1 Ω cm (300 K), which is eight orders of magnitude lower than that of pure VOPO4 nanosheet thin film (3.0 × 107 Ω cm at 300 K). With the VOPO4 nanosheets integrated on the graphene layers, the 2D VOPO4/graphene hybrid film possessed the much improved electrical conductivity, making possible embodiment of outstanding electrochemical performance of VOPO4 nanosheets.

FUPA performance

To further study the electrochemical properties of the VOPO4 graphene-like materials, a FUPA based on 2D VOPO4/graphene hybrid film was fabricated. The FUPA devices were configured and fabricated according to the typical principles of flexiblity, ultra-thinness and all-solid-state, as illustrated in Fig. 4a. In this regard, VOPO4/graphene hybrid film was transferred onto the gold-coated polyethylene terephthalate (PET) sheet as the working electrode. The polyvinyl alcohol (PVA)/LiCl was introduced as the solid electrolyte and separator to prevent potential dissolving of active material of VOPO4 nanosheets. Note that the salt LiCl could not be easily crystallized out during the process of gel drying and could provide a neutral pH medium, which makes PVA/LiCl an excellent electrolyte for vanadium-involved solid-state pseudocapacitors35. The as-assembled FUPA exhibited excellent electrochemical performance. Figure 4 summarizes the electrochemical performances of the as-fabricated FUPA based on VOPO4/graphene utrathin film with a thickness of ~ 90 nm. Figure 4b shows the cyclic voltammetry (CV) curve in the PVA/LiCl electrolyte from 0 to 1.2 V at scan rate of 0.1 mV s−1. The obvious redox current peaks at ~ 1.1 V (oxidation peak) and 0.9 V (reduction peak) in the CV plots correspond to the reversible pseudocapacitive reactions of VOPO4 nanosheets with Li+, which can be represented by the following equation:

(a) Schematic illustration of an as-fabricated flexible ultrathin-film pseudocapacitor, in which the VOPO4/graphene hybrid layers function as the working electrode and PVA/LiCl gel functions as the electrolyte. (b) CV curves of VOPO4/graphene hybrid film in PVA/LiCl electrolyte from 0 to 1.2 V at 0.1 mV s−1. (c) Galvanostatic cycling behaviour of the as-fabricated FUPA and its IR drop. (d) Galvanostatic charge–discharge curves at different current density of 0.2, 0.4, 0.6 and 1 A m−2. (e) Cycle test of the VOPO4/graphene hybrid film-based FUPA over 2,000 cycles. (f) Cycling stability of the FUPA under repeated bending/extending deformation.

The slight internal resistance (IR) drop of 0.098 V observed in Fig. 4c implied a small intrinsic series resistance of VOPO4/graphene hybrid film. Figure 4c shows the galvanostatic charge–discharge curves of the VOPO4/graphene-based FUPA, from which the specific capacitance is calculated to be 8,360.5 μF cm−2 at current density of 0.2 A m−2 (Supplementary Tables S1 and S2). Our areal capacitance of 8,360.5 μF cm−2 (that is, 928.9 F cm−3) is the highest value among all reported FUSAs18,19,20,36. The electrochemical performance of 2D VOPO4/graphene hybrid thin film is superior to that of bulk VOPO4, that of pure 2D VOPO4 nanosheets and even to that of other crystal forms of VOPO4. (Supplementary Figs S9—S12). Moreover, the FUPAs fabricated with higher mass loading of active materials (thickness up to ~ 10 μm) can still maintain good electrochemical performance, in which the areal capacitance increased 72 times when the thickness of electrode increased from ~ 90 nm to ~ 10 μm. (Supplementary Fig. S13). Employing pseudocapacitor in-plane, micro-electrodes can potentially further enhance the performance of 2D hybrid VOPO4/graphene thin film, as it could mitigate the issues from contact resistance and electrolyte ions diffusion in the case of much higher mass loading10,37. Furthermore, the discharge voltage up to ~ 1.0 V is a significant step for constructing high energy density supercapacitors. Our reported discharge voltage up to 1.0 V is a fairly high value compared with previously reported supercapacitors in the aqueous electrolytes13,14,15,16,17,18,19,20. The high specific capacitance (8,360.5 μF cm−2) and redox voltage (up to 1.0 V) lead to the ultrahigh energy density of 1.7 mWh cm−2 and power density of 5.2 mW cm−2. These are the highest values among the reported FUSAs as shown in Fig. 5 (Supplementary Tables S1 and S2). The improved energy density of FUSA with its high power density would make it more competitive for practical applications of energy storage devices38.

As shown in Fig. 4e, the as-fabricated FUPA had an excellent cycle life, as after 2,000 charge–discharge cycles specific capacitance retained 96% of the initial capacitance and Columbic efficiency was kept at ~ 90%, demonstrating excellent long-term cycling stability. Figure 4f demonstrates the excellent flexibility of the as-fabricated FUPA with negligible degradation of the specific capacitance even after 400 bending cycles. In short, the graphene-like VOPO4 materials have shown the fascinating electrochemical and mechnical characteristics for practical applications in high-performance, flexible energy storage devices catering for portable and flexible electronics.

Discussion

In summary, VOPO4 ultrathin nanosheets with less than six atomic layers, as a new inorganic graphene-like material, have been reported for the first time. The as-fabricated FUPAs based on hybrid structure of the newly found VOPO4 ultrathin nanosheets and graphene sheets exhibit extremely high specific capacitance (up to 8,360.5 μF cm−2), high redox voltage (up to 1 V), long cycle life (more than 2,000 cycles) and excellent flexibility, leading to an ultrahigh energy density of 1.7 mWh cm−2 and a power density of 5.2 mW cm−2. Our findings represent a promising direction and a significant step towards exploring new quasi-2D materials for flexible energy device with higher energy density in the near future.

Methods

Synthesis of bulk VOPO4·2H2O

Bulk VOPO4 2H2O was obtained according to a simple method reported in the previous literature39. The mixture, including V2O5 (4.8 g), H3PO4 (85% 26.6 ml) and H2O (115.4 ml), was refluxed at 110 °C for 16 h. Thereafter, the system was permitted cool down to room temperature. The yellow precipitate was finally collected by filtration and washed several times with water and acetone. The resulting sample was dried in vacuum at 60 °C for 3 h.

Assembly of the hybrid VOPO4/graphene film

The graphene used in our experiments was synthesized according to the procedure used in previous studies 40,41. The VOPO4/graphene hybrid film was assembled by a layer-by-layer strategy. Specifically, the VOPO4 and graphene dispersion were vacuum filtered in turns over a cellulose membrane with 0.22 μm pore size to form a homogeneous thin film. The thickness of the hybrid thin film can be tuned by changing the filtrated amount of the VOPO4 and graphene dispersion.

Preparation of gel electrolyte

Four grams of PVA powder was put into 40 ml distilled water with stirring at 95 °C (ref. 35). When the PVA powder was completely dissolved, 8.5 g LiCl was added into the solution under vigorous stirring. After the LiCl/PVA turned to into a transparent and clear gel, it was cooled down at room temperature. At last, the LiCl gel electrolyte was prepared.

Exfoliation of bulk precursor into graphene-like material

Bulk VOPO4·2H2O (30 mg) was dispersed in a sealed glass bottle with 25 ml 2-propanol and then the dispersion was ultrasonicated in iced water for 15 min forming the VOPO4 ultrathin nanosheets. The resultant yellow suspension was collected by vacuum filtration with a 0.22-μm pore size cellulose membrane, forming a homogeneous thin film, which can be easily transferred to arbitrary substrates by pressing another side of the cellulose membrane.

Fabrication of flexible supercapacitors in all-solid-state

FUPA devices typically include the working electrode, counter electrode, current collector and the flexible substrate. VOPO4/graphene hybrid film was transferred onto the gold-coated PET sheet as the working electrode, in which the mass percentage of VOPO4 in the electrodes was ~ 65% measured by inductively coupled plasma emission spectroscopy. The gold-coated PET sheet was used as the counter electrode; gold-coated PET sheet served dual functions as both the current collector and the flexible substrate. Meanwhile, PVA/LiCl was introduced as the solid electrolyte and separator to prevent the possible dissolving of the active material of VOPO4 nanosheets. The whole device was sealed carefully by the common transparent tape to make sure the device system is at a stable state.

Material characterizations

XRD was performed on a Philips X, Pert Pro Super diffractometer with Cu Kα radiation (λ=1.54178 Å). Raman spectra were recorded at room temperature with a LABRAM-HR confocal laser micro Raman spectrometer 750 K with a laser power of 0.5 mW. The TEM images were taken on a JEOL-2010 transmission electron microscope at an acceleration voltage of 200 kV. The field emission scanning electron microscopy images were obtained on a JEOL JSM-6700F SEM. High-resolution TEM images were taken on a JEOL-2010 microscope at an accelerating voltage of 200 kV. Tapping-mode atomic force microscopy images were taken on a DI Innova Multimode SPM platform. Electrochemical performance of the supercapacitor was studied in a two-electrode system by CV and galvanostatic charge–discharge at an electrochemical station (CHI660B). Potential range set for galvanostatic charge–discharge tests was from 0 to 1.2 V.

Additional information

How to cite this article: Wu, C. et al. Two-dimensional vanadyl phosphate ultrathin nanosheets for high energy density and flexible pseudocapacitors. Nat. Commun. 4:2431 doi: 10.1038/ncomms3431 (2013).

References

El-Kady, M. F., Strong, V., Dubin, S. & Kaner, R. B. Laser scribing of high-performance and flexible graphene-based electrochemical capacitors. Science 335, 1326–1330 (2012).

Pushparaj, V. L. et al. Flexible energy storage devices based on nanocomposite paper. Proc. Natl Acad. Sci. USA 104, 13574–13577 (2007).

Nishide, H. & Oyaizu, K. Toward flexible batteries. Science 319, 737–738 (2008).

Li, N., Chen, Z., Ren, W., Li, F. & Cheng, H.-M. Flexible graphene-based lithium ion batteries with ultrafast charge and discharge rates. Proc. Natl Acad. Sci. 109, 17360–17365 (2012).

Fu, Y. et al. Fiber Supercapacitors utilizing pen ink for flexible/wearable energy storage. Adv. Mater. 24, 5713–5718 (2012).

Jia, X. et al. High-performance flexible lithium-ion electrodes based on robust network architecture. Energy Environ. Sci. 5, 6845–6849 (2012).

Gwon, H. et al. Flexible energy storage devices based on graphene paper. Energy Environ. Sci. 4, 1277–1283 (2011).

Lang, X., Hirata, A., Fujita, T. & Chen, M. Nanoporous metal/oxide hybrid electrodes for electrochemical supercapacitors. Nat. Nanotech. 6, 232–236 (2011).

Bae, J. et al. Fiber Supercapacitors made of nanowire-fiber hybrid structures for wearable/flexible energy Ssorage. Angew. Chem. Int. Ed. 50, 1683–1687 (2011).

Chmiola, J., Largeot, C., Taberna, P.-L., Simon, P. & Gogotsi, Y. Monolithic carbide-derived carbon films for micro-supercapacitors. Science 328, 480–483 (2010).

Futaba, D. N. et al. Shape-engineerable and highly densely packed single-walled carbon nanotubes and their application as super-capacitor electrodes. Nat. Mater. 5, 987–994 (2006).

Eda, G., Fanchini, G. & Chhowalla, M. Large-area ultrathin films of reduced graphene oxide as a transparent and flexible electronic material. Nat. Nanotech. 3, 270–274 (2008).

Liu, J. et al. Co3O4 nanowire@MnO2 ultrathin nanosheet core/shell arrays: a new class of high-performance pseudocapacitive materials. Adv. Mater. 23, 2076–2081 (2011).

Wang, X. et al. Three-dimensional hierarchical GeSe2 nanostructures for high performance flexible all-solid-state supercapacitors. Adv. Mater. 25, 1479–1486 (2013).

Yu, G. et al. Solution-processed graphene/MnO2 nanostructured textiles for high-performance electrochemical capacitors. Nano Lett. 11, 2905–2911 (2011).

Brezesinski, T., Wang, J., Tolbert, S. H. & Dunn, B. Ordered mesoporous α-MoO3 with iso-oriented nanocrystalline walls for thin-film pseudocapacitors. Nat. Mater. 9, 146–151 (2010).

Wang, H., Casalongue, H. S., Liang, Y. & Dai, H. Ni(OH)2 nanoplates grown on graphene as advanced electrochemical pseudocapacitor materials. J. Am. Chem. Soc. 132, 7472–7477 (2010).

Yoo, J. J. et al. Ultrathin planar graphene supercapacitors. Nano Lett. 11, 1423–1427 (2011).

Feng, J. et al. Metallic few-layered VS2 ultrathin nanosheets: high two-dimensional conductivity for in-plane supercapacitors. J. Am. Chem. Soc. 133, 17832–17838 (2011).

Xie, J. et al. Layer-by-layer β-Ni(OH)2/graphene nanohybrids for ultraflexible all-solid-state thin-film supercapacitors with high electrochemical performance. Nano Energy 2, 65–74 (2013).

Wu, C. & Xie, Y. Promising vanadium oxide and hydroxide nanostructures: from energy storage to energy saving. Energy Environ. Sci. 3, 1191–1206 (2010).

Dupré, N. et al. Positive electrode materials for lithium batteries based on VOPO4 . Solid State Ionics 140, 209–221 (2001).

Azmi, B. M., Ishihara, T., Nishiguchi, H. & Takita, Y. Vanadyl phosphates of VOPO4 as a cathode of Li-ion rechargeable batteries. J. Power Sources 119–121, 273–277 (2003).

Azmi, B. M., Ishihara, T., Nishiguchi, H. & Takita, Y. Cathodic performance of VOPO4 with various crystal phases for Li ion rechargeable battery. Electrochim. Acta 48, 165–170 (2002).

Park, N.-G., Kim, K. M. & Chang, S. H. Sonochemical synthesis of the high energy density cathode material VOPO4·2H2O. Electrochem. Commun. 3, 553–556 (2001).

Luo, J.-Y., Cui, W.-J., He, P. & Xia, Y.-Y. Raising the cycling stability of aqueous lithium-ion batteries by eliminating oxygen in the electrolyte. Nat. Chem. 2, 760–765 (2010).

Fan, Z. et al. Asymmetric supercapacitors based on graphene/MnO2 and activated carbon nanofiber electrodes with high power and energy density. Adv. Funct. Mater. 21, 2366–2375 (2011).

Beneš, L., Melánová, K., Svoboda, J. & Zima, V. Intercalation chemistry of layered vanadyl phosphate: a review. J. Incl. Phenom. Macro. 73, 33–53 (2012).

Markovitch, O. & Agmon, N. Structure and energetics of the hydronium hydration shells. J. Phys. Chem. A 111, 2253–2256 (2007).

Yan, B. et al. Single-crystalline V2O5 ultralong nanoribbon waveguides. Adv. Mater. 21, 2436–2440 (2009).

Beneš, L., Melánová, K., Trchová, M., Čapková, P. & Matějka, P. Water/Ethanol displacement reactions in vanadyl phosphate. Eur. J. Inorg. Chem. 12, 2289–2294 (1999).

Yan, Z. et al. Growth of bilayer graphene on insulating substrates. ACS Nano 5, 8187–8192 (2011).

Zhu, Y. et al. Graphene and graphene oxide: synthesis, properties, and applications. Adv. Mater. 22, 3906–3924 (2010).

Malard, L. M., Pimenta, M. A., Dresselhaus, G. & Dresselhaus, M. S. Raman spectroscopy in graphene. Phys. Rep. 473, 51–87 (2009).

Wang, G. et al. LiCl/PVA gel electrolyte stabilizes vanadium oxide nanowire electrodes for pseudocapacitors. ACS Nano 6, 10296–10302 (2012).

Jung, H. Y., Karimi, M. B., Hahm, M. G., Ajayan, P. M. & Jung, Y. J. Transparent, flexible supercapacitors from nano-engineered carbon films. Sci. Rep. 2, 773–777 (2012).

Peng, L. et al. Ultrathin Two-Dimensional MnO2/Graphene hybrid nanostructures for high-performance, flexible planar supercapacitors. Nano Lett. 13, 2151–2157 (2013).

Lu, Q. et al. Supercapacitor electrodes with high-energy and power densities prepared from nonolithic NiO/Ni nanocomposites. Angew. Chem. Int. Ed. 123, 6979–6982 (2011).

Yamamoto, N., Hiyoshi, N. & Okuhara, T. Thin-layered sheets of VOHPO4·0.5H2O prepared from VOPO4·2H2O by intercalation− exfoliation−reduction in alcohol. Chem. Mater. 14, 3882–3888 (2002).

Marcano, D. C. et al. Improved synthesis of graphene oxide. ACS Nano 4, 4806–4814 (2010).

Nkovich, S. et al. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45, 1558–1565 (2007).

Acknowledgements

C.W. and Y.X. acknowledge financial support from the National Basic Research Program of China (No. 2009CB939901), National Natural Science Foundation of China (No. 21222101, 11074229, 11132009, 11079004, J1030412), Chinese Academy of Science (XDB01020300), Program for New Century Excellent Talents in University. G.Y. acknowledges the start-up funding support from Cockrell School of Engineering at The University of Texas at Austin.

Author information

Authors and Affiliations

Contributions

C.W., Y.X. and G.Y. conceived the idea, co-wrote the paper and supervised the whole project. C.W., X.L. and L.P., experimentally realized the idea and wrote the paper; X.L., L.P., X.K. and X.P. carried out the examples synthesis, characterization and data analysis; J.H. performed the atomic force microscopy investigation. All the authors discussed the results, commented on and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures S1-S13, Supplementary Tables S1-S2 and Supplementary References (PDF 1431 kb)

Rights and permissions

About this article

Cite this article

Wu, C., Lu, X., Peng, L. et al. Two-dimensional vanadyl phosphate ultrathin nanosheets for high energy density and flexible pseudocapacitors. Nat Commun 4, 2431 (2013). https://doi.org/10.1038/ncomms3431

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms3431

This article is cited by

-

Why is graphene an extraordinary material? A review based on a decade of research

Frontiers of Materials Science (2022)

-

Self-Supported Graphene Nanosheet-Based Composites as Binder-Free Electrodes for Advanced Electrochemical Energy Conversion and Storage

Electrochemical Energy Reviews (2022)

-

Nanostructured transition metal vanadates as electrodes for pseudo-supercapacitors: a review

Journal of Nanoparticle Research (2021)

-

Rechargeable quasi-solid-state aqueous hybrid Al3+/H+ battery with 10,000 ultralong cycle stability and smart switching capability

Nano Research (2021)

-

Low-temperature molten salt synthesis and luminescence properties of Eu(III)-based coordination polymer nanosheets

Rare Metals (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.