Abstract

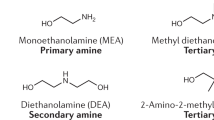

Copper and zinc form an important group of hydroxycarbonate minerals that include zincian malachite, aurichalcite, rosasite and the exceptionally rare and unstable—and hence little known and largely ignored1—georgeite. The first three of these minerals are widely used as catalyst precursors2,3,4 for the industrially important methanol-synthesis and low-temperature water–gas shift (LTS) reactions5,6,7, with the choice of precursor phase strongly influencing the activity of the final catalyst. The preferred phase2,3,8,9,10 is usually zincian malachite. This is prepared by a co-precipitation method that involves the transient formation of georgeite11; with few exceptions12 it uses sodium carbonate as the carbonate source, but this also introduces sodium ions—a potential catalyst poison. Here we show that supercritical antisolvent (SAS) precipitation using carbon dioxide (refs 13, 14), a process that exploits the high diffusion rates and solvation power of supercritical carbon dioxide to rapidly expand and supersaturate solutions, can be used to prepare copper/zinc hydroxycarbonate precursors with low sodium content. These include stable georgeite, which we find to be a precursor to highly active methanol-synthesis and superior LTS catalysts. Our findings highlight the value of advanced synthesis methods in accessing unusual mineral phases, and show that there is room for exploring improvements to established industrial catalysts.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Bridge, P. J., Just, J. & Hey, M. H. Georgeite, a new amorphous copper carbonate from the Carr Boyd Mine, Western Australia. Mineral. Mag. 43, 97–98 (1979)

Spencer, M. S. The role of zinc oxide in Cu/ZnO catalysts for methanol synthesis and the water-gas shift reaction. Top. Catal. 8, 259–266 (1999)

Behrens, M. Meso- and nano-structuring of industrial Cu/ZnO/(Al2O3) catalysts. J. Catal. 267, 24–29 (2009)

Fujitani, T. & Nakamura, J. The effect of ZnO in methanol synthesis catalysts on Cu dispersion and the specific activity. Catal. Lett. 56, 119–124 (1998)

Chinchen, G. C., Denny, P. J., Jennings, J. R., Spencer, M. S. & Waugh, K. C. Synthesis of methanol. Part 1. Catalysts and kinetics. Appl. Catal. 36, 1–65 (1988)

Rhodes, C., Hutchings, G. J. & Ward, A. M. Water-gas shift reaction: finding the mechanistic boundary. Catal. Today 23, 43–58 (1995)

Short, G. D., Chinchen, G. C. & Williamson, J. G. Synthesis of methanol; finely divided oxides of zinc, aluminum, magnesium; with metallic copper. US patent 4, 788,175 (1988)

Behrens, M. et al. The active site of methanol synthesis over Cu/ZnO/Al2O3 industrial catalysts. Science 336, 893–897 (2012)

Baltes, C., Vukojevic, S. & Schueth, F. Correlations between synthesis, precursor, and catalyst structure and activity of a large set of CuO/ZnO/Al2O3 catalysts for methanol synthesis. J. Catal. 258, 334–344 (2008)

Bems, B. et al. Relations between synthesis and microstructural properties of copper/zinc hydroxycarbonates. Chemistry 9, 2039–2052 (2003)

Pollard, A. M. et al. Georgeite and azurite as precursors in the preparation of coprecipitated copper/zinc oxide catalysts. Appl. Catal. A 85, 1–11 (1992)

Prieto, G., de Jong, K. P. & de Jongh, P. E. Towards ‘greener’ catalyst manufacture: reduction of wastewater from the preparation of Cu/ZnO/Al2O3 methanol synthesis catalysts. Catal. Today 215, 142–151 (2013)

Tang, Z.-R. et al. New nanocrystalline Cu/MnOx catalysts prepared from supercritical antisolvent precipitation. ChemCatChem 1, 247–251 (2009)

Reverchon, E. Supercritical antisolvent precipitation of micro- and nano-particles. J. Supercrit. Fluids 15, 1–21 (1999)

Rogers, A. P. A review of the amorphous minerals. J. Geol. 25, 515–541 (1917)

Pollard, A. M., Thomas, R. G., Williams, P. A., Just, J. & Bridge, P. J. The synthesis and composition of georgeite and its reactions to form other secondary copper(II) carbonates. Mineral. Mag. 55, 163–166 (1991)

Behrens, M. et al. Performance improvement of nanocatalysts by promoter-induced defects in the support material: methanol synthesis over Cu/ZnO:Al. J. Am. Chem. Soc. 135, 6061–6068 (2013)

Campbell, J. S. Influences of catalyst formulation and poisoning on the activity and die-off of low temperature shift catalysts. Ind. Eng. Chem. Process Des. Dev. 9, 588–595 (1970)

Schur, M. et al. Continuous coprecipitation of catalysts in a micromixer: nanostructured Cu/ZnO composite for the synthesis of methanol. Angew. Chem. Int. Edn 42, 3815–3817 (2003)

Rothe, J., Hormes, J., Bonnemann, H., Brijoux, W. & Siepen, K. In situ X-ray absorption spectroscopy investigation during the formation of colloidal copper. J. Am. Chem. Soc. 120, 6019–6023 (1998)

Klokishner, S. et al. Cation ordering in natural and synthetic (Cu1-xZnx)2CO3(OH)2 and (Cu1-xZnx)5(CO3)2(OH)6 . J. Phys. Chem. A 115, 9954–9968 (2011)

Behrens, M. & Girgsdies, F. Structural effects of Cu/Zn substitution in the malachite-rosasite System. Z. Anorg. Allg. Chem. 636, 919–927 (2010)

Michel, F. M. et al. Short- to medium-range atomic order and crystallite size of the initial FeS precipitate from pair distribution function analysis. Chem. Mater. 17, 6246–6255 (2005)

Harding, M. M., Kariuki, B. M., Cernik, R. & Cressey, G. The structure of aurichalcite, (CuZn)5(OH)6(CO3)2 determined from a microcrystal. Acta Crystallogr. B 50, 673–676 (1994)

Belokoneva, E. L., Gubina, Y. K. & Forsyth, J. B. The charge density distribution and antiferromagnetic properties of azurite Cu3[CO3]2(OH)2 . Phys. Chem. Miner. 28, 498–507 (2001)

Perchiazzi, N. & Merlino, S. The malachite-rosasite group: crystal structures of glaukosphaerite and pokrovskite. Eur. J. Mineral. 18, 787–792 (2006)

Belin, S. et al. CuAu/SiO2 catalysts for the selective oxidation of propene to acrolein: the impact of catalyst preparation variables on material structure and catalytic performance. Catal. Sci. Technol. 3, 2944–2957 (2013)

Chinchen, G. C., Waugh, K. C. & Whan, D. A. The activity and state of the copper surface in methanol synthesis catalysts. Appl. Catal. 25, 101–107 (1986)

Behrens, M. et al. The potential of microstructural optimization in metal/oxide catalysts: higher intrinsic activity of copper by partial embedding of copper nanoparticles. Chem. Cat. Chem . 2, 816–818 (2010)

Coelho, A. A. TOPAS Academic: General Profile and Structure Analysis Software for Powder Diffraction Data (Bruker AXS, Karlsruhe, 2010)

Balzar, D. et al. Size-strain line-broadening analysis of the ceria round-robin sample. J. Appl. Cryst. 37, 911–924 (2004)

Newville, M. IFEFFIT: interactive XAFS analysis and FEFF fitting. J. Synchrotron Radiat. 8, 322–324 (2001)

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005)

Chupas, P. J. et al. Rapid-acquisition pair distribution function (RA-PDF) analysis. J. Appl. Cryst. 36, 1342–1347 (2003)

Soper, A. K. & Barney, E. R. Extracting the pair distribution function from white-beam X-ray total scattering data. J. Appl. Cryst. 44, 714–726 (2011)

Keen, D. A. A comparison of various commonly used correlation functions for describing total scattering. Angew. Chem. Int. Edn 53, 7043–7047 (2014)

Fichtl, M. B. et al. Counting of oxygen defects versus metal surface sites in methanol synthesis catalysts by different probe molecules. J. Appl. Cryst. 34, 172–177 (2001)

Kuld, S., Conradsen, C., Moses, P. G., Chorkendorff, I. & Sehested, J. Quantification of zinc atoms in a surface alloy on copper in an industrial-type methanol synthesis catalyst. Angew. Chem. Int. Edn 53, 5941–5945 (2014)

Hansen, T. W., Wagner, J. B. & Dunin-Borkowski, R. E. Aberration corrected and monochromated environmental transmission electron microscopy: challenges and prospects for materials science. Mater. Sci. Technol. 26, 1338–1344 (2010)

Acknowledgements

We thank C. Brookes, L. Van de Water, H. Stanness and C. Ramson for technical assistance. We thank Johnson Matthey and the Engineering and Physical Sciences Research Council (EPSRC) for funding though a CASE award, and acknowledge funding from the UK Technology Strategy Board and the EPSRC and UK Catalysis Hub (grants EP/K014714/1, EP/K014714/1, EP/K014668/1, EP/K014706/1, EP/H000925/1 and EP/I019693/1). We used the B18 beamline at the Diamond Light Source (allocation number SP8071) with the help of D. Gianolio and G. Cibin; and we used the I15 beamline, which contributed to the PDF results. This research used the resources of the Advanced Photon Source (APS)—a US Department of Energy (DOE) Office of Science User Facility, operated for the DOE Office of Science by Argonne National Laboratory under contract DE-AC02-06CH11357; we thank K. Chapman for collecting PDF data at beamline 11-ID-B, APS. C.J.K acknowledges funding from the National Science Foundation Major Research Instrumentation program (GR#MRI/DMR-1040229). M.J.R. is a Royal Society Research Professor. We thank the A.P. Møller and Chastine Mc-Kinney Møller Foundation for contributing to the establishment of the Center for Electron Nanoscopy in the Technical University of Denmark. Source data for Figs 1, 2, 3 are available at http://dx.doi.org/10.17035/d.2015.0008102108.

Author information

Authors and Affiliations

Contributions

S.A.K., J.K.B., S.H.T., M.S.S., G.J.K., C.W.P., M.J.R., C.J.K. and G.J.H. designed the experiments. S.A.K. and P.J.S. prepared samples for TGA/EGA analysis and IR spectroscopy; S.A.K., P.J.S. and J.H.C. carried out the catalysis evaluation and determination of copper surface area; S.A.K., P.J.S. and P.A.C. carried out the XRD analysis; P.A.C. carried out the PDF analysis; P.P.W., S.A.K. and P.J.S. carried out the XAFS and interpretation; L.L. and C.J.K. carried out the TEM and interpretation; E.M.F., J.B.W., C.J.K. and S.A.K. carried out the ETEM and interpretation; D.J.M., P.J.S. and S.A.K. carried out the XPS and interpretation. S.A.K., C.J.K., J.B.W., G.J.K., M.J.R. and G.J.H. wrote and edited the manuscript. G.J.H. directed the research.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Extended data figures and tables

Extended Data Figure 1 FT-IR and XRD characterization of SAS copper and copper/zinc acetate precipitates.

Key: i, SAS-prepared copper acetate; ii, SAS-prepared georgeite; iii, malachite prepared by co-precipitation; iv, 2/1 copper/zinc malachite prepared by co-precipitation; v, SAS-prepared 2/1 copper/zinc georgeite; vi, SAS-prepared 1/1 copper/zinc georgeite; vii, SAS-prepared zmithsonite (ZnCO3). a, XRD analysis of copper-only samples. b, FT-IR analysis of copper-only samples. c, FT-IR band assignment of copper-only samples, with (reference) designated as received copper(ii) acetate monohydrate. Values given are for IR band positions in wavenumbers (cm−1). *The presence of this band shows that SAS precipitation with no additional water co-solvent produced some georgeite as well as amorphous copper acetate. We attribute the formation of georgeite to the small amount of water present from the monohydrated starting salt. d, IR spectrum of mineralogical georgeite, reproduced with the permission of the Mineralogical Society of Great Britain and Ireland from ref. 11. e, FT-IR spectra of copper/zinc samples. f, XRD of copper/zinc samples.

Extended Data Figure 2 Elemental composition of copper and copper/zinc samples, with supplementary TGA analysis.

a, Elemental composition of SAS-prepared georgeite and co-precipitated malachite samples. Elemental composition was determined by CHN analysis and ICP-MS. Densities were determined by helium pycnometry. aValues from ref. 11. bValues from ref. 16. *Density determined by sink–float (SF) method. The helium pycnometry used in our present study provides a skeletal density that negates buoyancy effects. b, Comparison of experimental and calculated mass losses for georgeite and malachite from TGA measurements. *Calculated from the assumption of final products being 2/1 copper oxide/zinc oxide. The lower-than-expected mass losses for the zincian phases could be associated with the inclusion of copper ions in the zinc oxide lattice. c, TGA analysis of 2/1 copper/zinc georgeite (red line) and 1/1 copper/zinc georgeite (black line).

Extended Data Figure 3 Representative STEM micrographs of the zincian georgeite precursor.

Left, dark-field (DF) STEM micrograph. Right, bright-field (BF) micrograph. The general morphology of the zincian-georgeite precursor is shown in the DF-STEM micrograph. It typically consists of very characteristic, irregularly shaped agglomerates, about 100–200 nm in diameter, that are composed of ‘amorphous’ non-faceted particles about 40 nm wide. Closer inspection by BF-STEM shows that these non-faceted particles consist of an amorphous matrix phase in which are embedded largely disconnected, sub-2-nm crystallites of ordered material exhibiting clear lattice fringes. The amorphous matrix, probably containing the carbonate and hydroxyl species, is by far the majority phase, while the nanocrystallites make up less than 10% of the material by volume. This observation is consistent with our other characterization data, as signals from the matrix phase would dominate the XAFS analysis, whereas the nanocrystallites are too small in dimension to be detected by XRD. Analysis of fringe spacings and interplanar angles of individual nanocrystallites from such images suggests that some of the grains could be CuO (tenorite, where the copper is fourfold coordinated by oxygen), while others fit better to Cu2O (cuprite, where the copper has a coordination number of 2). No convincing matches of the lattice fringes to either ZnO or ZnCO3 could be found.

Extended Data Figure 4 Further catalyst testing in methanol-synthesis and LTS reactions.

Filled red triangles, 2/1 Cu/Zn georgeite; open triangles, 1/1 Cu/Zn georgeite; open squares, industrial standard; filled blue squares, 2/1 Cu/Zn malachite (this test was terminated after 190 °C because of poor activity). a, b, Methanol-synthesis data, normalized to total catalyst mass (a) and copper mass (b), at 190–250 °C. The dashed line shows the representative reactor-bed temperature. Reaction conditions were as follows: pressure 25 bar; gas composition CO/CO2/H2/N2 = 6/9.2/67/17.8; MHSV = 7,200 l kg−1 h−1. c, Concentration of byproducts that were collected in the condensate pot after the methanol-synthesis reaction, as determined by gas-chromatographic (GC) analysis. Byproducts are: ethanol (blue), propanol (red), butanol (green), iso-butanol (purple), and methyl iso-butyl ketone (turquoise). d, e, LTS-reaction data, normalized to total catalyst mass (d) and copper mass (e). Reaction conditions were as follows: temperature 220 °C; pressure 27.5 bar; gas composition H2O/CO/CO2/H2/N2 = 50/2/8/27.35/12.5; MHSV = 75,000 l kg−1 h−1. f, Concentration of methanol collected in the condensate pot after the LTS reaction, as determined by GC analysis. g, Methanol-synthesis productivities and LTS activities, normalized by copper surface area. *Copper surface area analysis determined by N2O reactive frontal chromatography before testing. §Methanol-synthesis data acquired at 190 °C, with steady state being at 18 hours’ time-on-line. ^LTS data acquired at 220 °C, with steady state being at 40 hours time-on-line. Note that LTS simulation testing showed that copper surface area dropped markedly after 40 hours (to 17 m2 g−1 and 19 m2 g−1 for zincian-georgeite-derived and zincian-malachite-derived catalysts, respectively). The inverse correlation between copper surface area and initial productivity also suggests that loss of surface area occurs rapidly during the reaction and that the initial rate data are therefore likely to be inaccurate.

Extended Data Figure 5 Spectroscopic analysis of the addition of zinc to georgeite.

a, Diffuse reflectance UV–vis spectra of zincian malachite (red) and zincian georgeite (black). b, Copper K-edge EXAFS (χ) comparison of zincian georgeite (with a 4/1 or 2/1 copper/zinc ratio) with georgeite. c, Zinc K-edge XANES comparison of zincian georgeite with SAS-prepared smithsonite. d, Zinc K-edge EXAFS (χ) comparison of zincian georgeite with SAS-prepared smithsonite. e, Comparison of observed georgeite PDF data with simulated data for crystalline hydroxycarbonate minerals with similar compositions to that of georgeite—namely aurichalcite, azurite, rosasite, zincian malachite and malachite.

Extended Data Figure 6 Representative DF-STEM and BF-STEM micrographs of zincian georgeite and zincian malachite, calcined at 300 °C.

a, DF-STEM of calcined zincian georgeite. Higher-magnification imaging reveals that, after much of the carbonate and hydroxyl content is lost by calcination, most of the disordered matrix material in the precursor has crystallized, and only a small amount of amorphous material remains. The crystallized material is entirely in a nanocrystalline form, with a mean grain diameter of 3–4 nm, which is just below the detection limit for XRD. Analysis of the fringe spacings and interplanar angles from individual grains suggests that the material is now mainly an intimate mixture of zinc and copper oxides; the small amount of disordered material corresponds to the residual occluded carbonate material, as detected by TGA/EGA analysis of this material. b, BF-STEM of calcined zincian georgeite. c, DF-STEM of calcined zincian malachite. d, BF-STEM of calcined zincian malachite.

Extended Data Figure 7 X-ray diffraction analysis of calcined zincian georgeite and zincian malachite.

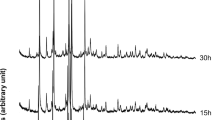

a, PDF of zincian georgeite, as prepared and after calcination at 120 °C, 200 °C, 250 °C, 300 °C and 450 °C. There is little change in the observed PDF up to 250 °C, other than a slight peak broadening, which can be attributed to a reduction in short-range order. The dashed line shows the position of the C–O peak, which is retained until temperatures higher than 300 °C. b, PDF and c, Rietveld fits of zincian georgeite after calcination at 450 °C. The measured data are shown as open circles; the fit is a solid black line; the difference is a grey line. Both techniques determine the product to be a mixture of copper oxide and zinc oxide (weight ratio of 68/32 by PDF; 67.7(4)/32.3(4) by Rietveld). d, Ex situ XRD patterns following calcination of zincian georgeite for 2 hours at 250 °C, 300 °C and 450 °C. Open circles, copper oxide; filled squares, zinc oxide. e, f, In situ XRD analysis of zincian georgeite (d) and zincian malachite (e) during calcination between 300 °C and 500 °C under an atmosphere of static air, with XRD scans every 25 °C.

Extended Data Figure 8 Copper K-edge XAFS analysis of zincian georgeite and zincian malachite calcined at 300 °C.

a, EXAFS (χ) comparison of copper oxide, calcined zincian georgeite, zincian georgeite and georgeite. b, EXAFS (R) comparison of copper oxide (green), calcined zincian georgeite (black) and zincian georgeite (blue). c–e, Linear combination fit of copper oxide and zinc oxide with zincian malachite calcined at 300 °C.

Extended Data Figure 9 In situ characterization of final-state, reduced copper/zinc-oxide catalysts derived from zincian georgeite and zincian malachite, calcined at 300 °C.

a, XRD of zincian-georgeite-derived catalyst after in situ hydrogen reduction (2% H2/N2 at 225 °C for 1 hour). Fine dotted lines indicate zinc-oxide reflections; dashed lines indicate metallic copper. b, Copper K-edge EXAFS Fourier transorm of final reduced catalysts derived from zincian georgeite and zincian malachite. c, Copper K-edge EXAFS fit of reduced catalysts. d, Zinc K-edge EXAFS Fourier transform of final reduced catalysts derived from zincian georgeite and zincian malachite. e, Zinc K-edge EXAFS fit of reduced catalysts. f, Electron energy-loss spectra (EELS) of georgeite and malachite, respectively, during reduction in the ETEM experiment. The EELS data were acquired in 2 mbar H2 at 225 ºC, and show the fine structure of the Cu L2,3 ionization edges, which are characteristic of metallic Cu0. g, EXAFS fitting data for copper and zinc K-edge data. Fitting parameters for K-edge copper: amplitude-reduction factor (S02) = 0.91, as deduced from copper-foil standard; fit range 3<k<11.2, 1<R<5.5 (with k denoting the fitting window from the χ data, and R, the path length, denoting the fitting from the Fourier transform of the χ data); number of independent points = 23; *denotes multiple scattering path. Fitting parameters for K-edge Zn: S20=0.90 as deduced from a ZnO2 standard; fit range 3.3<k<9.5, 1<R<4.8; number of independent points = 16; *denotes multiple scattering path. h, XPS analysis of calcined and reduced catalysts derived from zincian georgeite and zincian malachite.

Rights and permissions

About this article

Cite this article

Kondrat, S., Smith, P., Wells, P. et al. Stable amorphous georgeite as a precursor to a high-activity catalyst. Nature 531, 83–87 (2016). https://doi.org/10.1038/nature16935

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature16935

This article is cited by

-

Perovskite Supported Catalysts for the Selective Oxidation of Glycerol to Tartronic Acid

Catalysis Letters (2023)

-

Highlights and challenges in the selective reduction of carbon dioxide to methanol

Nature Reviews Chemistry (2021)

-

Following the structure of copper-zinc-alumina across the pressure gap in carbon dioxide hydrogenation

Nature Catalysis (2021)

-

Self-regeneration of supported transition metals by a high entropy-driven principle

Nature Communications (2021)

-

CO2 Hydrogenation to Methanol over Copper Catalysts: Learning from Syngas Conversion

Topics in Catalysis (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.