Abstract

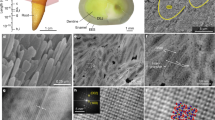

Tooth enamel comprises parallel microscale and nanoscale ceramic columns or prisms interlaced with a soft protein matrix1,2,3. This structural motif is unusually consistent across all species from all geological eras4,5,6. Such invariability—especially when juxtaposed with the diversity of other tissues—suggests the existence of a functional basis. Here we performed ex vivo replication of enamel-inspired columnar nanocomposites by sequential growth of zinc oxide nanowire carpets followed by layer-by-layer deposition of a polymeric matrix around these. We show that the mechanical properties of these nanocomposites, including hardness, are comparable to those of enamel despite the nanocomposites having a smaller hard-phase content. Our abiotic enamels have viscoelastic figures of merit (VFOM) and weight-adjusted VFOM that are similar to, or higher than, those of natural tooth enamels—we achieve values that exceed the traditional materials limits of 0.6 and 0.8, respectively. VFOM values describe resistance to vibrational damage, and our columnar composites demonstrate that light-weight materials of unusually high resistance to structural damage from shocks, environmental vibrations and oscillatory stress can be made using biomimetic design. The previously inaccessible combinations of high stiffness, damping and light weight that we achieve in these layer-by-layer composites are attributed to efficient energy dissipation in the interfacial portion of the organic phase. The in vivo contribution of this interfacial portion to macroscale deformations along the tooth’s normal is maximized when the architecture is columnar, suggesting an evolutionary advantage of the columnar motif in the enamel of living species. We expect our findings to apply to all columnar composites and to lead to the development of high-performance load-bearing materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

He, L. H. & Swain, M. V. Understanding the mechanical behaviour of human enamel from its structural and compositional characteristics. J. Mech. Behav. Biomed. Mater. 1, 18–29 (2008)

Moradian-Oldak, J. Protein-mediated enamel mineralization. Front. Biosci. Landmark Ed. 17, 1996–2023 (2012)

Palmer, L. C., Newcomb, C. J., Kaltz, S. R., Spoerke, E. D. & Stupp, S. I. Biomimetic systems for hydroxyapatite mineralization inspired by bone and enamel. Chem. Rev. 108, 4754–4783 (2008)

Hwang, S. H. The evolution of dinosaur tooth enamel microstructure. Biol. Rev. Camb. Phil. Soc. 86, 183–216 (2011)

Weiner, S. & Addadi, L. Design strategies in mineralized biological materials. J. Mater. Chem. 7, 689–702 (1997)

Balooch, G. et al. Evaluation of a new modulus mapping technique to investigate microstructural features of human teeth. J. Biomech. 37, 1223–1232 (2004)

Meyers, M. A., McKittrick, J. & Chen, P. Y. Structural biological materials: critical mechanics-materials connections. Science 339, 773–779 (2013)

Espinosa, H. D., Rim, J. E., Barthelat, F. & Buehler, M. J. Merger of structure and material in nacre and bone — perspectives on de novo biomimetic materials. Prog. Mater. Sci. 54, 1059–1100 (2009)

Weaver, J. C. et al. The stomatopod dactyl club: a formidable damage-tolerant biological hammer. Science 336, 1275–1280 (2012)

Jackson, A. P., Vincent, J. F. V. & Turner, R. M. The mechanical design of nacre. Proc. R. Soc. Lond. B 234, 415–440 (1988)

Wang, R. Z., Suo, Z., Evans, A. G., Yao, N. & Aksay, I. A. Deformation mechanisms in nacre. J. Mater. Res. 16, 2485–2493 (2001)

Tang, Z., Kotov, N. A., Magonov, S. & Ozturk, B. Nanostructured artificial nacre. Nat. Mater. 2, 413–418 (2003)

Sarikaya, M. Biomimetics: materials fabrication through biology. Proc. Natl Acad. Sci. USA 96, 14183–14185 (1999)

Cuif, J.-P., Dauphin, Y., Nehrke, G., Nouet, J. & Perez-Huerta, A. Layered growth and crystallization in calcareous biominerals: impact of structural and chemical evidence on two major concepts in invertebrate biomineralization studies. Minerals 2, 11–39 (2012)

Achrai, B. & Wagner, H. D. Micro-structure and mechanical properties of the turtle carapace as a biological composite shield. Acta Biomater. 9, 5890–5902 (2013)

Wang, R. Z., Addadi, L. & Weiner, S. Design strategies of sea urchin teeth: structure, composition and micromechanical relations to function. Phil. Trans. R. Soc. Lond. B 352, 469–480 (1997)

Munch, E. et al. Tough, bio-inspired hybrid materials. Science 322, 1516–1520 (2008)

Killian, C. E. et al. Mechanism of calcite co-orientation in the sea urchin tooth. J. Am. Chem. Soc. 131, 18404–18409 (2009)

Cho, B.-K., Jain, A., Gruner, S. M. & Wiesner, U. Mesophase structure-mechanical and ionic transport correlations in extended amphiphilic dendrons. Science 305, 1598–1601 (2004)

Erb, R. M., Libanori, R., Rothfuchs, N. & Studart, A. R. Composites reinforced in three dimensions by using low magnetic fields. Science 335, 199–204 (2012)

Meaud, J. et al. Simultaneously high stiffness and damping in nanoengineered microtruss composites. ACS Nano 8, 3468–3475 (2014)

Greene, L. E. et al. Low-temperature wafer-scale production of ZnO nanowire arrays. Angew. Chem. 42, 3031–3034 (2003)

Podsiadlo, P. et al. Ultrastrong and stiff layered polymer nanocomposites. Science 318, 80–83 (2007)

Ruan, Q. et al. Amelogenin and enamel biomimetics. J. Mater. Chem. B 3, 3112–3129 (2015)

Lowenstam, H. & Weiner, S. On Biomineralization (Oxford Univ. Press, 1989)

Wang, Y. C., Ludwigson, M. & Lakes, R. S. Deformation of extreme viscoelastic metals and composites. Mater. Sci. Eng. A 370, 41–49 (2004)

Lakes, R. S., Lee, T., Bersie, A. & Wang, Y. C. Extreme damping in composite materials with negative-stiffness inclusions. Nature 410, 565–567 (2001)

Ryou, H., Romberg, E., Pashley, D. H., Tay, F. R. & Arola, D. Nanoscopic dynamic mechanical properties of intertubular and peritubular dentin. J. Mech. Behav. Biomed. Mater. 7, 3–16 (2012)

Zhang, P. & To, A. C. Highly enhanced damping figure of merit in biomimetic hierarchical staggered composites. J. Appl. Mech. 81, 051015 (2014)

Hu, K., Kulkarni, D. D., Choi, I. & Tsukruk, V. V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 39, 1934–1972 (2014)

Li, Y., Waas, A. M. & Arruda, E. M. The effects of the interphase and strain gradients on the elasticity of layer by layer (LBL) polymer/clay nanocomposites. Int. J. Solids Struct. 48, 1044–1053 (2011)

Acknowledgements

We acknowledge support from DARPA (grant HR0011-10-C-0192, MATLOG programme) and NextGen Aeronautics. We also acknowledge support from the NSF under grants ECS-0601345, CBET 0933384, CBET 0932823 and CBET 1036672. This work was also partially supported by the US Department of Defense under grant award no. MURI W911NF-12-1-0407. We thank the University of Michigan’s Electron Microscopy and Analysis Laboratory (EMAL) for assistance with electron microscopy, and the NSF for grants (numbers DMR-0320740 and DMR-9871177) funding the purchase of the JEOL 2010F analytical electron microscope used in this work. This work was supported by a National Research Foundation of Korea (NRF) grant (no. NRF-2015R1D1A1A01058029) funded by the Government of Korea (Ministry of Education). We also thank A. Jung for help with scanning electron microscopy.

Author information

Authors and Affiliations

Contributions

N.A.K. and B.Y. conceived the project and designed the experiments. B.Y. and S.H.C. carried out the design and fabrication of the columnar composites and LBL films, and performed the mechanical testing experiments. T.S., A.M.W. and E.M.A. were responsible for the finite-element modelling data and assisted in the mechanical testing of the composites. N.L. was responsible for selecting the coarse grained model, and for performing molecular dynamics simulations and analysing the data. D.B. performed SEM imaging of the teeth. N.A.K., B.Y., T.S. and N.L. co-wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

This file contains Supplementary Text and Data, Supplementary Figures 1-10, Supplementary Tables 1-2, Supplementary Comments 1-2 and additional references. (PDF 1289 kb)

Rights and permissions

About this article

Cite this article

Yeom, B., Sain, T., Lacevic, N. et al. Abiotic tooth enamel. Nature 543, 95–98 (2017). https://doi.org/10.1038/nature21410

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature21410

This article is cited by

-

Inorganic ionic polymerization: From biomineralization to materials manufacturing

Nano Research (2024)

-

Research progress of biomimetic materials in oral medicine

Journal of Biological Engineering (2023)

-

Occlusive membranes for guided regeneration of inflamed tissue defects

Nature Communications (2023)

-

Biomimetic Construction of the Enamel-like Hierarchical Structure

Chemical Research in Chinese Universities (2023)

-

Graphene oxide bulk material reinforced by heterophase platelets with multiscale interface crosslinking

Nature Materials (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.