Abstract

Recent advances in genome engineering have further widened the gap between our ability to implement essentially any genetic change and understanding the impact of these changes on cellular function. We lack efficient methods to diagnose limiting steps in engineered pathways. Here, we develop a generally applicable approach to reveal limiting steps within a synthetic pathway. It is based on monitoring metabolite dynamics and simplified kinetic modelling to differentiate between putative causes of limiting product synthesis during the start-up phase of the pathway with near-maximal rates. We examine the synthetic N-acetylglucosamine (GlcNAc) pathway in Bacillus subtilis and find none of the acetyl-, amine- or glucose-moiety precursors to limit synthesis. Our dynamic metabolomics approach predicts an energy-dissipating futile cycle between GlcNAc6P and GlcNAc as the primary problem in the pathway. Deletion of the responsible glucokinase more than doubles GlcNAc productivity by restoring healthy growth of the overproducing strain.

Similar content being viewed by others

Introduction

Metabolic engineering is a key technology for cellular property improvement in the green and sustainable production of biofuels, fine chemicals and pharmaceuticals1,2. The past 5 years have revolutionized our ability to engineer genomes, enabling high-precision strain construction at large-scale, for instance through multiplex automated genome engineering3, Cas9-mediated genome editing4 or modular pathway engineering5. Although these methods effectively removed all limitations for manipulating existing pathways and constructing synthetic ones to desired products, they further widened the already large gap between our ability to identify the engineering targets in the first place and precise diagnosis of arising bottlenecks and other complications. In other words: What is limit of production and how can we abolish the limitation?

The current repertoire to answer these questions ranges from computational methods that are often based on genome-scale models6,7,8 to omics methods that monitor cellular responses at the level of molecular component concentrations or metabolic fluxes9,10,11,12,13,14. A particular problem is diagnosis of rate-limiting steps in supply or within synthetic pathways from omics-type data. As most diagnosis tools are rather time-consuming, typical applications focus on steady-state analyses, such as transcriptome-based identification of an intermediate for pool size increase to improve riboflavin production10, proteome-based identification of two rate-limiting steps in isopentenol synthesis11 or metabolomics-based identification of an optimal intermediate feeding approach to improve tacrolimus production12. In particular, dynamic metabolomics has great diagnostic potential as was elegantly demonstrated by bottleneck identification within in vitro reconstituted glycolysis15 and a new method for near real-time metabolomics16. Surprisingly, applications of such dynamic investigations to biotechnological production systems are rare, presumably because design of meaningful experiments and data interpretation are not trivial. Consequently, diagnosis has so far largely been restricted to ad hoc identification of limitations in precursor supply that can easily be validated by precursors feeding without fundamentally optimizing structure and kinetic parameters of synthetic networks. Examples include identification of bottlenecks in biosynthesis pathways for lipids, recombinant antibodies and heterologous proteins17,18,19, and substrate degradation in xylose-fermenting Saccharomyces cerevisiae20.

Here we show that metabolite dynamics during the ‘start-up phase’ of a synthetic pathway with near maximal initial rates provide valuable information about limitations. We identify potential pathway bottlenecks from the comparison of metabolomics data with simulations of a simple kinetic model that can be generically applied to linear pathways. Specifically, we examined Bacillus subtilis metabolism during production of the amino sugar N-acetylglucosamine (GlcNAc) used for pharmaceutical and nutraceutical treatment of osteoarthritis and maintaining joint health21. The previously engineered strain with optimized GlcNAc synthesis and blocked GlcNAc catabolism21,22 (Fig. 1a) is productive in complex media but has poor performance and growth in industrial media with single carbon sources. The combination of dynamic metabolomics and coarse-grained modelling identified a major bottleneck and a potential metabolic engineering target, namely, the reactions between GlcNAc6P and GlcNAc, for improved cell growth and GlcNAc yield on glucose. Dynamic isotope tracing then diagnosed an energy-dissipating phosphorylation/dephosphorylation cycle as the molecular cause. Disrupting this futile cycle through deleting the encoding gene of the here newly identified responsible enzyme, glucokinase GlcK, restored intracellular GlcNAc6P concentrations and more than doubled GlcNAc productivity and GlcNAc yield on glucose.

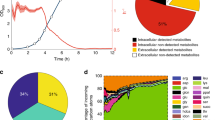

(a) Metabolic pathway of GlcNAc synthesis. (b) Comparison of specific cell growth rate and specific GlcNAc production rate of B. subtilis 168, the GlcNAc-overproducing B. subtilis BSGN6-PxylA-glmS-P43-GNA1 (BSGN) strain, BSGN with mutation in 6-phosphofructokinase (BSGN-Pfk*), BSGN with glutamate synthase overexpression (BSGN-GS). AcCoA, acetyl-coenzyme A; DHAP, dihydroxyacetone phosphate; F6P, fructose-6-phosphate; FBP, fructose-1,6,-bis-phosphate; G6P, glucose-6-phosphate; GlcN6P, glucosamine-6-phosphate; GlcNAc6P, N-acetylglucosamine-6-phosphate; GlmS, glucosamine synthase; Gln, glutamine; Glu, glutamate; GNA1, GlcN6P N-acetyltransferase; PEP, phosphoenolpyruvic acid; PGI, glucose-6-phosphate isomerase; PTS, phosphotransferase system; PYR, pyruvate; OD600, optical density at 600 nm. Triplicate experiments were done for physiological measurements, and error bars represent standard deviation.

Results

GlcNAc overproducing B. subtilis on minimal glucose medium

An engineered GlcNAc production strain B. subtilis BSGN6-PxylA-glmS-P43-GNA1, abbreviated BSGN hereafter, was recently obtained based on modular pathway optimization to fine-tune a synthetic GlcNAc pathway in our previous research21. In brief, BSGN was constructed by overexpression of glucosamine (GlcN)-6-phosphate synthase (GlmS) under the control of an inducible promoter PxylA and GlcN-6-phosphate N-acetyltransferase (Gna1) under the control of a constitutive promoter P43 in the background of absent GlcNAc catabolism via knockout of nagP, gamP, nagA, nagB and gamA. In glucose minimal medium, the growth rate of BSGN was only a fifth of the parent strain (Fig. 1 and Supplementary Table 1). Because GlcNAc production is coupled to cell growth, GlcNAc productivity dropped dramatically by 82.7 % to 32.6 mg g−1 dry cell weight per hour in glucose minimal medium with a yield of 65.0 mg GlcNAc per gram glucose. Here we address the problem of cell growth and product formation in the industrially relevant condition of glucose minimal medium. Given that GlcNAc overproduction requires three central metabolic precursors (fructose-6-P, acetyl-CoA (AcCoA) and the nitrogen donor glutamine), competition between growth-related metabolism and the synthetic pathway is expected. Hence, we first examined the effect of precursor supply on native metabolism and the synthetic pathway.

To probe whether precursor supply constrained either GlcNAc formation or native metabolism, we genetically modulated fluxes through the supply pathways. First, we diverted fructose-6-P availability from native metabolism to GlcNAc by replacing the native phosphofructokinase (Pfk) with a reduced activity of Arg252Ala-mutated Pfk23. Surprisingly, the mutation had no effect on growth and specific production rate of BSGN-Pfk* were similar to BSGN (Fig. 1b). Therefore, fructose-6-P supply neither limits GlcNAc production nor cell growth. Likewise, increased supply of glutamine for GlcNAc synthesis and central nitrogen metabolism in strain BSGN-GS by overexpression of glutamine synthase (GS) did not improve growth or GlcNAc production rate (Fig. 1b and Supplementary Table 2), but increased the specific glucose uptake rate about 1.5-fold relative to BSGN and BSGN-Pfk*. Also addition of glutamine to the cultivation medium had no effect on specific growth rate and GlcNAc-specific production rate (Supplementary Fig. 1). Thus, we conclude that precursor supply would be sufficient for a much higher GlcNAc production and cell growth than observed in BSGN.

Metabolomics reveals abundant precursor and bottleneck

To identify the primary limitation in GlcNAc biosynthesis, we determined intracellular metabolite concentrations in wild-type B. subtilis, the GlcNAc production strain BSGN and the two producing strains BSGN-Pfk* and BSGN-GS with modulated precursor supply during mid-exponential growth (at an optical density at 600 nm of 0.5) in minimal glucose medium. Almost all metabolite concentrations were lower in BSGN compared with wild-type, and, in particular, the GlcNAc pathway precursors fructose-6-P, citrate (directly connected to AcCoA) and the nitrogen donor glutamine were markedly decreased (Fig. 2, Supplementary Fig. 2 and Supplementary Tables 3 and 4). How did modifications of precursor supply change this profile? Although the Pfk mutation in BSGN-Pfk* had no further effect on metabolite concentrations, GS overexpression in BSGN-GS restored nearly wild-type levels for most metabolites, suggesting that GlcNAc production impaired cellular nitrogen metabolism, presumably through low levels of glutamine. Nevertheless, BSGN-GS grew as slowly as the ancestral BSGN despite restored metabolite levels (Fig. 1b). Thus, the decreased metabolite concentrations were neither consequence nor major cause of slow growth, strongly suggesting that other mechanisms impair growth and GlcNAc synthesis.

Pool sizes of metabolite in glycolysis, the TCA cycle, amino acids and amino sugars were compared. Triplicate experiments were done for metabolite pool size measurements. Asterisk (*) denotes P<0.05 (two-tailed test). The standard deviations values of all the fold changes of triplicate experiments were less than 20% of the value of fold changes.

The essentially only and very striking difference between all three production strains and wild type was a more than 300-fold increased GlcNAc-6-P concentration from 0.06 mM in the wild type to 20–34 mM in the GlcNAc-producing strains (Fig. 2). These abnormal concentrations suggest a metabolic bottleneck in the vicinity of GlcNAc6P. As the concentration of phosphosugars is normally tightly controlled, such extraordinarily high GlcNAc6P concentrations may cause phosphosugar stress, affecting for instance nucleic acid metabolism and triggering degradation of ptsG messenger RNA regulated by the small RNA SgrS at the posttranscriptional level, which, in turn, inhibits glucose uptake in E. coli24,25,26. Based on steady-state data alone, however, one cannot differentiate between different molecular causes such as, for example, low activity of the dephosphorylating enzyme or transport limitations that jam the pathway.

Different bottlenecks lead to distinct metabolite dynamics

Given that metabolite levels respond very fast, we reasoned that they would be a sensitive indicator of arising bottlenecks during a transition from low to high activity of the synthetic pathway and we sought to test putative dynamics using a metabolic model16,27 (Fig. 3a). For this purpose, we developed a linear pathway model, which consists of three intermediate metabolites, the intracellular and the extracellular products. To simulate a transition from low to high pathway activity, initial concentrations of the first two intermediates are randomly sampled from a sub-saturating concentration range (between 0 and 10% of average Km values). Initial concentrations of the other three metabolites are randomly sampled from a near-saturating concentration range (50 and 150 % of average Km values). All reactions are described by Michaelis–Menten kinetics and Km values are randomly sampled between 0 and 2, resulting in an average Km of one. Concentrations of metabolites and Km parameters are arbitrary units but their range account for low and high saturating conditions of enzymes. In a base model, all maximal reaction rates were fixed to 1, except influx which was 0.5 in order to assuring that no reaction in the pathway is limiting. Simulations of the base model (i) show a continuous increase of product and asymptotic equilibration of intermediates at the average Km of one (Fig. 3b). Next, we simulated possible scenarios of frequently encountered pathway limitations, including end-product inhibition, as well as futile cycles and limiting enzyme capacities at several nodes of the pathway (Fig. 3b). In case of feedback inhibition (ii), concentrations of intermediates equilibrate at average inhibition constants and overproduction are reduced. (iii) A typical bottleneck reaction with low turnover has a continuously accumulating intermediate upstream of the bottleneck, whereas the downstream intermediate decreases strongly below the average Km value. In case of the futile cycles shown in scenario (iv) and (v), the dynamic response is similar to a limiting reaction in scenario (iii). However, intermediates up- and downstream of the futile cycle equilibrate faster than in case of a limiting reaction. Quantitatively, the response of intermediates depends on the degree of futile cycle and the bottleneck, with much stronger responses in the latter case (Supplementary Fig. 3). Finally, if product export does not match the synthesis rate the intracellular product accumulates (vi). Thus, although metabolite dynamics are difficult to predict quantitatively, their qualitative features bear sufficient information to distinguish between different putative bottlenecks.

(a) A linear production pathway with five reactions (v1–v5), four intracellular metabolites (x1-x4) and one extracellular product x5. (b) Simulation results of the linear pathway assuming different scenarios: (i) no limitation in the pathway; (ii) feedback inhibition in the pathway; (iii) a rate-limiting step in the pathway; (iv) a futile cycle in the pathway; (v) a futile cycle at the end of the pathway or (vi) insufficient intracellular product export in the pathway. One hundred simulation results using 100 random parameter sets for initial concentrations and Km values (lines indicate mean and shaded areas the standard deviation). Colours are as shown in above in a. The model is described in detail in the Methods section.

To experimentally realize a transition from low to high activity of the GlcNAc pathway, exponentially growing cells were harvested and resuspended in medium without carbon source. Low precursor availability was ensured by 30 min incubation without carbon source that effectively stopped GlcNAc production and lead to constant intra- and extracellular metabolite concentrations without significant changes in pathway enzyme expression (Fig. 4a and Supplementary Figs 4 and 5). Addition of glucose induced GlcNAc synthesis at a rate of 34.8 μmol g−1 dry cell weight per hour that remained constant for 1 h (Fig. 4a). Monitoring metabolite dynamics during the first 2 min after glucose addition revealed the known response of glycolytic intermediates to glucose; that is, rapid increase of phosphorylated sugars and decrease of the phosphotransferase system substrate phosphoenolpyruvic acid (Fig. 4b). Concentrations of the three GlcNAc precursors fructose-6-P and glutamine increased rapidly above the Km values of their cognate enzymes25,28 (Fig. 4b and Supplementary Table 5), confirming our hypothesis of absent limitations in the precursor supply into the pathway. Within the simulated responses of possible scenarios, the scenario with a futile cycle or a limiting reaction at the end of the pathway would be consistent with the experimentally detected dynamics (Figs 3b and 4b). As GlcNAc6P concentrations equilibrate already after 2 min and intracellular GlcNAc remained high (5 mM), we hypothesized that a futile cycle is more likely than a limiting dephosphorylation (Fig. 3 and Supplementary Fig. 3). Next, we sought to investigate if indeed the product GlcNAc is re-phosphorylated by an unknown enzyme, resulting in an ATP dissipating futile cycle.

(a) Dynamic experiment setup and dynamic change of GlcNAc and GlcNAc6P. Cells were harvested by centrifugation and resuspended in M9 medium without any carbon source. Next, cells were incubated in the no carbon source condition for 30 min until depletion of substrate of synthetic pathway and no further change of GlcNAc was observed. Glucose was then added to initiate GlcNAc synthesis (t=0). Intracellular metabolite concentrations and metabolite concentrations in whole-cell broth were analysed. DCW, dry cell weight. (b) Dynamics of intracellular metabolite in glycolysis and GlcNAc synthetic pathway by adding glucose was added as substrate at t=0. The known Km values of pathway enzymes for F6P, GlcN6P and Gln were shown by dashed lines. Triplicate experiments were done for metabolite dynamics analyses, and error bars represent standard deviation.

Validation and preventing the ATP dissipating futile cycle

To experimentally validate the above-hypothesized futile cycle, we used isotopic tracer experiments. As intracellular GlcNAc decreased upon pathway start-up (Fig. 4a), futile re-phosphorylation to GlcNAc6P should occur to a large extent from unlabelled GlcNAc molecules during the initial phase. To verify that the initial source of accumulating GlcNAc6P was indeed GlcNAc rather than glucose via the normal synthesis route, we started the experiment with uniformly labelled [U-13C]glucose (Fig. 5a). Within the first 60 s of [U-13C]glucose addition, the relative concentration of unlabelled [U-12C]GlcNAc6P (M+0) increased 36% (Fig. 5b), whereas no fully labelled [U-13C]GlcNAc6P was yet formed (Fig. 5c), demonstrating that re-phosphorylation dominates during this period. Thus, an energy-dissipating phosphorylation/dephosphorylation futile cycle operates between GlcNAc6P and GlcNAc, effectively blocking GlcNAc synthesis. The resulting accumulation of GlcNAc6P may further trigger phosphosugar stress and impair cell growth and GlcNAc production. Alleviating GlcNAc6P accumulation and improving the GlcNAc production would require disruption of the futile cycle between GlcNAc and GlcNAc6P. However, a GlcNAc kinase has so far not been annotated in B. subtilis. To identify candidate genes encoding such a GlcNAc kinase, we performed homology analysis using the amino-acid sequence of E. coli GlcNAc kinase NagK29,30. Among the 106 kinases in B. subtilis, the highest homology was found for the annotated glucokinase GlcK (26% sequence identity), and we deleted glcK in the BSGN strain (yielding strain BSGNK). Repeating the dynamic labelling experiment with BSGNK abolished formation of GlcNAc6P M+0 and labelled GlcNAc6P M+8 increased strongly, because of de novo synthesis from glucose (Fig. 5c). Thus, we conclude that deletion of glcK resulted in drastic reduction of the futile cycle.

(a) Labelling patterns of GlcNAc6P with substrate from [U-13C]glucose and GlcNAc, respectively. Black circles indicate 13C pattern carbon atoms; blue circles indicate 12C pattern carbon atoms. (b) Comparison of intensity fold change of GlcNAc6P mass isotopomer GlcNAc6P M+0 and GlcNAc6P M+8 after [U-13C]glucose addition in BSGN and BSGN with glucokinase encoding gene (glcK) deletion (BSGNK). (c) Comparison of intensity fold change of GlcNAc6P mass isotopomer GlcNAc6P GlcNAc6P M+8 after [U-13C]glucose addition in BSGN and BSGNK. (d) Comparison of cell growth in BSGN and BSGNK in a shake flask production system. (e) Comparison of GlcNAc production in BSGN and BSGNK in a shake flask production system. (f) Comparison of specific cell growth rate and GlcNAc productivity of BSGN and BSGNK strain in a shake flask production system. Triplicate experiments were done for dynamic labelling of GlcNAc6P, and error bars represent standard deviation.

Beyond the short-term dynamics, we next investigated GlcNAc synthesis in BSGNK under more production relevant conditions in steady-state cultures grown in minimal medium with glucose. Indeed, breaking the futile cycle through the glcK deletion circumvented the detrimental increase of intracellular GlcNAc6P (0.06 mM in BSGNK versus 33.71 mM in BSGN, Supplementary Fig. 6). The decrease of intracellular GlcNAc6P relieved potential phosphosugar stress for the cell and restored a more healthy growth physiology with a more than doubled specific cell growth rate and more than doubled GlcNAc productivity (9.20 mg l−1 h−1; Fig. 5d–f). Therefore, the glcK deletion experiments confirmed the deleterious role of the futile cycle between GlcNAc6P and GlcNAc for cell growth and GlcNAc production in engineered B. subtilis. Moreover, the energy charge increased from 0.68±0.03 in BSGN to 0.81±0.04 in BSGNK (+/− values represent standard deviation from triplicate experiments), further confirming that eliminating the ATP-dissipating futile cycle improved energy metabolism (Supplementary Fig. 7). Moreover, the GlcNAc yield on glucose (147.5 mg g−1 glucose) and dry cell weight on glucose (138.3 mg g−1 glucose) in BSGNK were 2.3-fold higher than in BSGN. As the specific GlcNAc production rate was similar in BSGN (32.6 mg g−1 DCW h−1) and BSGNK (33.2 mg g−1 DCW h−1), improved performance of BSGNK resulted from restored healthy growth with a high growth rate, which is apparently coupled to GlcNAc production (Supplementary Table 1).

Discussion

Identification of bottlenecks within engineered pathway still hampers rational metabolic engineering. To differentiate between limitations within a synthetic pathway or in precursors supply to it, we first used comparative steady-state metabolomics profiling of genetically perturbed supply pathway strains. To hypothesize bottlenecks within a synthetic pathway, we outlined an approach based on dynamic metabolomics experiments and simplified kinetic modelling to differentiate between different putative causes in limiting GlcNAc synthesis during the start-up phase of the pathway with near maximal rates. The potential of this generically applicable approach was demonstrated by identifying an unexpected futile phosphorylation–dephosphorylation cycle in the GlcNAc production with B. subtilis, genetic intervention of which greatly improved GlcNAc productivity and yield on glucose. Relieving the energy drain induced by this synthetic pathway restored the cellular energy homeostasis and healthy growth and thus in consequence volumetric GlcNAc productivity.

Methods

Strains and plasmids and cultivation

Strains and plasmids used in this study are listed in Supplementary Table 6. The previously constructed GlcNAc production strain BSGN21 is characterized by (i) a block of GlcNAc catabolism through marker-free deletion of all relevant encoding genes and (ii) overexpression of the GlcNAc synthesis enzymes GlmS and GNA1. BSGN-Pfk* was constructed by introducing site-directed mutation in native pfk Arg252Ala via a markerless genome editing system31 for B. subtilis with the primers listed in Supplementary Table 7. In brief, front and back homology fragments with the mutation (Arg252Ala, CGC to GCC) in direct repeated sequences were amplified with primers AL-F/AL-R and AR-F/AR-R, respectively. The mazF cassette was amplified with primers AZ-F and AZ-R from the B. subtilis 168 genome. Next, fusion PCR was performed to fuse the front homology fragment, mazF cassette, and back homology fragment. The resulting DNA fragment was transformed into BSGN0 via screening on a Luria–Bertani (LB) plate with spectinomycin. Transformants with mutation site integration were then plated on LB plates with 2% xylose to screen strains with the desired mutation and mazF cassette eviction via single-crossover between directed repeated sequences. To construct BSGN-GS, we constructed DNA multimer plasmids pP43-GNA1-GS via DNA multimer-based vector construction manipulation32. In brief, encoding sequences of GNA1 and GS were amplified with primers GNA1-F/GNA1-R and GS-F/GS-R from plasmid pP43-GNA1 and the B. subtilis 168 genome. For encoding sequences of GNA1, 3′ overlapped fragment of the vector sequence was introduced. For encoding sequences of GS, 5′ overlapped fragment of the vector sequence was introduced. The vector sequence was amplified with PCR using primers V-F and V-R. The resulting encoding sequences of GNA1 and GS were fused via fusion PCR. Prolonged-overlap extension PCR was then performed with the GNA1-GS and vector fragments to generate DNA multimer plasmids, which were transformed into BSGN0 via multimer plasmid cleavage of the host strain forming a circular plasmid and yielding BSGN-GS. BSGNK was constructed by knockout of glucose kinase encoding gene sequence glcK. In brief, primers GlcK-F/GlcK-R were used to amplify glcK disrupt cassette from B. subtilis 168 ΔglcK (Professor Jörg Stülke, Georg-August-Universität Göttingen). The amplified glcK disrupt cassette was transformed into BSGN, yielding BSGNK.

Cultivation for genetic experiments was done in LB broth or agar plates (10 g l−1 tryptone, 5 g l−1 yeast extract and 10 g l−1 NaCl) at 37 °C. Cultivation for physiological experiments was done in M9 mineral salts medium with 2 g l−1 glucose (1 g l−1 NH4Cl, 0.5 g l−1 NaCl, 8.5 g l−1 Na2HPO4·H2O, KH2PO4, 1 ml of 1 M MgSO4 per litre, 1 ml of 0.1 M CaCl2 per litre, 1 ml of 0.05 M FeCl3 and 10 ml trace element solution containing 60 mg l−1 CoCl2·6H2O, 43 mg l−1 CuCl2·2H2O, 100 mg l−1 MnCl2·4H2O, 60 mg l−1 Na2MoO4·2H2O and 170 mg l−1 ZnCl2). Appropriate antibiotics were added to the medium at the following final concentrations: kanamycin (20 μg ml−1) and spectinomycin (100 μg ml−1). To evaluate effects of Gln feeding on cell growth and GlcNAc production, Gln was added to final concentration 0.5 mmol l−1 in M9 mineral salts medium.

Steady-state targeted metabolomics

B. subtilis strains were cultured in M9 medium in a shake flask at 37 °C and 300 r.p.m. Cells were harvested in the mid-exponential phase when the optical density at 600 nm reached 0.5. Fast-filtration was used to collect cells on a filter, and the cells were further quenched and extracted in acetonitrile/methanol/H2O (40:40:20) solution with 13C internal standard addition. Next, the extract solution was dried and resuspended in H2O for ultrahigh-performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS) detection using the following conditions33: Waters Acquity UHPLC (Waters Corporation) equipped with Waters Acquity T3 C18 column (150 × 2.1 × 1.8 μm3, Waters Corporation) was tandemed with Thermo TSQ Quantum Ultra triple quadrupole instrument (Thermo Fisher Scientific) with a heated electrospray ionization source (Thermo Fisher Scientific). Temperature of UHPLC column was controlled at 40 °C. Mobile phase A (10 mM tributylamine, 15 mM acetic acid, 5% (v/v) methanol) and B (2-propanol) were used for gradient elution for metabolite separation. The MS was operated in negative mode, and following parameters of MS were used: Ion spray voltage 2,500 V, ion sweep gas pressure 5 arbitrary units, auxiliary gas pressure 50 arbitrary units, curtain gas pressure 80 arbitrary units. Tube lens voltage, collision energy and fragment ions were optimized individually for all compounds33. Metabolite fold changes between recombinant strains and wild-type B. subtilis 168 were calculated based on metabolite concentrations.

Metabolite dynamics analysis and dynamic labelling

Cells were cultivated in LB medium and harvested via centrifugation (4,500g, 5 min) when optical density at 600 nm reached 1.0. Next, the cells were resuspended in M9 medium without glucose and incubated at 37 °C with magnetic stirring at 400 r.p.m. At t=0, glucose was added to a final concentration of 2 g l−1. Then, samples of whole-cell broth for total metabolite concentration measurements, including both intracellular and extracellular concentrations, were taken after glucose addition and immediately quenched and extracted in acetonitrile/methanol/H2O (40:40:20) solution. Cells for intracellular metabolite concentration measurements were collected on a 0.45-μm pore size nitrocellulose filter membranes (Millipore). 13C internal standard was added before the samples were dried. After sample resuspension in H2O, UHPLC-MS/MS was performed to detect metabolites33.

For the dynamic labelling experiment, 100% [U-13C]glucose was used as the substrate. Data of mass isotopomers GlcNAc6P M+0 and M+8 were acquired via Xcalibur software version 2.07 SP1 (Thermo Fisher Scientific). Peak integrations were performed with Xcalibur software version 2.07 SP1 (Thermo Fisher Scientific) and a Matlab R2014b (The Mathworks Inc.)-based in-house integration software for intensity calculation.

Dynamic simulation

MATLAB R2014b was used for all calculations and the dynamic simulation. Base Model (Model 1—no limitation): The linear pathway is shown in Fig. 3a in the main text. It consists of four intracellular metabolites x(1)–x(4) and the extracellular product x(5). Reaction kinetics of five reactions are:

Influx of precursor:

Michaelis–Menten kinetics are used to describe reactions kinetics of reaction v(2), v(3), v(4) and v(5):

Mass balances for all metabolites result in the differential equations:

Parameters: The maximum reaction rates v(2)max, v(3)max, v(4)max and v(5)max are 1 and v(1)max is 0.5. The binding constants Km2, Km3, Km4, Km5 were randomly sampled between 0 and 2. The initial concentrations of x(1) and x(2) were sampled between 0 and 0.1, initial concentrations of x(3), x(4) and x(5) were sampled between 0.5 and 1.5.

The models for the different scenarios (ii)–(vi) are:

Model 2: To describe the scenario with feedback inhibition (Fig. 3b), intracellular product x(4) inhibits the first reaction v(1), according to Hill kinetics. The Hill coefficient n was sampled between 0 and 4, and Ki between 0 and 1.

Model 3: To describe the scenario with a limiting enzyme abundance v(4)max was 0.1, and in Supplementary Fig. 3 as indicated.

Model 4 and model 5: To describe the scenario with a futile cycle, an additional reaction was added v(6), described again by Michaelis–Menten kinetics. The binding constants Km6 was randomly sampled between 0 and 2.

v(6)max was 1 in Fig. 3, and in Supplementary Fig. 3 as indicated.

Model 6: To describe the scenario with insufficient intracellular product exportation v(5)max was 0.1.

Transcriptional level comparison of GlcNAc pathway enzymes

The following cells are harvested, frozen in liquid nitrogen and stored in −80 °C freezer for RNA extraction and quantitative real-time PCR analysis: (i) exponentially growing BSGN cell in M9 minimum medium, (ii) exponentially growing BSGN cell in LB medium, (iii) exponentially growing BSGN cell in LB medium with resuspension in M9 minimum medium without glucose for 15 min substrate depletion and (iv) exponentially growing BSGN cell in LB medium with resuspension in M9 minimum medium without glucose for 30 min substrate depletion. Total RNA of above cells was extracted via Qiagen RNeasy Mini Kit (QIAGEN). cDNA was obtain for RNA using PrimeScrip RT reagent Kit (Takara). Primers used for qRT–PCR were listed in Supplementary Table 6. LightCycler 480 II real-time PCR instrument (Roche Applied Science) was used to quantify cDNA with SYBR Premix Ex Taq (Takara). Gene expression levels of exponentially growing cell without incubation were defined as 100%. Relative gene expression changes were calculated based on normalized data to 16s rRNA. Triplicate experiments were done for relative gene expression assay.

Data availability

The Matlab code used in this study and data that support the findings of this study are available from the corresponding author upon request.

Additional information

How to cite this article: Liu, Y. et al. A dynamic pathway analysis approach reveals a limiting futile cycle in N-acetylglucosamine overproducing Bacillus subtilis. Nat. Commun. 7:11933 doi: 10.1038/ncomms11933 (2016).

References

Woolston, B. M., Edgar, S. & Stephanopoulos, G. Metabolic engineering: past and future. Annu. Rev. Chem. Biomol. Eng. 4, 259–288 (2013).

Jullesson, D., David, F., Pfleger, B. & Nielsen, J. Impact of synthetic biology and metabolic engineering on industrial production of fine chemicals. Biotechnol. Adv. 33, 1395–1402 (2015).

Wang, H. H. et al. Programming cells by multiplex genome engineering and accelerated evolution. Nature 460, 894–898 (2009).

Sander, J. D. & Joung, J. K. CRISPR-Cas systems for editing, regulating and targeting genomes. Nature Biotechnol. 32, 347–355 (2014).

Xu, P. et al. Modular optimization of multi-gene pathways for fatty acids production in E. coli. Nat. Commun 4, 1409 (2013).

O’Brien, E. J., Monk, J. M. & Palsson, B. O. Using genome-scale models to predict biological capabilities. Cell 161, 971–987 (2015).

Link, H., Christodoulou, D. & Sauer, U. Advancing metabolic models with kinetic information. Curr. Opin. Biotechnol. 29, 8–14 (2014).

Cho, C., Choi, S. Y., Luo, Z. W. & Lee, S. Y. Recent advances in microbial production of fuels and chemicals using tools and strategies of systems metabolic engineering. Biotechnol. Adv. 33, 1455–1466 (2015).

Lee, J. W. et al. Systems metabolic engineering of microorganisms for natural and non-natural chemicals. Nat. Chem. Biol. 8, 536–546 (2012).

Shi, S., Chen, T., Zhang, Z., Chen, X. & Zhao, X. Transcriptome analysis guided metabolic engineering of Bacillus subtilis for riboflavin production. Metab. Eng. 11, 243–252 (2009).

George, K. W. et al. Correlation analysis of targeted proteins and metabolites to assess and engineer microbial isopentenol production. Biotechnol. Bioeng. 111, 1648–1658 (2014).

Xia, M. et al. Enhanced FK506 production in Streptomyces tsukubaensis by rational feeding strategies based on comparative metabolic profiling analysis. Biotechnol. Bioeng. 110, 2717–2730 (2013).

Sévin, D. C., Kuehne, A., Zamboni, N. & Sauer, U. Biological insights through nontargeted metabolomics. Curr. Opin. Biotechnol. 34, 1–8 (2015).

Buescher, J. M. et al. A roadmap for interpreting 13C metabolite labeling patterns from cells. Curr. Opin. Biotechnol. 34, 189–201 (2015).

Bujara, M., Schümperli, M., Pellaux, R., Heinemann, M. & Panke, S. Optimization of a blueprint for in vitro glycolysis by metabolic real-time analysis. Nat. Chem. Biol. 7, 271–277 (2011).

Link, H., Fuhrer, T., Gerosa, L., Zamboni, N. & Sauer, U. Real-time metabolome profiling of the metabolic switch between starvation and growth. Nat. Methods 12, 1091–1097 (2015).

Ho, S.-H. et al. Optimizing biodiesel production in marine Chlamydomonas sp. JSC4 through metabolic profiling and an innovative salinity-gradient strategy. Biotechnol. Biofuels 7, 97 (2014).

Sellick, C. A. et al. Metabolite profiling of recombinant CHO cells: designing tailored feeding regimes that enhance recombinant antibody production. Biotechnol. Bioeng. 108, 3025–3031 (2011).

Korneli, C., Bolten, C. J., Godard, T., Franco-Lara, E. & Wittmann, C. Debottlenecking recombinant protein production in Bacillus megaterium under large-scale conditions-targeted precursor feeding designed from metabolomics. Biotechnol. Bioeng. 109, 1538–1550 (2012).

Klimacek, M., Krahulec, S., Sauer, U. & Nidetzky, B. Limitations in xylose-fermenting Saccharomyces cerevisiae, made evident through comprehensive metabolite profiling and thermodynamic analysis. Appl. Environ. Microbiol. 76, 7566–7574 (2010).

Liu, Y. et al. Modular pathway engineering of Bacillus subtilis for improved N-acetylglucosamine production. Metab. Eng. 23, 42–52 (2014).

Liu, Y. et al. Pathway engineering of Bacillus subtilis for microbial production of N-acetylglucosamine. Metab. Eng. 19, 107–115 (2013).

Valdez, B. C., French, B. A., Younathan, E. S. & Chang, S. Site-directed mutagenesis in Bacillus stearothermophilus fructose-6-phosphate 1-kinase. Mutation at the substrate-binding site affects allosteric behavior. J. Biol. Chem. 264, 131–135 (1989).

Papenfort, K., Sun, Y., Miyakoshi, M., Vanderpool, C. K. & Vogel, J. Small RNA-mediated activation of sugar phosphatase mRNA regulates glucose homeostasis. Cell 153, 426–437 (2013).

Morita, T., El-Kazzaz, W., Tanaka, Y., Inada, T. & Aiba, H. Accumulation of glucose 6-phosphate or fructose 6-phosphate is responsible for destabilization of glucose transporter mRNA in Escherichia coli. J. Biol. Chem. 278, 15608–15614 (2003).

Durand, P., Golinelli-Pimpaneau, B., Mouilleron, S., Badet, B. & Badet-Denisot, M. A. Highlights of glucosamine-6P synthase catalysis. Arch. Biochem. Biophys. 474, 302–317 (2008).

Link, H., Kochanowski, K. & Sauer, U. Systematic identification of allosteric protein-metabolite interactions that control enzyme activity in vivo. Nature Biotechnol. 31, 357–361 (2013).

Mio, T., Yamada-Okabe, T., Arisawa, M. & Yamada-Okabe, H. Saccharomyces cerevisiae GNA1, an essential gene encoding a novel acetyltransferase involved in UDP-N-acetylglucosamine synthesis. J. Biol. Chem. 274, 424–429 (1999).

Uehara, T. & Park, J. T. The N-acetyl-D-glucosamine kinase of Escherichia coli and its role in murein recycling. J. Bacteriol. 186, 7273–7279 (2004).

Smith, T. J., Blackman, S. A. & Foster, S. J. Autolysins of Bacillus subtilis: multiple enzymes with multiple functions. Microbiology 146, 249–262 (2000).

Yu, H. et al. Efficient and precise construction of markerless manipulations in the Bacillus subtilis genome. J. Microbiol. Biotechn 20, 45–53 (2010).

You, C., Zhang, X.-Z. & Zhang, Y. H.P. Simple cloning via direct transformation of PCR product (DNA multimer) to Escherichia coli and Bacillus subtilis. Appl. Environ. Microb 78, 1593–1595 (2012).

Buescher, J. M., Moco, S., Sauer, U. & Zamboni, N. Ultrahigh performance liquid chromatography− tandem mass spectrometry method for fast and robust quantification of anionic and aromatic metabolites. Anal. Chem. 82, 4403–4412 (2010).

Acknowledgements

We thank Dr Xin Yan (Nanjing Agriculture University) for providing plasmid pDGREF. We thank Dr Manuel Hörl for help for dynamic labelling experiment design. This work was supported by China Scholarship Council, 111 Project (111-2-06) and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Contributions

Y.L. designed and performed the experiments. H.L. designed and performed the modelling. Y.L., H.L., L.L., G.D., U.S. and J.C. conceived the project, analysed the data and wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1-7 and Supplementary Tables 1-7 (PDF 1199 kb)

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Liu, Y., Link, H., Liu, L. et al. A dynamic pathway analysis approach reveals a limiting futile cycle in N-acetylglucosamine overproducing Bacillus subtilis. Nat Commun 7, 11933 (2016). https://doi.org/10.1038/ncomms11933

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms11933

This article is cited by

-

CRISPR–dCas12a-mediated genetic circuit cascades for multiplexed pathway optimization

Nature Chemical Biology (2023)

-

Chitin oligosaccharides for the food industry: production and applications

Systems Microbiology and Biomanufacturing (2023)

-

Engineering the transmission efficiency of the noncyclic glyoxylate pathway for fumarate production in Escherichia coli

Biotechnology for Biofuels (2020)

-

Titrating bacterial growth and chemical biosynthesis for efficient N-acetylglucosamine and N-acetylneuraminic acid bioproduction

Nature Communications (2020)

-

Improving enzyme activity of glucosamine-6-phosphate synthase by semi-rational design strategy and computer analysis

Biotechnology Letters (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.