Abstract

We report the growth of high-quality GaN films on large-size graphene films for visible light-emitting diodes (LEDs). The graphene films were synthesized by chemical vapor deposition and then transferred onto amorphous silica (SiO2) substrates that do not have an epitaxial relationship with GaN. Before growing the high-quality GaN thin films, ZnO nanowalls were grown on the graphene films as an intermediate layer. The structural and optical characteristics of the GaN films were investigated, and the films exhibited stimulated emission even at room temperature, a highly c-axis-oriented crystal structure, and a preferred in-plane orientation. Visible LEDs that emitted strong electroluminescence under room illumination were fabricated using the GaN thin films.

Similar content being viewed by others

Introduction

Hybrid heterostructures composed of high-quality inorganic thin films grown directly on atomic-scale layered sheets, such as graphene and boron nitride, offer a novel material system for transferable electronics and optoelectronics.1, 2, 3 Although graphene has been considered to be an ideal supporting layer for the growth of inorganic materials because of its high thermal and mechanical stability and flexibility, inorganic semiconductor thin films exhibit excellent material characteristics, including a high carrier mobility, a radiative recombination rate and long-term stability. For example, as recently reported, graphene layers exfoliated mechanically from graphite powder and their hybrid heterostructures with inorganic semiconductor films are transferable onto arbitrary substrates, such as glass, metal or plastic.1 Nevertheless, the size limitation associated with mechanically exfoliated graphene has been a major obstacle for using inorganic semiconductors grown on graphene for many device applications, including displays and solar cells. Recently, large-size graphene films have become available, and hybrid heterostructures using these large-scale graphene films open up significant opportunities to fabricate various electronic and optoelectronic devices for commercial use. Here, we describe a method of growing high-quality GaN films on large-scale chemical vapor-deposited (CVD) graphene films and fabricating light-emitting devices directly on the films prepared on amorphous substrates. Furthermore, the light-emitting diodes (LEDs) fabricated on the graphene-coated amorphous substrates exhibited strong light emission under room illumination.

Optoelectronic devices fabricated on large-size substrates are of significant interest for applications to general illumination light sources, flat panel displays and solar cells.4, 5 For device applications, the growth of amorphous inorganic semiconductors6, 7 and organic thin films8 on amorphous substrates has widely been studied. However, the devices based on single-crystalline compound semiconductors such as GaN show much higher efficiencies, reliability and long-term stability.9, 10 Nevertheless, because high-quality, single-crystalline nitride films could be grown only on a lattice-matched single-crystal substrate, the use of amorphous substrates, such as fused silica, yielded poor thin film quality, including a rough surface morphology and a polycrystalline structure.11 Thus, the obstacle to growing large high-quality nitride films on large-size amorphous substrates must be resolved in order to use inorganic LEDs in displays and flat light sources.12

Materials and methods

Growth of GaN thin films on CVD graphene films

Large CVD graphene films were used as a substrate for the growth of high-quality GaN films and the fabrication of LEDs on amorphous SiO2 substrates. The graphene films were prepared on Cu foil by a previously reported method.13 The films exhibited excellent optical transparencies and had fairly uniform and homogenous surface morphologies. Then, the CVD graphene films were transferred onto amorphous SiO2 substrates. Before the transfer process, the Cu foil was removed from the graphene films. Then, an oxygen plasma treatment was performed to enhance the formation of ZnO nanowalls across the entire surface of the graphene films. The oxygen plasma was applied to the CVD graphene films for 1 s at an oxygen pressure of 100 mTorr and a plasma power of 30 W.

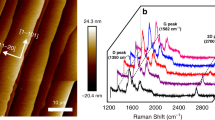

Nitride thin films were grown on CVD graphene films using an intermediate layer of ZnO nanowalls. After preparing the oxygen plasma-treated graphene films, vertically aligned ZnO nanowalls were grown by metal-organic chemical vapor deposition (inset of Figure 1a). The height and density of the ZnO nanowalls were 200–400 nm and 1010 cm−2, respectively. GaN epitaxial layers were grown on the ZnO-coated graphene films using three-step growth by metal-organic chemical vapor deposition. In the first step, a thin GaN protecting layer was grown at 540–600 °C for 10 min with nitrogen as an ambient gas to prevent the degradation of ZnO nanowalls and prohibit reactions between ZnO and GaN layers at a higher temperature. In the second step, GaN layers were grown at temperatures of 1000–1100 °C for 15 min with hydrogen as an ambient gas to improve the lateral overgrowth of GaN layers. Finally, after further growth for 1 h at 1120–1180 °C, high-quality GaN layers were obtained.

Effect of CVD graphene film as a substrate on the surface morphology of GaN films grown on amorphous substrates. Surface morphologies of GaN films grown on amorphous SiO2 substrates coated with CVD graphene films (a) and without CVD graphene films (b). The inset of a shows ZnO nanowalls grown on oxygen plasma-treated CVD graphene films at a tilting angle of 30°.

Measurements

The morphology of GaN thin films grown on graphene-coated amorphous SiO2 substrates was investigated by scanning electron microscopy (JEOL 6510, Tokyo, Japan), and the crystal structure was determined by an X-ray diffractometer (PANalytical X’pert Pro, Almelo, Netherlands). The electroluminescence (EL) and current–voltage (I–V) characteristics of the devices were measured by applying a DC voltage to the device using a source meter (Keithley 2400, Cleveland, OH, USA). The EL and photoluminescence (PL) spectra were measured using a detection system equipped with a monochromator and a charge-coupled device. A continuous He-Cd laser (325 nm) or a pulsed Nd:YAG laser (355 nm) was employed as an optical excitation source for the PL spectroscopy. The temperature-dependent PL measurements were performed using a He Displex refrigerating system.

Results and Discussion

We investigated the effect of using a CVD graphene film as an intermediate layer on the surface morphology of GaN films grown on amorphous substrates. As shown in Figure 1a, GaN films grown on a CVD graphene-coated amorphous SiO2 substrate exhibited a flat and smooth morphology, presumably due to the heteroepitaxial relations between GaN on ZnO and ZnO on graphene. Meanwhile, a rough surface morphology with a few micron-sized irregular hillocks was observed for films directly grown on the SiO2 substrates in the absence of a graphene film (Figure 1b), indicating that the CVD graphene film significantly affects the surface morphology of the GaN film. In addition, the surface roughness was reduced using a CVD graphene film: the root mean square surface roughness over a 5 × 5 μm area was 11 nm for GaN films grown using the graphene film, 20 times smaller than that for GaN films grown directly on the amorphous substrates.

The crystal structure and growth orientation of the GaN films grown on CVD graphene films were examined by X-ray diffraction. Figure 2a shows θ–2θ scan results for GaN films grown on various amorphous substrates using a CVD graphene film and mechanically exfoliated graphene as well as GaN films grown without using any graphene layers. Diffraction peaks for the GaN films grown on the substrates coated with graphene films were observed only at 34.47° and 72.87°. These peaks correspond to the (002) and (004) orientations of wurtzite GaN, respectively. Additional (101), (102) and (103) diffraction peaks were observed for GaN films grown directly on amorphous substrates in the absence of graphene films. Because the GaN films were highly oriented in the c-axis direction, X-ray diffraction rocking curves could also be measured. For GaN films grown on the substrates with CVD graphene films, the full width at half maximum value of the X-ray diffraction rocking curves was as small as 0.8° (Figure 2b), indicating the good c-axis orientation of the GaN film. This full width at half maximum value is much smaller than previously reported values (3−6°) for GaN films grown on mechanically exfoliated graphene layers and on SiO2 substrates using a ZnO layer.14 This result strongly suggests that the graphene film has a critical role in forming GaN films with good vertical alignment.

X-ray diffraction (XRD) spectra of GaN films grown on amorphous SiO2 substrates. (a) θ−2θ scans of GaN films made with CVD graphene films (top), with mechanically exfoliated graphene layers (middle), and without graphene films (bottom). (b) Rocking curve of GaN films on CVD graphene films. (c) Φ-scans of GaN films made with CVD graphene films (black solid line), with mechanically exfoliated graphene layers (red solid line), and without graphene films (blue solid line).

We also investigated the in-plane orientation of the GaN films by measuring azimuthal (Φ) scans of the {112} diffraction. As shown in Figure 2c, whereas the Φ-scan (blue solid line) of the GaN film grown without a CVD graphene film showed no distinct peaks, three different peaks displaying 20° shifts and sixfold symmetry (black solid line) were observed for the GaN films grown using a CVD graphene film. This result indicated that the GaN grains in the thin film had large grain angle boundaries and preferred in-plane orientations. Similar in-plane orientations for CVD graphene films synthesized on Cu foil have previously been reported,15, 16, 17 suggesting that the in-plane orientation of GaN results from using the CVD graphene film. Only one set of peaks possessing sixfold symmetry was observed for the Φ-scan (red solid line) of GaN films grown on an exfoliated graphene layer, indicating that the GaN films were single crystals without large-angle grain boundaries, similar to previous reports.18

The optical characteristics of GaN films grown on CVD graphene-coated amorphous SiO2 substrates were investigated using PL spectroscopy. Figure 3 shows the power-dependent PL spectra measured at room temperature using a pulsed Nd:YAG laser. At a low excitation laser power, below the threshold value (Ith) of the optical pumping power, the GaN thin films exhibited a dominant PL peak at 3.40 eV due to spontaneous emission. For excitation powers above the Ith, the GaN films exhibited a strong and sharp PL peak at 3.33 eV rising from the shoulder of the dominant peak. The integrated PL intensities of the GaN films increased superlinearly with the pumping power above the Ith, consistent with stimulated emission (inset of Figure 3). The Ith of the GaN films grown on the graphene-coated amorphous substrates was 0.6–0.7 MW cm−2, comparable to previously reported values for GaN films grown on mechanically exfoliated graphene layers and on single-crystal sapphire and silicon substrates.1, 19, 20 The high optical quality of the GaN films was also confirmed as determined by low-temperature PL spectroscopy (see Supplementary Figure S1).

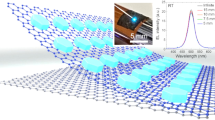

The GaN films grown on CVD graphene-coated amorphous SiO2 substrates could be used with many optoelectronic devices, such as LEDs and solar cells, because they are of high optical quality. We fabricated LEDs as an example of a device application. Although the nitride thin films grown on CVD graphene films are not single crystals, the flat and uniform surface morphology with a high c-axis orientation of the nitride thin films enables us to fabricate LEDs even on amorphous SiO2 substrates. The LEDs were composed of an n-GaN layer, three-period InxGa1–xN/GaN multiple quantum wells (MQWs), and a p-GaN layer (Figure 4a). After growing the LED structures, lithography and BCl3 reactive ion etching were used for the exposure of n-GaN layers. Ni/Au (with a thickness of 8/8 nm) and Ti/Au (20/20 nm) bilayers were deposited on the p- and n-GaN surfaces, respectively, and annealed to make ohmic contacts and reduce the contact resistance of the electrodes.

Visible thin-film LEDs fabricated on CVD graphene-coated amorphous SiO2 substrates. (a) Schematics of an array (left) of LED pixels and one LED pixel (right) that is composed of n-GaN, multiple quantum wells, and p-GaN layers. (b) EL emission images of the LEDs under room illumination at different applied currents.

The GaN-based thin-film LEDs fabricated on CVD graphene-coated amorphous SiO2 substrates emitted strong blue light emissions that could be seen with the unaided eye under typical room illumination conditions (Figure 4b). The light emission from the LED at a driving current of 3.1 mA was fairly uniformly distributed over the p-contact area of 70 × 70 μm2. This result suggests that the hybrid heterostructure, composed of inorganic semiconductors directly grown on large-scale graphene films, constitutes a new functional material system for developing unconventional inorganic optoelectronic devices in large-scale forms that takes advantage of both inorganic semiconductors and graphene films. Moreover, creating hybrid heterostructures on various substrates, including metal foils, may allow inorganic LEDs to be fabricated in flexible large-scale displays.

We further investigated the EL characteristics of the LEDs fabricated on the CVD graphene-coated SiO2 substrates. Room temperature EL spectra and the I−V characteristics of the LEDs were measured at various applied current levels (Figure 5a). The EL intensity gradually increased without a considerable EL peak shift as the applied current increased from 0.8 to 4.4 mA. Moreover, above the turn-on voltage of 6 V, both the current and the integrated EL intensity of the LEDs increased simultaneously upon increasing the applied bias voltage (inset of Figure 5a). This result indicates that the EL mechanism involves carrier transport through the p–n junctions in the LEDs. Furthermore, the emission color of the LEDs could be controlled by changing the growth temperature of InxGa1–xN QW layers because the level of indium incorporated into the QW layers depended on the growth temperature.21 As shown in Figure 5b, blue (453 nm) and green (504 nm) EL images were obtained from the LEDs with the InxGa1–xN layer grown at 800 °C and 760 °C, respectively.

Characteristics of GaN-based thin-film LEDs fabricated on graphene-coated amorphous silica substrates. (a) Power-dependent EL spectra measured at room temperature. The inset of a shows the current and integrated EL intensity as a function of the applied bias voltage. (b) Room temperature EL spectra and corresponding EL images of the LEDs made with InxGa1–xN grown at 800 and 760 °C.

In conclusion, high-quality GaN epitaxial films were heteroepitaxially grown on large-size CVD graphene films using a ZnO nanowall intermediate layer. The structural and optical characteristics of GaN thin films grown on CVD graphene films were comparable to GaN films grown on graphene layers mechanically exfoliated from graphite powder. Furthermore, the simple technique used to obtain high-quality inorganic semiconductor thin films even on amorphous substrates makes it possible to fabricate LEDs on large-area noncrystalline solid substrates and to provide and manufacture large and cost-effective optoelectronic and electronic devices.

References

Chung, K., Lee, C. -H. & Yi, G. -C. Transferable GaN layers grown on ZnO-coated graphene layers for optoelectronic devices. Science 330, 655–657 (2010).

Kobayashi, Y., Kumakura, K., Akasaka, T. & Makimoto, T. Layered boron nitride as a release layer for mechanical transfer of GaN-based devices. Nature 484, 223–227 (2011).

Park, W. I., Lee, C. -H., Lee, J. M., Kim, N. J. & Yi, G. -C. Inorganic nanostructures grown on graphene layers. Nanoscale 3, 3522–3533 (2011).

Sirringhaus, H., Tessler, N. & Friend, R. H. Integrated optoelectronic devices based on conjugated polymers. Science 280, 1741–1744 (1998).

Yoon, J., Jo, S., Chun, I. S., Jung, I., Kim, H. -S., Meitl, M., Menard, E., Li, X., Coleman, J. J., Paik, U. & Rogers, J. A. GaAs photovoltaics and optoelectronics using releasable multilayer epitaxial assemblies. Nature 465, 329–333 (2010).

Yang, J., Banerjee, A. & Guha, S. Amorphous silicon based photovoltaics—from earth to the ‘final frontier’. Sol. Energy Mater. Sol. Cells 78, 597–612 (2003).

Özgür, Ü., Alivov, Y. I., Liu, C., Teke, A., Reshchikov, M. A., Doğan, S., Avrutin, V., Cho, S. -J. & Morkoç, H. A comprehensive review of ZnO materials and devices. J. Appl. Phys. 98, 041301 (2005).

Forrest, S. R. The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature 428, 911–918 (2004).

Ponce, F. A. & Bour, D. P. Nitride-based semiconductors for blue and green light-emitting devices. Nature 386, 351–359 (1997).

Nakamura, S. The roles of structural imperfections in InGaN-based blue light-emitting diodes and laser diodes. Science 281, 956–961 (1998).

Bour, D. P., Nickel, N. M., Van de Walle, C. G., Kneisslm, M. S., Krusor, B. S., Mei, P. & Johnson, N. M. Polycrystalline nitride semiconductor light-emitting diodes fabricated on quartz substrates. Appl. Phys. Lett. 76, 2182–2184 (2000).

Choi, J. H., Zoulkarneev, A., Kim, S. I., Baik, C. W., Yang, M. H., Park, S. S., Suh, H., Kim, U. J., Son, H. B., Lee, J. S., Kim, M., Kim, J. M. & Kim, K. Nearly single-crystalline GaN light-emitting diodes on amorphous glass substrates. Nat. Photonics. 5, 763–769 (2011).

Bae, S., Kim, H., Lee, Y., Xu, X., Park, J. -S., Zheng, Y., Balakrishnan, J., Lei, T., Kim, H. R., Song, Y. I., Kim, Y. -J., Kim, K. S., Özyilmaz, B., Ahn, J. -H., Hong, B. H. & Iijima, S. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol 5, 574–578 (2010).

Yadav, B. S., Singh, S., Ganguli, T., Kumar, R., Major, S. S. & Srinivasa, R. S. Highly oriented GaN films grown on ZnO buffer layer over quartz substrates by reactive sputtering of GaAs target. Thin Solid Films 517, 488–493 (2008).

Kim, K., Lee, Z., Regan, W., Kisielowski, C., Crommie, M. F. & Zettl, A. Grain boundary mapping in polycrystalline graphene. ACS Nano 5, 2142–2146 (2011).

An, J., Voelkl, E., Suk, J. W., Li, X., Magnuson, C. W., Fu, L., Tiemeijer, P., Bischoff, M., Freitag, B., Popova, E. & Ruoff, R. S. Domain (grain) boundaries and evidence of ‘twinlike’ structures in chemically vapor deposited grown graphene. ACS Nano 5, 2433–2439 (2011).

Huang, P. Y., Ruiz-Vargas, C. S., van der Zande, A. M., Whitney, W. S., Levendorf, M. P., Kevek, J. W., Garg, S., Alden, J. S., Hustedt, C. J., Zhu, Y., Park, J., McEuen, P. L. & Muller, D. A. Grains and grain boundaries in single-layer graphene atomic patchwork quilts. Nature 469, 389–393 (2011).

Yoo, H., Chung, K., Choi, Y. S., Kang, C. S., Oh, K. H., Kim, M. & Yi, G. -C. Microstructures of GaN thin films grown on graphene layers. Adv. Mater. 24, 515–518 (2012).

Khan, M. A., Olson, D. T., Vanhove, J. M. & Kuznia, J. N. Vertical-cavity, room-temperature stimulated-emission from photopumped GaN films deposited over sapphire substrates using low-pressure metalorganic chemical vapor-deposition. Appl. Phys. Lett. 58, 1515–1517 (1991).

Yablonskii, G. P., Lutsenko, E. V., Pavlovskii, V. N., Zubialevich, V. Z., Gurskii, A. L., Kalisch, H., Szymakowskii, A., Jansen, R. A., Alam, A., Dikme, Y., Schineller, B. & Heuken, M. Luminescence and stimulated emission from GaN on silicon substrates heterostructures. Phys. Status Solidi A 192, 54–59 (2002).

Nakamura, S. III-V nitride based light-emitting devices. Solid State Commun. 102, 237–248 (1997).

Acknowledgements

This work was financially supported by the National Creative Research Initiative Project (grant no. R16-2004-004-01001-0) of the Korea Science and Engineering Foundations (KOSEF) and the Future-based Technology Development Program (Nano Fields, 2010-0029325) through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Supplementary information

Rights and permissions

This work is licensed under the Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Chung, K., In Park, S., Baek, H. et al. High-quality GaN films grown on chemical vapor-deposited graphene films. NPG Asia Mater 4, e24 (2012). https://doi.org/10.1038/am.2012.45

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/am.2012.45

Keywords

This article is cited by

-

Unveiling the mechanism of remote epitaxy of crystalline semiconductors on 2D materials-coated substrates

Nano Convergence (2023)

-

Dimension- and position-controlled growth of GaN microstructure arrays on graphene films for flexible device applications

Scientific Reports (2021)

-

Growth of continuous GaN films on ZnO buffer layer by chemical vapor deposition for ultraviolet photodetector

Journal of Materials Science: Materials in Electronics (2021)

-

Fabrication of gallium nitride and nitrogen doped single layer graphene hybrid heterostructures for high performance photodetectors

Scientific Reports (2020)

-

Understanding the Growth Mechanism of GaN Epitaxial Layers on Mechanically Exfoliated Graphite

Nanoscale Research Letters (2018)