Abstract

The generation, manipulation and detection of a pure spin current (i.e., the flow of spin angular momentum without a charge current) are prospective approaches for realizing next-generation spintronic devices with ultra-low electric power consumption. Conventional ferromagnetic electrodes such as Co and NiFe have been utilized as spin injectors to generate pure spin currents in nonmagnetic channels. However, the generation efficiency of pure spin currents is extremely low at room temperature, giving rise to a serious obstacle for device applications. Here we demonstrate the generation of giant pure spin currents at room temperature in lateral spin valve devices with a highly ordered Heusler-compound Co2FeSi (CFS) spin injector. The generation efficiency of pure spin currents from the CFS spin injectors is 10 times greater than that of the NiFe injectors, indicating that Heusler compound spin injectors with high spin polarization enable us to materialize a high-performance lateral spin device. The present study is a technological jump in spintronics, and indicates the great potential of ferromagnetic Heusler compounds with half metallicity for generating pure spin currents.

Similar content being viewed by others

Introduction

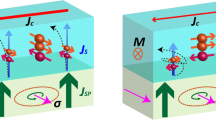

Electrical spin injection from a ferromagnet (F) into a nonmagnet (N) can generate a spin current (i.e., the flow of spin angular momentum) even in a nonmagnetic channel.1, 2, 3, 4, 5 In general, the spin current is induced by diffusing non-equilibrium spin accumulations in the vicinity of the F/N interface under spin injection. However, because the difference in the density of states between the majority and minority spins (i.e., the spin polarization P) is not so large for a conventional F, such as Co or NiFe (Py), the induced spin current in the N mainly returns back to the F (Figure 1a). This phenomenon gives rise to an extremely low injection efficiency of the spin current in the N.6, 7 If we utilize a highly spin-polarized F as a spin injector, the spin-polarized electrons can be efficiently injected into the N, and the backflow of the spin currents can be strongly suppressed, resulting in a dramatical improvement of the injection efficiency of the spin currents in the N (Figure 1b). A charge current can also be extracted with nonlocal electrical spin injection in a mesoscopic lateral geometry, and a spin current can be transferred without the charge current, that is, a pure spin current, in the nonmagnetic channel (Figures 1c and d). In this scheme,1, 3, 4, 8, 9, 10, 11, 12, 13, 14, 15, 16 the use of highly spin-polarized F spin injectors is critical for generating a giant pure spin current in the N.

Concept of efficient generation of a pure spin current. (a, b) Schematic diagrams of the electrical spin injection from a conventional ferromagnet (F) or a highly spin-polarized F (HSF) into a nonmagnet (N). For the conventional F, most of the original spin currents return back to the F (a backflow of the spin current), giving rise to a significant reduction in the injected spin current. For the HSF, the original spin current is effectively injected into the N by preventing the backflow. (c) Generation of a pure spin current with nonlocal spin injection. The electron charges are extracted toward left hand side while the spin currents diffuse into both sides symmetrically. (d) Spatial distributions of the spin-dependent electro-chemical potentials (μ↑, μ↓), in the N. Although the charge current ∝∂(μ↑+μ↓)/∂x is zero in the right hand side, a finite spin current ∝∂(μ↑−μ↓)/∂x is generated over the spin diffusion length. Thus, the pure spin current can be generated in the right hand side of the N.

As materials with highly spin-polarized F, we focus on Co-based Heusler compounds in which the half-metallic properties are theoretically predicted.17, 18 In fact, huge tunnel magnetoresistance and giant magnetoresistance effects have been reported in vertical stacking device structures.19, 20, 21 Therefore, the combination of the high-performance Co-based Heusler compounds with laterally configured device structures is a prospective challenge for highly efficient generation of pure spin currents. Recently, a nonlocal spin injection using polycrystalline CoFeAl was reported. However, the relatively large resistivity of the CoFeAl utilized in Bridoux et al.22 indicates that the crystal structure and the spin polarization are far from those of an ideal Heusler compound (see Supplementary information). In the present study, we show that an epitaxially grown Co-based Heusler compound, Co2FeSi (CFS) with a highly ordered L21 structure, enables the highly efficient injection of pure spin currents.

Materials and methods

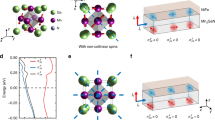

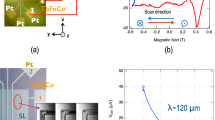

Our device structure is a lateral spin valve (LSV) consisting of a CFS spin injector and detector bridged by a Cu strip (Figure 2a), in which the CFS thin film with highly ordered L21 structures has been epitaxially grown on Si(111).23 A conventional electron-beam lithography and Ar ion milling technique are employed to form the wire-shaped CFS spin injector and a detector with a width of 300 nm. Here, one CFS wire is connected to two square pads to facilitate domain wall nucleation, whereas the other has pointed-end edges. Using the two different wire shapes, we can control the magnetization configuration by adjusting the external magnetic fields (H), where H is applied along the CFS wires. Finally, the top Cu strips (200 nm wide and 100 nm thick) bridging the CFS wires and bonding pads were patterned by a conventional lift-off technique. Before the Cu deposition, the surfaces of the CFS wires are well cleaned by Ar ion milling with a low accelerating voltage, producing in low resistive ohmic interfaces with RCFS/Cu≈1 fΩm2. Here, the optimization for the milling conditions of the CFS surface is performed by changing the milling time and acceleration voltage. The transport measurements are carried out by a conventional current-bias lock-in technique (∼200 Hz). The resistivities for the prepared CFS and Cu wires are 90.5 and 2.5 μΩcm, respectively, at room temperature (RT), and 54.6 and 1.2 μΩcm, respectively, at 80 K. As shown in Figure 2b, a pure spin current generated by the nonlocal spin injection from CFS1 can be detected by CFS2 after propagation through the 600-nm distance in the Cu strip.

Enhanced nonlocal spin valve effect. (a) A scanning electron microscope image of the fabricated Co2FeSi(CFS)/Cu lateral spin valve (LSV). (b) Schematic of a nonlocal spin valve measurement. Spin-polarized electrons are injected from contact 2, and electron charges are extracted from contact 1. A nonlocal voltage is measured between contact 3 and contact 4. (c) A room-temperature nonlocal spin-valve signal for the CFS/Cu LSV, together with that for the Py/Cu LSV. The signal varies according to the relative magnetization orientation of two wire-shaped CFS electrodes, as shown in the inset illustrations. (d) A room-temperature local spin-valve signals for the Py/Cu and CFS/Cu LSVs. The inset shows the current–voltage probe configuration (i.e., the current is injected from contact 2 and extracted from contact 3), and the voltage is measured between contact 5 and contact 6. The low and high resistance states correspond to the parallel and anti-parallel magnetization alignments, respectively. The expected magnetization configurations agree with those observed in the nonlocal spin valve signal. (e) Nonlocal spin signal ΔRS as a function of Jinj at the injecting junction, normalized by ΔRS at a small bias current density of J0∼109 A m−2, for the CFS/Cu LSV (red solid squares) and the Py/Cu LSV (blue open circles). (f) Temperature dependence of ΔRS for the CFS/Cu LSV (red solid squares) and the Py/Cu LSV (blue open circles), normalized by ΔRS at 20 K. The inset shows a nonlocal spin-valve effect of the CFS/Cu LSV at T=70 K. The scale bars in (c), (d), and the inset of (f) are 1, 2 and 5 mΩ, respectively.

Results and discussion

Figure 2c shows the nonlocal magnetoresistance of the CFS/Cu LSV measured at RT, together with that of a Py/Cu LSV. Here, the size of the CFS/Cu junction is three times as large as that of the Py/Cu junction. A giant spin signal (ΔRS) of 2.3 mΩ is seen for the CFS/Cu LSV (Figure 2c), which is approximately 10 times as large as that of the Py/Cu LSV. As the spin injection efficiency is inversely proportional to the size of the F/N junctions,6 the large ΔRS demonstrated in the CFS/Cu LSV with larger junctions implies a signigicant possibility for the present CFS/Cu LSV.

We also show the local spin valve signals at RT for the same CFS/Cu and Py/Cu LSVs (Figure 2d). The values are almost twice those of the non-local ΔRS, which are in reasonable agreement with the values of the previous reports.2, 6 This result means that the one-dimensional spin diffusion model provides a good description of the spin transport in the present CFS/Cu LSV. Figure 2e shows the dependence of ΔRS on the bias current density (Jinj) at the injecting junction for the CFS/Cu LSV, which is almost the same as that of the Py/Cu LSV. The reduction of ΔRS is less than 20% even under a high-bias current density (∼1011 A m−2), indicating much superior properties to those of the LSV consisting of the high-resistive tunnel junctions, in which ΔRS drastically decreases even at low-bias current density (∼108 A m−2).11 The temperature dependence of ΔRS for the CFS/Cu LSV is also almost the same as that of the Py/Cu LSV, in which ΔRS takes its maximum value around 20 K, below which the ΔRS decreases with decreasing temperature (Figure 2f). This behavior can be explained by an enhancement of the spin-flip scattering at the Cu surface for the CFS/Cu LSV below 20 K, as discussed in Kimura et al.10 Surprisingly, the ΔRS for the CFS/Cu exceeds 10 mΩ below 70 K (inset of Figure 2f). From these results, we recognize that the present CFS/Cu LSV can be treated as a conventional ohmic LSV, and it can generate a giant pure spin current with a much less electric power than the previously reported LSVs.1, 2, 6, 7, 8, 9, 10, 11, 12, 13, 14

To quantitatively evaluate the device performance of the present LSVs from their nonlocal spin signals, we measure ΔRS of the CFS/Cu LSV devices with various distances (d; where d is the center–center distance between spin injector and detector) and Py/Cu LSV devices as references. Here we introduce a characteristic value in the LSV devices by extending the resistance change area product, which is commonly utilized to characterize the device performance of the vertical spin devices.24, 25 The resistance change area product for the nonlocal spin signal (ΔRSA) is defined as ΔRS(SinjSdet/SN), where Sinj, Sdet and SN are the junction sizes in the spin injector and detector, and the cross section of the nonmagnetic strip. This ΔRSA allows us to equivalently compare the device performances between our CFS/Cu and the Py/Cu LSV devices. The plot of ΔRSA versus d at RT for the CFS/Cu LSVs and Py/Cu LSVs is shown in Figure 3, and the plot at 80 K is shown in the inset. The value of ΔRSA increases with decreasing d for both the CFS/Cu and Py/Cu LSV devices. By solving the one-dimensional spin diffusion equation6, 26 (see Supplementary information), ΔRSA can be expressed as follows:

where PF and PI are the bulk and interface spin polarizations for F, respectively; λF and λN are the spin diffusion lengths for F and N, respectively; and ρF and ρN are the resistivities for F and N, respectively. As shown in Figure 3, the plots of ΔRSA versus d for both the CFS/Cu and Py/Cu LSV devices are well reproduced by the fitting curves with λCu=500 nm and λCu=1300 nm at RT and 80 K,1, 2, 6, 7 respectively. For the Py/Cu LSVs, assuming that λPy,RT=3 nm and λPy,80 K=5 nm, we obtain a reasonable PPy values of 0.3 and 0.35 at RT and 80 K, respectively.1, 2, 6 Thus, the above equation reliably expresses the generation efficiency of the pure spin current among various LSVs. We then estimate the spin polarization for CFS (PCFS). As it is impossible to determine the spin polarization and the spin diffusion length independently from the present results, we assume that λCFS is of the same order as that of Co2FeSi0.5Al0.5 (see Supplementary information). Using the experimentally obtained values of ρCFS, ρCu and λCu and assuming that λCFS,RT=3 nm and λCFS,80 K=4 nm,24, 25 PCFS can be estimated to be 0.55 at RT and 0.73 at 80 K. These values for CFS are larger than those for Py, and they are consistent with the relatively large value of 0.59 obtained in one of our CFS films with a point-contact Andreev reflection measurement.25 Although the present CFS epitaxial layers have highly ordered structures with a high magnetic moment above 5 μB/f.u.,24 the value is still smaller than 6 μB/f.u. in the perfectly ordered CFS.20, 21 As further enhancement of the PCFS will be achieved by improving the crystal growth technique, a scaling characteristic with P=1 will ultimately be obtainable (see dashed line).

Scaling plot for lateral spin valve (LSV) devices with metallic junctions. The resistance change area product for the nonlocal spin signal (ΔRSA) as a function of d for CFS/Cu LSVs (filled squares), together with that for Py/Cu LSVs (open circles). The main panel and inset show the data at RT and 80 K, respectively. The solid curves are fitting results with λCu=500 nm at RT (red line) and λCu=1300 nm at 80 K (blue line), and the dashed curves are theoretical upper limits using P=1, calculated from the equation,  .

.

In the present CFS/Cu LSV, the non-negligible backflow of the spin current remains. However, the results described above indicate that the device performance of the LSV is strongly improved with the CFS spin injector instead of the Py injector. To evaluate the device performance of our developed CFS/Cu LSV quantitatively, we compare the generation efficiency of the pure spin current in the CFS/Cu LSV to that in the Py/Cu LSV. Using Eq. (1), the injection efficiency of the pure spin current  , which is defined by the ratio of the spin current (IS) injected into the ferromagnetic detector to the excited charge current (IC), can be calculated as follows:

, which is defined by the ratio of the spin current (IS) injected into the ferromagnetic detector to the excited charge current (IC), can be calculated as follows:

The injection efficiency of the present CFS/Cu LSV with d=200 nm is estimated to be 0.27, which is much larger than the value of 0.022 for the Py/Cu LSV. Thus, the injection efficiency is strongly improved with the CFS spin injector, although the non-negligible backflow of the spin current remains. We then evaluate the power consumption for switching the magnetization by injecting the pure spin current with CFS and Py spin injectors. The injection power for switching can be estimated as  , where ISCR is the critical spin current for switching and R is the device resistance, which is mainly dominated by the resistance of the ferromagnetic injector. Assuming that ISCR is the same in devices with either spin injector (see Supplementary information), we find that the CFS injector substantially reduces the power consumption for switching to 3% of that required for the Py injector. The present result represents a significant technological advance in spintronics using pure spin currents, which are generated by Heusler-compound spin injectors with high spin polarization.

, where ISCR is the critical spin current for switching and R is the device resistance, which is mainly dominated by the resistance of the ferromagnetic injector. Assuming that ISCR is the same in devices with either spin injector (see Supplementary information), we find that the CFS injector substantially reduces the power consumption for switching to 3% of that required for the Py injector. The present result represents a significant technological advance in spintronics using pure spin currents, which are generated by Heusler-compound spin injectors with high spin polarization.

References

Johnson, M. & Silsbee, R. H. Interfacial charge-spin coupling: Injection and detection of spin magnetization in metals. Phys. Rev. Lett. 55, 1790–1793 (1985).

van Son, C. P., van Kempen, H. & Wyder, P. Boundary resistance of the ferromagnetic-nonferromagnetic metal interface. Phys. Rev. Lett. 58, 2271–2273 (1987).

Jedema, J. F., Filip, T. A. & van Wees, J. B. Electrical spin injection and accumulation at room temperature in an all-metal mesoscopic spin valve. Nature 410, 345–348 (2001).

Jedema, J. F., Nijboer, S. M., Filip, T. A. & van Wees, J. B. Spin injection and spin accumulation in all-metal mesoscopic spin valves. Phys. Rev. B 67, 085319 (2003).

Chappert, C., Fert, A. & Van Dau, F. N. The emergence of spin electronics in data storage. Nature Mater. 6, 813–823 (2007).

Žutič, I., Fabian, J. & Sarma, D. S. Spintronics: Fundamentals and applications. Rev. Mod. Phys. 76, 323–410 (2004).

Schmidt, G., Ferrand, D., Molenkamp, W. L., Filip, T. A. & van Wees, J. B. Fundamental obstacle for electrical spin injection from a ferromagnetic metal into a diffusive semiconductor. Phys. Rev. B 62, R4790–R4793 (2000).

Kimura, T., Hamrle, J. & Otani, Y. Estimation of spin-diffusion length from the magnitude of spin-current absorption: Multiterminal ferromagnetic/nonferromagnetic hybrid structures. Phys. Rev. B 72, 014461 (2005).

Kimura, T., Otani, Y. & Hamrle, J. Enhancement of spin accumulation in a nonmagnetic layer by reducing junction size. Phys. Rev. B 73, 132405 (2006).

Godfrey, R. & Johnson, M. Spin Injection in Mesoscopic Silver Wires: Experimental Test of Resistance Mismatch. Phys. Rev. Lett. 96, 136601 (2006).

Yang, T., Kimura, T. & Otani, Y. Giant spin-accumulation signal and pure spin-current-induced reversible magnetization switching. Nature Phys. 4, 851–854 (2008).

Kimura, T., Sato, T. & Otani, Y. Temperature evolution of spin relaxation in a NiFe/Cu lateral spin valve. Phys. Rev. Lett. 100, 066602 (2007).

Valenzuela, O. S. & Tinkham, M. Spin-polarized tunneling in room-temperature mesoscopic spin valves. Appl. Phys. Lett. 85, 5914–5916 (2004).

Kimura, T. & Otani, Y. Large spin accumulation in a permalloy-silver lateral spin valve. Phys. Rev. Lett. 99, 196604 (2007).

Mihajlovic, G., Pearson, E. J., Bader, D. S. & Hoffmann, A. Surface spin flip probability of mesoscopic Ag wires. Phys. Rev. Lett. 104, 237202 (2010).

Idzuchi, H., Fukuma, Y., Wang, L. & Otani, Y. Spin Diffusion Characteristics in Magnesium Nanowires. Appl. Phys. Express 3, 063002 (2010).

Graf, T., Felser, C. & Parkin, S. S. P. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 39, 1–50 (2011).

Wurmehl, S., Fecher, G. H., Kandpal, H. C., Ksenofontov, V., Felser, C., Lin, H. & Morais, J. Geometric, electronic, and magnetic structure of Co2FeSi: Curie temperature and magnetic moment measurements and calculations. Phys. Rev. B 72, 184434–184443 (2005).

Inomata, K., Ikeda, N., Tezuka, N., Goto, R., Sugimoto, S., Wojcik, M. & Jedryka, E. Highly spin-polarized materials and devices for spintronics. Sci. Technol. Adv. Mater. 9, 014101 (2008).

Balke, B., Wurmehl, S., Fecher, H. G., Felser, C. & Kübler, J. Rational design of new materials for spintronics: Co2Fe Z (Z=Al, Ga, Si, Ge). Sci. Technol. Adv. Mater. 9, 014102 (2008).

Sakuraba, Y., Hattori, M., Oogane, M., Ando, Y., Kato, H., Sakuma, A., Miyazaki, T. & Kubota, H. Giant tunneling magnetoresistance in Co2MnSi/Al-O/Co2MnSi magnetic tunnel junctions. Appl. Phys. Lett. 88, 192508 (2006).

Bridoux, G., Costache, M. V., Van de Vondel, J., Neumann, I. & Valenzuela, S. O. Enhanced spin signal in nonlocal devices based on a ferromagnetic CoFeAl alloy. Appl. Phys. Lett. 99, 102107 (2011).

Yamada, S., Hamaya, K., Yamamoto, K., Murakami, T., Mibu, K. & Miyao, M. Significant growth-temperature dependence of ferromagnetic properties for Co2FeSi/Si(111) prepared by low-temperature molecular beam epitaxy. Appl. Phys. Lett. 96, 082511 (2010).

Nakatani, M. T., Furubayashi, T., Kasai, S., Sukegawa, H., Takahashi, K. Y., Mitani, S. & Hono, K. Bulk and interfacial scatterings in current-perpendicular-to-plane giant magnetoresistance with Co2Fe(Al0.5Si0.5) Heusler alloy layers and Ag spacer. Appl. Phys. Lett. 96, 212501 (2010).

Sakuraba, Y., Izumi, K., Iwase, T., Bosu, S., Saito, K., Takanashi, K., Miura, K., Futatsukawa, K., Abe, K. & Shirai, M. Mechanism of large magnetoresistance in Co2MnSi/Ag/Co2MnSi devices with current perpendicular to the plane. Phys. Rev. B 82, 094444 (2010).

Takahashi, S. & Maekawa, S. Spin injection and detection in magnetic nanostructures. Phys. Rev. B 67, 052409 (2003).

Yamada, S., Hamaya, K., Murakami, T., Varaprasad, B., Takahashi, Y. K., Rajanikanth, A., Hono, K. & Miyao, M. Low-temperature grown quaternary Heusler-compound Co2Mn1−xFexSi films on Ge(111). J. Appl. Phys. 109, 07B113 (2011).

Acknowledgements

This work was supported by Fundamental Research Grants from CREST-JST and PRESTO-JST. Author information: T. K., N. H. and K. H. carried out the device fabrications and the transport measurements. S. Y., M. M. and K. H. prepared the epitaxial Co2FeSi films. T. K. and K. H. performed the data analysis. T. K., M. M. and K. H. planned the present project and wrote the paper.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Supplementary information

Rights and permissions

This work is licensed under the Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Kimura, T., Hashimoto, N., Yamada, S. et al. Room-temperature generation of giant pure spin currents using epitaxial Co2FeSi spin injectors. NPG Asia Mater 4, e9 (2012). https://doi.org/10.1038/am.2012.16

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/am.2012.16

Keywords

This article is cited by

-

Strain-induced specific orbital control in a Heusler alloy-based interfacial multiferroics

NPG Asia Materials (2024)

-

Giant converse magnetoelectric effect in a multiferroic heterostructure with polycrystalline Co2FeSi

NPG Asia Materials (2022)

-

Disorder Induced Magnetic Behavior of Non-Stoichiometric Co0.75Mn0.5Fe0.75Si Full-Heusler Alloy

Journal of Superconductivity and Novel Magnetism (2022)

-

Spin injection through energy-band symmetry matching with high spin polarization in atomically controlled ferromagnet/ferromagnet/semiconductor structures

NPG Asia Materials (2020)

-

A review of phase equilibria in Heusler alloy systems containing Fe, Co or Ni

Journal of Materials Science (2016)