Abstract

Passive anti-icing surfaces, or icephobic surfaces, are an area of great interest because of their significant economic, energy and safety implications in the prevention and easy removal of ice in many facets of society. The complex nature of icephobicity, which requires performance in a broad range of icing scenarios, creates many challenges when designing ice-repellent surfaces. Although superhydrophobic surfaces incorporating micro- or nanoscale roughness have been shown to prevent ice accumulation under certain conditions, the same roughness can be detrimental in other environments. Surfaces that present a smooth liquid interface can eliminate some of the drawbacks of textured superhydrophobic surfaces, but additional study is needed to fully realize their potential. As attention begins to shift towards alternative anti-icing strategies, it is important to consider and to understand the nature of ice repellency in all environments to identify the limitations of current solutions and to design new materials with robust icephobicity.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Cassie, A. B. D. & Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 40, 546–551 (1944).

Holman, H. P. & Jarrell, T. D. The effects of waterproofing materials and outdoor exposure upon the tensile strength of cotton yarn. Ind. Eng. Chem. 15, 236–240 (1923).

McBurney, D. Coated fabrics in construction industry. Ind. Eng. Chem. 27, 1400–1403 (1935).

Young, T. An essay on the cohesion of fluids. Phil. Trans. R. Soc. 95, 65–87 (1805).

Rickard, T. A. & Ralston, O. C. Flotation (Mining and Scientific Press, 1917).

Gibbs, J. W. On the equilibrium of heterogeneous substances. Trans. Connect. Acad. Arts Sci. 3, 343–524 (1878).

Eral, H. B., ’t Mannetje, D. J. C. M. & Oh, J. M. Contact angle hysteresis: a review of fundamentals and applications. Colloid Polym. Sci. 291, 247–260 (2013).

Krasovitski, B. & Marmur, A. Drops down the hill: theoretical study of limiting contact angles and the hysteresis range on a tilted plate. Langmuir 21, 3881–3885 (2005).

Nosonovsky, M. Model for solid–liquid and solid–solid friction of rough surfaces with adhesion hysteresis. J. Chem. Phys. 126, 224701 (2007).

Tadmor, R. Line energy and the relation between advancing, receding, and young contact angles. Langmuir 20, 7659–7664 (2004).

Wenzel, R. N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 28, 988–994 (1936).

Cassie, A. B. D. Contact angles. Discuss. Faraday Soc. 3, 11–16 (1948).

de Gennes, P.-G., Brochard-Wyart, F. & Quéré, D. Capillarity and Wetting Phenomena: Drops, Bubbles, Pearls, Waves (Springer Science & Business Media, 2013).

Carraher, C. E. Jr Introduction to Polymer Chemistry (CRC, 2012).

Ulman, A. Formation and structure of self-assembled monolayers. Chem. Rev. 96, 1533–1554 (1996).

Onda, T., Shibuichi, S., Satoh, N. & Tsujii, K. Super-water-repellent fractal surfaces. Langmuir 12, 2125–2127 (1996).

Barthlott, W. & Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 202, 1–8 (1997).

Simpson, J. T., Hunter, S. R. & Aytug, T. Superhydrophobic materials and coatings: a review. Rep. Prog. Phys. 78, 086501 (2015).

Liu, K. & Jiang, L. Metallic surfaces with special wettability. Nanoscale 3, 825–838 (2011).

Si, Y. & Guo, Z. Superhydrophobic nanocoatings: from materials to fabrications and to applications. Nanoscale 7, 5922–5946 (2015).

Quéré, D. Wetting and roughness. Annu. Rev. Mater. Res. 38, 71–99 (2008).

Quéré, D. Non-sticking drops. Rep. Prog. Phys. 68, 2495–2532 (2005).

Ahuja, A. et al. Nanonails: a simple geometrical approach to electrically tunable superlyophobic surfaces. Langmuir 24, 9–14 (2008).

Tuteja, A. et al. Designing superoleophobic surfaces. Science 318, 1618–1622 (2007).

Liu, T. L. & Kim, C.-J. C. Turning a surface superrepellent even to completely wetting liquids. Science 346, 1096–1100 (2014).

Wong, T.-S. et al. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 477, 443–447 (2011).

Lafuma, A. & Quéré, D. Slippery pre-suffused surfaces. Europhys. Lett. 96, 56001 (2011).

Aizenberg, J., Aizenberg, M., Kang, S. H., Wong, T. S. & Kim, P. Slippery surfaces with high pressure stability, optical transparency, and self-healing characteristics. US patent 9-121-306 (2013).

Aizenberg, J., Aizenberg, M., Kang, S. H., Wong, T. S. & Kim, P. Slippery surfaces with high pressure stability, optical transparency, and self-healing characteristics. US patent 9-121-307 (2013).

Kim, P. et al. Liquid-infused nanostructured surfaces with extreme anti-ice and anti-frost performance. ACS Nano 6, 6569–6577 (2012). This work establishes the potential of liquid-infused surfaces for icephobicity, demonstrating very low ice adhesion in addition to high performance in frosting environments that cause traditional SHSs to fail.

Anand, S., Paxson, A. T., Dhiman, R., Smith, J. D. & Varanasi, K. K. Enhanced condensation on lubricant-impregnated nanotextured surfaces. ACS Nano 6, 10122–10129 (2012).

Manabe, K., Nishizawa, S., Kyung, K. & Shiratori, S. Optical phenomena and antifrosting property on biomimetics slippery fluid-infused antireflective films via layer-by-layer comparison with superhydrophobic and antireflective films. ACS Appl. Mater. Interfaces 6, 13985–13993 (2014).

Ma, W., Higaki, Y., Otsuka, H. & Takahara, A. Perfluoropolyether-infused nano-texture: a versatile approach to omniphobic coatings with low hysteresis and high transparency. Chem. Commun. 49, 597–599 (2013).

Sunny, S., Vogel, N., Howell, C., Vu, T. L. & Aizenberg, J. Lubricant-infused nanoparticulate coatings assembled by layer-by-layer deposition. Adv. Funct. Mater. 24, 6658–6667 (2014).

Huang, X., Chrisman, J. D. & Zacharia, N. S. Omniphobic slippery coatings based on lubricant-infused porous polyelectrolyte multilayers. ACS Macro Lett. 2, 826–829 (2013).

Liu, Q. et al. Durability of a lubricant-infused electrospray silicon rubber surface as an anti-icing coating. Appl. Surf. Sci. 346, 68–76 (2015).

Vogel, N., Belisle, R. A., Hatton, B., Wong, T.-S. & Aizenberg, J. Transparency and damage tolerance of patternable omniphobic lubricated surfaces based on inverse colloidal monolayers. Nat. Commun. 4, 2176 (2013).

Bhushan, B. Biomimetics inspired surfaces for drag reduction and oleophobicity/philicity. Beilstein J. Nanotechnol. 2, 66–84 (2011).

Liu, K. & Jiang, L. Bio-inspired self-cleaning surfaces. Annu. Rev. Mater. Res. 42, 231–263 (2012).

Lv, J., Song, Y., Jiang, L. & Wang, J. Bio-inspired strategies for anti-icing. ACS Nano 8, 3152–3169 (2014).

Zhang, P. & Lv, F. Y. A review of the recent advances in superhydrophobic surfaces and the emerging energy-related applications. Energy 82, 1068–1087 (2015).

Attinger, D. et al. Surface engineering for phase change heat transfer: a review. MRS Energy Sustain. 1, E4 (2014).

Carriveau, R., Edrisy, A. & Cadieux, P. Ice adhesion issues in renewable energy infrastructure. J. Adhes. Sci. Technol. 26, 37–41 (2012).

Laforte, J. L., Allaire, M. A. & Laflamme, J. State-of-the-art on power line de-icing. Atmos. Res. 46, 143–158 (1998).

Ryerson, C. C. Assessment of superstructure ice protection as applied to offshore oil operations safety: problems, hazards, needs, and potential transfer technologies Report No. ERDC/CRREL TR-08-14 (US Army Corps of Engineers, 2008).

Laakso, T. et al. State-of-the-art of wind energy in cold climates Report No. VTT-WORK-152 (VTT Technical Research Centre of Finland, 2010).

Cucchiella, F. & Dadamo, I. Estimation of the energetic and environmental impacts of a roof-mounted building-integrated photovoltaic systems. Renew. Sustain. Energy Rev. 16, 5245–5259 (2012).

Jelle, B. P. The challenge of removing snow downfall on photovoltaic solar cell roofs in order to maximize solar energy efficiency — research opportunities for the future. Energy Build. 67, 334–351 (2013).

Gent, R. W., Dart, N. P. & Cansdale, J. T. Aircraft icing. Phil. Trans. R. Soc. A 358, 2873–2911 (2000).

Environmental Protection Agency. Effluent limitation guidelines and new source performance standards for the airport deicing category (EPA, 2012).

U.S. Department of Energy. Energy savings potential and R&D opportunities for commercial refrigeration final report (Navigant Consulting, 2009).

Machielsen, C. H. M. & Kerschbaumer, H. G. Influence of frost formation and defrosting on the performance of air coolers: standards and dimensionless coefficients for the system designer. Int. J. Refrig. 12, 283–290 (1989).

Leary, W. M. We freeze to please: a history of NASA's icing research tunnel and the quest for flight safety Report No. NASA SP-2002-4226 (NASA, 2002).

Schutzius, T. M. et al. Physics of icing and rational design of surfaces with extraordinary icephobicity. Langmuir 31, 4807–4821 (2015).

Richard, D., Clanet, C. & Quéré, D. Contact time of a bouncing drop. Nature 417, 811 (2002).

Richard, D. & Quéré, D. Bouncing water drops. Europhys. Lett. 50, 769–775 (2000).

Cao, L., Jones, A. K., Sikka, V. K., Wu, J. & Gao, D. Anti-icing superhydrophobic coatings. Langmuir 25, 12444–12448 (2009).

Tourkine, P., Le Merrer, M. & Quéré, D. Delayed freezing on water repellent materials. Langmuir 25, 7214–7216 (2009).

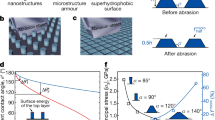

Mishchenko, L. et al. Design of ice-free nanostructured surfaces based on repulsion of impacting water droplets. ACS Nano 4, 7699–7707 (2010). This study features an experimental analysis and proposed mechanism for the dynamic icephobicity of SHSs, which can rapidly shed incoming droplets before they freeze even at temperatures as low as −25 to −30 °C.

Wang, Y., Xue, J., Wang, Q., Chen, Q. & Ding, J. Verification of icephobic/anti-icing properties of a superhydrophobic surface. ACS Appl. Mater. Interfaces 5, 3370–3381 (2013).

Ruan, M. et al. Preparation and anti-icing behavior of superhydrophobic surfaces on aluminum alloy substrates. Langmuir 29, 8482–8491 (2013).

Alizadeh, A. et al. Dynamics of ice nucleation on water repellent surfaces. Langmuir 28, 3180–3186 (2012).

Bahadur, V. et al. Predictive model for ice formation on superhydrophobic surfaces. Langmuir 27, 14143–14150 (2011).

Bahadur, V. & Garimella, S. V. Preventing the Cassie–Wenzel transition using surfaces with non-communicating roughness elements. Langmuir 25, 4815–4820 (2009).

Bartolo, D. et al. Bouncing or sticky droplets: impalement transitions on superhydrophobic micropatterned surfaces. Europhys. Lett. 74, 299–305 (2006).

Reyssat, M., Yeomans, J. M. & Quéré, D. Impalement of fakir drops. Europhys. Lett. 81, 26006 (2008).

Deng, T. et al. Nonwetting of impinging droplets on textured surfaces. Appl. Phys. Lett. 94, 18–20 (2009).

Extrand, C. W. Designing for optimum liquid repellency. Langmuir 22, 1711–1714 (2006).

Liu, B. & Lange, F. F. Pressure induced transition between superhydrophobic states: configuration diagrams and effect of surface feature size. J. Colloid Interface Sci. 298, 899–909 (2006).

Ishino, C., Okumura, K. & Quéré, D. Wetting transitions on rough surfaces. Europhys. Lett. 68, 419–425 (2007).

Boreyko, J. B., Baker, C. H., Poley, C. R. & Chen, C.-H. Wetting and dewetting transitions on hierarchical superhydrophobic surfaces. Langmuir 27, 7502–7509 (2011).

Sarshar, M. A., Swarctz, C., Hunter, S., Simpson, J. & Choi, C. H. Effects of contact angle hysteresis on ice adhesion and growth on superhydrophobic surfaces under dynamic flow conditions. Colloid Polym. Sci. 291, 427–435 (2013).

Bird, J. C., Dhiman, R., Kwon, H. M. & Varanasi, K. K. Reducing the contact time of a bouncing drop. Nature 503, 385–388 (2013).

Maitra, T. et al. Supercooled water drops impacting superhydrophobic textures. Langmuir 30, 10855–10861 (2014).

Heydari, G., Thormann, E., Ja, M., Tyrode, E. & Claesson, P. M. Hydrophobic surfaces: topography effects on wetting by supercooled water and freezing delay. J. Phys. Chem. C 117, 21752–21762 (2013).

Sun, X., Damle, V. G., Liu, S. & Rykaczewski, K. Bioinspired stimuli-responsive and antifreeze-secreting anti-icing coatings. Adv. Mater. Interfaces 2, 1400479 (2015).

He, M., Li, H., Wang, J. & Song, Y. Superhydrophobic surface at low surface temperature. Appl. Phys. Lett. 98, 2009–2012 (2011).

Yin, L. et al. In situ investigation of ice formation on surfaces with representative wettability. Appl. Surf. Sci. 256, 6764–6769 (2010).

Jung, S. et al. Are superhydrophobic surfaces best for icephobicity? Langmuir 27, 3059–3066 (2011).

Eberle, P., Tiwari, M. K., Maitra, T. & Poulikakos, D. Rational nanostructuring of surfaces for extraordinary icephobicity. Nanoscale 6, 4874–4881 (2014).

Fletcher, N. H. Size effect in heterogeneous nucleation. J. Chem. Phys. 29, 572–576 (1958).

Li, K. et al. Investigating the effects of solid surfaces on ice nucleation. Langmuir 28, 10749–10754 (2012).

Li, K. et al. Viscosity of interfacial water regulates ice nucleation. Appl. Phys. Lett. 104, 10–14 (2014).

Jung, S., Tiwari, M. K., Doan, N. V. & Poulikakos, D. Mechanism of supercooled droplet freezing on surfaces. Nat. Commun. 3, 615 (2012). This study examines the mechanism of ice nucleation and growth in supercooled droplets deposited on various surfaces, particularly highlighting the effect of environmental factors such as humidity and airflow.

Kalikmanov, V. I. Nucleation Theory Vol. 860 (Springer, 2013).

Lum, K., Chandler, D. & Weeks, J. D. Hydrophobicity at small and large length scales. J. Phys. Chem. B 103, 4570–4577 (1999).

Ewart, K. V., Lin, Q. & Hew, C. L. Structure, function and evolution of antifreeze proteins. Cell. Mol. Life Sci. 55, 271–283 (1999).

Clark, M. S. & Worland, M. R. How insects survive the cold: molecular mechanisms—a review. J. Comp. Physiol. B 178, 917–933 (2008).

Atıcı, Ö. & Nalbantoğlu, B. Antifreeze proteins in higher plants. Phytochemistry 64, 1187–1196 (2003).

Gwak, Y. et al. Creating anti-icing surfaces via the direct immobilization of antifreeze proteins on aluminum. Sci. Rep. 5, 12019 (2015).

Charpentier, T. V., Neville, A., Millner, P., Hewson, R. & Morina, A. An investigation of freezing of supercooled water on anti-freeze protein modified surfaces. J. Bion. Eng. 10, 139–147 (2013).

Esser-Kahn, A. P., Trang, V. & Francis, M. B. Incorporation of antifreeze proteins into polymer coatings using site-selective bioconjugation. J. Am. Chem. Soc. 132, 13264–13269 (2010). Using antifreeze proteins found in Arctic fish and insects, a polymer–protein conjugate is demonstrated that can inhibit frost formation when applied as a thin film on glass substrates.

Hao, Q. et al. Mechanism of delayed frost growth on superhydrophobic surfaces with jumping condensates: more than interdrop freezing. Langmuir 30, 15416–15422 (2014).

Smith, J. D. et al. Droplet mobility on lubricant-impregnated surfaces. Soft Matter 9, 1772–1780 (2013).

Lee, C., Kim, H. & Nam, Y. Drop impact dynamics on oil-infused nanostructured surfaces. Langmuir 30, 8400–8407 (2014).

Narhe, R. D. & Beysens, D. A. Growth dynamics of water drops on a square-pattern rough hydrophobic surface. Langmuir 23, 6486–6489 (2007).

Narhe, R. D. & Beysens, D. A. Nucleation and growth on a superhydrophobic grooved surface. Phys. Rev. Lett. 93, 076103 (2004).

Wier, K. A. & McCarthy, T. J. Condensation on ultrahydrophobic surfaces and its effect on droplet mobility: ultrahydrophobic surfaces are not always water repellant. Langmuir 22, 2433–2436 (2006).

Narhe, R. D. & Beysens, D. A. Water condensation on a super-hydrophobic spike surface. Europhys. Lett. 75, 98–104 (2007).

Varanasi, K. K., Hsu, M., Bhate, N., Yang, W. & Deng, T. Spatial control in the heterogeneous nucleation of water. Appl. Phys. Lett. 95, 094101 (2009).

Varanasi, K. K., Deng, T., Smith, J. D., Hsu, M. & Bhate, N. Frost formation and ice adhesion on superhydrophobic surfaces. Appl. Phys. Lett. 97, 234102 (2010). This paper demonstrates the vulnerability of microstructured SHSs to frost formation and reveals the corresponding increase in ice adhesion that can occur when water is frozen in the Wenzel state.

Cheng, Y. T. & Rodak, D. E. Is the lotus leaf superhydrophobic? Appl. Phys. Lett. 86, 1–3 (2005).

Mockenhaupt, B., Ensikat, H. J., Spaeth, M. & Barthlott, W. Superhydrophobicity of biological and technical surfaces under moisture condensation: stability in relation to surface structure. Langmuir 24, 13591–13597 (2008).

Lafuma, A. & Quéré, D. Superhydrophobic states. Nat. Mater. 2, 457–460 (2003).

Zhang, Q. et al. Condensation mode determines the freezing of condensed water on solid surfaces. Soft Matter 8, 8285–8288 (2012).

Guo, P. et al. Icephobic/anti-icing properties of micro/nanostructured surfaces. Adv. Mater. 24, 2642–2648 (2012).

Zhang, Y., Yu, X., Wu, H. & Wu, J. Facile fabrication of superhydrophobic nanostructures on aluminum foils with controlled-condensation and delayed-icing effects. Appl. Surf. Sci. 258, 8253–8257 (2012).

Wen, M., Wang, L., Zhang, M., Jiang, L. & Zheng, Y. Antifogging and icing-delay properties of composite micro- and nanostructured surfaces. ACS Appl. Mater. Interfaces 6, 3963–3968 (2014).

Beysens, D. Dew nucleation and growth. Comptes Rendus Phys. 7, 1082–1100 (2006).

Chen, C. H. et al. Dropwise condensation on superhydrophobic surfaces with two-tier roughness. Appl. Phys. Lett. 90, 23–25 (2007).

Boreyko, J. B. & Chen, C.-H. Self-propelled dropwise condensate on superhydrophobic surfaces. Phys. Rev. Lett. 103, 184501 (2009).

Liu, T. Q., Sun, W., Sun, X. Y. & Ai, H. R. Mechanism study of condensed drops jumping on super-hydrophobic surfaces. Colloids Surf. A 414, 366–374 (2012).

He, M. et al. Hierarchically structured porous aluminum surfaces for high-efficient removal of condensed water. Soft Matter 8, 6680–6683 (2012).

Chen, X. et al. Nanograssed micropyramidal architectures for continuous dropwise condensation. Adv. Funct. Mater. 21, 4617–4623 (2011).

Rykaczewski, K. et al. How nanorough is rough enough to make a surface superhydrophobic during water condensation? Soft Matter 8, 8786–8794 (2012).

Feng, J., Qin, Z. & Yao, S. Factors affecting the spontaneous motion of condensate drops on superhydrophobic copper surfaces. Langmuir 28, 6067–6075 (2012).

Miljkovic, N. et al. Jumping-droplet-enhanced condensation on scalable superhydrophobic nanostructured surfaces. Nano Lett. 13, 179–187 (2013).

Boreyko, J. B. & Collier, C. P. Delayed frost growth on jumping-drop superhydrophobic surfaces. ACS Nano 7, 1618–1627 (2013).

Zhang, Q. et al. Anti-icing surfaces based on enhanced self-propelled jumping of condensed water microdroplets. Chem. Commun. 49, 4516–4518 (2013).

Chen, X. et al. Activating the microscale edge effect in a hierarchical surface for frosting suppression and defrosting promotion. Sci. Rep. 3, 2515 (2013).

Boreyko, J. B. et al. Dynamic defrosting on nanostructured superhydrophobic surfaces. Langmuir 29, 9516–9524 (2013).

Wilson, P. W. et al. Inhibition of ice nucleation by slippery liquid-infused porous surfaces (SLIPS). Phys. Chem. Chem. Phys. 15, 581–585 (2013).

Wexler, J. S., Jacobi, I. & Stone, H. A. Shear-driven failure of liquid-infused surfaces. Phys. Rev. Lett. 114, 168301 (2015).

Howell, C. et al. Stability of surface-immobilized lubricant interfaces under flow. Chem. Mater. 27, 1792–1800 (2015).

Daniel, D., Mankin, M. N., Belisle, R. A., Wong, T. S. & Aizenberg, J. Lubricant-infused micro/nano-structured surfaces with tunable dynamic omniphobicity at high temperatures. Appl. Phys. Lett. 102, 231603 (2013).

Wexler, J. S. et al. Robust liquid-infused surfaces through patterned wettability. Soft Matter 11, 5023–5029 (2015).

Kim, P., Kreder, M. J., Alvarenga, J. & Aizenberg, J. Hierarchical or not? Effect of the length scale and hierarchy of the surface roughness on omniphobicity of lubricant-infused substrates. Nano Lett. 13, 1793–1799 (2013).

Rykaczewski, K., Anand, S., Subramanyam, S. B. & Varanasi, K. K. Mechanism of frost formation on lubricant-impregnated surfaces. Langmuir 29, 5230–5238 (2013).

Rykaczewski, K., Landin, T., Walker, M. L., Scott, J. H. J. & Varanasi, K. K. Direct imaging of complex nano- to microscale interfaces involving solid, liquid, and gas phases. ACS Nano 6, 9326–9334 (2012).

Verho, T. et al. Mechanically durable superhydrophobic surfaces. Adv. Mater. 23, 673–678 (2011).

Xiao, R., Miljkovic, N., Enright, R. & Wang, E. N. Immersion condensation on oil-infused heterogeneous surfaces for enhanced heat transfer. Sci. Rep. 3, 1988 (2013).

Zhu, L. et al. Ice-phobic coatings based on silicon-oil-infused polydimethylsiloxane. ACS Appl. Mater. Interfaces 5, 4053–4062 (2013).

Yao, X. et al. Fluorogel elastomers with tunable transparency, elasticity, shape-memory, and antifouling properties. Angew. Chem. Int. Ed. Engl. 53, 4418–4422 (2014).

MacCallum, N. et al. Liquid-infused silicone as biofouling-free medical material. ACS Biomater. Sci. Eng. 1, 43–51 (2015).

Cui, J., Daniel, D., Grinthal, A., Lin, K. & Aizenberg, J. Dynamic polymer systems with self-regulated secretion for the control of surface properties and material healing. Nat. Mater. 14, 790–795 (2015).

Urata, C., Dunderdale, G. J., England, M. W. & Hozumi, A. Self-lubricating organogels (SLUGs) with exceptional syneresis-induced anti-sticking properties against viscous emulsions and ices. J. Mater. Chem. A 3, 12626–12630 (2015).

Wang, Y. et al. Organogel as durable anti-icing coatings. Sci. China Mater. 58, 559–565 (2015).

Wilen, L. A., Wettlaufer, J. S., Elbaum, M. & Schick, M. Dispersion-force effects in interfacial premelting of ice. Phys. Rev. B 52, 12426–12433 (1995).

Ryzhkin, I. A. & Petrenko, V. F. Physical mechanisms responsible for ice adhesion. J. Phys. Chem. 5647, 6267–6270 (1997).

Hays, D. A. in Fundamentals of Adhesion (ed. Lee, L.-H. ) 249–278 (Springer, 1991).

Petrenko, V. F. & Peng, S. Reduction of ice adhesion to metal by using self-assembling monolayers (SAMs). Can. J. Phys. 81, 387–393 (2003).

Jellinek, H. H. G., Kachi, H., Kittaka, S., Lee, M. & Yokota, R. Ice releasing block-copolymer coatings. Colloid Polym. Sci. 256, 544–551 (1978).

Laforte, C. & Beisswenger, A. Icephobic material centrifuge adhesion test in IWAIS XI (Anti-icing Materials International Laboratory, 2005).

Makkonen, L. Ice adhesion — theory, measurements and countermeasures. J. Adhes. Sci. Technol. 26, 413–445 (2012).

Chen, J., Luo, Z., Fan, Q., Lv, J. & Wang, J. Anti-ice coating inspired by ice skating. Small 10, 4693–4699 (2014).

Chernyy, S. et al. Superhydrophilic polyelectrolyte brush layers with imparted anti-icing properties: effect of counter ions. ACS Appl. Mater. Interfaces 6, 6487–6496 (2014).

Farhadi, S., Farzaneh, M. & Kulinich, S. A. Anti-icing performance of superhydrophobic surfaces. Appl. Surf. Sci. 257, 6264–6269 (2011).

Fu, Q. et al. Development of sol–gel icephobic coatings: effect of surface roughness and surface energy. ACS Appl. Mater. Interfaces 6, 20685–20692 (2014).

Ge, L. et al. Anti-icing property of superhydrophobic octadecyltrichlorosilane film and its ice adhesion strength. J. Nanomater. 2013, 1–5 (2013).

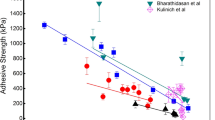

Kulinich, S. A. & Farzaneh, M. How wetting hysteresis influences ice adhesion strength on superhydrophobic surfaces. Langmuir 25, 8854–8856 (2009).

Meuler, A. J. et al. Relationships between water wettability and ice adhesion. ACS Appl. Mater. Interfaces 2, 3100–3110 (2010). This comprehensive study establishes a link between the practical work of adhesion for liquid water and the ice adhesion on smooth surfaces with a broad range of chemistries.

Momen, G., Jafari, R. & Farzaneh, M. Ice repellency behaviour of superhydrophobic surfaces: effects of atmospheric icing conditions and surface roughness. Appl. Surf. Sci. 349, 211–218 (2015).

Sojoudi, H., McKinley, G. H. & Gleason, K. K. Linker-free grafting of fluorinated polymeric cross-linked network bilayers for durable reduction of ice adhesion. Mater. Horiz. 2, 91–99 (2015).

Subramanyam, S. B., Rykaczewski, K. & Varanasi, K. K. Ice adhesion on lubricant-impregnated textured surfaces. Langmuir 29, 13414–13418 (2013).

Susoff, M., Siegmann, K., Pfaffenroth, C. & Hirayama, M. Evaluation of icephobic coatings — screening of different coatings and influence of roughness. Appl. Surf. Sci. 282, 870–879 (2013).

Wang, C., Fuller, T., Zhang, W. & Wynne, K. J. Thickness dependence of ice removal stress for a polydimethylsiloxane nanocomposite: Sylgard 184. Langmuir 30, 12819–12826 (2014).

Yin, X. et al. Integration of self-lubrication and near-infrared photothermogenesis for excellent anti-icing/deicing performance. Adv. Funct. Mater. 25, 4237–4245 (2015).

Zou, M. et al. Effects of surface roughness and energy on ice adhesion strength. Appl. Surf. Sci. 257, 3786–3792 (2011).

Dou, R. et al. Anti-icing coating with an aqueous lubricating layer. ACS Appl. Mater. Interfaces 6, 6998–7003 (2014).

Kulinich, S. A., Farhadi, S., Nose, K. & Du, X. W. Superhydrophobic surfaces: are they really ice-repellent? Langmuir 27, 25–29 (2011).

Chen, J. et al. Robust prototypical anti-icing coatings with a self-lubricating liquid water layer between ice and substrate. ACS Appl. Mater. Interfaces 5, 4026–4030 (2013).

Beisswenger, A., Guy, F. & Laforte, C. Advances in ice adherence and accumulation reduction testing at the anti-icing materials international laboratory (AMIL) (Anti-icing Materials International Laboratory, 2010).

Saito, H., Takai, K. & Yamauchi, G. Water- and ice-repellent coatings. Surf. Coatings Int. 80, 168–171 (1997).

Nishino, T., Meguro, M., Nakamae, K., Matsushita, M. & Ueda, Y. The lowest surface free energy based on –CF3 alignment. Langmuir 15, 4321–4323 (1999).

Kulinich, S. A. & Farzaneh, M. Ice adhesion on super-hydrophobic surfaces. Appl. Surf. Sci. 255, 8153–8157 (2009).

Davis, A., Yeong, Y. H., Steele, A., Bayer, I. S. & Loth, E. Superhydrophobic nanocomposite surface topography and ice adhesion. ACS Appl. Mater. Interfaces 6, 9272–9279 (2014).

Hejazi, V., Sobolev, K. & Nosonovsky, M. From superhydrophobicity to icephobicity: forces and interaction analysis. Sci. Rep. 3, 2194 (2013).

Chen, J. et al. Superhydrophobic surfaces cannot reduce ice adhesion. Appl. Phys. Lett. 101, 111603 (2012).

Boinovich, L. & Emelyanenko, A. M. Role of water vapor desublimation in the adhesion of an iced droplet to a superhydrophobic surface. Langmuir 30, 12596–12601 (2014).

Yang, S. et al. Research on the icephobic properties of fluoropolymer-based materials. Appl. Surf. Sci. 257, 4956–4962 (2011).

Jellinek, H. H. G. Liquid-like (transition) layer on ice. J. Colloid Interface Sci. 25, 192–205 (1967).

Ryzhkin, I. & Petrenko, V. Violation of ice rules near the surface: a theory for the quasiliquid layer. Phys. Rev. B 65, 012205 (2001).

Rosenberg, R. Why is ice slippery? Phys. Today 58, 50–55 (2005).

Fletcher, N. H. Surface structure of water and ice. Philos. Mag. 7, 255–269 (1962).

Fletcher, N. H. Surface structure of water and ice: II. A revised model. Philos. Mag. 18, 1287–1300 (1968).

Jin, H., Tian, X., Ikkala, O. & Ras, R. H. A. Preservation of superhydrophobic and superoleophobic properties upon wear damage. ACS Appl. Mater. Interfaces 5, 485–488 (2013).

Tesler, A. B. et al. Extremely durable biofouling-resistant metallic surfaces based on electrodeposited nanoporous tungstite films on steel. Nat. Commun. 6, 8649 (2015).

Wegst, U. G. K., Bai, H., Saiz, E., Tomsia, A. P. & Ritchie, R. O. Bioinspired structural materials. Nat. Mater. 14, 23–36 (2014).

Acknowledgements

The authors thank A. Grinthal and K.-C. Park for their comments on the manuscript. M.J.K. thanks Natural Sciences and Engineering Research Council (NSERC) for a Postgraduate Scholarships-Doctoral (PGS D) scholarship. The information, data, or work presented herein was funded in part by the Advanced Research Projects Agency-Energy (ARPA-E), US Department of Energy, under Award Number DE-AR0000326.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

J.A. and P.K. are founders of SLIPS Technologies.

Rights and permissions

About this article

Cite this article

Kreder, M., Alvarenga, J., Kim, P. et al. Design of anti-icing surfaces: smooth, textured or slippery?. Nat Rev Mater 1, 15003 (2016). https://doi.org/10.1038/natrevmats.2015.3

Published:

DOI: https://doi.org/10.1038/natrevmats.2015.3

This article is cited by

-

Unraveling the role of vaporization momentum in self-jumping dynamics of freezing supercooled droplets at reduced pressures

Nature Communications (2024)

-

Interfacial ice sprouting during salty water droplet freezing

Nature Communications (2024)

-

Droplet shedding on hydrophilic and superhydrophobic surfaces under the effect of air shear flow

Journal of Coatings Technology and Research (2024)

-

Probing surface wetting across multiple force, length and time scales

Communications Physics (2023)

-

Omniphobic liquid-like surfaces

Nature Reviews Chemistry (2023)