Abstract

Although possessing extremely high energy density, lithium-oxygen (Li-O2) battery suffered from large charge overpotential, low round-trip efficiency and poor cycling life, which limited the practical application of this smart system. Ru particles functionalized graphene aerogels (Ru-GAs) were designed and directly used as a free-standing cathode for Li-O2 battery. The Ru-GAs showed hierarchical pores, which had the pore volumes of 2.8 and 14.1 cm3 g−1 below and above critical pore diameter of 100 nm. The Ru-GA cathode in Li-O2 battery delivered a high capacity of more than 12 000 mAh g−1 and excellent cycling retention, which was mainly attributed to the three-dimensional porosity, abundant active sites with Ru particles and chemical stability arising from the character of binder-free cathode. Based on the results of in situ gas chromatography–mass spectrometry analysis, the reaction mechanism during charge process in aprotic electrolyte was proposed by the theory of three oxidation stages.

Similar content being viewed by others

Introduction

The rechargeable lithium-oxygen (Li-O2) battery system is considered the most promising battery system for meeting the requirement of electric vehicles and household electric devices because of their extremely huge theoretical specific energy, environmental friendliness and low cost.1, 2, 3, 4 In a nonaqueous Li-O2 battery, oxygen is reduced at the cathode to form insoluble Li2O2 by combining with Li ions during discharge. In the subsequent charge process, solid Li2O2 deposited in the cathode reversibly decomposes and releases O2 gas. An ideal cathode material for a nonaqueous Li-O2 battery should possess the following attributes: sufficient electronic conductivity, low density, stability over the operating voltage (typically 2.0–4.0 V vs Li+/Li), stability toward nucleophilic attack by O2− and O22−, low cost, nontoxicity and ability to be formed into a porous electrode.5

Carbon is widely used as a cathode material because of its excellent electronic conductivity, light weight, low cost and porosity.6, 7, 8, 9, 10 However, carbon decomposes during the oxidation of Li2O2 when charging above 3.0 V (owing to be attacked by intermediates of Li2O2 oxidation) and actively promotes electrolyte decomposition upon discharge and charge.11 Thus, carbon seems unsuitable for nonaqueous Li-O2 batteries. To circumvent parasitic reactions arising from carbon, carbon-free materials have been proposed.4 Nanoporous gold,12, 13 titanium carbide,5 indium tin oxide14 and Sb-doped tin oxide15 have been applied as alternative cathode materials for nonaqueous Li-O2 batteries. Unfortunately, noble metals are expensive and difficult to fabricate as a porous electrode with high surface area, whereas other metals can be easily oxidized or have little catalytic activity. Most metal oxides suffer from low electronic conductivity. Furthermore, these carbon-free materials with superior stability compromise the specific energy of Li-O2 batteries because of their high density. Compared with carbon-free materials, carbon certainly has unique advantageous properties for use as an electrode if one could alleviate the reactivity of carbon against self-decomposition and catalytic decomposition of electrolyte.

Another challenge for carbon is its low catalytic activity toward oxygen evolution reaction (OER), which induces large overpotential and low round-trip efficiency. Given the catalytically active surface and large specific surface area of graphene, it has been investigated as a cathode material in Li-O2 batteries. Our group has previously demonstrated that metal-free graphene nanosheets (GNSs) show good performance as catalyst in Li-O2 battery with hybrid electrolyte.16 Catalytic activity is ascribed to edge and defect sites on the surface of graphene nanosheets, which can serve as active sites for electrochemical reactions. Whereas the deposition of Li2O2 in cathode will still block the electrolyte and oxygen pathway, and eventually limits capacity and cycling life.17, 18 Thus, to apply graphene to nonaqueous Li-O2 batteries, optimizing the porous structure in consideration of insoluble Li2O2 formed during discharge is possibly essential.19, 20 It is worth mentioning that final pore volume and porosity of the electrode are significantly influenced by lamination process and binder addition.21 The use of insulating binders further results in increased impedance of cell fading.22, 23 Moreover, the stability of binders within Li-O2 battery has been questioned.24, 25, 26 Black et al.26 observed the decomposition of poly(vinylidene difluoride), one of the widely used binders in Li-O2 batteries, through dehydrofluorination along with the formation of H2O2 by the chemically generated LiO2. Therefore, design and preparation of a binder-free cathode with optimally porous structure for high-performance Li-O2 batteries are urgent.

As previous reports, Ru and RuO2 incorporated into the matrix indeed contributed to reducing charge overpotential and improving cycling stability.27, 28 However, the multifunctional and reasonable porous structure for catalyst matrix has not been proposed. In the present work, Ru functionalized graphene aerogels (Ru-GAs) with free-standing character were designed and directly used as a cathode for Li-O2 battery. Hierarchical and continuous porosity in Ru-GAs cathode are expected to provide tunnels for diffusion of oxygen and electrolyte. The electrochemical performance of Ru-GAs cathode in Li-O2 battery was extensively investigated. More importantly, the reaction mechanism during charge in the aprotic electrolyte was analyzed based on the results of differential electrochemical mass spectrometry (DEMS).

Experimental procedure

Synthesis of GA and Ru-GA

In a typical synthesis process, 320 mg of graphene oxide (GO) was firstly dispersed in 160 ml of deionized water by ultrasonication for 2 h. Then, 3.5 ml of 0.038 mol l−1 RuCl3 aqueous solution was slowly added to the above GO dispersion under magnetic stirring for another 2 h to form a stable aqueous suspension. The resultant mixture was removed into an autoclave and hydrothermally treated at 180 °C for 12 h to form a graphene-based three-dimensional hydrogel. After washing with deionized water and ethanol several times, the as-prepared hydrogel was cut into slices, which were dried via a supercritical CO2 drying treatment to maintain the three-dimensional porous structure. Finally, the obtained aerogel slices was heated slowly to 800 °C at a heating rate of 2 °C min−1 and calcined at the same temperature for 5 h under 5% H2/Ar atmosphere. An identical process was applied for preparing bare GA without adding RuCl3 aqueous solution.

Battery assembly

The assembling of R2032 coin-type battery was carried out in an argon-filled glovebox with moisture and oxygen contents both <0.1 p.p.m. The positive cover had seven machine-drilled holes for oxygen access. The tetraethylene glycol dimethyl ether (TEGDME) and lithium triflate (LiCF3SO3) were both purchased from Sigma-Aldrich (St Louis, MO, USA). The electrolyte used here was prepared by mixing LiCF3SO3 in TEGDME with a molar ratio of 1:4 and stirring them for 24 h in an argon-filled glovebox with H2O content <1 p.p.m. Later, a fresh Li foil was put into the electrolyte to remove the residual moisture. The R2032 coin-type battery consisted of a Li metal as the anode, a TEGDME-LiCF3SO3 electrolyte immersing in a glass fiber separator, a GA or Ru-GA slice directly used as binder-free cathode and a carbon paper as the gas diffusion layer. The amount of electrolyte used was around 50 μl. The assembled battery was transferred to a glass chamber and purged with O2 before electrochemical test.

Measurements and characterization

All the electrochemical tests of Li-O2 batteries were carried out at 25 °C under O2 atmosphere with a pressure 1 atm. Galvanostatic discharge/charge cycles were conducted on a LAND 2001A Battery Testing System from Wuhan Land Electronic (Wuhan, China). The specific capacities reported here are normalized by the mass of GAs. The discharged and charged batteries were disassembled in the argon-filled glovebox and the cathodes was then removed, washed with TEGDME solvent and dried to remove the residual solvent. After that, the cathodes were enclosed with a thin transparent polymer film to reduce their exposure to air during characterization.

Thermogravimetric analysis was carried out using a TA Instrument SDT Q600 (Waters, Milford, MA, USA) at a heating rate of 10 °C min−1 in air. The pore distribution below 100 nm and Brunauer–Emmett–Teller-specific surface area of sample were measured by N2 adsorption–desorption with a Micrometritics ASAP 2020 instrument (Norcross, GA, USA). The pore size distribution and pore volume in this range were calculated by the Barrett–Joyner–Halenda method from the adsorption branch of the isotherms. Mercury intrusion method was used to confirm pore distribution exceeding 100 nm with a PoreMaster GT-60 porosimeter (Quantachrome, Boynton Beach, FL, USA). The accumulated pore volume exceeding 100 nm was calculated by the intruded volume of mercury during the test. X-ray diffraction (XRD) was performed using a Bruker D8 Advanced diffractometer (Berlin, Germany) with Cu-Kα radiation. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) images were taken on a Hitachi S-4800 (Tokyo, Japan) and JEOL JEM-2100 (Tokyo, Japan), respectively. The DEMS system uses a custom-built Swagelok cell designed to exhibit excellent hermetic integrity. Each tested battery was discharged with a fixed specific capacity of 500 mAh g−1 at 0.1 mA cm−2 in the Swagelok cell under O2 atmosphere. Before the charge test, the system was purged with a pure He stream for 6 h to eliminate the background O2. Online gas analysis was performed using a quadrupole mass spectrometer (Clarus SQ 8S; Perkin-Elmer, Waltham, MA, USA) to quantify the O2 and CO2 evolved during charge.

Results and discussion

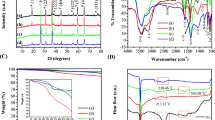

The synthesis of GAs and Ru-GAs is illustrated in Supplementary Figure S1, and detailed information is given in the Experimental procedure section. Thermogravimetric analysis revealed that the total weight loss of Ru-GA sample was 76.3% at 800 °C (Supplementary Figure S2). Given the oxidation of Ru to RuO2, the Ru content of nanocomposite was about 18.0%. Structure and morphology of samples were investigated by XRD, SEM and TEM. The broad XRD peak at about 26.0° of resulting products indicated the poor ordering of graphene sheets along their stacking direction and reflected that frameworks of samples were composed of few-layer stacked graphene sheets (Supplementary Figure S3). Interlayer spaces of graphene were calculated to be 3.74 Å, which was slightly higher than that of natural graphite (3.37 Å). In the case of Ru-GA sample, diffraction peaks of metallic Ru cannot be observed from the XRD pattern, which was ascribed to ultra-small size and low content of Ru.

SEM images (Figures 1a and b and Supplementary Figures S4a and b) confirmed that GA and Ru-GA samples possessed an interconnected three-dimensional continuous porous structure. Pore sizes of network ranged within several nanometers to hundreds nanometers, and pore walls consisted of thin layers of stacked graphene sheets (Supplementary Figure S4c). Furthermore, the high-resolution TEM image (inset of Figure 1a) indicated that GAs was mainly composed of multilayered graphene. Figure 1c and Supplementary Figure S4d present TEM and high-resolution TEM images of Ru-GA sample, revealing the firm attachment of Ru particles onto graphene sheets even after ultrasonication to disperse samples for TEM observation. High-resolution TEM image showed that the particle size of Ru nanoparticles was below 5 nm (insets of Figure 1c). Lattice fringes with an interplane spacing of 2.14 Å corresponded with the (0 0 2) plane of Ru. Another Ru-GA nanocomposite with lower Ru content (L-Ru-GAs) was also synthesized and the corresponding characterizations have been presented in Supplementary Figure S5.

Figure 1d shows that the pore-size distribution of Ru-GA sample, as characterized by N2 adsorption and mercury intrusion methods for determining pore size. The pore volume of Ru-GAs was 2.8 and 14.1 cm3 g−1 below and above 100 nm, respectively. According to previous research, micropores mainly benefit O2 transportation, whereas mesopores and macropores ideally suit product deposition and electrolyte diffusion.29 Furthermore, Supplementary Figure S6 demonstrates that Ru-GA sample had a typical type-IV isotherm with a type-H3 hysteresis loop, which was characteristic of the existence of many mesopores. Brunauer–Emmett–Teller surface area was 596 m2 g−1. The high specific surface area will provide more surfaces to uniformly disperse catalytic particles, and hence more active sites will be offered for the electrochemical reactions.

Electrochemical performances of GA and Ru-GA cathodes were both examined in Li-O2 batteries. TEGDME-based electrolytes were used in our Li-O2 batteries because of its relatively stability against oxygen radicals.30, 31, 32, 33 Slices of GAs and Ru-GAs with a mass of ~2.0 mg were directly used as binder-free cathodes. Galvanostatic discharge–charge measurements were carried out to evaluate electrochemical performance at a current density of 0.1 mA cm−2 at room temperature. Initial discharge–charge voltage profiles of Li-O2 batteries are shown in Figure 2a, revealing that a high specific capacity of above 10 000 mAh g−1 can be obtained with GA cathode. It should be pointed out that the contribution of carbon paper to discharge capacity, which was used as the gas diffusion layer, is quite limited and can be negligible in comparison with that delivered by GA, as depicted in Supplementary Figure S7. However, charge voltage plateau of GA cathode ranged from 4.1 to 4.5 V, suggesting a large overpotential. With the addition of Ru nanoparticles to GAs, discharge capacity increased to 12 000 mAh g−1. More importantly, charge voltage was lower compared with that of bare GA cathode 0.4 V, whereas discharge voltage plateau was similar. This result was also consistent with previous reports involving Ru-based catalysts.28, 34, 35 The advantages in structural characteristics of designed Ru-GA cathode were presented by a schematic diagram. As shown in Figure 3, GA electrode had unique properties with a hierarchically porous structure that facilitated electrolyte permeation and oxygen diffusion, three-dimensional network structures that can enable easy electron transfer through GA, high specific surface area that offered abundant active sites for electrochemical reaction and an ultra-large pore volume that can accommodate plenty of discharge products. Ru nanoparticles supported on graphene sheets also had superior catalytic activity toward OER and can efficiently catalyze the decomposition of the discharge product Li2O2.

(a) Initial discharge–charge voltage profiles of lithium-oxygen (Li-O2) batteries with graphene aerogel (GA) and Ru particles functionalized GA (Ru-GA) cathodes at a current density of 0.1 mA cm−2. (b) Discharge–charge voltage profiles with GA cathode of 1st, 10th, 20th and 30th cycle under specific capacity limit of 500 mAh g−1. (c) Discharge–charge voltage profiles with Ru-GA cathode of 1st, 10th, 20th, 30th, 40th and 50th cycle under specific capacity limit of 500 mAh g−1. (d) The medium charge voltage depending on cycle number of Li-O2 batteries with GA and Ru-GA cathodes.

To identify discharge and charge products of Li-O2 batteries with Ru-GA cathode, XRD analysis was performed. Figure 4a shows that the diffraction peak of pristine electrode at 36.2° can be assigned to the thin transparent polymer film, which was used to eliminate effects of moisture and CO2 during testing. Compared with pristine electrode, new diffraction peaks (2θ≈32.9°, 35.0° and 58.7°) appeared after discharge to 2.0 V and can be ascribed to (1 0 0), (1 0 1) and (1 1 0) planes of Li2O2, indicating that Li2O2 was the dominant crystalline product in discharge. After recharge, all diffraction peaks associated with Li2O2 disappeared, indicating the reversible decomposition of Li2O2 in subsequent charge. XRD analysis confirmed the good reversibility of Li-O2 with Ru nanoparticles-functionalized GA cathodes. For further insight into the discharge of Li-O2 batteries with Ru-GA cathodes, SEM and TEM techniques were used to observe discharge products after discharge to 2.0 V. As shown in Figure 4b, numerous toroidal Li2O2 particles were observed on Ru-GA cathode, and the diameter of Li2O2 particles was ~400–500 nm (Figure 4c). Li2O2 particles came in close contact with graphene sheets and Ru nanoparticles, as shown in Figure 4d. Graphene sheets can provide easy electron transfer through cathode, and Ru nanoparticles offered abundant active sites for electrochemical reaction, which reduces the charge overpotential relating to the decomposition of Li2O2. The discharged cathodes of GA and L-Ru-GA exhibited similar morphology, as shown in Supplementary Figure S9.

(a) X-ray powder diffraction (XRD) patterns of the pristine, discharged and charged cathodes of Ru particles functionalized graphene aerogel (Ru-GA). (b) Scanning electron microscope (SEM) image of the discharged cathode of Ru-GA. (c and d) Transmission electron microscopy (TEM) images of the discharged cathode of Ru-GA.

As reported previously, lower charge voltage provides significantly less influence on parasitic degradation reactions during charge, thereby contributing to improved cycle stability.11, 36 For confirmation, cycling performances of Li-O2 batteries with GA and Ru-GA cathodes were investigated under capacity-controlled regimens of 500 mAh g−1 at a current density of 0.1 mA cm−2. As shown in Figure 2b, battery with bare GA cathode can maintain about 30 cycles, and charge voltage gradually increased upon cycle. By contrast, Ru-GA cathode showed better cycling stability over 50 cycles (Figure 2c), demonstrating that Ru particles had an important role in maintaining the cycling stability of Li-O2 batteries. Figure 2d shows a plot of medium charge voltage, which was defined as charge voltage corresponding with a specific capacity of 250 mAh g−1, against cycle number. Apparently, Li-O2 battery with Ru-GA cathode obtained much lower charge voltage and exhibited better cycling stability. The electrochemical performances of Li-O2 batteries with L-Ru-GA cathode were also examined and the results are demonstrated in Supplementary Figure S8.

The reaction during charge in the aprotic electrolyte is a complex multiphase process involving solid (catalyst cathode), liquid (electrolyte) and gas (oxygen). It is considered to be an effective method to search the reaction mechanism by in situ analysis of charge product. DEMS was used to measure the amount of O2 and CO2 gas evolved upon charge. Li-O2 batteries were first discharged up to the specific capacity of 500 mAh g−1. During charge, amounts of gases evolved from the battery were analyzed. The galvanostatic discharge–charge profile of Li-O2 battery with Ru-GA cathode and the evolution of O2 and CO2 gas as a function of charge specific capacity are presented in Figure 5a. In light of the amount of O2 and CO2 gas evolved upon charge, charge process occurred in three distinct stages. The first stage occurred below 3.8 V and exhibited a sloping voltage profile followed by a flat voltage plateau. Only O2 gas evolved, and no CO2 was detected in the stage. This charge could be attributed to the delithiation of Li2O2 to form LiO2-like species and subsequent bulk oxidation. The reactions were as follows:37

(a) The initial discharge–charge voltage profile of the lithium-oxygen (Li-O2) battery with Ru particles functionalized graphene aerogel (Ru-GA) cathode and the corresponding differential electrochemical mass spectrometry (DEMS) result. (b) The schematic representation of the charging process: (I) only O2 gas evolves, which is attributed to the delithiation of Li2O2 to form LiO2-like species and subsequent bulk oxidation. (II) CO2 started to evolve, assigned to the decomposition of by-products and accompanied by the oxidation of Li2O2.

The second stage occurred between 3.8 and 4.0 V, and CO2 started to evolve, which can be assigned to the decomposition of by-products, such as lithium carboxylates (HCO2Li and CH3CO2Li) and Li2CO3. As noted in a previous paper, these by-products were derived from electrolyte decomposition and the reaction between Li2O2 and carbon on discharge. These by-products can be oxidized on subsequent charge.11, 38, 39, 40 Notably, this stage may also be accompanied by the oxidation of Li2O2 because of the amount of O2 gas evolved. A new charge voltage plateau above 4.2 V appeared in the third stage. The amount of CO2 gas evolved was decreasing and no O2 gas was detected during this process, which can be ascribed to electrolyte decomposition owing to the fact that specific capacity exceeded that of discharge. Similar results were also obtained by using GA and L-Ru-GA cathodes (Supplementary Figure S10). The schematic of the charging process was depicted in Figure 5b.

Conclusion

In summary, free-standing and hierarchically porous graphene aerogels were successfully prepared by a one-pot reaction and directly used as binder-free cathode in nonaqueous Li-O2 batteries. A large specific capacity of above 10 Ah g−1 can be achieved because of unique properties of GAs with a hierarchically porous structure that facilitated electrolyte permeation and oxygen diffusion; three-dimensional network structures that can provide easy electron transfer through gas; high specific surface area that offered abundant active sites for electrochemical reaction; and an ultra-large pore volume that can accommodate plenty of discharge products. Ru nanoparticles were further decorated on graphene sheets of GA and demonstrated superior catalytic activity toward OER. Resulting nanocomposites can efficiently enhance discharge-specific capacity, reduce charge overpotential and improve cycling stability up to 50 cycles at a curtailing capacity of 500 mAh g−1. Furthermore, we proposed that charge occurred in three distinct stages according to DEMS results. The first stage occurring below 3.8 V can be attributed to the delithiation of Li2O2 to form LiO2-like species and subsequent bulk oxidation caused by the detection of only O2 gas. The second stage occurred between 3.8 and 4.0 V and CO2 started to evolve, which can be assigned to by-product decomposition. This process may also be accompanied by the oxidation of Li2O2 because of the amount of O2 gas evolved. A new charge voltage plateau above 4.2 V corresponding with electrolyte decomposition appeared in the last stage. During this process, the amount of CO2 gas evolved was decreasing and no O2 was detected.

References

Abraham, K. M. & Jiang, Z. A polymer electrolyte-based rechargeable lithium/oxygen battery. J. Electrochem. Soc. 143, 1–5 (1996).

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J. M. Li-O2 and Li-S batteries with high energy storage. Nat. Mater. 11, 19–29 (2012).

Lu, J., Li, L., Park, J. B., Sun, Y. K., Wu, F. & Amine, K. Aprotic and aqueous Li-O2 batteries. Chem. Rev. 114, 5611–5640 (2014).

Li, F. J., Zhang, T. & Zhou, H. S. Challenges of non-aqueous Li-O2 batteries: electrolytes, catalysts, and anodes. Energy Environ. Sci. 6, 1125–1141 (2013).

Thotiyl, M. M. O., Freunberger, S. A., Peng, Z. Q., Chen, Y. H., Liu, Z. & Bruce, P. G. A stable cathode for the aprotic Li-O2 battery. Nat. Mater. 12, 1049–1055 (2013).

Yang, X. H., He, P. & Xia, Y. Y. Preparation of mesocellular carbon foam and its application for lithium/oxygen battery. Electrochem. Commun. 11, 1127–1130 (2009).

Mitchell, R. R., Gallant, B. M., Thompson, C. V. & Shao-Horn, Y. All-carbon-nanofiber electrodes for high-energy rechargeable Li-O2 batteries. Energy Environ. Sci. 4, 2952–2958 (2011).

Chen, Y., Li, F. J., Tang, D. M., Jian, Z. L., Liu, C., Golberg, D., Yamada, A. & Zhou, H. S. Multi-walled carbon nanotube papers as binder-free cathodes for large capacity and reversible non-aqueous Li-O2 batteries. J. Mater. Chem. A 1, 13076–13081 (2013).

Guo, Z. Y., Wang, J., Wang, F., Zhou, D. D., Xia, Y. Y. & Wang, Y. G. Leaf-like graphene oxide with a carbon nanotube midrib and its application in energy storage devices. Adv. Funct. Mater. 23, 4840–4846 (2013).

Li, Y. L., Li, X. F., Geng, D. S., Tang, Y. J., Li, R. Y., Dodelet, J. P., Lefevre, M. & Sun, X. L. Carbon black cathodes for lithium oxygen batteries: influence of porosity and heteroatom-doping. Carbon 64, 170–177 (2013).

Thotiyl, M. M. O., Freunberger, S. A., Peng, Z. Q. & Bruce, P. G. The carbon electrode in nonaqueous Li-O2 cells. J. Am. Chem. Soc. 135, 494–500 (2013).

Peng, Z. Q., Freunberger, S. A., Chen, Y. H. & Bruce, P. G. A reversible and higher-rate Li-O2 battery. Science 337, 563–566 (2012).

Chen, Y. H., Freunberger, S. A., Peng, Z. Q., Fontaine, O. & Bruce, P. G. Charging a Li-O2 battery using a redox mediator. Nat. Chem. 5, 489–494 (2013).

Li, F. J., Tang, D. M., Chen, Y., Golberg, D., Kitaura, H., Zhang, T., Yamada, A. & Zhou, H. S. Ru/ITO: a carbon-free cathode for nonaqueous Li-O2 battery. Nano Lett. 13, 4702–4707 (2013).

Li, F. J., Tang, D. M., Jian, Z. L., Liu, D. Q., Golberg, D., Yamada, A. & Zhou, H. S. Li-O2 battery based on highly efficient Sb-doped tin oxide supported Ru nanoparticles. Adv. Mater. 26, 4659–4664 (2014).

Yoo, E. & Zhou, H. S. Li-air rechargeable battery based on metal-free graphene nanosheet catalysts. ACS Nano 5, 3020–3026 (2011).

Xu, J. J., Wang, Z. L., Xu, D., Meng, F. Z. & Zhang, X. B. 3D ordered macroporous LaFeO3 as efficient electrocatalyst for Li-O2 batteries with enhanced rate capability and cyclic performance. Energy Environ. Sci. 7, 2213–2219 (2014).

Guo, Z. Y., Zhou, D. D., Dong, X. L., Qiu, Z. J., Wang, Y. G. & Xia, Y. Y. Ordered hierarchical mesoporous/macroporous carbon: a high-performance catalyst for rechargeable Li-O2 batteries. Adv. Mater. 25, 5668–5672 (2013).

Xiao, J., Mei, D. H., Li, X. L., Xu, W., Wang, D. Y., Graff, G. L., Bennett, W. D., Nie, Z. M., Saraf, L. V., Aksay, I. A., Liu, J. & Zhang, J. G. Hierarchically porous graphene as a lithium-air battery electrode. Nano Lett. 11, 5071–5078 (2011).

Wang, Z. L., Xu, D., Xu, J. J., Zhang, L. L. & Zhang, X. B Graphene oxide gel-derived, free-standing, hierarchically porous carbon for high-capacity and high-rate rechargeable Li-O2 batteries. Adv. Funct. Mater. 22, 3699–3705 (2012).

Shao, Y. Y., Ding, F., Xiao, J., Zhang, J., Xu, W., Park, S., Zhang, J. G., Wang, Y. & Liu, J Making Li-air batteries rechargeable: material challenges. Adv. Funct. Mater. 23, 987–1004 (2013).

Younesi, R., Hahlin, M., Treskow, M., Scheers, J., Johansson, P. & Edstrom, K. Ether based electrolyte, LiB(CN)4 salt and binder degradation in the Li-O2 battery studied by hard X-ray photoelectron spectroscopy (HAXPES). J. Phys. Chem. C 116, 18597–18604 (2012).

Cui, Y. M., Wen, Z. Y., Lu, Y., Wu, M. F., Liang, X. & Jin, J. Functional binder for high-performance Li-O2 batteries. J. Power Sources 244, 614–619 (2013).

Xu, W., Viswanathan, V. V., Wang, D. Y., Towne, S. A., Xiao, J., Nie, Z. M., Hu, D. H. & Zhang, J. G. Investigation on the charging process of Li2O2-based air electrodes in Li-O2 batteries with organic carbonate electrolytes. J. Power Sources 196, 3894–3899 (2011).

Nasybulin, E., Xu, W., Engelhard, M. H., Nie, Z. M., Li, X. H. S. & Zhang, J. G. Stability of polymer binders in Li-O2 batteries. J. Power Sources 243, 899–907 (2013).

Black, R., Oh, S. H., Lee, J. H., Yim, T., Adams, B. & Nazar, L. F. Screening for superoxide reactivity in Li-O2 batteries: Effect on Li2O2/LiOH crystallization. J. Am. Chem. Soc. 134, 2902–2905 (2012).

Jian, Z. L., Liu, P., Li, F. J., He, P., Guo, X. W., Chen, M. W. & Zhou, H. S. Core-Shell-Structured CNT@RuO2 composite as a high-performance cathode catalyst for rechargeable Li-O2 batteries. Angew. Chem. Int. Ed. 53, 442–446 (2014).

Li, F. J., Chen, Y., Tang, D. M., Jian, Z. L., Liu, C., Golberg, D., Yamada, A. & Zhou, H. S. Performance-improved Li-O2 battery with Ru nanoparticles supported on binder-free multi-walled carbon nanotube paper as cathode. Energy Environ. Sci. 7, 1648–1652 (2014).

Wu, D. F., Guo, Z. Y., Yin, X. B., Pang, Q. Q., Tu, B. B., Zhang, L. J., Wang, Y. G. & Li, Q. W. Metal-organic frameworks as cathode materials for Li-O2 batteries. Adv. Mater. 26, 3258–3262 (2014).

Jung, H. G., Hassoun, J., Park, J. B., Sun, Y. K. & Scrosati, B. An improved high-performance lithium-air battery. Nat. Chem. 4, 579–585 (2012).

Oh, S. H., Black, R., Pomerantseva, E., Lee, J. H. & Nazar, L. F. Synthesis of a metallic mesoporous pyrochlore as a catalyst for lithium-O2 batteries. Nat. Chem. 4, 1004–1010 (2012).

Black, R., Lee, J. H., Adams, B., Mims, C. A. & Nazar, L. F. The role of catalysts and peroxide oxidation in lithium-oxygen batteries. Angew. Chem. Int. Ed. 52, 392–396 (2013).

Li, F. J., Zhang, T., Yamada, Y., Yamada, A. & Zhou, H. S. Enhanced cycling performance of Li-O2 batteries by the optimized electrolyte concentration of LiTFSA in glymes. Adv. Energy Mater. 3, 532–538 (2013).

Sun, B., Munroe, P. & Wang, G. X. Ruthenium nanocrystals as cathode catalysts for lithium-oxygen batteries with a superior performance. Sci. Rep. 3, 2247–2253 (2013).

Sun, B., Huang, X. D., Chen, S. Q., Munroe, P. & Wang, G. X. Porous graphene nanoarchitectures: an efficient catalyst for low charge-overpotential, long life, and high capacity lithium-oxygen batteries. Nano Lett. 14, 3145–3152 (2014).

Bergner, B. J., Schurmann, A., Peppler, K., Garsuch, A. & Janek, J. TEMPO: a mobile catalyst for rechargeable Li-O2 batteries. J. Am. Chem. Soc. 136, 15054–15064 (2014).

Lu, Y. C. & Shao-Horn, Y. Probing the reaction kinetics of the charge reactions of nonaqueous Li-O2 batteries. J. Phys. Chem. Lett. 4, 93–99 (2013).

Freunberger, S. A., Chen, Y. H., Drewett, N. E., Hardwick, L. J., Barde, F. & Bruce, P. G. The lithium-oxygen battery with ether-based electrolytes. Angew. Chem. Int. Ed. 50, 8609–8613 (2011).

Gallant, B. M., Mitchell, R. R., Kwabi, D. G., Zhou, J. G., Zuin, L., Thompson, C. V. & Shao-Horn, Y. Chemical and morphological changes of Li-O2 battery electrodes upon cycling. J. Phys. Chem. C 116, 20800–20805 (2012).

Liu, Y. L., Wang, R., Lyu, Y. C., Li, H. & Chen, L. Q. Rechargeable Li/CO2-O2 (2:1) battery and Li/CO2 battery. Energy Environ. Sci. 7, 677–681 (2014).

Acknowledgements

We are grateful for the financial support from the National Key Basic Research Program of China (2014CB932302 and 2014CB932303), National Natural Science Foundation of China (21373111, 21403107 and 51202106), Natural Science Foundation of Jiangsu Province of China (BK2012309, BK20140055) and Project on the Integration of Industry, Education and Research of Jiangsu Province (BY2015069-01).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Jiang, J., He, P., Tong, S. et al. Ruthenium functionalized graphene aerogels with hierarchical and three-dimensional porosity as a free-standing cathode for rechargeable lithium-oxygen batteries. NPG Asia Mater 8, e239 (2016). https://doi.org/10.1038/am.2015.141

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/am.2015.141

This article is cited by

-

Conversion reaction lithium metal batteries

Nano Research (2023)

-

Functionalization of 2D materials for enhancing OER/ORR catalytic activity in Li–oxygen batteries

Communications Chemistry (2019)

-

Hierarchically nanostructured transition metal oxides for supercapacitors

Science China Materials (2018)

-

Reduced graphene oxide decorated with Bi2O2.33 nanodots for superior lithium storage

Nano Research (2017)

-

CeO2@NiCo2O4 nanowire arrays on carbon textiles as high performance cathode for Li-O2 batteries

Science China Chemistry (2017)